Professional Documents

Culture Documents

Cembinder 8 TDS

Uploaded by

kbkshanaka0 ratings0% found this document useful (0 votes)

339 views1 pageNano silica specification

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentNano silica specification

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

339 views1 pageCembinder 8 TDS

Uploaded by

kbkshanakaNano silica specification

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Cembinder® 8

SEPARATION AND STABILITY CONTROL

OF HIGH PERFORMANCE CONCRETE

Key Benefit Summary Addition

The addition rate of CEMBINDER® 8 is 0.1 to 1.5 % by

• Improves stability in self-consolidating concrete weight of cement. Normally the addition is around 0.5 %

in a concrete with a w/c ratio of 0.3 - 0.5. Due to specific

• Enables cement and filler reduction

conditions and demands other addition rates may be

• Enhances early strength appropriate.

• Makes the concrete more cohesive and robust

• Easy handling improves production efficiency Packaging

• Non-returnable 220 litre / 55 gallon (US) plastic drums

PRODUCT INFORMATION • Non-returnable semi-bulk containers (IBC)

• Bulk tank trucks

CEMBINDER® 8 is a part of a product range for

cementitous applications based on the new technology

patented by EKA Chemicals. The active compound is an TECHNICAL INFORMATION

inorganic, highly reactive, water based colloidal silica. Description

CEMBINDER® 8 is based on amorphous silicondioxide.

Compatibility The product is defined as a polydispersion of silicon

The product in the CEMBINDER® range are fully dioxide particles in water.

compatible with existing admixtures in general and with

existing polycarboxylate based high range water reducers Typical characteristics

in particular. CEMBINDER® 8

Usage Density, g/cm3 (20°C) 1,4

CEMBINDER 8 is used to control the stability,

®

pH 9,5

segregation and water loss in highly fluid concretes Scc.

CEMBINDER® 8 will stabilize most concretes where the Viscosity (cPS) < 15

water content is at a medium to low level, corresponding Solid content (wt%) 50

to w/c ratios below 0.5.

Appearance Opalescent, no smell or taste

The product is normally added in sequence with the high

range water reducer and does not require any prolonged Storage and handling

mixing time. CEMBINDER® 8 is frost sensitive and should be stored at

+5 to +35°C. For storage purposes dark, closed tanks

The use of CEMBINDER® 8 enables a substantial made from resistant materials such as stainless or coated

reduction in the amounts of cement and/or filler, with a steel or plastic should be used. Aluminium, copper or

maintained or higher early strength. regular steel tanks should be avoided. Stored accordingly

product stability and quality is garanteed for twelve

months.

HEALTH, SAFETY AND ENVIRONMENT

Before handling this material, read the corresponding

Material Safety Data Sheet and environmental

information.

www.colloidalsilica.com Revision date: September 2006

HEAD OFFICE: Eka Chemicals AB, Industrial Specialties, SE-445 80 Bohus, Sweden. Phone: +46 31 58 70 00 Fax: +46 31 58 78 59

CENTRAL EUROPE: Akzo Nobel Chemicals GmbH, Industrial Specialities, Kreuzauer Str. 46, DE-52355 Düren, Germany.

Phone: +49 (0)2421 595633 Fax: +49 (0)2421 595635

NORTH AMERICA: Eka Chemicals Inc., Industrial Specialities, 1775 West Oak Commons Court Marietta, GA 30062, USA.

Phone: +1 770 578 0858 Fax: + 1 770 321 5885

ASIA: Akzo Nobel Asia Pte. Ltd, Taiwan Branch, 6F, B1, No 51, Sec.2., Gongyi Road, Taichung, 408, Taiwan , ROC.

Phone: + 886 4 2327 0520 Fax: + 886 4 2327 0580

Information herein is accurate to the best of our knowledge.

Suggestions are made without warranty or guarantee of results.

Before using, user should determine the suitability of the product for

his intended use and user assumes the risk and liability in connection

therewith. We do not suggest violation of any existing patents or give

permission to practice any patented invention without a license.

You might also like

- Modified Polymers, Their Preparation and Properties: Main Lectures Presented at the Fourth Bratislava Conference on Polymers, Bratislava, Czechoslovakia, 1-4 July 1975From EverandModified Polymers, Their Preparation and Properties: Main Lectures Presented at the Fourth Bratislava Conference on Polymers, Bratislava, Czechoslovakia, 1-4 July 1975A. RomanovRating: 5 out of 5 stars5/5 (1)

- Cembinder For WcementinglDocument38 pagesCembinder For Wcementinglcementacioneshoy100% (2)

- AkzoNobel Cembinder W Colloidal Silica Dispersions Tcm135-59253Document4 pagesAkzoNobel Cembinder W Colloidal Silica Dispersions Tcm135-59253Albert GhobrialNo ratings yet

- Astm C31/31MDocument6 pagesAstm C31/31MIrene Grace BatalaoNo ratings yet

- Admixture and Fresh ConcreteDocument57 pagesAdmixture and Fresh ConcretegoogkitNo ratings yet

- Recent Trend: Use of Metakaolin As Admixture: A ReviewDocument7 pagesRecent Trend: Use of Metakaolin As Admixture: A ReviewAJER JOURNALNo ratings yet

- Masterroc® FLC 100 (Formerly Known As Meyco® Flowcable)Document2 pagesMasterroc® FLC 100 (Formerly Known As Meyco® Flowcable)Ryan LasacaNo ratings yet

- Nano ConcreteDocument17 pagesNano ConcretebuntyNo ratings yet

- Recent Progress in Concrete-Polymer CompositesDocument10 pagesRecent Progress in Concrete-Polymer Compositesswathi1105No ratings yet

- Duracrete TDSDocument2 pagesDuracrete TDSpsrikanthan67% (3)

- The Use of Bonding Agents For Portland Cement PlasteringDocument3 pagesThe Use of Bonding Agents For Portland Cement PlasteringbatteekhNo ratings yet

- Aci 221R-96Document3 pagesAci 221R-96farhadamNo ratings yet

- Guide For The Use of Polymers in Concrete PDFDocument29 pagesGuide For The Use of Polymers in Concrete PDFMEGA_ONENo ratings yet

- Conplast SP360 : High Performance Water Reducing Admixture Uses Technical SupportDocument4 pagesConplast SP360 : High Performance Water Reducing Admixture Uses Technical Supportpravi3434No ratings yet

- High Strength Non-Shrink Grout for Post-Tensioned CablesDocument3 pagesHigh Strength Non-Shrink Grout for Post-Tensioned CablesVenkata RaoNo ratings yet

- Masterflow 928 Spec PDFDocument8 pagesMasterflow 928 Spec PDFDavid Toyohashi BioGenNo ratings yet

- Introduction of Cement: When Was Cement Begin?Document11 pagesIntroduction of Cement: When Was Cement Begin?مايف سعدونNo ratings yet

- Waterproofing Admixture PDFDocument2 pagesWaterproofing Admixture PDFSegun100% (1)

- Admixtures For ConcreteDocument5 pagesAdmixtures For ConcreteShahril ZainulNo ratings yet

- Chemical Bonding Agents and MortarsDocument14 pagesChemical Bonding Agents and MortarsakurilNo ratings yet

- Isobond: SBR Bonding AdmixtureDocument3 pagesIsobond: SBR Bonding AdmixtureHussain MarzooqNo ratings yet

- BS890Document21 pagesBS890ianbramleyNo ratings yet

- ASTM C1019 GroutingDocument4 pagesASTM C1019 GroutingTrung Hieu NguyenNo ratings yet

- Elastomeric Cellular Preformed Gasket and Sealing Material: Standard Specification ForDocument5 pagesElastomeric Cellular Preformed Gasket and Sealing Material: Standard Specification ForĐường Nguyễn ThừaNo ratings yet

- Crystalline Waterproofing Protects Concrete InfrastructureDocument12 pagesCrystalline Waterproofing Protects Concrete InfrastructureJoseph ChenNo ratings yet

- Calcium Sulfate Filler Brochure en IG172Document8 pagesCalcium Sulfate Filler Brochure en IG172Leonardo CalvinNo ratings yet

- Concrete BasicsDocument27 pagesConcrete BasicsPradeepLokhandeNo ratings yet

- Types of AdmixturesDocument3 pagesTypes of AdmixturesvanamgouthamNo ratings yet

- Bsen 934 P2Document11 pagesBsen 934 P2askarahNo ratings yet

- MS 14 - Internal Waterproofing PDFDocument3 pagesMS 14 - Internal Waterproofing PDFsullamsNo ratings yet

- No Fines ConcreteDocument5 pagesNo Fines ConcretedannyNo ratings yet

- Nano WaterproofingDocument2 pagesNano Waterproofingmbvyass1979100% (1)

- Determination of Water-Cement Ratio of HardenedDocument6 pagesDetermination of Water-Cement Ratio of HardenedMárcio AlvesNo ratings yet

- Astm C199 PDFDocument2 pagesAstm C199 PDFdeivisbtsNo ratings yet

- Conplast SP430 0914Document4 pagesConplast SP430 0914Vipul AroraNo ratings yet

- Carbonation of Flyash ConcretDocument6 pagesCarbonation of Flyash ConcretAnshul SoniNo ratings yet

- Fresh Concrete Testing EquipmentDocument1 pageFresh Concrete Testing EquipmentNovi RahmayantiNo ratings yet

- Technical Report TR 5 Conc Mix DesignDocument18 pagesTechnical Report TR 5 Conc Mix DesignSunil ReddyNo ratings yet

- Comparation Glycerol Degradation by Microwave Heating and by Hydrothermal TreatmentDocument6 pagesComparation Glycerol Degradation by Microwave Heating and by Hydrothermal TreatmentzaedmohdNo ratings yet

- Design and Application of Self Compacting ConcreteDocument38 pagesDesign and Application of Self Compacting ConcreteAby AnjaliseNo ratings yet

- AerogelDocument18 pagesAerogelBanala shivani100% (1)

- Formulation Techniques Using Feve Resins in Waterborne and HighDocument10 pagesFormulation Techniques Using Feve Resins in Waterborne and HighManuel ChireNo ratings yet

- AdmixtureDocument7 pagesAdmixturevinay rodeNo ratings yet

- Sika Fibre 2011 - PDSDocument4 pagesSika Fibre 2011 - PDSIbnu SenaNo ratings yet

- AdmixtureDocument6 pagesAdmixtureDunvillNo ratings yet

- Shrinkage Compensating Admixtures by Sunanda CoatingsDocument2 pagesShrinkage Compensating Admixtures by Sunanda Coatingss.skumar10% (1)

- New Ansi 118.15Document2 pagesNew Ansi 118.15Tensile TestingNo ratings yet

- Concrete Technology Lec01: Compressive & Tensile StressDocument2 pagesConcrete Technology Lec01: Compressive & Tensile StressfaizanNo ratings yet

- Grouts Standards and TestingDocument12 pagesGrouts Standards and TestingmithileshNo ratings yet

- Waterglass - and PhosphatesDocument4 pagesWaterglass - and PhosphatesChris BothaNo ratings yet

- Materials For Bridge Deck Waterproofing Membrane SystemsDocument2 pagesMaterials For Bridge Deck Waterproofing Membrane SystemstenNo ratings yet

- TCVN 6260 - 2009 Portland Blended Cement SpecificationsDocument4 pagesTCVN 6260 - 2009 Portland Blended Cement SpecificationsLong LêNo ratings yet

- Mechanical Properties of Concrete Incorporating High Volumes of Fly Ash From Sources in The U.S.Document10 pagesMechanical Properties of Concrete Incorporating High Volumes of Fly Ash From Sources in The U.S.Afifah FauziNo ratings yet

- C W Rystalline Aterproofing: (An 9001: 2015, 14001: 2015 & 18001: 2007 Certified Company) ISO ISO OhsasDocument8 pagesC W Rystalline Aterproofing: (An 9001: 2015, 14001: 2015 & 18001: 2007 Certified Company) ISO ISO OhsasgangadevimgmNo ratings yet

- Super Plasticizers: Classification and Uses - Concrete TechnologyDocument8 pagesSuper Plasticizers: Classification and Uses - Concrete TechnologyLASA VADODARANo ratings yet

- Repair Manual King Fahd SaDocument27 pagesRepair Manual King Fahd SaPrasobh Shamohan100% (1)

- Rehabilitation of Concrete Tank Using Epoxy and FRP LiningDocument5 pagesRehabilitation of Concrete Tank Using Epoxy and FRP LiningChaitanya ShahNo ratings yet

- Green Concrete PresentationDocument17 pagesGreen Concrete PresentationSivaramakrishnan PNo ratings yet

- ASTM D 1144 - 99 Determining Strength Development of Adhesive BondsDocument2 pagesASTM D 1144 - 99 Determining Strength Development of Adhesive Bondsalin2005No ratings yet

- W.P.T. - Penetron ChemicalsDocument30 pagesW.P.T. - Penetron ChemicalsguptasonsonNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Test Standard Sample Size Length (MM) Width (MM) Thickness (MM) Tensile Stress ASTM D3039 203.2 12.7 3.2 Tensile ModulusDocument1 pageTest Standard Sample Size Length (MM) Width (MM) Thickness (MM) Tensile Stress ASTM D3039 203.2 12.7 3.2 Tensile ModuluskbkshanakaNo ratings yet

- LabelDocument2 pagesLabelkbkshanakaNo ratings yet

- City of Colombo Developmenty PlanDocument107 pagesCity of Colombo Developmenty PlanJeganath KabilNo ratings yet

- Test Standard Sample Size Length (MM) Width (MM) Thickness (MM) Tensile Stress ASTM D3039 203.2 12.7 3.2 Tensile ModulusDocument1 pageTest Standard Sample Size Length (MM) Width (MM) Thickness (MM) Tensile Stress ASTM D3039 203.2 12.7 3.2 Tensile ModuluskbkshanakaNo ratings yet

- Hemp concrete compression test resultsDocument1 pageHemp concrete compression test resultskbkshanakaNo ratings yet

- ICTAD-DEV-14 - Fire Regulations (Not Available) PDFDocument17 pagesICTAD-DEV-14 - Fire Regulations (Not Available) PDFAvk SanjeevanNo ratings yet

- City of Colombo Developmenty PlanDocument107 pagesCity of Colombo Developmenty PlanJeganath KabilNo ratings yet

- Hemp in Construction - Shanaka2Document31 pagesHemp in Construction - Shanaka2kbkshanakaNo ratings yet

- Dangerous Goods: Property or The Environment"Document1 pageDangerous Goods: Property or The Environment"kbkshanakaNo ratings yet

- ICTAD-DEV-14 - Fire Regulations (Not Available) PDFDocument17 pagesICTAD-DEV-14 - Fire Regulations (Not Available) PDFAvk SanjeevanNo ratings yet

- Test Standard Sample Size Length (MM) Width (MM) Thickness (MM) Tensile Stress ASTM D3039 203.2 12.7 3.2 Tensile ModulusDocument1 pageTest Standard Sample Size Length (MM) Width (MM) Thickness (MM) Tensile Stress ASTM D3039 203.2 12.7 3.2 Tensile ModuluskbkshanakaNo ratings yet

- ICTAD-DEV-14 - Fire Regulations (Not Available) PDFDocument17 pagesICTAD-DEV-14 - Fire Regulations (Not Available) PDFAvk SanjeevanNo ratings yet

- Dangerous Goods: Property or The Environment"Document1 pageDangerous Goods: Property or The Environment"kbkshanakaNo ratings yet

- GFRP Predicted Results SummaryDocument1 pageGFRP Predicted Results SummarykbkshanakaNo ratings yet

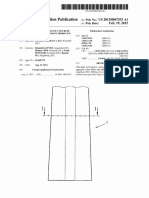

- Us 20150047533Document5 pagesUs 20150047533kbkshanakaNo ratings yet

- Silica Fume - High Strength ConcreteDocument2 pagesSilica Fume - High Strength ConcretekbkshanakaNo ratings yet

- Abaqus Analysis User's Manual (6Document3 pagesAbaqus Analysis User's Manual (6kbkshanakaNo ratings yet

- Silica Fume - High Strength ConcreteDocument2 pagesSilica Fume - High Strength ConcretekbkshanakaNo ratings yet

- Silica Fume - High Strength ConcreteDocument2 pagesSilica Fume - High Strength ConcretekbkshanakaNo ratings yet

- Test Standard Sample Size Length (MM) Width (MM) Thickness (MM) Tensile Stress ASTM D3039 203.2 12.7 3.2 Tensile ModulusDocument1 pageTest Standard Sample Size Length (MM) Width (MM) Thickness (MM) Tensile Stress ASTM D3039 203.2 12.7 3.2 Tensile ModuluskbkshanakaNo ratings yet

- Times Me ReportDocument49 pagesTimes Me ReportHitesh BhatiaNo ratings yet

- Plasiticity Theory and Implementation in Exp and ImplirityDocument230 pagesPlasiticity Theory and Implementation in Exp and ImpliritykbkshanakaNo ratings yet

- Concrete EOS According To MAT 72 R3Document1 pageConcrete EOS According To MAT 72 R3kbkshanakaNo ratings yet

- Gies Barbecu E: August 8 at 2. 00pmDocument1 pageGies Barbecu E: August 8 at 2. 00pmkbkshanakaNo ratings yet

- Rate Dependent Plasticity Theory ManualDocument69 pagesRate Dependent Plasticity Theory ManualkbkshanakaNo ratings yet

- Concrete ModelDocument13 pagesConcrete ModelkbkshanakaNo ratings yet

- HPC Applications in France - ToutlemondeDocument18 pagesHPC Applications in France - ToutlemondekbkshanakaNo ratings yet

- Concrete ModelDocument13 pagesConcrete ModelkbkshanakaNo ratings yet

- Pile Foundation As Per IRC 112Document59 pagesPile Foundation As Per IRC 112ARVIND SINGH RAWAT0% (1)

- Stroke RecoveryDocument20 pagesStroke RecoveryVanessa SnowNo ratings yet

- Time ManagementDocument30 pagesTime ManagementVaibhav Vithoba NaikNo ratings yet

- Burns SeminarDocument66 pagesBurns SeminarPratibha Thakur100% (1)

- Jose Irizarry ResumeDocument2 pagesJose Irizarry ResumeAnastasia GloverNo ratings yet

- Research On Motivation TheoriesDocument15 pagesResearch On Motivation TheoriesNayeem Md SakibNo ratings yet

- Observations of Children's Interactions With Teachers, PeersDocument25 pagesObservations of Children's Interactions With Teachers, PeersMazlinaNo ratings yet

- Mulching Paper Laying Machine SynopsisDocument17 pagesMulching Paper Laying Machine SynopsisSiddhesh Zirpe50% (2)

- Trabeculectomy Complications: Characteristics and ManagementDocument31 pagesTrabeculectomy Complications: Characteristics and ManagementalfarizyjefryNo ratings yet

- Veterinary Medicines ReportDocument28 pagesVeterinary Medicines Reportvikram chhabraNo ratings yet

- ASTM D1123 Contenido Agua en Glicol PDFDocument5 pagesASTM D1123 Contenido Agua en Glicol PDFdianacalixtogNo ratings yet

- Sugar Crisis in Pakistan Research PaperDocument10 pagesSugar Crisis in Pakistan Research Paperrehan9891No ratings yet

- ERAS DR - TESAR SP - AnDocument26 pagesERAS DR - TESAR SP - AnAhmad Rifai R ANo ratings yet

- Social Learning TheoryDocument23 pagesSocial Learning TheoryJacqueline Lacuesta100% (2)

- Champagne Making Process: Benjamin CochainDocument13 pagesChampagne Making Process: Benjamin CochainSrikanth ReddyNo ratings yet

- Grade 8 Science Activity 1 Quarter 4Document8 pagesGrade 8 Science Activity 1 Quarter 4yoshirabul100% (2)

- Silver Chloride Dissolution in ARDocument5 pagesSilver Chloride Dissolution in ARAFLAC ............No ratings yet

- Finding the Right Pharmacy for Your NeedsDocument4 pagesFinding the Right Pharmacy for Your Needsprabakar VNo ratings yet

- The Following Present A List of Different Attributes and Rules For Assigning Numbers To Objects. Try ToDocument4 pagesThe Following Present A List of Different Attributes and Rules For Assigning Numbers To Objects. Try Togetacdeme2011No ratings yet

- Palm Avenue ApartmentsDocument6 pagesPalm Avenue Apartmentsassistant_sccNo ratings yet

- NPD High Level Status: Concept Development FeasibilityDocument22 pagesNPD High Level Status: Concept Development FeasibilityRaviNo ratings yet

- Shavuot 5774Document4 pagesShavuot 5774Andrea KingNo ratings yet

- Experimental Animals Vol1Document209 pagesExperimental Animals Vol1JohnNo ratings yet

- Household Chemical Poisoning GuideDocument9 pagesHousehold Chemical Poisoning GuideAshley DayagNo ratings yet

- Comparison Between China and Sri-Lanka GDPDocument6 pagesComparison Between China and Sri-Lanka GDPcracking khalifNo ratings yet

- Maternity and Pediatric Nursing 3rd EditionDocument347 pagesMaternity and Pediatric Nursing 3rd EditionTaylor Talley80% (15)

- Chloe Kho - Assignment 5 - MTT PracticeDocument5 pagesChloe Kho - Assignment 5 - MTT PracticeanthonyNo ratings yet

- Kuratif RacunDocument18 pagesKuratif RacunYsrwncyNo ratings yet

- Chapter 1 EconomicsDocument5 pagesChapter 1 Economicsjordan cedeñoNo ratings yet

- 4th QUARTER EXAMINATION IN TLE 8Document3 pages4th QUARTER EXAMINATION IN TLE 8judy ann sottoNo ratings yet

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlFrom EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlRating: 4 out of 5 stars4/5 (4)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Guidelines for Siting and Layout of FacilitiesFrom EverandGuidelines for Siting and Layout of FacilitiesNo ratings yet

- Operational Excellence: Journey to Creating Sustainable ValueFrom EverandOperational Excellence: Journey to Creating Sustainable ValueNo ratings yet

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- Guidelines for Developing Quantitative Safety Risk CriteriaFrom EverandGuidelines for Developing Quantitative Safety Risk CriteriaNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Bow Ties in Risk Management: A Concept Book for Process SafetyFrom EverandBow Ties in Risk Management: A Concept Book for Process SafetyNo ratings yet

- Guidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisFrom EverandGuidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisNo ratings yet

- Perfume Engineering: Design, Performance and ClassificationFrom EverandPerfume Engineering: Design, Performance and ClassificationRating: 4 out of 5 stars4/5 (5)

- Fragrance Chemistry: The Science of the Sense of SmellFrom EverandFragrance Chemistry: The Science of the Sense of SmellRating: 3 out of 5 stars3/5 (2)

- Practical Process Control for Engineers and TechniciansFrom EverandPractical Process Control for Engineers and TechniciansRating: 5 out of 5 stars5/5 (3)

- Temperature-Responsive Polymers: Chemistry, Properties, and ApplicationsFrom EverandTemperature-Responsive Polymers: Chemistry, Properties, and ApplicationsNo ratings yet