Professional Documents

Culture Documents

Sliding Contact Bearing

Uploaded by

Sp Patel0 ratings0% found this document useful (0 votes)

99 views4 pagesED

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentED

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

99 views4 pagesSliding Contact Bearing

Uploaded by

Sp PatelED

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

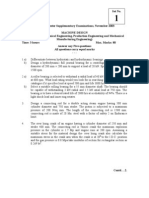

Laxmi Institute of Technology, Sarigam

Auto/Mech Department

Year: 2018-19

Academic

Name of Subject : ACD/MD Date:

Subject Code : 2170202

Sliding Contact Bearing

Sr.

Name of Question Remarks

No.

Explain Petroff’s equation for hydrodynamic journal

1

bearings

Explain following terms for Journal Bearing Bearing

Characteristic Number, Viscosity Index, Sommer feld

2

Number, and Bearing Modulus.

Explain difference between Hydrostatic &

3

Hydrodynamic Bearing

4

Explain Mc keys Investigation.

Explain Raimondi and Boyd method for journal

bearings.

The following data is given for a hydrostatic thrust

bearing:

3 Thrust load=500 kN., shaft speed=720 rpm, shaft

diameter=500 rpm, recess diameter=300 mm, film

thickness=0.15 mm, viscosity of lubricant=160 SUS,

specific gravity=0.86. Calculate (i) Supply pressure, (ii)

flow requirement in litres/min (iii) power loss in pumping

Laxmi Institute of Technology, Sarigam

Auto/Mech Department

Year: 2018-19

Academic

(iv) frictional power loss.

The following data is given for a 360 ° hydrodynamic

bearing:

Radial load=3.2 kN, Journal speed=1490 rpm, Journal

diameter=50 mm, bearing length=50 mm, radial

clearance=0.05mm, viscosity of lubricant=25cP. Assuming

that total heat generated in the bearing is carried by the total

4 oil flow in the bearing, calculate

Coefficient of friction

Power lost in friction

Minimum oil film thickness

Flow requirements in 1 litres/min; and

Temperature rise

Design a journal bearing from the following data: Radial

load = 20 kN, Diameter of journal =100 mm Speed of

journal =900 r.p.m. Oil SAE 10 with viscosity at 550C =

0.017 kg/m-sec Ambient temperature =15.50C Maximum

5 bearing pressure = 1.5 MPa Permissible rise in oil

temperature = 100C Heat dissipation coefficient = 1232

W/m2/0C L/D ratio = 1.6 Design parameter ZN/p = 28

Clearance ratio = 0.0013 Specific heat of oil = 1900

J/kg/0C

Laxmi Institute of Technology, Sarigam

Auto/Mech Department

Year: 2018-19

Academic

The following data is given for a 3600 hydrodynamic

bearings: Radial load : 3.1 kN Journal diameter : 50 mm

Bearing length : 50 mm Journal speed : 1440 rpm Radial

clearance : 50 microns Viscosity of lubricant : 25 cP

Density of lubricant : 860 kg / m3 Sp. Heat of lubricant :

6 1.76 kJ / kg 0C Assuming that the total heat generated in

the bearing is carried by the total oil flow in the bearing.

Calculate: i) Sommerfeld Number ii) Minimum oil-film

thickness iii) The coefficient of friction iv) The power

lost in friction v) The total flow rate of lubricant in liter

/minute vi) Side leakage

A Petroff’s sleeve bearing consists of a sleeve having a

bore diameter of 100.1 mm and a length of 100 mm. A

shaft having 100 mm diameter supports a load of 4000 N.

7 A shaft runs at 2880 r.p.m in the sleeve. If the frictional

torque on the shaft is 10 N-m, find i) The absolute

viscosity of lubrication ii) The bearing pressure iii) The

coefficient of friction and iv) The power lost in bearing.

The dimensions of a hydrostatic thrust bearing with a

rectangular oilgroove A, are shown in Fig-2. The

pressure distribution can be assumed to be linear, varying

8 from supply pressure at the inner edge of the groove to

atmospheric pressure at the outer edge of the pad. The

flow over the corners can be neglected. The thrust load is

100 kN and the film thickness is 0.02 mm. the viscosity

Laxmi Institute of Technology, Sarigam

Auto/Mech Department

Year: 2018-19

Academic

of the lubrication oil is 300 cP. Calculate: (i) supply

pressure, and (ii) requirement of flow.

Date of Submission:-

Name & Sign of Subject In-charge :

You might also like

- Yamaha 2006 Service Manual Ar230Document358 pagesYamaha 2006 Service Manual Ar230Dont Bugme80% (5)

- Genset Dkaf Parts Manual - 0981-0254 - I3 - 201405Document140 pagesGenset Dkaf Parts Manual - 0981-0254 - I3 - 201405theunauthorised100% (1)

- TDS 11S TrainingDocument221 pagesTDS 11S TrainingMohammed TidjaniNo ratings yet

- Dec ManualDocument50 pagesDec Manualjesus paul cuellar zegarraNo ratings yet

- Catalogus VMLGDocument148 pagesCatalogus VMLGgeorgekc77No ratings yet

- Fiesta R2 Caja de CambioDocument14 pagesFiesta R2 Caja de CambioMartinito MacraméNo ratings yet

- Omnicone 937 Parts List-OMNIDocument2 pagesOmnicone 937 Parts List-OMNIgusjav2014c12No ratings yet

- Hydraulic Fan Motor: Series F10 Fixed DisplacementDocument24 pagesHydraulic Fan Motor: Series F10 Fixed DisplacementFederico Tomi100% (1)

- Question Bank Sliding Contact BearingsDocument2 pagesQuestion Bank Sliding Contact BearingsShree PrajapatiNo ratings yet

- DMM-2 Question BankDocument3 pagesDMM-2 Question BankrajuNo ratings yet

- 2 Tutorial Sliding Contact BearingDocument2 pages2 Tutorial Sliding Contact BearingNirav100% (1)

- ASSIGNMENT (Sliding Contact Bearing) PDFDocument3 pagesASSIGNMENT (Sliding Contact Bearing) PDFRakesh Kumar Shukla KEC0% (1)

- Assignment No. 3 (Sliding Contact Bearings) : SpeedDocument2 pagesAssignment No. 3 (Sliding Contact Bearings) : SpeedJai SharmaNo ratings yet

- MD-III - TUT - 5 and 6Document5 pagesMD-III - TUT - 5 and 6Sushil ThakkarNo ratings yet

- The Copperbelt University School of EngiDocument3 pagesThe Copperbelt University School of Engiyousef mohamedNo ratings yet

- 1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringDocument3 pages1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringChadaram JagadishNo ratings yet

- Gujarat Technological University: Subject Code: 2171909 Date: Subject Name: Machine Design Time: Total Marks: 70Document3 pagesGujarat Technological University: Subject Code: 2171909 Date: Subject Name: Machine Design Time: Total Marks: 70NILESH SUTHARNo ratings yet

- Silver Oak College of Engineering & Technology Aditya Silver Oak Institute of TechnologyDocument2 pagesSilver Oak College of Engineering & Technology Aditya Silver Oak Institute of TechnologyShree PrajapatiNo ratings yet

- DMM-2 3 1 Q&aDocument6 pagesDMM-2 3 1 Q&aAnand vinayNo ratings yet

- Supp Nov 2009Document10 pagesSupp Nov 2009prk74No ratings yet

- r05320305 Design of Machine Members IIDocument11 pagesr05320305 Design of Machine Members IISrinivasa Rao G100% (4)

- rr320305 Design of Machine Members IIDocument8 pagesrr320305 Design of Machine Members IISRINIVASA RAO GANTANo ratings yet

- Unit III Sliding Contact BearingDocument26 pagesUnit III Sliding Contact BearingSHUBHAM GOVILNo ratings yet

- Unit 4 Bearings Important ProblemsDocument3 pagesUnit 4 Bearings Important ProblemsBrijpal PatleNo ratings yet

- rr320305 Design of Machine Members IIDocument8 pagesrr320305 Design of Machine Members IISrinivasa Rao GNo ratings yet

- DMM 2Document8 pagesDMM 2Robin MessiNo ratings yet

- 15A03602 Design of Machine Members - IIDocument2 pages15A03602 Design of Machine Members - IIJagannath CherkuNo ratings yet

- Design of FlywheelsDocument2 pagesDesign of FlywheelsSp Patel0% (1)

- Design of Machine ElementsDocument3 pagesDesign of Machine ElementsHariharanAutoNo ratings yet

- TribologyDocument8 pagesTribologyKamal ChaitanyaNo ratings yet

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyNo ratings yet

- Assignment 3 (Unit 5 and 6)Document4 pagesAssignment 3 (Unit 5 and 6)Sankit IngaleNo ratings yet

- 05-04 Machine Design & Cad-II (Me)Document2 pages05-04 Machine Design & Cad-II (Me)Abdul AhadNo ratings yet

- r05320305 Design of Machine Members IIDocument9 pagesr05320305 Design of Machine Members IISRINIVASA RAO GANTANo ratings yet

- 15A03602 Design of Machine Members - IIDocument2 pages15A03602 Design of Machine Members - IIJagannath CherkuNo ratings yet

- Me 154 A06Document1 pageMe 154 A06Marriel Kayne MalateNo ratings yet

- AECD QuestionsDocument7 pagesAECD QuestionssbkNo ratings yet

- ASSIGNMENT TribologyDocument3 pagesASSIGNMENT TribologyShabbir WahabNo ratings yet

- HW6 201Document4 pagesHW6 201Y7ya73No ratings yet

- 15A03602 Design of Machine Members - IIDocument2 pages15A03602 Design of Machine Members - IIJagannath CherkuNo ratings yet

- rr321401 Principles of Machine DesignDocument8 pagesrr321401 Principles of Machine DesignSRINIVASA RAO GANTA100% (1)

- Design of Machine Members-II Feb 2022Document3 pagesDesign of Machine Members-II Feb 2022Anand KedhariNo ratings yet

- Makalah GTWDocument8 pagesMakalah GTWfaisalNo ratings yet

- Ei HTH Mester B.E D: USN G Se - Eg eDocument2 pagesEi HTH Mester B.E D: USN G Se - Eg esrinivasa c vNo ratings yet

- Terminal Examination: (A) Endurance Limit. (B) Notch SensitivityDocument1 pageTerminal Examination: (A) Endurance Limit. (B) Notch SensitivityMuhammad SherjeelNo ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- MD II Assignment 3Document1 pageMD II Assignment 3Harshal KolheNo ratings yet

- Seventh Semester B.Tech. Degree Examination, June 2009 03-703: Design of Machine Elements - Ii (M)Document3 pagesSeventh Semester B.Tech. Degree Examination, June 2009 03-703: Design of Machine Elements - Ii (M)Harish ChandranNo ratings yet

- ' "" 'I F 5:t"il) I:"h'xt'ilffi' : Pappr ID: (. (08191Document2 pages' "" 'I F 5:t"il) I:"h'xt'ilffi' : Pappr ID: (. (08191RaJan GargNo ratings yet

- Rolling Contact BearingDocument2 pagesRolling Contact BearingSp PatelNo ratings yet

- Design of Machine Members - II April 2017Document8 pagesDesign of Machine Members - II April 2017Abhishek Goud AkkapalliNo ratings yet

- Assignment 7221 MD-IIIDocument2 pagesAssignment 7221 MD-IIIkalikaNo ratings yet

- Ecc AssignmentDocument7 pagesEcc AssignmentBgmi TacticianNo ratings yet

- rr321401 Principles of Machine DesignDocument8 pagesrr321401 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- Minimum Film Thickness: Machine ComponentsDocument20 pagesMinimum Film Thickness: Machine ComponentsThanhluan NguyenNo ratings yet

- r05321403 Principles of Machine DesignDocument8 pagesr05321403 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- 05 MEP 461 Final Examination 2020Document5 pages05 MEP 461 Final Examination 2020Ahmed Shaaban Soliman HamedNo ratings yet

- Instructions:: No of Pages Course CodeDocument2 pagesInstructions:: No of Pages Course CodeCRAZY PIANO PLAYERNo ratings yet

- 15M502Document3 pages15M502CRAZY PIANO PLAYERNo ratings yet

- Iii Me Ii Sem Q.bank 2016-17Document32 pagesIii Me Ii Sem Q.bank 2016-17Abhishek SakatNo ratings yet

- NR 320301 Machine DesignDocument8 pagesNR 320301 Machine DesignSrinivasa Rao GNo ratings yet

- 07a6ec05 Designofmachinemembers IIDocument11 pages07a6ec05 Designofmachinemembers IIzahid_polyNo ratings yet

- r05312401 Design of Machine ElementsDocument8 pagesr05312401 Design of Machine ElementsSrinivasa Rao GNo ratings yet

- 1.steam Turbine Rotor GroovesDocument7 pages1.steam Turbine Rotor GroovesRaheem JunaidiNo ratings yet

- 2018sme 7 Sem Design of Mechanical Drives Summer 2018Document2 pages2018sme 7 Sem Design of Mechanical Drives Summer 2018Komal HingeNo ratings yet

- B Tech - 6 Sem (CBGS) Course Code: ME 602 Subject Name: Machine Component & Design Important Questions Unit - 1Document6 pagesB Tech - 6 Sem (CBGS) Course Code: ME 602 Subject Name: Machine Component & Design Important Questions Unit - 1suneel kumar rathoreNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- LETTERDocument1 pageLETTERSp PatelNo ratings yet

- Cover Page: Machine Design-II Semester: 8: in This Subject Student Are Learn About Below Given PointDocument8 pagesCover Page: Machine Design-II Semester: 8: in This Subject Student Are Learn About Below Given PointSp PatelNo ratings yet

- Shivanagar Vidya Prasarak Mandal'S: Paper Presentation OnDocument13 pagesShivanagar Vidya Prasarak Mandal'S: Paper Presentation OnSp PatelNo ratings yet

- 3310702fundamentals of Digital ElectronicsDocument5 pages3310702fundamentals of Digital ElectronicsSp PatelNo ratings yet

- Machine Design ManualDocument20 pagesMachine Design ManualSp PatelNo ratings yet

- Assignment: 1 Chapter: Introduction: Sr. No QuestionsDocument1 pageAssignment: 1 Chapter: Introduction: Sr. No QuestionsSp PatelNo ratings yet

- Machine Design ManualDocument21 pagesMachine Design ManualSp PatelNo ratings yet

- Assignment: 3 Chapter: Metal Joining Process: Sr. No QuestionsDocument1 pageAssignment: 3 Chapter: Metal Joining Process: Sr. No QuestionsSp PatelNo ratings yet

- Assignment: 4 Chapter: Forming and Shaping Process: Sr. No QuestionsDocument1 pageAssignment: 4 Chapter: Forming and Shaping Process: Sr. No QuestionsSp PatelNo ratings yet

- Assignment: 6 Chapter: Super Finishing Process: Sr. No QuestionsDocument1 pageAssignment: 6 Chapter: Super Finishing Process: Sr. No QuestionsSp PatelNo ratings yet

- Assignment: 5 Chapter: Plastic Technology: Sr. No QuestionsDocument1 pageAssignment: 5 Chapter: Plastic Technology: Sr. No QuestionsSp PatelNo ratings yet

- Assignment: 2 Chapter: Foundary Technology: Sr. No QuestionsDocument1 pageAssignment: 2 Chapter: Foundary Technology: Sr. No QuestionsSp PatelNo ratings yet

- Design of FlywheelsDocument2 pagesDesign of FlywheelsSp Patel0% (1)

- AES Mid 2 Question Bank - 2019Document1 pageAES Mid 2 Question Bank - 2019Sp PatelNo ratings yet

- Passed S.S.C. Exam 87.43 Distinction 2006 Gujarat Secondary and Higher Secondary Education B Gujarat 1 B344829Document2 pagesPassed S.S.C. Exam 87.43 Distinction 2006 Gujarat Secondary and Higher Secondary Education B Gujarat 1 B344829Sp PatelNo ratings yet

- Circular: Ref: Gtu/Central Techfest-2020/2196 Date: 25.02.2020Document1 pageCircular: Ref: Gtu/Central Techfest-2020/2196 Date: 25.02.2020Sp PatelNo ratings yet

- Design EnggDocument4 pagesDesign EnggSp PatelNo ratings yet

- Notice: Laxmi Institute of Technoloy, SarigamDocument1 pageNotice: Laxmi Institute of Technoloy, SarigamSp PatelNo ratings yet

- DCN Mid 1 Question Paper - July 2019Document1 pageDCN Mid 1 Question Paper - July 2019Sp PatelNo ratings yet

- C ProgramsDocument5 pagesC ProgramsSp PatelNo ratings yet

- Rolling Contact BearingDocument2 pagesRolling Contact BearingSp PatelNo ratings yet

- Introduction CHAPTER 1Document12 pagesIntroduction CHAPTER 1Sp PatelNo ratings yet

- Gear BoxDocument2 pagesGear BoxSp PatelNo ratings yet

- Product Guide 2015 LowDocument111 pagesProduct Guide 2015 LowRhaanzah100% (2)

- Ilovepdf MergedDocument107 pagesIlovepdf MergedDeb Sankar MukhopadhyayNo ratings yet

- Maintenance and Application Guide For Centrifugal PumpDocument256 pagesMaintenance and Application Guide For Centrifugal Pumpjprakashbandaru100% (2)

- Igtm - CT Igtm - Im Gas Turbine Meter: Installation, Operation and Maintenance Manual (IOM)Document48 pagesIgtm - CT Igtm - Im Gas Turbine Meter: Installation, Operation and Maintenance Manual (IOM)eka pramudia santosoNo ratings yet

- 2 AOD-PL Spare Parts ManualDocument41 pages2 AOD-PL Spare Parts ManualmakremNo ratings yet

- Hertz Contact Points For Machines PDFDocument478 pagesHertz Contact Points For Machines PDFNicholas FeatherstonNo ratings yet

- Bearing Installation & ReplacementDocument50 pagesBearing Installation & Replacementshwekhon100% (1)

- Allcv Service Manual: Propeller ShaftDocument10 pagesAllcv Service Manual: Propeller ShaftMohan CharanchathNo ratings yet

- NRL Traning ProjectDocument69 pagesNRL Traning ProjectAmit Narayan SinhaNo ratings yet

- CNC New Syllabus TopicsDocument51 pagesCNC New Syllabus TopicsVISMAY PATEL100% (1)

- LGGB 2: SKF Biodegradable Bearing GreaseDocument2 pagesLGGB 2: SKF Biodegradable Bearing GreaseJurun_BidanshiNo ratings yet

- patent-US2629213-Crankshaft Grinding DeviceDocument9 pagespatent-US2629213-Crankshaft Grinding DeviceMahnooshNo ratings yet

- 6700 Series BearingsDocument2 pages6700 Series Bearingsmanju2designNo ratings yet

- 499839Document8 pages499839Virginia Venus Visuette MarínNo ratings yet

- W 460 Rear Bearing ReplacementDocument5 pagesW 460 Rear Bearing Replacementhv4000No ratings yet

- Mobilgear 600XP Series DATA SHEETDocument3 pagesMobilgear 600XP Series DATA SHEETmitch1973No ratings yet

- Iso 11687 1 2020Document11 pagesIso 11687 1 2020Alwin VinothNo ratings yet

- AXEL - Noion Ebook - Aug2017-Web PDFDocument5 pagesAXEL - Noion Ebook - Aug2017-Web PDFMilena GonzalezNo ratings yet

- SKF Concentra ProductsDocument8 pagesSKF Concentra ProductsAdrian BravoNo ratings yet

- Global Institute of Technology, Jaipur Blown Up 6ME4-04:: Iii Year B.Tech. Vi Semester Design of Machine Elements-IIDocument3 pagesGlobal Institute of Technology, Jaipur Blown Up 6ME4-04:: Iii Year B.Tech. Vi Semester Design of Machine Elements-IIGautam GunjanNo ratings yet

- Power Shovel XC4100 P&H SpecDocument2 pagesPower Shovel XC4100 P&H SpecChristian Situmeang100% (1)

- IOM Manual C132355.SflbDocument14 pagesIOM Manual C132355.SflbVenkat SubramanianNo ratings yet