Professional Documents

Culture Documents

KMT Orifice-Cutting Speeds Data

Uploaded by

Anonymous VRspXsmCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KMT Orifice-Cutting Speeds Data

Uploaded by

Anonymous VRspXsmCopyright:

Available Formats

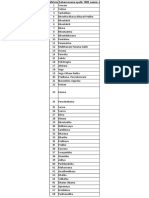

Machining allowances and tolerances for hot-forged

products • UNI 7486: 1975

Round Square Flat

a = machining allowance

b, h, l = dimensions after machining

B, H, L = raw material dimensions

dimension For length > 6000 mm, tolerances and allowances have to be agreed while placing the order

b or h Carbon steels and low-alloyed steels, max L 3500 Carbon steels and low-alloyed steels, max L 3500 - 6000 High-alloyed steels, max L 3500

after mechanical (% of every alloy elements < 5) (% of every alloy element < 5) (% of every alloy element ≥ 5)

processing

increase deviation increase deviation increase deviation increase deviation increase deviation increase deviation

mm

b or h (2 a) B or H l (2 a) L b or h (2 a) B or H l (2 a) L b or h (2 a) B or H l (2 a) L

> 100 < 125 14 ± 3,8 17 + 17 / - 10 17 ± 4,8 22 + 21 / - 13 10 ± 2,0 16 + 14 / - 11

> 125 < 160 16 ± 4,2 19 + 18 / - 11 19 ± 5,4 24 + 22 / - 14 12 ± 2,3 18 + 14 / - 11

> 160 < 200 18 ± 4,9 22 + 20 / - 13 21 ± 6,3 26 + 22 / - 15 14 ± 2,8 20 + 14 / - 14

> 200 < 250 21 ± 5,6 24 + 22 / - 14 24 ± 7,2 29 + 26 / - 17 17 ± 3,4 23 + 16 / - 16

> 250 < 315 25 ± 6,5 28 + 26 / - 15 28 ± 8,4 32 + 29 / - 19 21 ± 4,2 26 + 18 / - 18

> 315 < 400 30 ± 7,7 32 + 28 / - 18 33 ± 10,0 36 + 33 / - 22 26 ± 5,1 30 + 21 / - 21

> 400 < 500 36 ± 9,2 38 + 33 / - 22 40 ± 11,9 42 + 38 / - 25 32 ± 6,3 36 + 25 / - 25

> 500 < 630 44 ± 11,0 45 + 39 / - 25 48 ± 14,3 49 + 46 / - 29 39 ± 7,8 42 + 29 / - 29

> 630 < 800 54 ± 13,5 55 + 45 / - 30 58 ± 17,4 58 + 51 / - 34 49 ± 9,8 52 + 35 / - 35

> 800 < 1000 66 ± 16,3 67 + 55 / - 36 71 ± 21,3 69 + 61 / - 41 61 ± 12,1 63 + 42 / - 42

Measures are expressed in mm. e.g. non-alloyed round bars b = 330 mm and l ≤ 3500 mm. Diameter of turned raw material B = 330 + 30 = 360 ± 7,7

dimension For length > 6000 mm, tolerances and allowances have to be agreed while placing the order

b or h Low-alloyed steels, L 3500 - 6000

Tool steels L 3500 max Tool steels L 3500 - 6000

after mechanical (% of every alloy elements ≥ 5)

processing

increase deviation increase deviation increase deviation increase deviation increase deviation increase deviation

mm

b or h (2 a) B or H l (2 a) L b or h (2 a) B or H l (2 a) L b or h (2 a) B or H l (2 a) L

> 100 < 125 13 ± 4,0 21 + 18 / - 12 7 ± 1,5 14 + 14 / - 11 10 ± 2,1 17 + 14 / - 10

> 125 < 160 15 ± 4,6 22 + 20 / - 13 9 ± 1,8 15 + 14 / - 11 12 ± 2,5 19 + 15 / - 12

> 160 < 200 18 ± 5,2 25 + 22 / - 14 11 ± 2,2 17 + 14 / - 14 14 ± 2,9 21 + 16 / - 14

> 200 < 250 21 ± 6,0 27 + 24 / - 16 13 ± 2,6 20 + 16 / - 16 17 ± 3,5 23 + 17 / - 17

> 250 < 315 24 ± 7,0 30 + 27 / - 18 16 ± 3,2 23 + 18 / - 18 21 ± 4,2 26 + 19 / - 19

> 315 < 400 29 ± 8,4 35 + 31 / - 21 19 ± 4,0 27 + 21 / - 21 26 ± 5,0 30 + 22 / - 22

> 400 < 500 35 ± 10,0 40 + 35 / - 24 24 ± 4,9 32 + 25 / - 25 32 ± 6,2 35 + 26 / - 26

> 500 < 630 42 ± 12,0 47 + 42 / - 28 30 ± 6,0 38 + 29 / - 29 39 ± 7,5 41 + 31 / - 31

> 630 < 800 52 ± 14,9 55 + 49 / - 33 37 ± 7,4 47 + 35 / - 35 49 ± 9,4 49 + 36 / - 36

> 800 < 1000 64 ± 18,1 66 + 59 / - 40 46 ± 9,3 57 + 42 / - 42 61 ± 11,6 59 + 44 / - 44

Measures are expressed in mm. e.g. tool steels round b = 260 mm and l ≤ 4000 mm. Diameter of turned raw material B = 260 + 21 = 281 ± 4,2. Only for rounds, ovalization is not higher than the tolerance corresponding to diameter B. Flats tolerances and allowances values

are valid if: b/h ≤ 8 for alloyed, non-alloyed, quality or special steels; b/h ≤ 5 for base non-alloyed steels. Lucefin Group tolerance for rough products on b or h is + 1 mm / + 3 mm.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Welding Cost Estimation For 12 Joints in 8 NPS SCH 80 PDFDocument1 pageWelding Cost Estimation For 12 Joints in 8 NPS SCH 80 PDFAnonymous VRspXsmNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Acme Thread DimensionsDocument74 pagesAcme Thread DimensionsJorge Forero50% (4)

- Atlas Engineering Metals HandbookDocument136 pagesAtlas Engineering Metals HandbookMatt KurtzeNo ratings yet

- Induction Heating Parameters On Forging BilletDocument85 pagesInduction Heating Parameters On Forging BilletAnonymous VRspXsmNo ratings yet

- Bench Grinder: DO NOT Use This Machine Unless A Teacher Has InstructedDocument2 pagesBench Grinder: DO NOT Use This Machine Unless A Teacher Has InstructedNabil Qayyum Roslee100% (1)

- Hourly Labour Costs 2016Document14 pagesHourly Labour Costs 2016Anonymous VRspXsmNo ratings yet

- Lost Wax Casting ProcessDocument2 pagesLost Wax Casting ProcessgabaldoniNo ratings yet

- MCQ Workshop Engg: Workshop Technology Objective Questions With Answers - Set 07Document5 pagesMCQ Workshop Engg: Workshop Technology Objective Questions With Answers - Set 07l8o8r8d8s8i8v8100% (1)

- Fulfill Instructions Quotation Analysis FormDocument2 pagesFulfill Instructions Quotation Analysis FormAnonymous VRspXsm100% (1)

- Section 2 Tooling Fo Die Casting OptDocument22 pagesSection 2 Tooling Fo Die Casting OptAnonymous VRspXsmNo ratings yet

- An Integrated Framework For Die and Mold Cost Estimation Using Design Features and Tooling ParametersDocument12 pagesAn Integrated Framework For Die and Mold Cost Estimation Using Design Features and Tooling ParametersAnonymous VRspXsmNo ratings yet

- Fulfill Instructions Quotation Analysis FormDocument5 pagesFulfill Instructions Quotation Analysis FormAnonymous VRspXsmNo ratings yet

- Girl Baby NameDocument40 pagesGirl Baby NameAnonymous VRspXsmNo ratings yet

- Cutting Data Ramax HH EngDocument6 pagesCutting Data Ramax HH EngAnonymous VRspXsmNo ratings yet

- CastingDocument18 pagesCastingAnonymous VRspXsmNo ratings yet

- Sprint Capacity Planner 27 NovDocument11 pagesSprint Capacity Planner 27 NovAnonymous VRspXsmNo ratings yet

- Hourly Cost To Run A WaterjetDocument3 pagesHourly Cost To Run A WaterjetAnonymous VRspXsmNo ratings yet

- Introduction To Powder MetallurgyDocument3 pagesIntroduction To Powder MetallurgyAnonymous VRspXsmNo ratings yet

- Krusty, 3D "Krusty": KROMM Steel WorksDocument17 pagesKrusty, 3D "Krusty": KROMM Steel Worksxx xxxNo ratings yet

- DJF21012 Sand Casting 1006Document15 pagesDJF21012 Sand Casting 1006Sakinah KamalNo ratings yet

- Module-2 Machining Process: Lesson ContentsDocument20 pagesModule-2 Machining Process: Lesson ContentsYashas KattemaneNo ratings yet

- Kansai DMM2203 D F PDFDocument31 pagesKansai DMM2203 D F PDFisrael amilNo ratings yet

- Drilling, Welding and Grinding MachinesDocument2 pagesDrilling, Welding and Grinding MachinesiamjemahNo ratings yet

- OCTOBER 2018 Surplus Record Machinery & Equipment DirectoryDocument715 pagesOCTOBER 2018 Surplus Record Machinery & Equipment DirectorySurplus RecordNo ratings yet

- 6 - Bulk Deformation ProcessesDocument34 pages6 - Bulk Deformation ProcessesZack MalikNo ratings yet

- Slotted Angles PDFDocument3 pagesSlotted Angles PDFmancas50No ratings yet

- Itemstockcost ItemstockcostDocument12 pagesItemstockcost ItemstockcostVignesh SNo ratings yet

- Operation Manual ESG-1224TDDocument106 pagesOperation Manual ESG-1224TDRikardo JimkarNo ratings yet

- CU400 CU500: Machine SpecificationDocument4 pagesCU400 CU500: Machine SpecificationГеорги НеновNo ratings yet

- Hand Tools 1Document2 pagesHand Tools 1Nikki AngelaNo ratings yet

- Bolt Imperial Size ChartDocument2 pagesBolt Imperial Size CharthendrobamaNo ratings yet

- S-Turbo Hardware Tool 2010 CatalogDocument60 pagesS-Turbo Hardware Tool 2010 CatalogscottckNo ratings yet

- W A U K E S H A: 102 FORM 6315 First EditionDocument2 pagesW A U K E S H A: 102 FORM 6315 First EditionMOHANNo ratings yet

- ch8 9Document1 pagech8 9Dumisani SitholeNo ratings yet

- A668Document8 pagesA668Vladimir JaraNo ratings yet

- Welding Lectures 1-2 PDFDocument33 pagesWelding Lectures 1-2 PDFKshitijGauravVermaNo ratings yet

- Parts List: Industrial Sewing MachinesDocument49 pagesParts List: Industrial Sewing Machinesabderrahman dahamNo ratings yet

- Accident Prevention Manual - Engineering and TechnologyDocument1,136 pagesAccident Prevention Manual - Engineering and TechnologyBinu NilamelNo ratings yet

- MetalTek Alloy Guide PDFDocument12 pagesMetalTek Alloy Guide PDFmohammed rafiNo ratings yet

- Cost Effective Design Tips For Machining: Complex PartsDocument8 pagesCost Effective Design Tips For Machining: Complex PartsGIYEONGNo ratings yet

- 760 Low Loft Bed: Fort Whorth, Texas 76140Document7 pages760 Low Loft Bed: Fort Whorth, Texas 76140مجدى الشامىNo ratings yet

- Difference Between Single Point and Multi Point Cutting ToolDocument10 pagesDifference Between Single Point and Multi Point Cutting ToolP. Morales EdgarNo ratings yet

- HAWE PSL-3 Seal KitDocument4 pagesHAWE PSL-3 Seal Kitbrunosamaeian100% (1)