Professional Documents

Culture Documents

Pressure Drop Calculations - BST-005 Flow:.15m3/hr Density:.860 Kg/m3 Viscocity:. 3186 CP

Uploaded by

Assure TurbinesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Drop Calculations - BST-005 Flow:.15m3/hr Density:.860 Kg/m3 Viscocity:. 3186 CP

Uploaded by

Assure TurbinesCopyright:

Available Formats

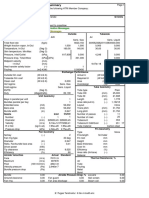

Pressure Drop Calculations - BST-005

Flow :.15m3/hr

Density :.860 Kg/m3

Viscocity:. 3186 Cp

Process At 100% Clean At 50% Clogged

Strainer Pipe Screen Condition Condition

Parameters

Outside

Size(mm) 150 16.83 Diameter of Screen - D (cm) 60.00 p - Density of Liquid in gm/cm3 0.860 0.860

Diameter(cm)

Basket

Type Pipe Schedule(Sch) STD Length of Screen -C (cm) 60.00 μ - viscosity of Liquid in gm/cm-s 31.860 31.860

Strainer

Surface Area

Class Rating 150 Thickness (cm) 0.711 11309.40 Flow in Cm3/sec 4166.550 4166.550

of Screen(SAS) (cm2) at Clean Condition

V - Superficial Velocity of fluid

Surface Area of Screen 1t 50%

Inside Diameter 15.4 5654.70 based upon the gross area of 1.906 3.812

Clogged

the screen cm/sec

Net Area of Screen used for filtering (cm2)

Area of Pipe 186.5 2185.99 V/α = 9.861 19.722

at Clean Condition

Net Area of Screen used for filtering @ 50%

1093.00 (p/μ) = 0.027 0.027

Clogged (cm2)

Ratio at Clean Condition 11.72 Re - Reynolds No=D*(V/α)*(p/μ) 0.005 0.010

C - Coefficient of discharge

Ratio at 50% Clogged 5.86 0.030 0.040

(From Perry page no. 5-40)

Q - % opening in 80 Wire Mesh 37.90 g - Gravitational force cm/sec2 981.000 981.000

K - Velocity Head Loss =

P- Perforation (5mm Hole,6.5mm pitch) 51.00 28628.735 16103.663

(1/(C*C) * (1-(α*α)/(α*α)))

Pressure Drop (ΔP) =

D - Opening Width (cm) 0.02 45.589 102.575

(K*p*V*V)/2*g

Pressure Drop (ΔP) Inches of

α - Effective opening area mmSq 0.19 17.948 40.384

Water

Pressure Drop (ΔP) Kg/cm2(g) 0.045 0.101

Pressure Drop (ΔP) mBar 43.827 98.611

You might also like

- Spaghetti Bridge ReportDocument12 pagesSpaghetti Bridge ReportMuhd Syafiq Othman0% (2)

- VLE Curve for Cyclohexane-Toluene MixtureDocument6 pagesVLE Curve for Cyclohexane-Toluene MixtureAnuj SrivastavaNo ratings yet

- Pressure Drop Calculations - BST-001 Flow:.25m3/hr Density:.904 Kg/m3 Viscocity:. 457 CPDocument1 pagePressure Drop Calculations - BST-001 Flow:.25m3/hr Density:.904 Kg/m3 Viscocity:. 457 CPAssure TurbinesNo ratings yet

- Pressure drop calculation for item no. 2412A/BDocument1 pagePressure drop calculation for item no. 2412A/BKailas NimbalkarNo ratings yet

- Pressure drop calculations for item no. 8402 A/BDocument1 pagePressure drop calculations for item no. 8402 A/BKailas Nimbalkar0% (1)

- Pressure Drop Calculation for Item No. 2432 at Varying Clog ConditionsDocument1 pagePressure Drop Calculation for Item No. 2432 at Varying Clog ConditionsKailas NimbalkarNo ratings yet

- Conical Strainer PDC 40NBDocument1 pageConical Strainer PDC 40NBKailas Nimbalkar0% (1)

- DESIGN OF RC RETAINING WALLDocument1 pageDESIGN OF RC RETAINING WALLAHSANNo ratings yet

- FRNT ColDocument96 pagesFRNT ColARUN RAWATNo ratings yet

- NSW Pump Calculation 26-05-2017-r4Document28 pagesNSW Pump Calculation 26-05-2017-r4Ardian200% (1)

- Vibration analysis of heat exchangersDocument15 pagesVibration analysis of heat exchangersljv004No ratings yet

- Energy Cables Catalogue 150Document1 pageEnergy Cables Catalogue 150Thiago BarcelosNo ratings yet

- Jpf5-E-0022 - 17 08 22Document10 pagesJpf5-E-0022 - 17 08 22pradeep yadavNo ratings yet

- Section B H Tension Reinforcement Compression Reinforcement MM MM MM MM MM No. Dia No. Dia No. Dia No. Dia No. Dia No. C C CDocument4 pagesSection B H Tension Reinforcement Compression Reinforcement MM MM MM MM MM No. Dia No. Dia No. Dia No. Dia No. Dia No. C C Cazamislam726537No ratings yet

- HTRI Heat Exchanger Rating SummaryDocument6 pagesHTRI Heat Exchanger Rating SummaryCami Vander MeyNo ratings yet

- Design and Development of Reactor Level Control Valve PDFDocument21 pagesDesign and Development of Reactor Level Control Valve PDFstephinjacobNo ratings yet

- Purlin - Check - Hat SectionDocument2 pagesPurlin - Check - Hat SectionPrince MittalNo ratings yet

- 2.0 Design CalculationsDocument2 pages2.0 Design CalculationsfebousNo ratings yet

- GTB v6Document7 pagesGTB v6Chan Shiaw SyanNo ratings yet

- Duct Sizing - ReferenceDocument27 pagesDuct Sizing - ReferenceAnkurNo ratings yet

- 23-HA-103 - Rating Case - 1Document11 pages23-HA-103 - Rating Case - 1yadav yadavNo ratings yet

- DESIGN OF FLOOR SLAB (0.15m Thick)Document9 pagesDESIGN OF FLOOR SLAB (0.15m Thick)Living Life100% (1)

- WEB - Welding DesignDocument2 pagesWEB - Welding DesignAdam MillerNo ratings yet

- RC RetainDocument2 pagesRC RetainnikiiteaNo ratings yet

- ALDECK3Document5 pagesALDECK3Mustafa ÇakırNo ratings yet

- Chocolatos 2Document1 pageChocolatos 2Hariyono Rudi NovantoNo ratings yet

- b4.1Document1 pageb4.1EakJhuanNo ratings yet

- B9.1Document1 pageB9.1EakJhuanNo ratings yet

- Beam Cantiliever CalculationDocument16 pagesBeam Cantiliever CalculationAnonymous sfkedkymNo ratings yet

- Design E-100 GT PMB N GN Kemala 15 MM Main CaseDocument103 pagesDesign E-100 GT PMB N GN Kemala 15 MM Main Casewahyu hidayatNo ratings yet

- Design Discharge Computation For Lege Dechatu River: Annex-1Document5 pagesDesign Discharge Computation For Lege Dechatu River: Annex-1ebsiNo ratings yet

- Strainer Pre. Drop and Sizing CalcDocument6 pagesStrainer Pre. Drop and Sizing CalcChandrakant SalunkheNo ratings yet

- Slab DesignDocument9 pagesSlab Designsuleiman.ahNo ratings yet

- Calculation MOLDocument2 pagesCalculation MOLIrsyad RosyidiNo ratings yet

- Estribo de PuenteDocument48 pagesEstribo de PuenteManuel DGcNo ratings yet

- Rigid PavementDocument3 pagesRigid PavementPrabhakar LadNo ratings yet

- See Runtime Message Report For Warning MessagesDocument1 pageSee Runtime Message Report For Warning MessagesAnonymous Q2hxfbghNo ratings yet

- PadEye Genset 300kvaDocument3 pagesPadEye Genset 300kvadandy imam fauziNo ratings yet

- ACI CorbelDocument2 pagesACI CorbelmohamedNo ratings yet

- Appendix 16.a Example - Grass ChannelDocument4 pagesAppendix 16.a Example - Grass Channelkhoohuikiang100% (1)

- Gully Spacing CalculationDocument2 pagesGully Spacing CalculationRaoofNo ratings yet

- Pipe Guide and Welding Connection - h150x125x14x8.5Document13 pagesPipe Guide and Welding Connection - h150x125x14x8.5BenchNo ratings yet

- Simulation Summary of Horizontal EconomizerDocument1 pageSimulation Summary of Horizontal EconomizerHariyono Rudi NovantoNo ratings yet

- Beam Element Analysis ReportDocument17 pagesBeam Element Analysis ReportJair Andres Cuartas NovoaNo ratings yet

- Output Summary: See Data Check Messages Report For Warning Messages. See Runtime Message Report For Warning MessagesDocument1 pageOutput Summary: See Data Check Messages Report For Warning Messages. See Runtime Message Report For Warning MessagesIdil FitriNo ratings yet

- Output Summary: SI UnitsDocument1 pageOutput Summary: SI Unitsdaboo sanatNo ratings yet

- 1-Way Solid Concrete Slab Design to Bs 81101997 Table 3.12 - Revised 2.0Document7 pages1-Way Solid Concrete Slab Design to Bs 81101997 Table 3.12 - Revised 2.0Faris QoceyNo ratings yet

- Tonnage: Gate AreaDocument4 pagesTonnage: Gate AreaVishal RajputNo ratings yet

- Monorail Calculation Design ParametersDocument9 pagesMonorail Calculation Design ParametersBang OchimNo ratings yet

- Design of Isolated Footing (ECP-202)Document18 pagesDesign of Isolated Footing (ECP-202)mahmoud mohamedNo ratings yet

- DBR-L2P9 2.5X2.5X.3 1000 Co-12 PDFDocument1 pageDBR-L2P9 2.5X2.5X.3 1000 Co-12 PDFRudra MehtaNo ratings yet

- Idris Kris Shandy - 203303048Document1 pageIdris Kris Shandy - 203303048Idris KrisNo ratings yet

- Rectangular Beam Design SummaryDocument3 pagesRectangular Beam Design SummaryFrederick TanNo ratings yet

- Round Attachment Cylindrical Shell AnalysisDocument9 pagesRound Attachment Cylindrical Shell AnalysisakisdassasNo ratings yet

- Petroleum Regeneration and Processing Facility: Anchor Force CalculationDocument8 pagesPetroleum Regeneration and Processing Facility: Anchor Force CalculationPrasadNo ratings yet

- Tugas Take Home UTSDocument18 pagesTugas Take Home UTSdodikNo ratings yet

- Design of Flat Head For HydrotestDocument12 pagesDesign of Flat Head For HydrotestSAGAR100% (1)

- One Way SlabDocument23 pagesOne Way SlabmeerahNo ratings yet

- Slope Towards Heel: (Note:-Submerged 2/3rd Dry)Document2 pagesSlope Towards Heel: (Note:-Submerged 2/3rd Dry)AHSANNo ratings yet

- C058438A2Document1 pageC058438A2alberjimNo ratings yet

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- 4 AccumlatorDocument1 page4 AccumlatorAssure TurbinesNo ratings yet

- VedicReport3 25 20174 39 48PM PDFDocument47 pagesVedicReport3 25 20174 39 48PM PDFAssure TurbinesNo ratings yet

- 2.1 Fuels and CombustionDocument2 pages2.1 Fuels and CombustionAssure TurbinesNo ratings yet

- Fuels and Combustion OverviewDocument28 pagesFuels and Combustion OverviewDrupad PatelNo ratings yet

- Wood Fuels Handbook BTC enDocument83 pagesWood Fuels Handbook BTC enfelramNo ratings yet

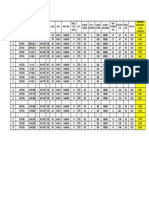

- Table For Pressure Drop-2Document1 pageTable For Pressure Drop-2Assure TurbinesNo ratings yet

- Stainless Steel Flange SpecificationsDocument2 pagesStainless Steel Flange SpecificationsAssure TurbinesNo ratings yet

- TP 108 15 All About Temp Plate®Document56 pagesTP 108 15 All About Temp Plate®goodspeed_ph100% (1)

- TV 22 2015 4 893 898Document6 pagesTV 22 2015 4 893 898Assure TurbinesNo ratings yet

- Office Elec Bill Payment PDFDocument1 pageOffice Elec Bill Payment PDFAssure TurbinesNo ratings yet

- Heat Recovery Workpaper (Original)Document33 pagesHeat Recovery Workpaper (Original)Assure TurbinesNo ratings yet

- Stainless Steel Flange SpecificationsDocument2 pagesStainless Steel Flange SpecificationsAssure TurbinesNo ratings yet

- Upgrade Your Air Preheater with BD Heat RecoveryDocument1 pageUpgrade Your Air Preheater with BD Heat RecoveryAssure TurbinesNo ratings yet

- Report On Lienz PlantDocument17 pagesReport On Lienz PlantAssure TurbinesNo ratings yet

- E6 35 43 00Document12 pagesE6 35 43 00dolphinNo ratings yet

- Promotion of The Organic Rankine Cycle Based Cogeneration: Opportunities and ChallengesDocument7 pagesPromotion of The Organic Rankine Cycle Based Cogeneration: Opportunities and ChallengesAssure TurbinesNo ratings yet

- Ssteel Bolts PDFDocument28 pagesSsteel Bolts PDFneelimasudhirNo ratings yet

- Detailed Project Report ON Waste Heat Recovery in Roller Kiln (Morbi Ceramic Cluster)Document47 pagesDetailed Project Report ON Waste Heat Recovery in Roller Kiln (Morbi Ceramic Cluster)Assure TurbinesNo ratings yet

- Waste heat recovery projects using Organic Rankine Cycle technologyDocument11 pagesWaste heat recovery projects using Organic Rankine Cycle technologyAssure TurbinesNo ratings yet

- Design, Construction and Evaluation of A Small Scale Solar DryerDocument15 pagesDesign, Construction and Evaluation of A Small Scale Solar DryerDinesh PoudelNo ratings yet

- B-144 - Datasheet - PSVDocument6 pagesB-144 - Datasheet - PSVRameez AhmedNo ratings yet

- Concrete reinforcement ratio calculation and stress analysisDocument36 pagesConcrete reinforcement ratio calculation and stress analysisMifthah Reino AnantaNo ratings yet

- Cambridge International General Certificate of Secondary EducationDocument20 pagesCambridge International General Certificate of Secondary Educationyuke kristinaNo ratings yet

- Benjamin, Barkley Accepted Thesis 04-25-13 FA 13Document64 pagesBenjamin, Barkley Accepted Thesis 04-25-13 FA 13eliasNo ratings yet

- DistributionatalogueDocument38 pagesDistributionatalogued22027lingmail.comNo ratings yet

- Is 11384Document19 pagesIs 11384Akhlaq HussainNo ratings yet

- Computational Fluid Dynamics 2006 Proceedings of The Fourth International Conference On Computational Fluid Dynamics ICCFD4 Ghent Belgium 10 14 JDocument914 pagesComputational Fluid Dynamics 2006 Proceedings of The Fourth International Conference On Computational Fluid Dynamics ICCFD4 Ghent Belgium 10 14 JMarcos AquinoNo ratings yet

- Coriolis Force: Classical MechanicsDocument9 pagesCoriolis Force: Classical MechanicsVanellope VonschweettzNo ratings yet

- THE PARTICULATE NATURE OF MATTER: STATES, CHANGES, AND THE KINETIC THEORYDocument32 pagesTHE PARTICULATE NATURE OF MATTER: STATES, CHANGES, AND THE KINETIC THEORYB R YNo ratings yet

- Liquid Solutions PDFDocument50 pagesLiquid Solutions PDFAniruddha KawadeNo ratings yet

- Liquid Penetrant Examination Procedure For Asme CodeDocument15 pagesLiquid Penetrant Examination Procedure For Asme Codeshabbir626No ratings yet

- Understanding Chemical EquilibriumDocument22 pagesUnderstanding Chemical EquilibriumYuvrajNo ratings yet

- Magnetic Field IndicatorsDocument2 pagesMagnetic Field IndicatorsdantegimenezNo ratings yet

- M410 Orifice Plate Assemblies: 2. Technical Details 3. Installation RequirementsDocument8 pagesM410 Orifice Plate Assemblies: 2. Technical Details 3. Installation RequirementsIvan RocoNo ratings yet

- De Almeida Et Al., 2015Document11 pagesDe Almeida Et Al., 2015lianyNo ratings yet

- Dop 10076 Paroc Extra en UsDocument2 pagesDop 10076 Paroc Extra en UsJānis DimantsNo ratings yet

- Plant Utilities - Instrument Air Systems PDFDocument5 pagesPlant Utilities - Instrument Air Systems PDFAnurag TripathiNo ratings yet

- Steel Structure Analysis Seminar ProjectDocument16 pagesSteel Structure Analysis Seminar ProjectDnyaneshwar GawaiNo ratings yet

- Microstructure Evolution and Mechanical Behaviour of Pure Aluminium and Aluminium Alloys Processed Through Constrained Groove PressingDocument10 pagesMicrostructure Evolution and Mechanical Behaviour of Pure Aluminium and Aluminium Alloys Processed Through Constrained Groove PressingMoin ANo ratings yet

- lc140 EngDocument2 pageslc140 EnganassNo ratings yet

- Chapter 18Document38 pagesChapter 18NewtinhooNo ratings yet

- Esas - 1Document37 pagesEsas - 1Rodeth Ann MendozaNo ratings yet

- Đề ANH chuyên 5Document7 pagesĐề ANH chuyên 5Phạm Ngô Hiền MaiNo ratings yet

- The Effects of Initial TemperatureDocument5 pagesThe Effects of Initial TemperatureErhan Sedat EnerNo ratings yet

- Atomic Structure: Atomic Structure: Overview of Bohr's Atomic ModelDocument38 pagesAtomic Structure: Atomic Structure: Overview of Bohr's Atomic Modelmanoj kumarNo ratings yet

- Heat Shrinking AllDocument46 pagesHeat Shrinking AllCaylie KirbyNo ratings yet

- Air-Cooled Chiller With Variable-Speed Screw Compressor: Performance InformationDocument2 pagesAir-Cooled Chiller With Variable-Speed Screw Compressor: Performance InformationVu Manh ThangNo ratings yet