Professional Documents

Culture Documents

TRN - Submersible Aerator PDF

Uploaded by

Gregorio Molina SosaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TRN - Submersible Aerator PDF

Uploaded by

Gregorio Molina SosaCopyright:

Available Formats

Submersible Aerator

TRN

Printed on recycled paper with soy ink – Amenities from Technology

Evidence of our commitment to the environment for People and the Earth

MODEL

MAJOR STANDARD SPECIFICATIONS APPLICATIONS

TRN

SUBMERSIBLE AERATOR

Self-Aspirating Design

Features of the TRN Series

Submersible Aerator

Excellent Stirring Performance

Air-inlet Bore

Treating Type of Fluid

Fluid

Fluid Temperature

Impeller

Structure Shaft Seal

mm 32

0 to 40˚C

50

Wastewater and Sewage

80

Semi-open Impeller (special)

100 150

Double Mechanical Seal (with Oil Lifter)

Pre-aeration and aeration at wastewater treatment plant

Supplying oxygen to water in aquafarm

STANDARD ACCESSORIES

Silencer & Valve Set ---------------------------------------- 1 set

Bearing Double-shielded Ball Bearing Screwed Flange

The specially designed impeller generates negative pressure The air contained in the air/liquid mixture discharged from the (with Packing & Bolts / 17kW and below) -------------- 1 set

around itself when rotating. This negative pressure draws in air aerator gives buoyancy to the mixture, and the upward flow of Impeller 410 Stainless Steel Casting 2

Aerator JIS 10kg/cm Flange

from above the water surface. As a result, this equipment aerates the buoyant liquid generates convection current in the tank.

Air Passage Gray Iron Casting (with Packing & Bolts / 24kW and above) -------------- 1 set

without the need for a blower. (A blower is required for deep- The current stirs the liquid so that it may even out the oxygen

water aeration.) translation throughout the tank. Materials Guide Vane Gray Iron Casting

In addition, no diffuser piping is required; the aerator requires air

intake piping only.

Outstanding Durability Suction Cover 410 Stainless Steel Casting CABTYRE CABLES

This aerator incorporates a double mechanical seal, Tsurumi’s

High Efficiency Dissolution of Oxygen field-proven shaft seal mechanism. An Oil Lifter is also provided Shaft Seal Silicon Carbide Motor 200~240V 380~575V

Output Cores x Dia. Cores x Dia. Material Length

The air drawn into the aerator is pressurized by the liquid to extend the service life of the mechanical seal. Dry Type Submersible Induction Motor kW mm2 mm mm2 m

mm

impelled by the impeller. Both the liquid and the pressurized air In addition, this aerator includes Tsurumi’s proprietary air seal Type, Pole

2, 4-pole (2.2kW and above) 0.75 4x1.25 11.1 4x1.25 11.1 PVC 6

are pushed toward the discharge port by the guide vane. As part mechanism, which significantly extends the service life of the

of this process, the air and liquid are mixed at a pressure higher shaft seal mechanism. Insulation Class F

1.5 4x1.25 11.1 4x1.25 11.1 PVC 6

than that produced by the depth of the water. This innovation

Phase Three-phase

contributes to highly efficient dissolution of oxygen. • Additional Features 2.2 4x2 11.8 4x2 11.8 PVC 6

This aerator features the same unique technologies adopted in

Direct on Line (7.5kW and below)

Air Seal Mechanism Tsurumi’s submersible pumps. These include the anti-wicking Starting Method 3.7 4x3.5 13.9 4x2 11.8 PVC 6

cable entry, which protects the motor from water intrusion through Star-Delta (12kW and above)

the cable conductors; motor protection device, which protects Chloroprene

5.5 4x3.5 14.1 4x3.5 14.1 8

motor from overload; and an oil seal that protects the mechanical Motor Circle Thermal Protector (7.5kW and below) Rubber

seal from abrasive particles. Protection Device (built-in) Chloroprene

Miniature Thermal Protector (12kW and above) 7.5 4x5.5 16.8 4x5.5 16.8 8

Rubber

Lubricant Turbine Oil (ISO VG32) 4x3.5 14.1 4x3.5 14.1

Chloroprene

12 3 x3.5 12.9 3 x3.5 12.9 8

Rubber

Frame Gray Iron Casting 2 x1.25 10.5 2 x1.25 10.5

4 x5.5 16.8 4 x5.5 16.8

Shaft 420 Stainless Steel Chloroprene

The air seal mechanism prevents pressure on the shaft seal during 17 3 x5.5 15.2 3 x5.5 15.2 8

Materials Rubber

its operation. 2 x1.25 10.5 2 x1.25 10.5

PVC (3.7kW and below) 4 x14 21.7 4 x14 21.7

Cable Chloroprene

Double Mechanical Seal & OIL LIFTER Chloroprene Rubber (5.5kW and above) 24 3 x14 19.7 3 x14 19.7

Rubber

10

2 x1.25 10.5 2 x1.25 10.5

6 (17kW and below) 4 x22 28.8 4 x14 21.7

No. of Outlets Chloroprene

8 (24kW and 40kW) 40 3 x22 26.1 3 x14 19.7 10

Oil Lifter Rubber

Mechanical

2 x1.25 10.5 2 x1.25 10.5

Guide Vane

Seal

Being located in a clean environment, the mechanical seal assures

STANDARD SPECIFICATIONS 50/60Hz

reliable sealing. The OIL LIFTER stabilizes and enhances mechanical

seal lubrication and cooling effect. Air-inlet Motor Speed Starting Max. Air Flow Rate*- No. of Impeller Dry

Model

Bore Output (S.S.) Method Water Depth Max.Water Depth Outlets Passage Weight **

Semi-open Impeller (special)

mm kW min-1 m m3/h mm kgs

32TRN2.75 0.75 3000/3600 D.O.L. 3.5 7/8 6 10 55

32

32TRN21.5 1.5 3000/3600 D.O.L. 3.5 20/17 6 12 55

50TRN42.2 2.2 1500/1800 D.O.L. 3.6 39/38 6 12 140

50 50TRN43.7 3.7 1500/1800 D.O.L. 4.0 55/60 6 12 150

CONVECTION PATTERN 50TRN45.5 5.5 1500/1800 D.O.L. 4.0 78/79 6 15 170

Sub-convection

• Main Convection Max. Main Sub-convection

Main Convection Model

Convection made by rising Water Depth Convection Circular Tank Square Tank 80TRN47.5 7.5 1500/1800 D.O.L. 4.5 124/112 6 15 190

bubbles. (The minimum m fm fm m

distance that must be 32TRN2.75 3.5 1.4 3.5 3

80 80TRN412 12 1500/1800 Star-Delta 6.0 157/155 6 15 200

provided between each 32TRN21.5 3.5 1.8 4.5 4

aerator) 50TRN42.2 3.6 2.4 6 5.5

80TRN417 17 1500/1800 Star-Delta 6.0 202/220 6 15 220

50TRN43.7 4 3 7 6.5

• Sub-convection 50TRN45.5 4 3.8 9 8

Diffused convection 100 100TRN424 24 1500/1800 Star-Delta 6.0 388/342 8 22 460

The maximum convection flow generated by the 80TRN47.5 4.5 4.4 10 9

that can keep solids sus- rising of bubbles

80TRN412 6 5.2 12 11

pended to prevent sedi- 150 150TRN440 40 1500/1800 Star-Delta 6.0 528/506 8 25 635

80TRN417 6 5.6 13 11.5

mentation of solids.

100TRN424 6 6.3 14.5 13

* The air flow rates are expressed at the standard condition. : Temperature 20˚C, 1 atm

150TRN440 6 7.3 17 15 **Weights excluding cable

S.S. 3000 min-1 S.S. 3600 min-1

S.S. 1500 min-1 S.S. 1800 min-1

60

120 120

AIR FLOW RATE

- WATER DEPTH 100 50T 100 Hz

RN 50T

CURVES 45. RN

45.5

Air Flow Rate (m3/h)

Air Flow Rate (m3/h)

5

80 80

T h e a i r f l ow ra t e s a r e 50T

50T RN4

expressed at the standard RN 3.7

43.

condition, i.e. temperature of 60 7 60

20 °C, 1 atm and may vary

by up to approximately 5%. 50TR

N42

40 .2 40

50TRN42.2

20 20

32TRN21.5

32TRN21.5

32TRN2.75 32TRN2.75

0 0

0 1 2 3 4 5 0 1 2 3 4 5

Water Depth (m) Water Depth (m)

-1 -1

S.S. 1500 min S.S. 1800 min

60

700 700

600 600 Hz

150TR 150TR

N440 N440

Air Flow Rate (m3/h)

Air Flow Rate (m3/h)

500 500

400 100TR 400

N424

100TRN424

300 300

80TRN 80TRN41

200 417 200 7

80TRN

412 80TRN412

100 80TRN47.5 100 80TRN47.5

0 0

0 1 2 3 4 5 6 7 8 0 1 2 3 4 5 6 7 8

Water Depth (m) Water Depth (m)

DIMENSIONS Silencer & Valve Set

A

fB

fA

Nominal

C

C

fB

D

D

fE Pipe Bore

Nominal

MODEL A B C D E Pipe Bore A B C D

32TRN2.75 32 400 473 81 371 f32 180 116 275

32TRN21.5 32 400 473 81 371 f50 230 154 370

50TRN42.2 50 700 689 123 660 f80 245 180 585

50TRN43.7 50 700 694 123 660 f100 345 256 760

50TRN45.5 50 700 835 123 660 f150 448 370 740 930

80TRN47.5 80 700 868 133 660

80TRN412 80 700 898 133 660

80TRN417 80 700 958 133 660

100TRN424 100 1000 1254 272 980

150TRN440 150 1000 1407 269 980

We reserve the right to change the specifications and designs for improvement without prior notice.

Your Dealer

CAT. IA130-B Printed in Japan

DC/NZ-G-C-M

You might also like

- Curva ASH 10x10SRH C4-2302Document1 pageCurva ASH 10x10SRH C4-2302BM Thaís100% (2)

- Ipal PDFDocument1 pageIpal PDFAjiNo ratings yet

- Well Connection Optimization in Integrated SubsurfDocument6 pagesWell Connection Optimization in Integrated Subsurfabood codNo ratings yet

- CPVC ModelDocument1 pageCPVC ModelZhu Chen ChuanNo ratings yet

- Worthington - RLR - 800-1900 Infologic-B - Reservoir Secheur - 9828083262-01 - Ed - 01Document1 pageWorthington - RLR - 800-1900 Infologic-B - Reservoir Secheur - 9828083262-01 - Ed - 01Abdoul-latif HammaNo ratings yet

- SD fh430v enDocument1 pageSD fh430v enAlex MđäNo ratings yet

- SD fs481v enDocument1 pageSD fs481v enZsolt Péter WalterNo ratings yet

- Curva BombasDocument1 pageCurva BombasRodrigo Reyes GaNo ratings yet

- SUBMERSUBAL PUMP SeriesDocument1 pageSUBMERSUBAL PUMP SeriesYehude Guillen RomeroNo ratings yet

- SCG238 Series PDFDocument2 pagesSCG238 Series PDFrika monikaNo ratings yet

- Dairy Capability Guide PDFDocument32 pagesDairy Capability Guide PDFAminur RahmanNo ratings yet

- Maintenance Kits-1Document16 pagesMaintenance Kits-1Carlos RiveraNo ratings yet

- Rig Up DiagramDocument1 pageRig Up DiagramDurvis RomeroNo ratings yet

- Auto Purge With Pneumatic Pinch Valve: APP SeriesDocument2 pagesAuto Purge With Pneumatic Pinch Valve: APP SeriesRyan DuhonNo ratings yet

- Solenoid Valves Pilot Operated 2/2 Series NCDocument2 pagesSolenoid Valves Pilot Operated 2/2 Series NCKhyle Laurenz DuroNo ratings yet

- Asco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm) PDFDocument2 pagesAsco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm) PDFKhyle Laurenz DuroNo ratings yet

- B 81417 EfaDocument2 pagesB 81417 EfaIshak EnginerNo ratings yet

- STAUFF SDB CV BreatherCatlogPagesDocument2 pagesSTAUFF SDB CV BreatherCatlogPagesryan940No ratings yet

- Wpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1Document1 pageWpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1Gabriel Alejandro Marino EstayNo ratings yet

- Ec140b 09Document6 pagesEc140b 09Fadli HernandoNo ratings yet

- European Catalog Solenoid Valves 2 2 Pilot Operated Built in Pilot Floating Diaphragm Series 238 Asco en 5080052Document2 pagesEuropean Catalog Solenoid Valves 2 2 Pilot Operated Built in Pilot Floating Diaphragm Series 238 Asco en 5080052Farhan HirsanNo ratings yet

- 8127-8130 5001474 A4 WebDocument4 pages8127-8130 5001474 A4 WebHoot 9eNo ratings yet

- Service Data Sheet: Fj180V KaiDocument1 pageService Data Sheet: Fj180V KaiThong KimNo ratings yet

- Service Data Sheet: Unleaded (E10 or Less. Min 91 RON) and 2-Stroke Oil Mix 50: 1Document1 pageService Data Sheet: Unleaded (E10 or Less. Min 91 RON) and 2-Stroke Oil Mix 50: 1tinperasovicNo ratings yet

- 1028905951-01 - Desenho Dimensional CPM - BMDocument2 pages1028905951-01 - Desenho Dimensional CPM - BMgetdatamachinaNo ratings yet

- 4AEF8B53.catalog SQ-M BSQ-MDocument12 pages4AEF8B53.catalog SQ-M BSQ-Mtaher shaikNo ratings yet

- ASCO Solenoid Valves Serie SCB316Document2 pagesASCO Solenoid Valves Serie SCB316katja kafkaNo ratings yet

- TargetDocument6 pagesTargetNovriansyah BrianNo ratings yet

- 08 Welltest EquipmentDocument4 pages08 Welltest EquipmentdronneNo ratings yet

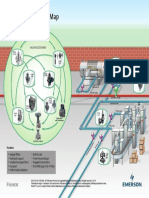

- Brochure Air Application Map Fisher en 138202Document1 pageBrochure Air Application Map Fisher en 138202Habib A. IslamNo ratings yet

- Water Treatment System Control Panel-Model PDFDocument1 pageWater Treatment System Control Panel-Model PDFClifford GatonNo ratings yet

- MixRite 2 5 Product Page 280615Document2 pagesMixRite 2 5 Product Page 280615RicardoArturoPerezNo ratings yet

- Pages From WARMAN PUMP-maintenance-manual 3Document1 pagePages From WARMAN PUMP-maintenance-manual 3mohadeseroustaNo ratings yet

- Sound Attenuation of Generator Sets: Your Reliable Guide For Power SolutionsDocument2 pagesSound Attenuation of Generator Sets: Your Reliable Guide For Power SolutionsBaher SalehNo ratings yet

- EagleBurgmann - E08121 - E1 - Mechanical Seal MR in Polymerization Reactor - 12.08Document1 pageEagleBurgmann - E08121 - E1 - Mechanical Seal MR in Polymerization Reactor - 12.08hasnaNo ratings yet

- Proportional Solenoid Valve Posiflow 2/2 203: Pilot Operated 3/8 - 1/2Document2 pagesProportional Solenoid Valve Posiflow 2/2 203: Pilot Operated 3/8 - 1/2Priya KaleNo ratings yet

- Swimming Pool PDFDocument1 pageSwimming Pool PDFharish amuthanNo ratings yet

- Filtrair Filter Media VNF M1 Series ENDocument2 pagesFiltrair Filter Media VNF M1 Series ENThái Hòa GiangNo ratings yet

- Refrigerant Pipe SizingDocument90 pagesRefrigerant Pipe SizingHasib KhanNo ratings yet

- Process Flow Diagram Magod Fusion Technologies PVT LTDDocument2 pagesProcess Flow Diagram Magod Fusion Technologies PVT LTDSamadhan MoreNo ratings yet

- Sps and Wetwell NTL 3Document1 pageSps and Wetwell NTL 3Project ManagerStructuresNo ratings yet

- 035 Pnevmoraspredeliteli Namur PDFDocument37 pages035 Pnevmoraspredeliteli Namur PDFbrij singhNo ratings yet

- Tank Levels, HMR (Compressors), Flushing Counter Title: Subject: Author: Status: Final Site Archive Archive: Pages: 1Document1 pageTank Levels, HMR (Compressors), Flushing Counter Title: Subject: Author: Status: Final Site Archive Archive: Pages: 1tomiNo ratings yet

- Bomba - Weir - Curvas Warman Horizontais-Versão MetálicaDocument18 pagesBomba - Weir - Curvas Warman Horizontais-Versão MetálicaWanderson Alcantara100% (1)

- Solenoid valves control hot and cold waterDocument2 pagesSolenoid valves control hot and cold waterMehrzadNo ratings yet

- Eriks - Hose Guide PDFDocument2 pagesEriks - Hose Guide PDFArdian20No ratings yet

- Cornell - AgricultureDocument8 pagesCornell - AgricultureSBM LagunaNo ratings yet

- General CatalogueDocument12 pagesGeneral CatalogueHamdi Naufel0% (1)

- 8.1 MOBILAIR Portable Compressors "Current Models": Genuine KAESER Maintenance PartsDocument4 pages8.1 MOBILAIR Portable Compressors "Current Models": Genuine KAESER Maintenance PartsAnne S. Sokolovska100% (1)

- Tanque de Agua Caliente Altura 7.7 M: Cervecería NacionalDocument2 pagesTanque de Agua Caliente Altura 7.7 M: Cervecería NacionalEdwin Andres Mora CarriónNo ratings yet

- Submersible Aerator Performance CurvesDocument3 pagesSubmersible Aerator Performance CurvesbuattugasmetlitNo ratings yet

- Hydraulic Filtration Product Guide PDFDocument286 pagesHydraulic Filtration Product Guide PDFCire Lop CastroNo ratings yet

- Hydraulic Filtration Product GuideDocument286 pagesHydraulic Filtration Product GuideThanapaet RittirutNo ratings yet

- Etp FlowchatDocument1 pageEtp FlowchatNaveenVermaNo ratings yet

- Adobe Scan Dec 20, 2022Document1 pageAdobe Scan Dec 20, 2022Prathmesh GhodvindeNo ratings yet

- Valve Cross SectionDocument1 pageValve Cross SectionJaya PrakashNo ratings yet

- Lit Vra DataDocument2 pagesLit Vra Dataaijaznm786No ratings yet

- Volvo B8R EU6 Data-Sheet 13 03Document3 pagesVolvo B8R EU6 Data-Sheet 13 03vahladianNo ratings yet

- Elongation Calculation-St52 3Document2 pagesElongation Calculation-St52 3Prabath MadusankaNo ratings yet

- Pre Trip Inspection Manual For CDLDocument11 pagesPre Trip Inspection Manual For CDLMaxim100% (1)

- Micro Analysis On LaminationDocument6 pagesMicro Analysis On LaminationPrasenjit PuriNo ratings yet

- DEORE Rear Derailleur: (10-Speed)Document1 pageDEORE Rear Derailleur: (10-Speed)Marcos ZanelliNo ratings yet

- ASME VIII - DIV.1 - UG-28 (F)Document1 pageASME VIII - DIV.1 - UG-28 (F)cwkimNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological Universitytamilselvan nNo ratings yet

- NL Dimensions&Torque en-UNC 201104Document4 pagesNL Dimensions&Torque en-UNC 201104carlos123tNo ratings yet

- Philippine Standard Occupational Classification (PSOC)Document166 pagesPhilippine Standard Occupational Classification (PSOC)Jennel Galicia Maquiñana100% (4)

- Determination of ViscosityDocument2 pagesDetermination of Viscositydarshan33% (3)

- Boeing 737 Pneumatic System Training ManualDocument65 pagesBoeing 737 Pneumatic System Training ManualTarik Benzineb83% (6)

- ForgingDocument35 pagesForgingGopalakrishnan KuppuswamyNo ratings yet

- Asih Ayu Nitiwati - Tugas Surface 2Document8 pagesAsih Ayu Nitiwati - Tugas Surface 2asih ayuNo ratings yet

- Quiz Show Mechanics FinalfinalDocument4 pagesQuiz Show Mechanics FinalfinalJustinMendiolaNo ratings yet

- Fluent 13.0 Lecture06 Turbulence 21 22Document4 pagesFluent 13.0 Lecture06 Turbulence 21 22DrAmrit Kr RoyNo ratings yet

- Physics 3 PDFDocument2 pagesPhysics 3 PDFNoor Ul Hudda MemonNo ratings yet

- Best Practice Guide Impulse Lines For Differential-Pressure FlowmetersDocument22 pagesBest Practice Guide Impulse Lines For Differential-Pressure FlowmetersamietkolteNo ratings yet

- Hydraulic Power Unit Local Control Cubicle: LEN-CK-1-03 AR-ALLDocument9 pagesHydraulic Power Unit Local Control Cubicle: LEN-CK-1-03 AR-ALLLy Thanh HaNo ratings yet

- Welker RegsDocument6 pagesWelker RegsChegg ChemNo ratings yet

- Project loop list for Arauco Mapa evaporatorDocument11 pagesProject loop list for Arauco Mapa evaporatorCarlos Mauricio Guzman ArayaNo ratings yet

- Fuel Pumps, Systems & Timing-2Document14 pagesFuel Pumps, Systems & Timing-2Nikhil SonarbagkerNo ratings yet

- Thermodynamics-I: Fall 2019Document11 pagesThermodynamics-I: Fall 2019muhammad umairNo ratings yet

- FEA of High-Pressure Air Bottle Flanged Adaptor ModificationsDocument1 pageFEA of High-Pressure Air Bottle Flanged Adaptor ModificationsAnonymous P8Bt46mk5INo ratings yet

- Mixing and AgitationDocument17 pagesMixing and AgitationTa Den April88% (8)

- DCATLCRGBDocument4 pagesDCATLCRGBAmani BelaliaNo ratings yet

- Leader in MINI Performance for 30+ YearsDocument36 pagesLeader in MINI Performance for 30+ YearsDustin ShampNo ratings yet

- Underground Mining LoaderDocument20 pagesUnderground Mining LoaderPedro Pablo Fernández Fernández100% (1)

- Catalogue 2017Document64 pagesCatalogue 2017alexandreruiz12345No ratings yet

- Electric Diagram MLT 845 - 120 LSU (Manitou)Document12 pagesElectric Diagram MLT 845 - 120 LSU (Manitou)Rudy HermawanNo ratings yet

- Hybrid Electric Vehicles: Author: E-Mail: Course: Class/Year: Main Functional Requirement: Design ParameterDocument7 pagesHybrid Electric Vehicles: Author: E-Mail: Course: Class/Year: Main Functional Requirement: Design ParameterDhanraj PatilNo ratings yet