Professional Documents

Culture Documents

Applying VRF?: Don't Overlook Standard 15

Uploaded by

Eric G. MagnayeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Applying VRF?: Don't Overlook Standard 15

Uploaded by

Eric G. MagnayeCopyright:

Available Formats

This article was published in ASHRAE Journal, July 2012. Copyright 2012 ASHRAE. Posted at www.ashrae.org.

This article may not be

copied and/or distributed electronically or in paper form without permission of ASHRAE. For more information about ASHRAE Journal, visit

www.ashrae.org.

Applying VRF?

Don’t Overlook Standard 15

By Stephen W. Duda, P.E., Member ASHRAE 2008 ASHRAE Journal,3 and the 2012

V

ASHRAE Handbook—HVAC Systems and

ariable refrigerant flow (VRF) systems have been used in Equipment.4 The 2012 ASHRAE Hand-

book—HVAC Systems and Equipment has

Japan for at least two decades, and are now receiving at- a full new chapter on VRF systems.

This article explores the following ob-

tention in North America as a potential HVAC system choice in com- jectives:

•• Why Standard 15 should not be

mercial, retail, institutional, hospitality, and multifamily residential overlooked when applying VRF;

•• How to find and look up the Refrig-

applications. Indeed, the recently renovated ASHRAE headquarters erant Concentration Limit (RCL);

•• How to calculate refrigerant applica-

in Atlanta includes such a system in a portion of the building. HVAC tion limits;

•• Understand what situations may

system designers who once applied water-source heat pump loops,

cause a VRF installation to violate Stan-

hydronic fan-coil networks, packaged terminal units, rooftop direct- dard 15;

•• Understand and use favorable design

expansion units and other all-air systems, are now applying VRF. techniques to apply VRF within Stan-

dard 15; and

Why VRF? In many cases, VRF can and cons of VRF systems are beyond the •• Address ambiguities in Standard 15.

be shown to offer good seasonal en- scope of this article; the intent of which

ergy efficiency at a reasonable first cost. is simply to remind design professionals

About the Author

VRF is mentioned in the Advanced En- of the relevant refrigerant safety require-

Stephen W. Duda, P.E., is assistant director of

ergy Design Guide Series,1 so there is ments found in Standard 15-2010. For mechanical engineering for Ross & Baruzzini in St.

certainly a sustainability component peer-reviewed literature on VRF, see the Louis. He has been a member of Standing Stan-

behind the interest in VRF. But the pros April 2007 ASHRAE Journal,2 the June dards Project Committee (SSPC) 15 since 2002.

18 ASHRAE Journal a s h r a e . o r g July 2012

(This article is based on a published conference paper by the

Condensing Unit

author,5 and the reader is referred to that paper for additional

technical detail.)

Typical

Standard 15 and VRF Evaporator

In part, Standard 15, Safety Standard for Refrigeration Sys- Unit Common

Refrigerant

tems,6 strives to ensure a safe system by limiting the maxi- Piping Network

mum quantity of refrigerant below that which is a danger to

human occupants if a leak occurs. Anecdotally, there is some-

times a misconception that Standard 15 applies only to large

chiller plants. In fact, Standard 15 applies to any mechanical

refrigeration system used in stationary applications (Standard

15-2010 §2.2.a).

The nature of a VRF system is such that multiple evapora-

tors are served by one common condensing unit and one com-

mon network of interconnecting refrigerant piping (Figure 1). Figure 1: Simplified variable refrigerant flow system.

Manufacturers of VRF system components advertise that 40 or

more evaporators can be included on one piping network, with frigerating System Classification must be selected. A VRF

more than 3,000 ft (914 m) of refrigerant pipe, all connected to system is classified as a Direct System (§5.1.1) for which the

a single condensing unit. The evaporator units may be ductless; evaporator coils are in direct contact with the air being cooled.

they may be installed above a ceiling with some distribution This is in contrast to an Indirect System; for example, a chilled

ductwork; or they may be ducted to serve two or more rooms. water fan-coil system in which only the water coil is in di-

A traditional DX split system applied room-by-room has rect contact with the air being cooled. Under Standard 15, a

one condensing unit for each evaporator, with no interconnec- VRF system is a High-Probability System (§5.2.1) because

tion to other split systems, and a refrigerant leak, therefore, the location of components (e.g., the evaporator) is such that a

would discharge only that refrigerant contained in one indi- leakage of refrigerant from a failed connection, seal, or com-

vidual split system. A water-source heat pump system uses ponent can enter the occupied space. A Direct System is also a

a modest amount of refrigerant in each individual heat pump High-Probability System as defined by Standard 15.

unit, but the interconnecting piping between rooms carries

water, not refrigerant. Because of the interconnecting refriger- Refrigerant Concentration Limit (RCL)

ant piping, a VRF system has the theoretical potential to dis- At this point, one must refer to ANSI/ASHRAE Standard

charge a much larger quantity of refrigerant to indoor spaces 34-20107 to determine the maximum allowable refrigerant

in a catastrophic leak occurrence. concentration, or RCL (refrigerant concentration limit) and

At first glance, one might suppose that a large direct ex- other pertinent safety classifications. (RCL was once found

pansion (DX) rooftop unit would have the potential to leak in Standard 15 but has been moved to Standard 34 beginning

and disperse a large charge of refrigerant into an occupied with the 2010 edition.)

space, similar to a VRF system. Of course, this is a concern A common refrigerant for commercial VRF systems is R-

which should be addressed via a careful application of Stan- 410A, and that refrigerant will be followed throughout this

dard 15. On close examination, one will see that a large DX article. Per Standard 34, Table 2, the safety classification of

rooftop unit serves many rooms through a network of ducts. R-410A is Group A1 (meaning non-flammable and non-toxic).

Should the evaporator in a rooftop unit open a catastrophic Even though R-410A is Group A1, its ability to displace oxygen

leak of refrigerant, the leaked refrigerant would be dispersed is a serious danger to occupants if released in large quantities

to multiple rooms via the ductwork, in some rough proportion into smaller-volume spaces. Therefore, Standard 34, Table 2

to the overall room-by-room volume based on the connected (through Addendum l*) has established an RCL for R-410A at

air-distribution system. A VRF system has a magnified con- 26 lbs of refrigerant per 1,000 ft3 of room volume (420 g/m3).

cern because it could potentially discharge all of a comparable Now the Occupancy Classification becomes important. For

refrigerant charge to one individual room. Institutional Occupancies such as patient care areas of hospi-

tals, the RCL is cut in half (§7.2.1), effectively changing the

Applying Standard 15 RCL for R-410A to 13 lb/1,000 ft3 (210 g/m3) in that clas-

Moving further into the application of Standard 15, Sec- sification.

tion 4 requires the design professional to select an Occupancy The volume of the smallest individual space(s) served by

Classification from among seven choices. In Section 5, a Re- an individual evaporator unit, or the smallest individual room

*ASHRAE Standard 34-2010 Addendum l recently increased this value from 25 to 26 lb/1,000 ft³ (420 g/m3). State or local codes10 that reference 34-2010 may

not include the addenda for code purposes, in which case the new value would not take effect until Standard 34-2013 edition (not yet published) is adopted by

those bodies.

July 2012 ASHRAE Journal 19

through which refrigerant piping is installed, is used to deter-

mine the maximum potential refrigerant concentration in the 10 ft

15 ft 25 ft

event of a leak (§7.3). If that room has permanent opening(s)

to adjacent room(s), the combined room volumes may be used

(�����������������������������������������������������������

§����������������������������������������������������������

7.3.1). The space above a suspended ceiling is not consid-

ered as part of the room volume unless it is used as part of the

air supply or return path (��������������������������������

§�������������������������������

7.3.2.2). Any proposed VRF sys- Sales Support Conference Room 15 ft

tem will need to respect the RCL of 26 lb/1,000 ft3 (420 g/m3),

or 13 lb/1,000 ft3 (210 g/m3) if institutional, for the smallest

space(s) served by an individual evaporator unit or crossed by Corridor 8 ft

refrigerant piping.

The Machinery Room paragraphs (Standard 15-2010 §8.11

and 8.12) are not discussed here. While Machinery Room

Office Private Computer Room 12 ft

provisions such as refrigerant leak detection, alarms and in-

creased ventilation will be familiar to experienced designers

of large chiller systems, Machinery Rooms are not an appli-

12 ft 30 ft

cable compliance path for VRF systems. Machinery Rooms 8 ft

are not to be occupied by anybody other than authorized

personnel (§8.11.8), effectively voiding any attempt to use a Figure 2: Commercial office layout. Seven evaporator units,

Machinery Room compliance path in a VRF system serving one installed within each room plus the corridor, are networked

occupied space. on one common refrigerant circuit with one condensing unit.

Example Calculations One common approach to compliance is the connecting

Published catalog data from manufacturers show a typical space clause. If the room includes permanent openings to ad-

factory refrigerant charge of 2 to 3 lb per nominal ton of ca- jacent rooms, those rooms may be combined in the volume

pacity (0.3 to 0.4 kg/kW), with an additional 1 to 3 lb per calculation (�������������������������������������������������

§������������������������������������������������

7.3.1). The room’s door probably does not quali-

nominal ton (0.1 to 0.4 kg/kW) contained in the field piping fy as a permanent opening, because the door will be closed at

(subject to routing and layout), for a practical range of 3 to 6 least some of the time, making the opening non-permanent. If

lb per ton (0.4 to 0.8 kg/kW). Operating pressures for R-410A one imagines this room is a human resource director’s office,

systems are on the order of 450 psig (3.1 MPa).9 These oper- for example, it should be assumed that room doors will be

ating parameters of commercial VRF systems are followed by occasionally closed for private conversations, and other per-

three examples. manent openings between rooms (such as air transfer grilles)

might not be permitted for reasons of crosstalk. More on this

Example 1: Commercial Office Building topic is found in the “Ambiguities” section.

One actual installed-and-operating VRF system the author Finally, we must discuss the corridor itself. Refrigerant pip-

viewed in preparation for this article served a commercial ing shall not be installed in an enclosed public stairway, stair

office. The VRF system’s condensing unit nameplate was landing, or means of egress (§8.10.2). If the corridor shown in

stamped 478 psig (3.3 MPa) high side and 320 psig (2.2 MPa) Figure 2 is a means of egress, one should route the piping so

low side; 550 psig (3.8 MPa) test pressure; 96 MBh (28 kW) it does not pass through the corridor, and the evaporator unit

capacity; 23.4 lbs (10.6 kg) factory charge of R-410A. The serving the corridor should be located outside the corridor.

network features three parallel field pipes (liquid, suction, and

hot gas) because the system is designed as a heat pump net- Tips Toward Compliance

work, allowing some zones to be in heat mode while other In Example 1, we found a potential safety issue with a high-

zones are in cooling mode. The total charge was 40 to 41 lb er-than-allowable system charge serving a small office. Sev-

(18 to 19 kg) when field piping was included. eral options are available to the design professional to avoid

A simplified sketch of the office layout is found in Figure this situation.

2. A total of seven ductless in-room console evaporator units, 1. One option is to remove the smallest office from the

one installed in each room plus the corridor, are networked VRF system and condition it with a separate unit, perhaps a

with one condensing unit. In this example, the smallest indi- packaged terminal air conditioner (PTAC), and route the VRF

vidual room with its own evaporator is 12 ft by 8 ft (3.7 m by refrigerant pipe so that it does not pass through the smallest

2.4 m), with a 9 ft (2.7 m) ceiling, for a volume of 864 ft3 (24.5 office. In Example 1, the next-smallest office becomes the

m3). Therefore, the maximum allowable refrigerant charge of critical room, at 12 ft by 12 ft (3.7 m by 3.7 m), with a 9 ft

R-410A is 22.4 lb (10.2 kg). Since the actual system charge (2.7 m) ceiling, for a volume of 1,296 ft3 (36.7 m3) and maxi-

is 40 to 41 lb (18 to 19 kg), it initially appears this installation mum allowable R-410A charge of 33.7 lbs (15.3 kg). With the

does not comply with Standard 15. reduced capacity found by eliminating one evaporator unit,

20 ASHRAE Journal a s h r a e . o r g July 2012

Advertisement formerly in this space.

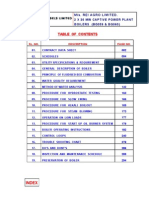

along with a re-optimized piping layout, “Critical” Maximum RCL Factor for Net System Refrigerant

perhaps the total system charge will now Example Room Size R-410A from Std 15 Concentration Limit

be in compliance. (ft3) (lb/1,000 ft3) (lb)

2. Another allowable “fix” would be 1a – Commercial

864 26 22.4

to use one common ducted evapora- Office Building

tor to condition the two smallest rooms

1b* 1,296 26 33.7

together, allowing both rooms to be

summed for purpose of compliance. 2 – Hotel 2,516 26 65.4

3. In lieu of an in-room console unit,

another option is to use an above-ceil- 3 – Hospital 1,700 13 22.1

ing evaporator unit ducted to one or *Similar to Example 1a with the smallest room removed from the variable refrigerant flow system.

more of the smaller rooms, while draw-

ing unducted return air through the Table 1: Summary of three example calculations.

ceiling cavity. Therefore, the ceiling

void space could now be counted as part of the room volume Since VRF evaporator units are often 100% recirculating

(§7.3.2.2). types, a separate system for delivering outdoor air, such as a

4. Finally, one could use two completely separate VRF sys- dedicated outdoor air system (DOAS) is often provided. An

tems: one for each side of the corridor, and avoid the corridor example is a hotel room continuously ventilated with outdoor

altogether, particularly if the corridor is a means of egress. air delivered to the sleeping area and exhaust air in the bath-

room. Can the parallel ventilation system be relied upon for

Example 2: Hotel Guest Rooms dilution of a hypothetical refrigerant leak? Formal Interpre-

Next, imagine a guest room floor of a hotel featuring a se- tation IC 15-2007-38 stated that increasing the allowable re-

ries of identical units of 350 ft2 (32.5 m2) with an 8.5 ft (2.6 frigerant limits for R-410A due to dilution by supply and/or

m) ceiling, for a volume of 2,975 ft3 (84.2 m3). A VRF system exhaust air ventilation should not be considered.

using R-410A is proposed, with a 1 ton (3.5 kW) evaporator

per guest unit. What is the maximum refrigerant capacity per- Example 3: Hospital Patient Rooms

mitted in one VRF network? The RCL is 26 lb/1,000 ft3 (420 Finally, consider the application of VRF to the in-patient room

g/m3) for R-410A in a Residential occupancy. Therefore, the wing of a hospital. At first glance, this may seem to be very

maximum permissible total refrigerant charge is 77.3 lb (35.1 similar to the previous hotel room example. However, recall

kg) including the condensing unit, all evaporator units, and the that for Institutional occupancies, the RCL is reduced by 50%.

field refrigerant piping. A typical hospital patient room (again excluding bathroom as

However, system designers should consider the ramifica- for the hotel) may be 200 ft2 (18.6 m2) with an 8.5 ft (2.6 m)

tions of the bathroom in a typical hotel guest room. Some hotel ceiling, for a volume of 1,700 ft3 (48.1 m3). A VRF system us-

guests close the door of their bathroom before sleeping. With ing R-410A is proposed, with one 0.75 ton (2.6 kW) evapora-

the bathroom door closed, the volume of space to which the re- tor per guest unit. Now the RCL is 13 lb/1,000 ft3 (210 g/m3)

frigerant may disperse now would exclude the bathroom. For- and the maximum permissible total system refrigerant charge

mal Interpretation IC 15-2007-28 implies that the bathroom of is 22.1 lb (10.0 kg). Again, assuming a refrigerant charge of 4.5

a typical hotel guest room should not be counted in the room lb per ton (0.6 kg/kW), the refrigerant charge limit would allow

volume calculation. If, for example, the bathroom is 54 ft2 (5.0 a 4.9 ton (16.6 kW) system, or a maximum of 6 rooms with a

m2), the effective volume of the guest room proper is reduced 0.75 ton (2.6 kW) capacity requirement per room.

to 2,516 ft3 (71.2 m3). In this case, the maximum permissible

total system refrigerant charge is 65.4 lb (29.7 kg). Ambiguities

How many of these guest rooms can be networked on one A key component of the previous example calculations

VRF system? For illustrative purposes only, let us assume is the determination of the volume of the smallest occupied

an R-410A refrigerant charge of 4.5 lb per ton (0.6 kg/kW). space not connected to other spaces through permanent open-

In the example above, a 65.4 lb (29.7 kg) refrigerant charge ings (�����������������������������������������������������

§����������������������������������������������������

7.3.1). If two or more rooms are connected by perma-

limit would allow a 14 ton (49 kW) system, or a maximum nent openings, the volume of those rooms may be combined to

of 14 rooms with a 1 ton (3.5 kW) capacity requirement per find the RCL. A potential ambiguity exists in the evaluation of

guest room. So a VRF system in this hypothetical hotel would what constitutes a permanent opening. Does an undercut door

meet the RCL limit, as long as guest rooms are grouped into or a transfer opening qualify? If so, how large an undercut or

separate VRF systems of not more than 14 rooms/each. The transfer opening would be needed? These questions are not

actual capacity, room size, load calculation, refrigerant type specifically addressed in Standard 15.

and refrigerant charge of each system must be evaluated on a Clearly, undercut doors or transfer openings would eventu-

case-by-case basis and may differ from this example, but these ally permit a large leak of refrigerant in one small room to dis-

figures lend some order-of-magnitude to the discussion. perse to adjacent rooms. However, without detailed study or

22 ASHRAE Journal a s h r a e . o r g July 2012

Advertisement formerly in this space.

modeling, we do not know that this will occur quickly enough tors are addressed is within the Machinery Room compliance

to protect the safety of the room’s occupants. The driving force path, which is not appropriate for occupied space. Further-

expelling R-410A from a ruptured refrigerant pipe may be on more, trapping of liquid refrigerant subject to hydrostatic ex-

the order of 450 psig (3.1 MPa) for the system high side, but pansion due to closing of isolation valves must be addressed by

the driving force pushing transfer air under a door or through a pressure relief devices and/or engineering controls (§9.4.3.1).

transfer opening is five or six orders-of-magnitude less. Ceil-

ing-mounted transfer ducts are also suspect, since most com- Conclusions

monly used refrigerants are heavier than air. The Engineer- This article intended simply to remind designers who are ap-

of-Record must decide whether to rely on undercut doors or plying VRF that careful application of Standard 15 is neces-

transfer openings as a path to compliance. sary. Within the bounds of Standard 15, VRF systems can be

It is clear that some ASHRAE research would be helpful properly selected, designed, installed, and operated. It may be

in better defining how to treat an undercut door or a transfer advantageous to remove small rooms from a VRF system and

opening. Concurrent with publication of this article, a research serve those rooms separately; or use more, smaller, separate

topic acceptance request (RTAR) is being processed through VRF system networks in lieu of one larger system, or serve

proper ASHRAE channels, proposing ASHRAE research on multiple small rooms with one common ducted evaporator.

this topic. Routing is also a key consideration, to avoid routing refrigerant

Finally, this author is anecdotally aware of another approach piping through smaller enclosed rooms with a lower maximum

to refrigerant leak management, one that involves the installa- allowable charge. Operating pressures are relatively high, mak-

tion of automatic shutoff valves within the field refrigerant pip- ing the integrity of all the field joints critical, so enforce speci-

ing. In conjunction with refrigerant leak detectors, the intent is fication language requiring pressure testing of field piping.

to isolate a leak to one piping segment and limit the quantity

of refrigerant that can be leaked between valves to a quantity Disclaimer

below the RCL. This approach is not addressed by Standard 15. The contents of this article shall not be construed as an of-

The only place within Standard 15 that refrigerant leak detec- ficial interpretation of Standard 15. While the author of this

article is a member of Standing Standards Project Commit-

tee (SSPC) 15, the information presented in the article is the

view of the author alone and does not necessarily represent the

views of SSPC 15. The summary of Standard 15 in this article

is specific to VRF systems, and many portions of the standard

not specific to these systems were not discussed for reasons of

brevity. All numerical examples provided in this article are for

illustrative purposes only; every building is unique and must

be studied with respect to Standard 15 on a case-by-case basis.

Official interpretations may be requested of SSPC 15 through

the ASHRAE website.

Advertisement formerly in this space. References

1. ASHRAE. 2011. Advanced Energy Design Guide for Small to

Medium Office Buildings: 50% Energy Savings.

2. Goetzler, W. 2007. “Variable refrigerant flow systems.” ASHRAE

Journal 49(4):24.

3. Afify, R. 2008. “Designing VRF systems.” ASHRAE Journal

50(6):52.

4. 2012 ASHRAE Handbook—Systems and Equipment, Chapter 18.

5. Duda, S. 2011. “Application of ASHRAE Standard 15-2010 with

respect to multi-evaporator split air-conditioning systems.” ASHRAE

Transactions 117(2).

6. ASHRAE Standard 15-2010, Safety Standard for Refrigeration

Systems.

7. ASHRAE Standard 34-2010, Designation and Safety Classifica-

tion of Refrigerants.

8. ASHRAE Standard 15-2007, Safety Standard for Refrigeration

Systems. Interpretations IC-15-2007-2 and IC-15-2007-3 as quoted

in this article were approved by vote of SSPC 15 on Jan. 30, 2011.

9. 2009 ASHRAE Handbook—Fundamentals, Chapter 30.31.

10. ICC. 2009. International Mechanical Code, Chapter 11. Chicago:

International Code Council, Inc.

24 A S H R A E J o u r n a l July 2012

You might also like

- ASHRAE-VRF Standard15Document7 pagesASHRAE-VRF Standard15jijijadjoe100% (1)

- 170 2013 Ae 20141008 PDFDocument8 pages170 2013 Ae 20141008 PDFDamir ĆavarNo ratings yet

- The Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationFrom EverandThe Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationRating: 1 out of 5 stars1/5 (1)

- Ashrae: StandardDocument52 pagesAshrae: StandardsamadonyNo ratings yet

- HVAC Handbook 9 Systems Applications CarrierDocument27 pagesHVAC Handbook 9 Systems Applications CarrierTanveer100% (3)

- HVAC Handbook CARRIER 2 Air DistributerDocument99 pagesHVAC Handbook CARRIER 2 Air DistributerTanveer100% (5)

- Carrier VRF 2018 enDocument116 pagesCarrier VRF 2018 enLD Jr Francis100% (1)

- Ashrae CalculationsDocument3 pagesAshrae Calculationsgulfpipinggmailcom0% (1)

- Car Park Jet FanDocument14 pagesCar Park Jet FanYan Aung100% (1)

- Ashrae Pocket Guide I P PDFDocument36 pagesAshrae Pocket Guide I P PDFMUKESH DAYMANo ratings yet

- 5 - HVAC Handbook - New Edition - Part.5 - Water ConditioningDocument52 pages5 - HVAC Handbook - New Edition - Part.5 - Water ConditioningIsak Tao100% (2)

- Owners Guide For Buildings Served by District Cooling 1Document69 pagesOwners Guide For Buildings Served by District Cooling 1madhivanansp100% (4)

- AshraeDocument85 pagesAshraelayth salah100% (7)

- Ashrae - Basic Chiller Plant DesignDocument59 pagesAshrae - Basic Chiller Plant DesignAmro Metwally El Hendawy100% (3)

- ASHRAE Workshop Control SamHui Part 4Document53 pagesASHRAE Workshop Control SamHui Part 4feliprolNo ratings yet

- Handbook of Dehumidification TechnologyFrom EverandHandbook of Dehumidification TechnologyRating: 2.5 out of 5 stars2.5/5 (2)

- Previews ASHRAE D 98044 PreDocument31 pagesPreviews ASHRAE D 98044 PreLee Chorney0% (1)

- HVAC Handbook New Edition Part 4 Refrigerant Brines OilsDocument71 pagesHVAC Handbook New Edition Part 4 Refrigerant Brines OilsShakir Ahmed Kalkundri100% (3)

- Heating and Cooling Load Calculations: International Series of Monographs In: Heating, Ventilation and RefrigerationFrom EverandHeating and Cooling Load Calculations: International Series of Monographs In: Heating, Ventilation and RefrigerationRating: 3.5 out of 5 stars3.5/5 (6)

- UBC ASHRAE Competition Report PDFDocument34 pagesUBC ASHRAE Competition Report PDFmech118100% (1)

- Carrier HVAC Handbook Part 7 Refrigeration EquipmentDocument71 pagesCarrier HVAC Handbook Part 7 Refrigeration EquipmentTanveer100% (3)

- Ashrae Pocket GuideDocument86 pagesAshrae Pocket GuideEdisonSimbaña50% (2)

- Ashrae 1342005 Ra 2014 Graphic Symbols For Heating VentilatiDocument84 pagesAshrae 1342005 Ra 2014 Graphic Symbols For Heating VentilatiDanZel Dan80% (5)

- TRG-TRC002-En Cooling and Heating Load EstimationDocument95 pagesTRG-TRC002-En Cooling and Heating Load Estimationhonisme50% (2)

- A Guide in Practical Psychrometrics for Students and EngineersFrom EverandA Guide in Practical Psychrometrics for Students and EngineersNo ratings yet

- Water 09 00098 v2Document40 pagesWater 09 00098 v2enlightened171880% (5)

- Symbols - STD 134Document32 pagesSymbols - STD 134Joaquim MonteiroNo ratings yet

- Specifications For Fire Rated Gi Duct WorksDocument2 pagesSpecifications For Fire Rated Gi Duct Workspsn_kylmNo ratings yet

- ASHRAE Standard 62 and LEED CertificationDocument41 pagesASHRAE Standard 62 and LEED Certificationriyaaz1101100% (4)

- Ahrae STD 90.1-Trane PDFDocument10 pagesAhrae STD 90.1-Trane PDFNitesh SinghNo ratings yet

- (Carrier) HVAC Handbook - New Edition - Part.7 - Refrigeration EquipmentDocument71 pages(Carrier) HVAC Handbook - New Edition - Part.7 - Refrigeration Equipmentlyly20983% (6)

- 2017-11-06 Guideline 36 Draft 3Document182 pages2017-11-06 Guideline 36 Draft 3Jack Ng100% (1)

- ANSI - AHRI Standard I34-2005 (RA2014)Document84 pagesANSI - AHRI Standard I34-2005 (RA2014)Guy BlouinNo ratings yet

- Ashrae Chill Water STDDocument8 pagesAshrae Chill Water STDKarthik Raj100% (1)

- Ashrae Pocket Guide For Air ConditioningDocument448 pagesAshrae Pocket Guide For Air Conditioningconstantin.iacomi3837100% (2)

- Carrier Cooling Load Hand Book-1 PDFDocument16 pagesCarrier Cooling Load Hand Book-1 PDFAsep Uhan SugandiNo ratings yet

- Duct DesignDocument18 pagesDuct DesignBay Mưa100% (1)

- Ashrae 90.1-2010Document92 pagesAshrae 90.1-2010asarlakNo ratings yet

- Ashrae Icc Usgbc Ies 189.1-2017Document156 pagesAshrae Icc Usgbc Ies 189.1-2017Mahmoud Gwaily100% (5)

- Seresco Natatorium Design Guide 2013Document36 pagesSeresco Natatorium Design Guide 2013Luis Giagante100% (1)

- Ansi Ashrae Acca 183-2007 (Ra 2014)Document10 pagesAnsi Ashrae Acca 183-2007 (Ra 2014)Ahmed Labib100% (3)

- CARRIER Part-11 - All-Water-SystemDocument35 pagesCARRIER Part-11 - All-Water-SystemNahiyan AbdullahNo ratings yet

- Psychrometric TDP PreviewDocument0 pagesPsychrometric TDP PreviewAnonymous 73gEYyEtL75% (4)

- Method of Testing To Determine Flow Resistance of HVAC Ducts and FittingsDocument6 pagesMethod of Testing To Determine Flow Resistance of HVAC Ducts and FittingsWacoman RazanNo ratings yet

- Previews ASHRAE D 90439 PreDocument21 pagesPreviews ASHRAE D 90439 PreCotejo GermieNo ratings yet

- HVAC Handbook CARRIER New Edition Part 12 Water and DX System PDFDocument23 pagesHVAC Handbook CARRIER New Edition Part 12 Water and DX System PDFalejandro100% (1)

- Trane - Coil Sizing Guide PDFDocument42 pagesTrane - Coil Sizing Guide PDFyousuffNo ratings yet

- Automatic Controls for Heating and Air Conditioning: Principles and ApplicationsFrom EverandAutomatic Controls for Heating and Air Conditioning: Principles and ApplicationsRating: 4 out of 5 stars4/5 (2)

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- Ashrae 15-34-Rev 3 MitsubishiDocument7 pagesAshrae 15-34-Rev 3 MitsubishiJosho SandovalNo ratings yet

- Articulo Standar Ashrae 15Document17 pagesArticulo Standar Ashrae 15fmlomaNo ratings yet

- ASHRAE STANDARD 15 Applied To Packaged, Split and VRF Systems PDFDocument6 pagesASHRAE STANDARD 15 Applied To Packaged, Split and VRF Systems PDFhabebeNo ratings yet

- Immersed Cross SectionsDocument17 pagesImmersed Cross SectionsAlexandra MoldovanNo ratings yet

- 150hp-2p-460vac-Frame 447VPDocument16 pages150hp-2p-460vac-Frame 447VPRicardo Espinosa RamírezNo ratings yet

- Cambridge International Advanced Subsidiary and Advanced LevelDocument20 pagesCambridge International Advanced Subsidiary and Advanced LevelGianra RadityaNo ratings yet

- PANAFLOW Caudalímetro Vortex (Ingles)Document83 pagesPANAFLOW Caudalímetro Vortex (Ingles)biotech666No ratings yet

- 05 - Kit-Liner-P-Robot - 001 - MIG-MAG Robot Welding TorchDocument8 pages05 - Kit-Liner-P-Robot - 001 - MIG-MAG Robot Welding Torchalecandro_90No ratings yet

- Mitsubishi L200 Challenger Edition 2019 UKDocument3 pagesMitsubishi L200 Challenger Edition 2019 UKsanomanjirovicNo ratings yet

- Numesh Engineered Wire Mesh Design TablesDocument20 pagesNumesh Engineered Wire Mesh Design TablesYakhoob KhanNo ratings yet

- Fluid Mechanics History EssayDocument16 pagesFluid Mechanics History EssayBorja MonDe YorkNo ratings yet

- T3W Instruction Manual - Feb 2014Document550 pagesT3W Instruction Manual - Feb 2014Jose Macias Acevedo100% (3)

- 950H - Sebp3866-24 - K5K - Vol 1Document898 pages950H - Sebp3866-24 - K5K - Vol 1pikinhos100% (6)

- Pressure Vessels Lectures 69Document1 pagePressure Vessels Lectures 69Adeel NizamiNo ratings yet

- Havells PumpsDocument8 pagesHavells PumpsNAVEEN JATNo ratings yet

- Technical Guide Wavin PVC Pressure Pipe SystemsDocument50 pagesTechnical Guide Wavin PVC Pressure Pipe SystemsShailendra RamchurnNo ratings yet

- Komatsu Truck HM400-2+SEN00239-03D ManualDocument1,356 pagesKomatsu Truck HM400-2+SEN00239-03D Manual江柄宏100% (8)

- A Analyti Transfe Cal and Er Func D Nume Ction in Bound Erical e N Ducts Dary Co Estimat S Consi Ondition Tion of Dering Ns F Acous G Gener Stic RalDocument10 pagesA Analyti Transfe Cal and Er Func D Nume Ction in Bound Erical e N Ducts Dary Co Estimat S Consi Ondition Tion of Dering Ns F Acous G Gener Stic Ralpela210No ratings yet

- Plan and Design For PhysicsDocument8 pagesPlan and Design For PhysicsDJ FIVE7No ratings yet

- Tablas Mecanicas KR C2 PDFDocument10 pagesTablas Mecanicas KR C2 PDFarturoNo ratings yet

- MHI Multi - 20R01EDocument88 pagesMHI Multi - 20R01EMinh PhatNo ratings yet

- Halton TsaDocument9 pagesHalton TsaNetri KrisztiánNo ratings yet

- RODAMIENTOS NSK BDocument296 pagesRODAMIENTOS NSK BFredy Hernan Sam ChocNo ratings yet

- Rei Vol IDocument297 pagesRei Vol IDineshNo ratings yet

- Hydraulic Cylinder For Use WTH:-HVL, HPS, HLS, HSS, Has, HHS, HHR, Hda & HgsDocument8 pagesHydraulic Cylinder For Use WTH:-HVL, HPS, HLS, HSS, Has, HHS, HHR, Hda & HgsKundan Kumar MishraNo ratings yet

- Vulnerability Assessment of StructuresDocument24 pagesVulnerability Assessment of StructuresMohan NaikNo ratings yet

- Gen II Automated Transmissions - TRTS0062 EN-US PDFDocument314 pagesGen II Automated Transmissions - TRTS0062 EN-US PDFsherzadNo ratings yet

- Manual HaulotteDocument82 pagesManual HaulotteRock Saybolt100% (3)

- 3408 Timing GeaarsDocument4 pages3408 Timing Geaarsmanu luvungaNo ratings yet

- John Deere STX30 Technical - Manual - DownloadDocument314 pagesJohn Deere STX30 Technical - Manual - DownloadHansruedi Stebler100% (1)

- Course: Advanced Thermodynamics For Chemical and Process EngineeringDocument2 pagesCourse: Advanced Thermodynamics For Chemical and Process Engineeringnaytpuri montemayorNo ratings yet

- Fsa 020-2011 PDFDocument12 pagesFsa 020-2011 PDFhadiranjiNo ratings yet