Professional Documents

Culture Documents

02 Electrical Equipment Damage r15

Uploaded by

Wrya SaeedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

02 Electrical Equipment Damage r15

Uploaded by

Wrya SaeedCopyright:

Available Formats

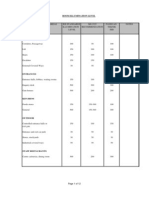

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Power System Protection

for Engineers

Electrical Equipment Damage

Copyright © SEL 2004

Electrical Equipment Damage_r15 1

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Electrical Equipment Damage

Objectives

l Understand the Effects of High Current on

Electrical Equipment

l Introduce the Use of Time-Current Curves

l Understand the Importance of High-Speed

Protection to Reduce Thermal and

Mechanical Damage Due to Faults

l Understand the Effect of Voltage Sags and

Hazards to System Stability

Electrical Equipment Damage_r15 2

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Faults in Electrical Systems

Produce Current Increments

a

b

c

I

Distribution Fault

Substation

I

Wire

Generally, short circuits cause very high magnitude system current (larger than the

normal load currents).

Electrical system components (overhead lines, cables, transformers, etc.) have

metallic conductors (wires) that experience this high current.

Electrical Equipment Damage_r15 3

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Temperature Rise From Current

Constant Current

I T

Equilibrium

T Te

Ti

dW

= I 2R

dt t

T(t)=( Ti - Te )e-t/t + Te

Any current (large or not) passing through a wire in free space causes a

temperature rise in the wire. The energy comes from the current, for which the

change over time (power) can be expressed with the following equation:

dW

= I2R

dt

In the former equation, “I” represents the rms value of the current.

Part of this energy heats up the conductor; convection transmits another part of

this energy to ambient. During normal load conditions, if we assume the current

has constant rms (steady state), the wire temperature reaches an equilibrium. This

means that the wire temperature T remains constant and all the energy the current

provides is transmitted to the surrounding medium.

For this simple system, the wire temperature as a function of time can be

expressed as follows:

T( t ) = ( Ti - Te )e - t / t + Te

Electrical Equipment Damage_r15 4

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Factors Influencing Wire Heating

Current Wire

Magnitude Material

Properties

I

Ambient

d

Temperature

and Other

Wire Size

Environmental

Factors

For a given material and a given set of constant environmental parameters, the

temperature change of the wire depends almost exclusively on the wire size and

the current magnitude (the rms value).

Expressed as an equation, the relationship is as follows:

T( t ) = ( Ti - Te )e - t / t + Te

The values Te, Ti and t strongly depend on the rms value of the current I.

Electrical Equipment Damage_r15 5

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Insulated Conductor (Cable)

Thermal Damage

Insulation

T

I

Te

Td Insulation damage

Ti

td

t

For an insulated conductor, the insulation will experience the temperature

increase.

Plastic insulation–such as that used in common cables–is instantaneously

damaged if the temperature exceeds a limit value called damage temperature ( Td

). This temperature is 150° C for common thermoplastic insulation.

If the current is large enough, the wire temperature could exceed the limit. The

time td needed for the temperature to reach the limit is called damage time.

Electrical Equipment Damage_r15 6

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Insulated Conductor Thermal Damage

I

t

T

I = I3 > I2

T

I = I2 > I1 Damage

I = I1 Curve

t1

Td I = Imd t2

t3

Ti

t3 t2 t1

t

Imd I1 I2 I3 I

We can show (experimentally and analytically) that:

• The damage time is shorter as the applied current is larger

• There is a current (Imd) that causes the equilibrium to equal the insulation damage

temperature. Equivalently, the damage time for this current is “infinite.”

The curve obtained by plotting the damage time vs. the applied current is called the damage

curve.

Electrical Equipment Damage_r15 7

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Electrical Equipment Component

Thermal Damage Curve

t Time vs. Current Plot

Damage

Curve

In Imd I

Rating

Time vs. current plots are widely used in protection.

The damage curve is also known as the thermal capacity curve, or the short-time

thermal damage curve.

Notice that the cable rating (rated current) is not the same as the minimum current

Imd. The nominal current In (rating) is the current that causes the wire to reach the

rated temperature of the cable in the steady state (equilibrium). This temperature,

in steady state, is the value at which the manufacturer guarantees the useful life of

the cable.

If a current with an rms value between Imd and In is applied to a given

component, this current will reach an equilibrium larger than the rated temperature

but smaller than the damage temperature. In this case, we say that the damage will

be in long time. This means that the equipment will lose years of life (accelerated

aging).

Electrical Equipment Damage_r15 8

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Insulated Cable Damage Curves

l Copper Conductors,

Thermoplastic

Insulation

l Damage

Temperature: 150° C

For relatively large currents (larger than three times the cable rating) it is possible

to approximate the damage curve with the following equation:

CA 2 [seconds]

td = 2

I

where C is a constant that depends on the wire material, the insulation

properties, and the ambient variables; and A is the cross section in square

inches or mm2 of the conductor.

Note that this is the following old and famous equation:

I2 t = K [A 2 s]

Electrical Equipment Damage_r15 9

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Distribution Conductor Damage Curves

l Stranded Aluminum

Conductors (Without

Insulation)

l Damage Time

Needed for

Annealing

In the case of conductors without insulation (as in overhead distribution lines), the

damage temperature is given by the annealing temperature.

Electrical Equipment Damage_r15 10

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Distribution Transformer Damage Curve

Transformer

Impedance: Z = 4%

I / In = 1 I / In = 2 I / In = 20

Many factors affect the shape of transformer damage curves. We will study these

curves later in this course.

Electrical Equipment Damage_r15 11

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Experiment

Expensive Cable T

Melting

Inexpensive

Wire Tm

T2 Damage

Td

I

T1

T1

tm td t

T2 tm < t d

The Inexpensive Wire is Sacrificed to

Protect the Expensive Cable

In this simple experiment, we sacrifice an inexpensive wire to save expensive

cable. In other words, for a given current, the inexpensive wire reaches melting

temperature before the expensive wire reaches damage temperature. The

inexpensive wire blows out and the cable is protected.

What do we call this inexpensive wire?

Electrical Equipment Damage_r15 12

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Fuse Melting

t

I = I3 > I2

T

I = I2 > I1

I = I1

Melting Melting

Tm Curve

I = Imm

t1

t2

Ti t3

t3 t2 t1 t

In Imm I1 I2 I3 I

Fuse Rating

As we did with damage time, we can show (experimentally and analytically) the following:

• The melting time decreases as applied current increases.

• There is a current (Imm) that causes the equilibrium to equal the fuse melting

temperature. Equivalently, the melting time for this current is “infinite.” It is

difficult to experimentally determine an accurate value for this current.

The curve obtained by plotting the damage time vs. the applied current is called the

minimum melting time curve.

Notice that the fuse rating (nominal current) is not the same as the minimum melting

current Imm.

Electrical Equipment Damage_r15 13

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Time vs. Current Plots

Protected t

Equipment

Fuse

Protected

td Equipment

I Damage curve

tm

Fuse

l First Approach to Basic Melting

Protection Principle: Curve

SPEED

In Imm Ix I

Fuse Rating

The result of the experiment described on the previous page can be represented in

a time vs. current plot.

As a first approach, we can say that, for every current value, the fuse must melt

before the protected equipment suffers damage.

Later in the course, we will improve this approach.

Electrical Equipment Damage_r15 14

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Fault Clearing

T

tarc

Vaporization i

Melting Tm Fuse

T

Ti

tm tc t

i

i

t

Melting Clearing

The melting time the former pages of this section describe refers to the time

before the fuse reaches melting temperature. The current does not become zero

immediately. The fuse goes through a series of different stages that terminate with

the development of an arc. The current disappears when this arc is completely

extinguished. At that moment, we say that the fault has been cleared.

The time period between the fault occurrence and the fault clearing is called the

total clearing time.

Electrical Equipment Damage_r15 15

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Fuse Curves

t

Total

Clearing

Time

tc

Curve

tm

Minimum

Melting

Time

In Imm Ix I Curve

Fuse Rating

As we did with melting time, we can draw a curve to represent the total clearing

time as a function of the current.

Following are the main characteristics of a fuse:

• The minimum melting time curve

• The total clearing time curve

• The fuse minimum melting current

• The fuse rating (nominal current) which should not be confused with the

minimum melting current.

We will describe further fuse characteristics later in this course.

Electrical Equipment Damage_r15 16

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Time vs. Current Plots

t l A Better Approach:

Consider the Total

Protected

Equipment

Clearing Time

td

Damage curve

tc Protected

Equipment

Fuse

Fuse

Curves

I

In Imm Ix I

To improve the first approach for overcurrent protection, we could say that the

total clearing time for the fuse should be less than the damage time for the

protected equipment.

We will describe practical details of fuse application later in this course.

Electrical Equipment Damage_r15 17

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Other Damage

l Mechanical Damage

l Voltage Sags

l Transient Stability

Electrical Equipment Damage_r15 18

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Mechanical Damage

l Very Destructive in Bus Bars, Isolators,

Supports, Transformers and Machines

l Damage is “Instantaneous”

Mechanical

Forces

f1 f2

i1

i2

Rigid Conductors f1(t) = k i1(t) i2(t)

Large short-circuit currents produce large mechanical forces.

Large mechanical forces cause permanent deformation in the shape of rigid

conductors and the destruction of supports.

The effect could be very destructive in transformers, motors, and generators.

Damage occurs “instantaneously” (in a very short time).

Electrical Equipment Damage_r15 19

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Voltage Sags

Unacceptable Voltage Variation

VOLTAGE (%)

100

ELECTRONIC DRIVER

90

80 COMPUTER

70

60

CONTACTOR

50

40

30

20

10

0

0 10 20 30 40 50 60 70 80 90 100

TIME (Cycles)

Electrical Equipment Damage_r15 20

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Voltage Sags

=Loads

I

S/E

Vs

V

Vs 1 p.u.

UVVR limit

(sensitive loads)

Clearing Time

t

Electrical equipment (which comprises load) has an unacceptable voltage

variation region (UVVR). The region indicates the equipment tolerance to voltage

variations. The clearing time and the recovery voltage in the system must remain

out of the UVVR.

Electrical Equipment Damage_r15 21

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Transient Stability

1 2

System

EÐ0 Fault EÐd

Generator

d Unstable d Stable

tcrit tclear t tclear tcrit t

With the introduction of distributed generation practices, electromechanical

stability problems become an important issue in modern distribution systems.

For synchronization of generators and utility systems after a fault, the clearing

time must be very short.

The upper permissible limit for this clearing time is traditionally known as the

critical clearing time.

For the simple case shown, the clearing time (tclear) of Circuit Breakers 1 and 2

must be less than machine characteristics and the critical clearing time (tcrit) the

system imposes.

Electrical Equipment Damage_r15 22

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Summary

l Thermal Damage

l Mechanical Damage

l Voltage Sags

l Transient Stability

PROTECTION SPEED

Electrical Equipment Damage_r15 23

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Damage is Extensive When Relays

Do Not Operate Correctly

Electrical Equipment Damage_r15 24

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Electrical Equipment Damage_r15 25

Power System Protection for Engineers – PROT 401

Section 2 - Electrical Equipment Damage

Electrical Equipment Damage_r15 26

You might also like

- Auto-Reclosing: Network Protection & Automation GuideDocument16 pagesAuto-Reclosing: Network Protection & Automation GuideShailesh ChettyNo ratings yet

- Broken Conductor Protection PDFDocument4 pagesBroken Conductor Protection PDFRandhir KumarNo ratings yet

- NEW Chapter 13 Generator Protection PDFDocument70 pagesNEW Chapter 13 Generator Protection PDFWrya SaeedNo ratings yet

- High Impedance Busbar ProtectionDocument2 pagesHigh Impedance Busbar ProtectionRK K100% (1)

- Differential ProtectionDocument25 pagesDifferential ProtectionAkinbode Sunday Oluwagbenga100% (5)

- Power System Protection PDFDocument12 pagesPower System Protection PDFBala MNo ratings yet

- Schneider EM RelaysDocument16 pagesSchneider EM RelaysMuneer MPNo ratings yet

- Relay Terst System Freja 300Document10 pagesRelay Terst System Freja 300Rahil TasawarNo ratings yet

- 220kV Feeder Control & Relay Panel - 07.09.18Document44 pages220kV Feeder Control & Relay Panel - 07.09.18Guru MishraNo ratings yet

- Argus 1 Diagrams and ParametersDocument17 pagesArgus 1 Diagrams and ParametersTamilventhan_sNo ratings yet

- Testing and Commissioning - High Impedence Busbar ProtectionDocument9 pagesTesting and Commissioning - High Impedence Busbar ProtectionsathiyaseelanNo ratings yet

- Broken Conductor ProtectionDocument2 pagesBroken Conductor ProtectionThirumalNo ratings yet

- Power System Balanced FaultsDocument42 pagesPower System Balanced FaultsJorge Corrales BarrazaNo ratings yet

- Protective Relaying Testing ST6Document6 pagesProtective Relaying Testing ST6Darwin MesaNo ratings yet

- Line Protection: Substation Automation ProductsDocument46 pagesLine Protection: Substation Automation ProductsRobert MihayoNo ratings yet

- Acids and Bases NotesDocument17 pagesAcids and Bases NotesNap DoNo ratings yet

- REF ProtectionDocument6 pagesREF ProtectionAshok KumarNo ratings yet

- High Impedance Busbar Protection Principles and CalculationsDocument19 pagesHigh Impedance Busbar Protection Principles and CalculationsCarlos Sucasaire ChuraNo ratings yet

- CT Grounding To Avoid Nuisance TrippingDocument2 pagesCT Grounding To Avoid Nuisance TrippingTravis WoodNo ratings yet

- 06 - Disturbance Recording and Handling PDFDocument62 pages06 - Disturbance Recording and Handling PDFAnonymous fM2c6BNo ratings yet

- Ladder DiagramDocument17 pagesLadder DiagramItsMeRyanCNo ratings yet

- Oracle Coherence Admin GuideDocument156 pagesOracle Coherence Admin Guidegisharoy100% (1)

- Switch Gear and Protection: Directional RelaysDocument11 pagesSwitch Gear and Protection: Directional Relaysshiny_vikram6365100% (1)

- 04.protection of 33KV Feeder.Document16 pages04.protection of 33KV Feeder.gnpr_10106080No ratings yet

- Generator Protection SettingsDocument4 pagesGenerator Protection Settingsmoses kakwenaNo ratings yet

- 04 TransformerDocument98 pages04 TransformerahmedNo ratings yet

- Feeding System PDFDocument52 pagesFeeding System PDFWrya SaeedNo ratings yet

- Testing of Semifinished Products of Thermoplastics Bases - Indications Directive DVS 2201-1Document4 pagesTesting of Semifinished Products of Thermoplastics Bases - Indications Directive DVS 2201-1OscarNo ratings yet

- Testing LFDC101/102 Relay Using F6150Document89 pagesTesting LFDC101/102 Relay Using F6150Sristhi GanguliNo ratings yet

- CT Class Very ImportantDocument6 pagesCT Class Very ImportantEngr Fahimuddin QureshiNo ratings yet

- P141Document8 pagesP141lcatelaniNo ratings yet

- Walt Kester, Joe Buxton: Section 5 Battery ChargersDocument25 pagesWalt Kester, Joe Buxton: Section 5 Battery Chargersarde50No ratings yet

- RET670 Relay Testing With F6150Document94 pagesRET670 Relay Testing With F6150Vinoth MahendranNo ratings yet

- Generator ProtectionDocument30 pagesGenerator ProtectionShahzad Bhatti100% (2)

- 03 PROT405 IndustrialPowerSystemProt r4Document79 pages03 PROT405 IndustrialPowerSystemProt r4Hector AguilarNo ratings yet

- Transformer Protection SchemesDocument5 pagesTransformer Protection SchemesIppiNo ratings yet

- Instantaneous Voltage Relay VAG11,21 High ResDocument4 pagesInstantaneous Voltage Relay VAG11,21 High ResManu ManojNo ratings yet

- Book How They Work Hydraulics PDFDocument41 pagesBook How They Work Hydraulics PDFWrya SaeedNo ratings yet

- Refinery TankagesDocument4 pagesRefinery Tankagesmayuresh1101100% (1)

- Wi Cswip 3.1 Part 13Document7 pagesWi Cswip 3.1 Part 13Ramakrishnan AmbiSubbiahNo ratings yet

- Power System Protection Power System Stability: Substation Automation ProductsDocument15 pagesPower System Protection Power System Stability: Substation Automation ProductsRobert Mihayo100% (1)

- Relay Setting Principles for Transmission Line ProtectionDocument32 pagesRelay Setting Principles for Transmission Line ProtectionSe SamnangNo ratings yet

- Busbar RatingDocument64 pagesBusbar RatingAbdulla Nashith100% (1)

- Busbar RatingDocument64 pagesBusbar RatingAbdulla Nashith100% (1)

- SEL Relays New York Application GuideDocument32 pagesSEL Relays New York Application Guidepistola2No ratings yet

- Differential ProtectionDocument24 pagesDifferential ProtectionRahul ThakurNo ratings yet

- Basic Power System ProtectionDocument15 pagesBasic Power System ProtectionMohammedSaadaniHassani100% (4)

- Open Hole Logs Introduction GR SP CALDocument21 pagesOpen Hole Logs Introduction GR SP CALmagedNo ratings yet

- Auxiliary Classical Ancillary Equipment CatalogueDocument94 pagesAuxiliary Classical Ancillary Equipment CatalogueĐinh ĐạtNo ratings yet

- 15 Busbar ProtectionDocument21 pages15 Busbar ProtectionSristick100% (8)

- 02 Thermal Motor Protection FunctionDocument36 pages02 Thermal Motor Protection FunctionDavid MendozaNo ratings yet

- Lecture 1. INTRODUCTION TO BASIC PROTECTION AND RELAYING SCHEMES PDFDocument57 pagesLecture 1. INTRODUCTION TO BASIC PROTECTION AND RELAYING SCHEMES PDFData-Aja TCNNo ratings yet

- 08 AutoreclosingDocument24 pages08 Autoreclosinganurag101No ratings yet

- P63x RestrictedEarthFault ApplicationGuide EN eDocument32 pagesP63x RestrictedEarthFault ApplicationGuide EN eAllama HasanNo ratings yet

- KBCH120 Relay Testing With F6150Document52 pagesKBCH120 Relay Testing With F6150TerezkaM100% (3)

- Application Notes For Micom P12X High Impedance ProtectionDocument29 pagesApplication Notes For Micom P12X High Impedance ProtectionHaleelu Abdul Jaleel100% (1)

- RelaySimTest AppNote Line Distance Protection Power Swing Blocking 2017 ENUDocument25 pagesRelaySimTest AppNote Line Distance Protection Power Swing Blocking 2017 ENUkondareddyNo ratings yet

- Process Control Fundamentals 2Document73 pagesProcess Control Fundamentals 2Otuekong Ukpong100% (2)

- Power Plant Design InformationDocument47 pagesPower Plant Design InformationSISWANTO100% (1)

- Areva Manual Book p126-p127Document546 pagesAreva Manual Book p126-p127Vijayaganthaan VisvanatthanNo ratings yet

- Research BulletsDocument18 pagesResearch BulletsVong Albios DogomeoNo ratings yet

- 2H34 Application & Commisioning Manual Rev2 PDFDocument16 pages2H34 Application & Commisioning Manual Rev2 PDFking_electricalNo ratings yet

- Transformer Protection DifferentialDocument48 pagesTransformer Protection Differentialrajesh100% (1)

- JVS Manual JRP 011Document12 pagesJVS Manual JRP 011Tamilventhan_sNo ratings yet

- Mva Power TransformerDocument22 pagesMva Power TransformerPooja DoshiNo ratings yet

- 7SA522 CatalogueDocument53 pages7SA522 Cataloguetayson2002No ratings yet

- CSC 211 ManualDocument48 pagesCSC 211 Manualsgshekar30No ratings yet

- Principles of Differential Protection Technology: Power Transmission and DistributionDocument19 pagesPrinciples of Differential Protection Technology: Power Transmission and DistributionDinesh Pitchaivel100% (1)

- Micom p94xDocument446 pagesMicom p94xkjfensNo ratings yet

- Neutral Displacement Relay PDFDocument4 pagesNeutral Displacement Relay PDFjoydeep_d3232No ratings yet

- Stability Studies For System Dependent Generator Protection Functions - 2011Document11 pagesStability Studies For System Dependent Generator Protection Functions - 2011Julián Estiben Mesa CalleNo ratings yet

- TT CPN1 Fuse Operation Under DC Conditions ENDocument7 pagesTT CPN1 Fuse Operation Under DC Conditions ENanak1.bintangNo ratings yet

- The Effect of Current Transformer Saturation on Differential Relay PerformanceDocument6 pagesThe Effect of Current Transformer Saturation on Differential Relay Performanceamir amirNo ratings yet

- وجية جرجس جزء 1Document207 pagesوجية جرجس جزء 1Anonymous mghI7I7pNo ratings yet

- VFD-S ΔϠδϠγ ϡΪΨΘγ ϞΒϗ ΐΘΘϜϟ άϫ ΎϤΩ ήϗDocument84 pagesVFD-S ΔϠδϠγ ϡΪΨΘγ ϞΒϗ ΐΘΘϜϟ άϫ ΎϤΩ ήϗWrya SaeedNo ratings yet

- تلخيص كود NEC في 200 صفحة فقطDocument204 pagesتلخيص كود NEC في 200 صفحة فقطWrya Saeed100% (1)

- Classic Control Course - Tamer AhmedDocument55 pagesClassic Control Course - Tamer Ahmedwadhahesmaeel100% (6)

- 4 Essential Ground-Fault Protective Schemes You Should Know About - EEPDocument16 pages4 Essential Ground-Fault Protective Schemes You Should Know About - EEPWrya SaeedNo ratings yet

- Bearing Capacity of Different Types of Soil - Engineering DiscoveriesDocument13 pagesBearing Capacity of Different Types of Soil - Engineering DiscoveriesWrya SaeedNo ratings yet

- Guide For LV Compensation CubiclesDocument44 pagesGuide For LV Compensation CubiclesARVINDNo ratings yet

- Classic Control Course - Tamer AhmedDocument55 pagesClassic Control Course - Tamer Ahmedwadhahesmaeel100% (6)

- Lossofexcitation 130805045350 Phpapp01Document52 pagesLossofexcitation 130805045350 Phpapp01ahvaz1392bNo ratings yet

- Ger 3183Document14 pagesGer 3183santoshkumar777No ratings yet

- 100% Stator Ground Fault Protection of Alternators by Low Frequency Injection and Using Real Power SignalDocument6 pages100% Stator Ground Fault Protection of Alternators by Low Frequency Injection and Using Real Power SignalWrya SaeedNo ratings yet

- Basics of SwitchboardsDocument60 pagesBasics of SwitchboardsRui Pedro SousaNo ratings yet

- مراحل التصميم المختلفة -كهرباءDocument5 pagesمراحل التصميم المختلفة -كهرباءWrya SaeedNo ratings yet

- Cathodic ProtectionDocument22 pagesCathodic ProtectionFakhr-e-Alam100% (1)

- Basics of SwitchboardsDocument60 pagesBasics of SwitchboardsRui Pedro SousaNo ratings yet

- Basics of Surge Protection SIEMENSDocument44 pagesBasics of Surge Protection SIEMENScleyvasNo ratings yet

- Shneider PDFDocument87 pagesShneider PDFWrya SaeedNo ratings yet

- مراحل التصميم المختلفة -كهرباءDocument5 pagesمراحل التصميم المختلفة -كهرباءWrya SaeedNo ratings yet

- تقدير الاحمال الكهربية لأي مبنيDocument5 pagesتقدير الاحمال الكهربية لأي مبنيWrya SaeedNo ratings yet

- Lighting Design Part.1Document29 pagesLighting Design Part.1Wrya SaeedNo ratings yet

- IESLuxLevel 1Document12 pagesIESLuxLevel 1tr_nisitNo ratings yet

- Kollidon 30 Technical InformationDocument10 pagesKollidon 30 Technical InformationhomarearisugawaNo ratings yet

- Connective TissueDocument6 pagesConnective TissuecrtgyhujikNo ratings yet

- Hargreaves 2007Document15 pagesHargreaves 2007Sam GonçalvesNo ratings yet

- Programming structures if, for and while loopsDocument16 pagesProgramming structures if, for and while loopsFrancisco AristizabalNo ratings yet

- Daikin RXS-K - Technical DataDocument21 pagesDaikin RXS-K - Technical DataPrestoneKNo ratings yet

- OM5510 05 (Positioner)Document16 pagesOM5510 05 (Positioner)JayeshJayarajanNo ratings yet

- Financial Accounting IIDocument16 pagesFinancial Accounting IIMiguel BuenoNo ratings yet

- DCT Dual Clutch TransmissionDocument16 pagesDCT Dual Clutch TransmissionSudharshan SrinathNo ratings yet

- CH 3Document19 pagesCH 3Abhishek GiriNo ratings yet

- Fault Report - Inventory Cpf1 Vs Caño LimomDocument37 pagesFault Report - Inventory Cpf1 Vs Caño LimomJessica RiveraNo ratings yet

- Debre Tabor University: Network and System AdministrationDocument33 pagesDebre Tabor University: Network and System AdministrationBethelhem YetwaleNo ratings yet

- Smart Card/Proximity Based Vehicle Identification & Access Control SystemDocument4 pagesSmart Card/Proximity Based Vehicle Identification & Access Control SystemkarunamoorthiNo ratings yet

- SamplingDocument12 pagesSamplingΔημητρηςΣαρακυρουNo ratings yet

- Product Documentation: Release NotesDocument3 pagesProduct Documentation: Release NotesArmando CisternasNo ratings yet

- Ef TechnologyDocument2 pagesEf TechnologyAdarsha SarpangalaNo ratings yet

- Correct AnswerDocument120 pagesCorrect Answerdebaprasad ghosh100% (1)

- Innovative High Throw Copper Electrolytic ProcessDocument6 pagesInnovative High Throw Copper Electrolytic Processyonathan fausaNo ratings yet

- Final Project Regenerative BrakingDocument6 pagesFinal Project Regenerative Brakingdims irifiyinNo ratings yet

- 478 - Phs 242 NotesDocument61 pages478 - Phs 242 NotesSovan ChakrabortyNo ratings yet

- Complete trip-free loop, PFC and PSC testerDocument2 pagesComplete trip-free loop, PFC and PSC testerGermanilloZetaNo ratings yet

- Essay For Villa Savoye AbstractDocument1 pageEssay For Villa Savoye AbstractFrancis PohNo ratings yet

- Linux OS LabDocument2 pagesLinux OS LabSubaNo ratings yet

- Tut 5. Two-Column Hammerhead Pier PDFDocument35 pagesTut 5. Two-Column Hammerhead Pier PDFOscar Varon BarbosaNo ratings yet