Professional Documents

Culture Documents

WHP-SPM-011 Rev. C General Welding-NDE Specification Piping Shop-Field Fabrication

Uploaded by

prihartono_diasCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WHP-SPM-011 Rev. C General Welding-NDE Specification Piping Shop-Field Fabrication

Uploaded by

prihartono_diasCopyright:

Available Formats

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION

PIPING SHOP-FIELD FABRICATION

DOC NO. : WHP-SPM-011 REV. C

RECORD OF REVISION

The revisions listed below have been incorporated in this copy of the document.

REV PAGE

SECTION DESCRIPTION OF CHANGES

NO. NO.

C All All Approved for Construction

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 2 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION

PIPING SHOP-FIELD FABRICATION

DOC NO. : WHP-SPM-011 REV. C

TABLE OF CONTENTS

1. GENERAL 4

1.1 Scope of Specification 4

1.2 Definition 4

1.3 Codes and Specification 4

1.4 Submittals 5

2. PRODUCT 5

2.1 Welding 5

2.2 Thermal Treatment 5

2.3 NDE (Non Destructive Examination) Requirements 6

2.4 Hardness Testing 7

2.5 Amine and Wet H2S Requirements 7

2.6 Delta Ferrite Testing 7

3. FIELD WELDING 7

ATTACHMENT – 1 8

PIPING WELDING DATA SHEET 8

ATTACHEMENT – 2 21

STANDARD WELD JOINT SYMBOL 21

ATTACHMENT – 3 23

STANDARD NDE/HEAT TREAT/TEST SYMBOL 23

ATTACHMENT – 4 25

GENERAL NOTES 25

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 3 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION

PIPING SHOP-FIELD FABRICATION

DOC NO. : WHP-SPM-011 REV. C

1. GENERAL

1.1 Scope of Specification

This specification prescribes standards for welding pressure-retaining piping, including non-

pressure attachments thereto and Non Destructive Examination for welds, fabricated parts and

component geometric configuration encountered in fabrication.

1.2 Definition

Company : Husky-CNOOC Madura Limited(HCML) as the ultimate user and owner or

the authorized representative of Company

Purchaser : The organization that issues the purchase order and specifications to the

Vendor. The purchaser is Husky-CNOOC Madura Limited’s(HCML)

appointed agent

Contractor : The party that carries out all or part of the design, engineering, procurement,

construction, commissioning or management of a project or operation of a

facility. The Principal may undertake all or part of the duties of the Contractor

Vendor : The Manufacturer of the equipment or the Manufacturer’s agent with the unit

responsibility

1.3 Codes and Specification

The latest editions of all applicable codes, specifications, and references shall define the

minimum requirements applicable to the subject work and no statement contained in this

Specification shall be construed as limiting the work to such minimum requirements.

Wherever conflicts or omissions between codes, specifications, and contract occur, the most

onerous condition shall apply. Contractor is responsible for reviewing the list below and informing

the Company of any omissions. All conflicts shall be formally brought to the attention of the

Company.

1.3.1 Applicable Codes

American Society Mechanical Engineering (ASME)

ASME B31.3 : Process Piping

ASME B31.8 : Gas Transmission and Distribution Piping

ASME Section V : Non Destructive Examination

ASME Section IX : Welding and Brazing Qualification

American Petroleum International (API)

API RP14E : Recommended Practice Design and Installation for Chemical, Oil and

Gas Industries

API RP582 : Welding Guidelines for chemical, Oil and Gas Industries

1.3.2 Related Project Specification

Work in this specification shall be coordinated with Project Specifications

WHP-SPM-507 : General Specification for Positive Material Identification (PMI)

WHP-SPM-512 : General Welding/NDE Specification for Pressure-Retaining

Components

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 4 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION

PIPING SHOP-FIELD FABRICATION

DOC NO. : WHP-SPM-011 REV. C

WHP-SPM-001 : Piping Material Specification Line Class - Process And Utility Piping

WHP-SPM-002 : Shop Fabrication and Handling Process And Utility Piping

WHP-SPM-003 : Field Fabrication And Installation Process And Utility Piping

1.4 Submittals

Submittals shall be made to the Purchaser or their designated representative in accordance with

the PO or Project Scope of Work and the following:

1.4.1 Welding

Submit WPSs (Welding Procedure Specifications) and PQRs (Procedure Qualification Records)

and a copy of Attachment-1 to this specification that has been filled in with the Vendor’s WPS

numbers to be used.

Note: WPS / PQR review will not proceed unless a completed copy of Attachment-1 is submitted

along with the WPS / PQRs.

2. PRODUCT

General design and fabrication requirements shall be in accordance with ASME B31.8 or ASME

B31.3, whichever is applicable.

2.1 Welding

2.1.1 Acceptable Welding Processes

See WHP-SPM-512 General Welding/NDE Specification For Pressure-Retaining Components for

a list of acceptable welding processes and associated limitations.

2.1.2 Weld Joint Fit-up

The engineering design document shall specify maximum pipe wall offset (hi-low) for single-

welded butt joints.

2.2 Thermal Treatment

2.2.1 Preheat and Interpass Requirements

The minimum preheating temperatures for welding, thermal cutting, and tack welding, including

bridge tacks, shall be as specified in the WPS, Attachment-1 or the applicable Code, whichever is

greater.

2.2.2 PWHT (Postweld Heat Treatment) Requirements

1. PWHT shall be in accordance with ASME B31.8 or ASME B31.3, whichever is applicable and

Attachment-1.

2. PWHT shall be performed in accordance with a written procedure that details the PWHT

method to be used, heating and cooling rates, holding time and temperature, and a

description of thermocouple locations for all pipe sizes to be PWHT'd.

3. The use of non-air hardening type filler metal on Cr-Mo fillet welds for the purpose of avoiding

PWHT is not permitted without written permission from the Purchaser or their designated

representative.

4. PWHT shall be performed in an enclosed furnace or by electrical resistance heating methods.

Purchaser permission is required to use other PWHT methods.

5. Exposed machined or threaded surfaces shall be protected from oxidation during PWHT.

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 5 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION

PIPING SHOP-FIELD FABRICATION

DOC NO. : WHP-SPM-011 REV. C

2.3 NDE (Non Destructive Examination) Requirements

The extent of NDE for each piping line class is specified in Attachment-1.

2.3.1 Visual Examination

Visual examination, evaluation and record of indications inspections is required and shall be in

accordance with ASME B31.8, Paragraph 826 or ASME B31.3, Paragraph 344.2, whichever is

applicable and ASME Code, Section V, Article 9.

2.3.2 Liquid Penetrant Examination

1. Liquid penetrant examination and evaluation of indications shall be in accordance with the

requirements and methods specified in ASME B31.3, Paragraph 344.4 or ASME B31.8,

Paragraph 826, whichever is applicable and ASME Code Section V, Article 6.

2. Penetrant materials shall meet the requirements of Paragraph T-641 of Article 6, Section V of

the ASME Code, for sulfur and halogen content, regardless of the type of material to be

examined. Chloride content of materials to be used on austenitic stainless steel shall not

exceed 50 PPM.

3. Liquid penetrant examination of welds shall include a band of base metal at least 1 inch (25

mm) wide on each side of the weld.

2.3.3 Magnetic Particle Examination

1. Magnetic particle examination and evaluation of indications shall be in accordance with the

requirements and methods specified in ASME B31.8, Paragraph 826 or ASME B31.3,

Paragraph 344.3, whichever is applicable and ASME Code, Section V, Article 7.

2. Magnetic particle examination of welds shall include a band of base metal at least 1 inch (25

mm) wide on each side of the weld. The AC magnetic yoke method shall be used.

3. In-process magnetic particle examination. When magnetic particle examination is substituted

for ultrasonic examination, the root pass, intermediate passes (if specified by the Purchaser),

and the finished weld shall be examined by the magnetic particle method.

2.3.4 Ultrasonic Examination

Ultrasonic examination and evaluation of indications shall be in accordance with the requirements

and methods specified in ASME B31.8, Paragraph 826 or ASME B31.3, Paragraph 344.6,

whichever is applicable and ASME Code Section V Article 5.

1. Ultrasonic examination may be substituted for radiographic examination when permitted by

the Purchaser.

2. When a single-wall radiographic technique cannot be used on weld joints requiring

radiography and the pipe wall thickness exceeds 1-1/4 inches (32 mm), the welds shall be

100% ultrasonically examined in lieu of radiographic examination.

2.3.5 Radiography Examination

Radiographic examination procedures, techniques, and evaluation of indications shall be in

accordance with ASME B31.8, Paragraph 826 or ASME B31.3, Paragraph 344.5, whichever is

applicable and ASME Code Section V, Article 2.

Additional requirements for radiographic examination shall be as follows:

A. Radiographs shall be made using industrial radiographic film.

B. Lead screens shall be used.

Approval from the Purchaser or their designated representative is required for use of

penetrameters other than those specified in the applicable Code. Wire type image quality

indicators (IQIs) equal to those meeting EN462-1, DIN 54109 or JIS-Z3104 requirements may

be substituted for those specified in ASME Section V provided an equivalent sensitivity is met.

C. Whenever less than 100% radiography is specified, the following rule shall apply:

The percent of welds specified on Attachment-1 shall be radiographed around their entire

circumference. A record shall be kept of the quality and extent of each welder's work. Each

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 6 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION

PIPING SHOP-FIELD FABRICATION

DOC NO. : WHP-SPM-011 REV. C

welder’s work shall be represented in the percentage of welds examined.

2.4 Hardness Testing

See WHP-SPM-512 General Welding/NDE Specification For Pressure-Retaining Components for

hardness testing requirements. See Appendix 02 of specification WHP-SPM-512 for hardness

testing of DSS (Duplex Stainless Steel).

2.5 Amine and Wet H2S Requirements

See WHP-SPM-512 General Welding/NDE Specification For Pressure-Retaining Components,

Appendix 01 for welding, NDE and PWHT requirements for equipment and piping in amine and

wet H2S service.

2.6 Delta Ferrite Testing

A. Five percent (5%) of pressure-retaining welds in austenitic stainless steel shall be tested for

delta ferrite in the weld deposit and the results recorded for production weldments.

B. Delta ferrite determinations made using magnetic instruments shall be performed before

PWHT when PWHT is required.

C. Delta ferrite content shall be 3 - 10 FN for operating temperatures of 800 °F (425°C) and

above, or for components that are PWHT’d. For components with operating temperatures

below 800 °F (425 °C), the delta ferrite content shall be 3 - 12 FN.

D. Delta ferrite shall be determined by a magnetic instrument calibrated in accordance with AWS

A4.2 (e.g., Severn gage or ferrite scope), or calculated using the Schaeffler or WRC 1988

Constitution Diagrams.

E. See Appendix 02 of specification WHP-SPM-512 for delta ferrite testing of DSS.

3. FIELD WELDING

Field fabrication and erection shall be performed in accordance with Section 2.0 of this

specification, except for the addition or deletion of items detailed in this section.

Welding shall not be done when the ambient air temperature is lower than 0°F (minus 18°C) or

when surfaces are wet, exposed to rain, snow, sleet, or high wind. The ambient air temperature

may be below 0°F (minus 18°C) during welding; however a heated structure or shelter around the

area being welded must maintain the air temperature adjacent to the weldment at 0°F (minus

18°C) or higher.

All weld areas shall be adequately protected from wind and moisture throughout welding

End Specification

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 7 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION

PIPING SHOP-FIELD FABRICATION

DOC NO. : WHP-SPM-011 REV. C

ATTACHMENT – 1

PIPING WELDING DATA SHEET

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 8 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION PIPING SHOP-FIELD

FABRICATION

DOC NO. : WHP-SPM-011 REV. C

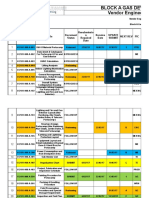

PIPING WELDING DATAS SHEET (SHEET-1)

Category: Normal General Hydrocarbon, Fuel Gas, Glycol, Sulfur Vapor, Design Code: ASME B31.3

Condensate, Steam, Boiler Feed Water, Combustion Air,

Hot Oil, ASME Flange Rating: 150, 300, 600, 900

Line Class(es): HP301, HP316, HS313, HP416, HP616, HS613, HP716

Special Criteria:

Piping Material: Killed Carbon Steel Attachment Material: Killed Carbon Steel Valve Material: Carbon Steel

P Number: P Number:

P-1 P Number: P-1 P-1

CVN Requirements: ASME B31.3 PMI Requirements: N/A Ferrite N/A

Requirements:

Pipe Wall Joint Heat Treat NDE Hardness Test

Dia Thick- Type

ness (Note B) (Notes A & C) Welding Procedures

NPS

Preheat PWHT CVN RT MT PT VT % Max. WPS No. (Note D)

All All SW Note 1 Note 2 No N/A N/A 100 % 100% None None

All ≤ ¾” BW Note 1 No No 100 % N/A N/A 100% None None

All > ¾” BW Note 1 Yes No 100 % N/A N/A 100% None None

All All SBR Note 1 Note 2 No N/A N/A N/A 100% None None

All All OL Note 1 Note 2 No N/A N/A N/A 100% None None

All All PFW Note 1 Note 2 No N/A N/A N/A 100% None None

All All FW Note 1 Note 2 No N/A 5% 5% 100% None None

Table Notes: General Notes:

1) 50º F Minimum for Base Metal <1” and 175º F minimum for Base Metal ≥ 1”. See Attachment - 4, for General Notes “A” through “D”.

2) PWHT branch welds and fillet welds when the thickness through the weld in any plane > ¾” Hardness testing after PWHT to be performed to

assure success of heat treatment

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 9 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION PIPING SHOP-FIELD

FABRICATION

DOC NO. : WHP-SPM-011 REV. C

PIPING WELDING DATA SHEET (SHEET – 2)

Category: Normal Sour Hydrocarbons, Sour Water, Closed Drains, Flare Vent, Design Code: ASME B31.3

Glycol, H2S Transfer, Sour Gas, Sour Water, Acid Gas, ASME Flange Rating: 150, 300, 600, 900

Produced Gas

Line Class(es): HP314, HP317, HP319, HP324, HP414, HP614, HP714

Special Criteria: NACE MR 01-75

Piping Material: Killed Carbon Steel Attachment Material: Killed Carbon Steel Valve Material: Carbon Steel

P Number: P Number:

P Number: P-1

P-1 P-1

CVN Requirements: ASME B31.3 PMI Requirements: N/A Ferrite Requirements: N/A

Pipe Wall Joint Heat Treat NDE Hardness Test

Dia Thick- Type

(Note B) (Notes A & C) Welding Procedures

ness

NPS

Preheat PWHT CVN RT MT PT VT % Max. WPS No. (Note D)

All All SW Note 1 Note 2 No N/A 100 % 100% 100% Note 3 Note 3

All ≤ ¾” BW Note 1 No No 100 % N/A N/A 100% Note 3 Note 3

All > ¾” BW Note 1 Yes No 100 % N/A N/A 100% Note 3 Note 3

All All SBR Note 1 Note 2 No N/A N/A N/A 100% Note 3 Note 3

All All OL Note 1 Note 2 No N/A N/A N/A 100% Note 3 Note 3

All All PFW Note 1 Note 2 No N/A N/A N/A 100% Note 3 Note 3

All All FW Note 1 Note 2 No N/A N/A N/A 100% None None

Table Notes: General Notes:

1) 50º F Minimum for Base Metal <1” and 175º F minimum for Base Metal ≥ 1”. See Attachment-4, for General Notes “A” through “D”.

2) PWHT branch welds and fillet welds when the thickness through the weld in any plane > ¾”. Hardness testing after PWHT to be performed to assure

3) See par. 5.0 of Appendix 01 of specification WHP-SPM-512. success of heat treatment

4) For sour service welds, 100% RT BW and 100% MT/PT on FW

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 10 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION PIPING SHOP-FIELD

FABRICATION

DOC NO. : WHP-SPM-011 REV. C

PIPING WELDING DATA SHEET (SHEET – 3)

Category: Normal Hydrocarbon (w/Amine <190F), Lean Amine, Hydrocarbon Design Code: ASME B31.3

(w/Amine >190F), Rich Amine, Lean Amine (Hot) ASME Flange Rating: 150, 300, 600, 900

Line Class(es): HP318, HP320, HP418, HP620, HP718

Special Criteria: Amine

Piping Material: Killed Carbon Steel Attachment Material: Killed Carbon Steel Valve Material: Carbon Steel

P Number: P Number:

P-1 P Number: P-1 P-1

CVN Requirements: ASME B31.3 PMI Requirements: N/A Ferrite Requirements: N/A

Pipe Wall Joint Heat Treat NDE Hardness Test

Dia Thick- Type (Note B) (Notes A & C) Welding Procedures

NPS ness Preheat PWHT CVN RT MT PT VT % Max. WPS No. (Note D)

All All SW Note 1 Yes No N/A N/A NA 100% Note 2 Note 2

All ≤¾” BW Note 1 Yes No 100% N/A N/A 100% Note 2 Note 2

All > ¾” BW Note 1 Yes No 100% N/A N/A 100% Note 2 Note 2

All All SBR Note 1 Yes No N/A N/A N/A 100% Note 2 Note 2

All All OL Note 1 Yes No N/A N/A N/A 100% Note 2 Note 2

All All PFW Note 1 Yes No N/A N/A N/A 100% Note 2 Note 2

All All FW Note 1 Yes No 100% 100% 100% 100% None None

Table Notes: General Notes:

1) 50º F Minimum for Base Metal <1” and 175º F minimum for Base Metal ≥ 1”. See Attachment - 4, for General Notes “A” through “D”.

2) See par. 5.0 of Appendix 01 of specification WHP-SPM-512. Hardness testing after PWHT to be performed to assure

success of heat treatment

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 11 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION PIPING SHOP-FIELD

FABRICATION

DOC NO. : WHP-SPM-011 REV. C

PIPING WELDING DATA SHEET (SHEET – 4)

Category: Liquid Sulfur Design Code: ASME B31.3

Jacketed (Removal Steam Jacketed) ASME Flange Rating: 150

Line Class(es): HP322

Special Criteria:

Piping Material: Killed Carbon Steel Attachment Material: Killed Carbon Steel Valve Material: Carbon Steel

P Number: P Number:

P-1 P Number: P-1 P-1

CVN Requirements: ASME B31.3 PMI Requirements: N/A Ferrite N/A

Requirements:

Pipe Wall Joint Heat Treat NDE Hardness Test

Dia Thick- Type (Note B) (Notes A & E) Welding Procedures

NPS ness Preheat PWHT CVN RT MT PT VT % Max. WPS No. (Note D)

All All SW Note 1 Note 2 No N/A N/A 100 % 100% None None

All ≤ ¾” BW Note 1 No No 100 % N/A N/A 100% None None

All > ¾” BW Note 1 Yes No 100 % N/A N/A 100% None None

All All SBR Note 1 Note 2 No N/A N/A N/A 100% None None

All All OL Note 1 Note 2 No N/A N/A N/A 100% None None

All All PFW Note 1 Note 2 No N/A N/A N/A 100% None None

All All FW Note 1 Note 2 No N/A 5% 5% 100% None None

Table Notes: General Notes:

1) 50º F Minimum for Base Metal <1” and 175º F minimum for Base Metal ≥ 1”. See Attachment - 4, for General Notes “A” through “D”.

2) PWHT branch welds and fillet welds when the thickness through the weld in any plane > ¾”. Hardness testing after PWHT to be performed to assure

success of heat treatment

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 12 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION PIPING SHOP-FIELD

FABRICATION

DOC NO. : WHP-SPM-011 REV. C

PIPING DATA SHEET (SHEET -5)

Category: Clad Wet Sour Hydrocarbon, Produced water, Wet Sour Design Code: ASME B31.3

Hydrocarbon ASME Flange Rating: 150, 300, 600, 900, API 10000

Line Classes: HP330, HP430, HP630, HP730, HPS30

Special Criteria:

Piping Material: Alloy 825 Clad C S (>4”) Attachment Material: Carbon Steel Valve Material: Alloy 825

P Number: P Number:

P-1/P-45 P Number: P-1 P-45

CVN Requirements: ASME B31.3 PMI Requirements: Note 3 Ferrite Requirements: N/A

Pipe Wall Joint Heat Treat NDE Hardness Test

Dia Thick- Type (Note B) (Notes A & C) Welding Procedures

NPS ness Preheat PWHT CVN RT MT PT VT % Max. WPS No. (Note D)

All All SW Note 1 Note 2 No N/A N/A 100 % 100% None None

All ≤ ¾” BW Note 1 No No 100% N/A N/A 100% None None

All > ¾” BW Note 1 Yes No 100% N/A N/A 100% None None

All All SBR Note 1 Note 2 No N/A N/A N/A 100% None None

All All OL Note 1 Note 2 No N/A N/A N/A 100% None None

All All PFW Note 1 Note 2 No N/A N/A N/A 100% None None

All All FW Note 1 Note 2 No 100% N/A N/A 100% None None

Table Notes: General Notes:

1) 50º F Minimum for P-1 Base Metal <1” and 175º F minimum for P-1 Base Metal ≥ 1”. See Attachment - 4, for General Notes “A” through “D”.

2) PWHT branch welds and fillet welds when the thickness through the P-1 material weld in any Hardness testing after PWHT to be performed to assure

plane exceeds ¾””. success of heat treatment on P-1 material

3) Per Project Specification WHP-SPM-507, for Alloy 825 cladding.

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 13 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION PIPING SHOP-FIELD

FABRICATION

DOC NO. : WHP-SPM-011 REV. C

PIPING WELDING DATA SHEET (SHEET – 6)

Category: Clad Wet Sour Hydrocarbon, Produced water, Wet Sour Design Code: ASME B31.3

Hydrocarbon ASME Flange Rating: 150, 600, 900, API 10000

Line Class(es): HP330, HP630, HP730, HPS30

Special Criteria:

Piping Material: Alloy 825 (≤4”) Attachment Material: Alloy 825 Valve Material: Alloy 825

P Number: P Number:

P-45 P Number: P-45 P-45

CVN Requirements: ASME B31.3 PMI Requirements: Note 1 Ferrite Requirements: N/A

Pipe Wall Joint Heat Treat NDE Hardness Test

Dia Thick- Type (Note B) (Notes A & C) Welding Procedures

NPS ness Preheat PWHT CVN RT MT PT VT % Max. WPS No. (Note D)

All All SW 50ºF No No N/A N/A 100 % 100% None None

All All BW 50ºF No No 100% N/A N/A 100% None None

All All SBR 50ºF No No N/A N/A N/A 100% None None

All All OL 50ºF No No N/A N/A N/A 100% None None

All All PFW 50ºF No No N/A N/A N/A 100% None None

All All FW 50ºF No No N/A N/A N/A 100% None None

Table Notes: General Notes:

1) Per Project Specification WHP-SPM-507.

See Attachment - 4, for General Notes “A” through “D”.

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 14 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION PIPING SHOP-FIELD

FABRICATION

DOC NO. : WHP-SPM-011 REV. C

PIPING WELDING DATA SHEET (SHEET 7)

Category: Normal Sour Hydrocarbons, Sour Water, Hydrocarbons (w/ Design Code: ASME B31.3

Amine>190F), Chemicals, Lube Oil, Seal Oil, Hydraulic

Valve Control System, Hydraulic System for Deck ASME Flange Rating: 150, 300, 600, 900, 1500, 2500

HP300G, HP400G, HP600G, HP700G, HP800G, HP900G

Line Class(es):

Special Criteria:

Piping Material: 316 / 316L SS Attachment Material: 316 / 316L SS Valve Material: 316 SS

P Number: P-8 P Number: P-8 P Number: P-8

CVN Requirements: ASME B31.3 PMI Requirements: Yes (Note 2) Ferrite Requirements: N/A

Pipe Wall Joint Heat Treat NDE Hardness Test

Dia Thick- Type (Note B) (Notes A & C) Welding Procedures

NPS ness Preheat PWHT CVN RT MT PT VT % Max. WPS No. (Note D)

All All SW Note 1 No No N/A N/A 100 % 100% None None

All All BW Note 1 No No 100 % N/A N/A 100% None None

All All SBR Note 1 No No N/A N/A N/A 100% None None

All All OL Note 1 No No N/A N/A N/A 100% None None

All All PFW Note 1 No No N/A N/A N/A 100% None None

All All FW Note 1 No No N/A N/A 100 % 100% None None

Table Notes: General Notes:

1) Preheat to 50º F minimum. Interpass temperature 350 º F maximum

2) As per Project Specification WHP-SPM-507. See Attachment - 4, for General Notes “A” through “D”.

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 15 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION PIPING SHOP-FIELD

FABRICATION

DOC NO. : WHP-SPM-011 REV. C

PIPING WELDING DATA SHEET (SHEET – 8)

Category: Normal Produced Gas Design Code: ASME B31.3

Line Class(es): HP309 ASME Flange Rating: 150

Special Criteria:

Piping Material: 2205 Duplex SS Attachment Material: 2205 Duplex SS Valve Material: 2205 Duplex SS

P Number:

P Number: P-10H P Number: P-10H P-10H

CVN Requirements: ASME B31.3 PMI Requirements: Yes (Note 2) Ferrite Requirements: Note 3

Pipe Wall Joint Heat Treat NDE Hardness Test

Dia Thick- Type (Note B) (Notes A & C) Welding Procedures

NPS ness Preheat PWHT CVN RT MT PT VT % Max. WPS No. (Note D)

All All SW Note 1 No No N/A N/A 100% 100% Note 4 Note 4

All All BW Note 1 No No 100% N/A 100% 100% Note 4 Note 4

All All SBR Note 1 No No N/A N/A 100% 100% Note 4 Note 4

All All OL Note 1 No No N/A N/A 100% 100% Note 4 Note 4

All All PFW Note 1 No No N/A N/A 100% 100% Note 4 Note 4

All All FW Note 1 No No N/A 100% 100% 100% Note 4 Note 4

Table Notes: General Notes:

1) Preheat to 50º F.

2) As per Project Specification WHP-SPM-507. See Attachment - 4, for General Notes “A” through “D”.

3) See par. 4.3 of Appendix 02 of specification WHP-SPM-512.

4) See par. 4.4 of Appendix 02 of specification WHP-SPM-512.

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 16 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION PIPING SHOP-FIELD

FABRICATION

DOC NO. : WHP-SPM-011 REV. C

PIPING WELDING DATA SHEET (SHEET – 9)

Category: Normal Hydrocarbon Design Code: ASME B31.8

Line Class(es): HP616P ASME Flange Rating: 600

Special Criteria:

Piping Material: Killed Carbon Steel Attachment Material: Killed Carbon Steel Valve Material: Carbon Steel

P Number:

P Number: P-1 P Number: P-1 P-1

CVN Requirements: ASME B31.8 PMI Requirements: N/A Ferrite Requirements: N/A

Pipe Wall Joint Heat Treat NDE Hardness Test

Dia Thick- Type (Note B) (Notes A & C) Welding Procedures

NPS ness Preheat PWHT CVN RT MT PT VT % Max. WPS No. (Note D)

All All SW Note 1 Note 2 No N/A N/A 100% 100% None None

All ≤ 1 ¼” BW Note 1 No No 100% N/A N/A 100% None None

All > 1 ¼” BW Note 1 Yes No 100% N/A N/A 100% None None

All All SBR Note 1 Note 2 No N/A N/A N/A 100% None None

All All OL Note 1 Note 2 No N/A N/A N/A 100% None None

All All PFW Note 1 Note 2 No N/A N/A N/A 100% None None

All All FW Note 1 Note 2 No N/A 10% 10% 100% None None

Table Notes: General Notes:

1) 50º F Minimum for Base Metal <1” and 175º F minimum for Base Metal ≥1”.

2) PWHT per par. 825 of ASME B31.8. See Attachment - 4, for General Notes “A” through “D”.

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 17 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION PIPING SHOP-FIELD

FABRICATION

DOC NO. : WHP-SPM-011 REV. C

PIPING WELDING DATA SHEET (SHEET – 10)

Category: Clad Wet Sour Hydrocarbons Design Code: ASME B31.8

Line Class(es): HP730P ASME Flange Rating: 900

Special Criteria:

Piping Material: Alloy 825 Clad C S (>4”) Attachment Material: Carbon Steel Valve Material: Alloy 825

P Number:

P Number: P-1/P-45 P Number: P-1 P-45

CVN Requirements: ASME B31.8 PMI Requirements: Note 3 Ferrite Requirements: N/A

Pipe Wall Joint Heat Treat NDE Hardness Test

Dia Thick- Type (Note B) (Notes A & C) Welding Procedures

NPS ness Preheat PWHT CVN RT MT PT VT % Max. WPS No. (Note D)

All All SW Note 1 Note 2 No N/A N/A 100% 100% None None

All ≤ 1 ¼” BW Note 1 No No 100% N/A N/A 100% None None

All > 1 ¼” BW Note 1 Yes No 100% N/A N/A 100% None None

All All SBR Note 1 Note 2 No N/A N/A N/A 100% None None

All All OL Note 1 Note 2 No N/A N/A N/A 100% None None

All All PFW Note 1 Note 2 No N/A N/A N/A 100% None None

All All FW Note 1 Note 2 No N/A 100% 100% 100% None None

Table Notes: General Notes:

1) 50º F Minimum for P-1 Base Metal <1” and 175º F minimum for P-1 Base Metal ≥1”. See Attachment - 4, for General Notes “A” through “D”.

2) PWHT per par. 825 of ASME B31.8 for P-1 material. Hardness testing after PWHT to be performed to assure

3) Per Project Specification WHP-SPM-507, for Alloy 825 cladding. success of heat treatment on P-1 material.

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 18 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION PIPING SHOP-FIELD

FABRICATION

DOC NO. : WHP-SPM-011 REV. C

PIPING WELDING DATA SHEET (SHEET – 11)

Category: Clad Wet Sour Hydrocarbon Design Code: ASME B31.8

Line Class(es): HP730P ASME Flange Rating: 900

Special Criteria:

Piping Material: Alloy 825 (≤4”) Attachment Material: Alloy 825 Valve Material: Alloy 825

P Number:

P Number: P-45 P Number: P-45 P-45

CVN Requirements: ASME B31.8 PMI Requirements: Note 1 Ferrite Requirements: N/A

Pipe Wall Joint Heat Treat NDE Hardness Test

Dia Thick- Type (Note B) (Notes A & C) Welding Procedures

NPS ness Preheat PWHT CVN RT MT PT VT % Max. WPS No. (Note D)

All All SW 50ºF No No N/A N/A 100% 100% None None

All All BW 50ºF No No 100% N/A N/A 100% None None

All All SBR 50ºF No No N/A N/A N/A 100% None None

All All OL 50ºF No No N/A N/A N/A 100% None None

All All PFW 50ºF No No N/A N/A N/A 100% None None

All All FW 50ºF No No N/A N/A N/A 100% None None

Table Notes: General Notes:

1) Per Project Specification WHP-SPM-507.

See Attachment - 4, for General Notes “A”.

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 19 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION PIPING SHOP-FIELD

FABRICATION

DOC NO. : WHP-SPM-011 REV. C

PIPING WELDING DATA SHEET (SHEET – 12)

Category: Normal Open Drains (Offshore), Diesel Fuel, Nitrogen, Potable Design Code: ASME B31.3

Water, Instrument Air, Utility Air, Utility Water. Black Water,

ASME Flange Rating: 150, 300

MGPS, Grey Water System, Air Vent, Sounding Tank,

HP301, HP306, HP307, U361, HP416,

Line Class(es):

Special Criteria:

Piping Material: Killed Carbon Steel Attachment Material: Killed Carbon Steel Valve Material: Carbon Steel

P Number: P Number:

P-1 P Number: P-1 P-1

CVN Requirements: ASME B31.3 PMI Requirements: N/A Ferrite Requirements: N/A

Pipe Wall Joint Heat Treat NDE Hardness Test

Dia Thick- Type (Note B) (Notes A & C) Welding Procedures

NPS ness Preheat PWHT CVN RT MT PT VT % Max. WPS No. (Note D)

All All SW Note 1 No No N/A N/A NA 100% None None

All ≤ ¾” BW Note 1 No No 10% N/A N/A 100% None None

All > ¾” BW Note 1 No No 10% N/A N/A 100% None None

All All SBR Note 1 No No N/A N/A N/A 100% None None

All All OL Note 1 No No N/A N/A N/A 100% None None

All All PFW Note 1 No No N/A N/A N/A 100% None None

All All FW Note 1 No No N/A N/A N/A 100% None None

Table Notes: General Notes:

1) 50º F Minimum for Base Metal <1” and 175º F minimum for Base Metal ≥1”. See Attachment - 4, for General Notes “A” through “D”.

2) PWHT branch welds and fillet welds when the thickness through the weld in any plane > ¾” Hardness testing after PWHT to be performed to assure

success of heat treatment

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 20 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION

PIPING SHOP-FIELD FABRICATION

DOC NO. : WHP-SPM-011 REV. C

ATTACHEMENT – 2

STANDARD WELD JOINT SYMBOL

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 21 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION

PIPING SHOP-FIELD FABRICATION

DOC NO. : WHP-SPM-011 REV. C

STANDARD WELD JOINT SYMBOL

ABBR TYPE OF OPERATION REMARKS

RT Radiography All types, Random and 100%

MT Magnetic Particle Examination All methods, Wet or Dry

PT Liquid Penetrant Examination All methods

UT Ultrasonic Examination All methods, excluding thickness testing

VT Visual Examination Dimensional checks, etc.

HT Hardness Test All methods

PMI Positive Material Identification All methods

FN Delta Ferrite Determination All methods

CVN Impact Testing Charpy V-Notch

PWHT Postweld Heat Treatment All methods

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 22 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION

PIPING SHOP-FIELD FABRICATION

DOC NO. : WHP-SPM-011 REV. C

ATTACHMENT – 3

STANDARD NDE/HEAT TREAT/TEST SYMBOL

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 23 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION

PIPING SHOP-FIELD FABRICATION

DOC NO. : WHP-SPM-011 REV. C

STANDARD NDE/HEAT TREAT/TEST SYMBOL

ABBR TYPE OF OPERATION REMARKS

RT Radiography All types, Random and 100%

MT Magnetic Particle Examination All methods, Wet or Dry

PT Liquid Penetrant Examination All methods

UT Ultrasonic Examination All methods, excluding thickness testing

VT Visual Examination Dimensional checks, etc.

HT Hardness Test All methods

PMI Positive Material Identification All methods

FN Delta Ferrite Determination All methods

CVN Impact Testing Charpy V-Notch

PWHT Postweld Heat Treatment All methods

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 24 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION

PIPING SHOP-FIELD FABRICATION

DOC NO. : WHP-SPM-011 REV. C

ATTACHMENT – 4

GENERAL NOTES

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 25 of 26

MADURA BD FIELD DEVELOPMENT - EPCI

GENERAL WELDING-NDE SPECIFICATION

PIPING SHOP-FIELD FABRICATION

DOC NO. : WHP-SPM-011 REV. C

GENERAL NOTES

The Vendor is required to fill in his WPS Number(s) for each applicable line under the “Welding

Procedures” column on the PWDS (Pipe Welding Data Sheets). A copy of the completed PWDS

shall be submitted for review along with the Vendor’s WPS/PQR(s) prior to the start of fabrication.

WPS/PQR review will not proceed until completed copies of the PWDS are submitted.

A. NDE shall be in accordance with paragraph 2.3 of this specification which includes spot RT in

addition to RANDOM/100% RT specified in the PWDS. NDE percentages referenced on the

PWDS are minimums. Progressive sampling for examination per ASME B31.3 paragraph

341.3.4 is required not only for radiography, but also for all other NDE methods as well.

B. Fabrication and heat treatment requirements for piping bends shall be in accordance with

ASME B31.3 or ASME B31.8, as applicable, and this Specification.

C. All welds shall be visually examined (VT). Documentation of this VT does not have to

reference each specific weld, but can be summarized and grouped in general on Certificates

of Conformance (CoC’s) or daily weld reports.

D. Vendor is to specify WPS number to be used for dissimilar welds on the PWDS under the

WPS No. column for each joint type (i.e., SW, BW, SBR, etc) when applicable.

MADURA BD FIELD DEVELOPMENT-EPCI

CONTRACT NO.:332003560 Page 26 of 26

You might also like

- Connector Industry: A Profile of the European Connector Industry - Market Prospects to 1999From EverandConnector Industry: A Profile of the European Connector Industry - Market Prospects to 1999No ratings yet

- KOST-NDT-RTP-02 ASME B31.3 Process Piping PDFDocument20 pagesKOST-NDT-RTP-02 ASME B31.3 Process Piping PDFmuhammad faizNo ratings yet

- KOST-NDT-MTP-02 ASME B31.3 Process Piping PDFDocument15 pagesKOST-NDT-MTP-02 ASME B31.3 Process Piping PDFmuhammad faiz100% (1)

- 12.6 Welding Procedures List (Li-002)Document31 pages12.6 Welding Procedures List (Li-002)Ana GameroNo ratings yet

- STD 1104 - Welding of Pipelines and Related FacilitiesDocument38 pagesSTD 1104 - Welding of Pipelines and Related FacilitiesGishnu SunilNo ratings yet

- Weld Map & TracebilityDocument2 pagesWeld Map & TracebilityvinothNo ratings yet

- Drafting Practices StandardDocument14 pagesDrafting Practices StandardJonathanNo ratings yet

- Welding Coordinator WeldMap Weld Data SheetDocument1 pageWelding Coordinator WeldMap Weld Data Sheetquocphong199No ratings yet

- Pages From ONGC-SPEC-02-MS-03Document12 pagesPages From ONGC-SPEC-02-MS-03Prathamesh OmtechNo ratings yet

- Insulating JointDocument17 pagesInsulating Jointreza329329100% (1)

- 1.0 Scope: General Welding Standard For PipingDocument7 pages1.0 Scope: General Welding Standard For PipingandhucaosNo ratings yet

- QP-SPC-R-010-1 - 1 - Welding Procedures PDFDocument40 pagesQP-SPC-R-010-1 - 1 - Welding Procedures PDFMohamed100% (1)

- PQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFDocument1 pagePQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFchandraNo ratings yet

- 17-020-Ms-002 Welding For Fuel Gas r2Document53 pages17-020-Ms-002 Welding For Fuel Gas r2Alaa M. GhazalahNo ratings yet

- Class P6A6Document24 pagesClass P6A6SalimNo ratings yet

- TES-WELD-API - Welding of Pipelines and Facilities SpecificationDocument37 pagesTES-WELD-API - Welding of Pipelines and Facilities SpecificationFederico QuintanaNo ratings yet

- 113012-SP-013-Rev A (Pipeline Welding Spec.)Document31 pages113012-SP-013-Rev A (Pipeline Welding Spec.)Anonymous hBBam1nNo ratings yet

- Specification For Fabrication, Construction & Testing of Steel Pipe SystemDocument43 pagesSpecification For Fabrication, Construction & Testing of Steel Pipe SystemALINo ratings yet

- WSM-PSFP-01 Piping Spool Fabrication Procedure PDFDocument14 pagesWSM-PSFP-01 Piping Spool Fabrication Procedure PDFMiky AndreanNo ratings yet

- Pms Eil BPCLDocument79 pagesPms Eil BPCLManjunatha VNo ratings yet

- WPS ListDocument2 pagesWPS ListAdeel OmerNo ratings yet

- Utoc Preliminary Wps Shell Project 270807 PDFDocument55 pagesUtoc Preliminary Wps Shell Project 270807 PDFErick HoganNo ratings yet

- Project:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportDocument4 pagesProject:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportEngr Saeed AnwarNo ratings yet

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Document12 pagesPoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXNo ratings yet

- Welder Qualification Test For GMAW STT FCAWDocument2 pagesWelder Qualification Test For GMAW STT FCAWSyed Mahmud Habibur RahmanNo ratings yet

- PipingDocument15 pagesPipingDerick Mendoza100% (1)

- Ke01 00 000 KD P ST 0009 000 - F01Document16 pagesKe01 00 000 KD P ST 0009 000 - F01Maffone NumerounoNo ratings yet

- API Welding Procedure Specification PDFDocument3 pagesAPI Welding Procedure Specification PDFBob LeeNo ratings yet

- Welder Performace Qualification Report 2014..Document132 pagesWelder Performace Qualification Report 2014..Kayra Riri ChirulNo ratings yet

- EBS1-PTFA27-SAPI-SPDI-1001-D00 - Specification For Piping Stress AnalysisDocument23 pagesEBS1-PTFA27-SAPI-SPDI-1001-D00 - Specification For Piping Stress AnalysisAhmedNo ratings yet

- Specifications of LR BendDocument11 pagesSpecifications of LR BendPrafulla PatilNo ratings yet

- Welding Procedure Specifica Tion (WPS) : I I I IDocument5 pagesWelding Procedure Specifica Tion (WPS) : I I I ITrinh DungNo ratings yet

- Daily Welding Record LPDocument27 pagesDaily Welding Record LProbby moneNo ratings yet

- Flanges ANSI16 5###Document48 pagesFlanges ANSI16 5###kunal shahNo ratings yet

- RTCC Manual WPS Approval WE-WPS-001Document7 pagesRTCC Manual WPS Approval WE-WPS-001Akansha SharmaNo ratings yet

- Chemical CompositionDocument1 pageChemical CompositionfrusdtNo ratings yet

- Curriculum Vitae: Total Experience 18.1 YearsDocument7 pagesCurriculum Vitae: Total Experience 18.1 Yearskbpatel123No ratings yet

- PT ReportDocument49 pagesPT ReportRajesh Owaiyar100% (1)

- Fsa HandbookDocument35 pagesFsa Handbookargari19No ratings yet

- Fabrication of Piping SpecificationDocument35 pagesFabrication of Piping SpecificationLeilei WangNo ratings yet

- Iqwq Ce1092 Qpqac 00 0002 - 0 Quality Control Procedure for Piping管道质量控制程序Document54 pagesIqwq Ce1092 Qpqac 00 0002 - 0 Quality Control Procedure for Piping管道质量控制程序Ali Majeed100% (1)

- Intsallation of Hot Tap Fittings SAEP0311 2003Document33 pagesIntsallation of Hot Tap Fittings SAEP0311 2003fishzlz_847012012No ratings yet

- 8384-2602-SQ-0720 B1 Spec Welding and NDTDocument100 pages8384-2602-SQ-0720 B1 Spec Welding and NDTHướng PhạmNo ratings yet

- 3SS NW00 00007 PDFDocument10 pages3SS NW00 00007 PDFKarthikNo ratings yet

- QCF312 WPQRDocument2 pagesQCF312 WPQRminhnnNo ratings yet

- PWPS 013 PRDocument2 pagesPWPS 013 PRRenjith Gopan100% (1)

- 9201 Spec Barred TeeDocument23 pages9201 Spec Barred TeeSoumya KumarNo ratings yet

- A1X3R1 - 2d - EPI-08-WP5-TW PDFDocument10 pagesA1X3R1 - 2d - EPI-08-WP5-TW PDFJose Anisio SilvaNo ratings yet

- CHF-ENG-SP-L-300 Rev 0 PDFDocument302 pagesCHF-ENG-SP-L-300 Rev 0 PDFMo'men Abu-SmaihaNo ratings yet

- Block A Gas Development Project Vendor Engineering Document ListDocument11 pagesBlock A Gas Development Project Vendor Engineering Document Listahmad kusumaNo ratings yet

- Quality Assurance Plan: High Frequency Electric Resistance Welded PipeDocument15 pagesQuality Assurance Plan: High Frequency Electric Resistance Welded PipeSachin KumarNo ratings yet

- Data Sheet For Barred Tee 010719 PDFDocument1 pageData Sheet For Barred Tee 010719 PDFkandraNo ratings yet

- RFI Fabrication Rev. 03Document22 pagesRFI Fabrication Rev. 03AdewaleNo ratings yet

- WPS PQR Procedure PDFDocument31 pagesWPS PQR Procedure PDFsudeesh kumarNo ratings yet

- 02 Samss 012 PDFDocument10 pages02 Samss 012 PDFnadeem shaikhNo ratings yet

- 6-44-0053 Rev 6 FlangesDocument7 pages6-44-0053 Rev 6 Flangesहेमंत कुमार मीणाNo ratings yet

- Line List: Project: Date Rev. No. Serial No. Doc. Type Discipline Phase Unit Plan/Project/SubDocument1 pageLine List: Project: Date Rev. No. Serial No. Doc. Type Discipline Phase Unit Plan/Project/SubAli AsadiNo ratings yet

- Bolted Flange and Gasket Joints Assembly ProcedureDocument9 pagesBolted Flange and Gasket Joints Assembly ProceduremohdNo ratings yet

- Nor R3Document29 pagesNor R3grsNo ratings yet

- p999999 100zd11 000 zd0001 - 0 Welding StandardDocument25 pagesp999999 100zd11 000 zd0001 - 0 Welding StandardJennyNo ratings yet

- AHSA27-S-DS-PS-009 0 Flow Control Valve Process Data Sheet RevisionDocument3 pagesAHSA27-S-DS-PS-009 0 Flow Control Valve Process Data Sheet Revisionprihartono_diasNo ratings yet

- Mark 695 Series - Piloted Tank Blanketing Regulator (2 Inch)Document4 pagesMark 695 Series - Piloted Tank Blanketing Regulator (2 Inch)prihartono_diasNo ratings yet

- GMS-SPT-013 Pneumatic On-Off Valve and Motor Operated Valve Specification - Rev 1Document20 pagesGMS-SPT-013 Pneumatic On-Off Valve and Motor Operated Valve Specification - Rev 1prihartono_diasNo ratings yet

- WHP LLP 001 REV.1 Line List SummaryDocument8 pagesWHP LLP 001 REV.1 Line List Summaryprihartono_diasNo ratings yet

- GMS-SPM-001 Piping Material Specification Line Class Process and Utility Piping - Rev 2Document59 pagesGMS-SPM-001 Piping Material Specification Line Class Process and Utility Piping - Rev 2prihartono_dias100% (1)

- KOSO General BrochureDocument15 pagesKOSO General Brochureprihartono_diasNo ratings yet

- Vent Combination ArresterDocument1 pageVent Combination Arresterprihartono_diasNo ratings yet

- Mustang Series M100 (Globe), M1100 (Angle) Specification SheetDocument3 pagesMustang Series M100 (Globe), M1100 (Angle) Specification SheetWattsNo ratings yet

- AHSA27-S-DS-IN-004 0 Instrument Data Sheet Pressure Regulator ValveDocument4 pagesAHSA27-S-DS-IN-004 0 Instrument Data Sheet Pressure Regulator Valveprihartono_diasNo ratings yet

- Indonesia Fact SheetDocument7 pagesIndonesia Fact Sheetprihartono_diasNo ratings yet

- 360 Bulletin P-360B0411ADocument16 pages360 Bulletin P-360B0411Aprihartono_diasNo ratings yet

- X54201lsr I&ODocument9 pagesX54201lsr I&Oprihartono_diasNo ratings yet

- TM 129 01Document35 pagesTM 129 01prihartono_diasNo ratings yet

- Indonesia Fact SheetDocument7 pagesIndonesia Fact Sheetprihartono_diasNo ratings yet

- Z VAC AssemblyDocument2 pagesZ VAC Assemblyprihartono_diasNo ratings yet

- Reference List Oversea LNG 2013 09 27 PDFDocument41 pagesReference List Oversea LNG 2013 09 27 PDFprihartono_diasNo ratings yet

- Sizing CalculationDocument4 pagesSizing Calculationprihartono_diasNo ratings yet

- Catalogue Valve Silencers Valvulas NacionalDocument4 pagesCatalogue Valve Silencers Valvulas Nacionaltiffanyyy00No ratings yet

- Weatherproof Float SwitchDocument4 pagesWeatherproof Float Switchprihartono_diasNo ratings yet

- FLOWSIC 600 Pipe Size Calculation: Reference ConditionDocument1 pageFLOWSIC 600 Pipe Size Calculation: Reference Conditionprihartono_diasNo ratings yet

- 24509-49 6 Panel General Brochure-2Document6 pages24509-49 6 Panel General Brochure-2prihartono_diasNo ratings yet

- X11SNI&ODocument23 pagesX11SNI&Oprihartono_diasNo ratings yet

- Z-POS Series™: Protect Your Processing or Storage Tank From Over-Pressurisation and VacuumDocument2 pagesZ-POS Series™: Protect Your Processing or Storage Tank From Over-Pressurisation and Vacuumprihartono_diasNo ratings yet

- Reference List Oversea LNG 2013 09 27 PDFDocument41 pagesReference List Oversea LNG 2013 09 27 PDFprihartono_diasNo ratings yet

- X76CTMI&ODocument38 pagesX76CTMI&Oprihartono_diasNo ratings yet

- Burnerlogix Adds Boiler Control To Flame Safeguard: A Burner'S Favorite ControlDocument1 pageBurnerlogix Adds Boiler Control To Flame Safeguard: A Burner'S Favorite Controlprihartono_diasNo ratings yet

- Product Overview - LeuschDocument32 pagesProduct Overview - Leuschprihartono_diasNo ratings yet

- Ceravalve - Ceramic Lined Ball ValvesDocument6 pagesCeravalve - Ceramic Lined Ball Valvesprihartono_diasNo ratings yet

- Newco Product Line BrochureDocument8 pagesNewco Product Line BrochureshahganNo ratings yet

- 32 Hyderabad HITEC City BisleriDocument23 pages32 Hyderabad HITEC City BisleriSridhar ViswanathanNo ratings yet

- Paul Spicker - The Welfare State A General TheoryDocument162 pagesPaul Spicker - The Welfare State A General TheoryTista ArumNo ratings yet

- LPS 1131-Issue 1.2-Requirements and Testing Methods For Pumps For Automatic Sprinkler Installation Pump Sets PDFDocument19 pagesLPS 1131-Issue 1.2-Requirements and Testing Methods For Pumps For Automatic Sprinkler Installation Pump Sets PDFHazem HabibNo ratings yet

- Paper 1 AnalysisDocument2 pagesPaper 1 AnalysisNamanNo ratings yet

- A Semi-Detailed Lesson Plan in MAPEH 7 (PE)Document2 pagesA Semi-Detailed Lesson Plan in MAPEH 7 (PE)caloy bardzNo ratings yet

- Rights of Parents in IslamDocument11 pagesRights of Parents in Islamstoneage989100% (2)

- Consent Form: Republic of The Philippines Province of - Municipality ofDocument1 pageConsent Form: Republic of The Philippines Province of - Municipality ofLucette Legaspi EstrellaNo ratings yet

- The Comma Rules Conversion 15 SlidesDocument15 pagesThe Comma Rules Conversion 15 SlidesToh Choon HongNo ratings yet

- March For Our LivesDocument22 pagesMarch For Our LivesLucy HanNo ratings yet

- Outline Calculus3Document20 pagesOutline Calculus3Joel CurtisNo ratings yet

- E-Mobility and SafetyDocument77 pagesE-Mobility and SafetySantosh KumarNo ratings yet

- Twin PregnancyDocument73 pagesTwin Pregnancykrishna mandalNo ratings yet

- Working Capital Management 2012 of HINDALCO INDUSTRIES LTD.Document98 pagesWorking Capital Management 2012 of HINDALCO INDUSTRIES LTD.Pratyush Dubey100% (1)

- Paul Wade - The Ultimate Isometrics Manual - Building Maximum Strength and Conditioning With Static Training-Dragon Door Publications (2020) - 120-146Document27 pagesPaul Wade - The Ultimate Isometrics Manual - Building Maximum Strength and Conditioning With Static Training-Dragon Door Publications (2020) - 120-146usman azharNo ratings yet

- Backwards Design - Jessica W Maddison CDocument20 pagesBackwards Design - Jessica W Maddison Capi-451306299100% (1)

- LLM Letter Short LogoDocument1 pageLLM Letter Short LogoKidMonkey2299No ratings yet

- Duo Interpretation Class PresentationDocument31 pagesDuo Interpretation Class PresentationPlanetSparkNo ratings yet

- WBCS 2023 Preli - Booklet CDocument8 pagesWBCS 2023 Preli - Booklet CSurajit DasNo ratings yet

- C. Robert Mesle (Auth.) - John Hick's Theodicy - A Process Humanist Critique-Palgrave Macmillan UK (1991)Document168 pagesC. Robert Mesle (Auth.) - John Hick's Theodicy - A Process Humanist Critique-Palgrave Macmillan UK (1991)Nelson100% (3)

- Cambridge IGCSE: CHEMISTRY 0620/42Document12 pagesCambridge IGCSE: CHEMISTRY 0620/42Khairun nissaNo ratings yet

- Ti05001 PDFDocument1 pageTi05001 PDFanggieNo ratings yet

- DN102-R0-GPJ-Design of Substructure & Foundation 28m+28m Span, 19.6m Width, 22m Height PDFDocument64 pagesDN102-R0-GPJ-Design of Substructure & Foundation 28m+28m Span, 19.6m Width, 22m Height PDFravichandraNo ratings yet

- Lab Manual Switchgear and Protection SapDocument46 pagesLab Manual Switchgear and Protection SapYash MaheshwariNo ratings yet

- ABI TM 13 16 SL - EngDocument1 pageABI TM 13 16 SL - EngJuan Carlos Benitez MartinezNo ratings yet

- Lancru hzj105 DieselDocument2 pagesLancru hzj105 DieselMuhammad MasdukiNo ratings yet

- Loop Types and ExamplesDocument19 pagesLoop Types and ExamplesSurendran K SurendranNo ratings yet

- Vieworks DR Panel BrochureDocument8 pagesVieworks DR Panel Brochuretito goodNo ratings yet

- Gujarat Urja Vikas Nigam LTD., Vadodara: Request For ProposalDocument18 pagesGujarat Urja Vikas Nigam LTD., Vadodara: Request For ProposalABCDNo ratings yet

- RECYFIX STANDARD 100 Tipe 010 MW - C250Document2 pagesRECYFIX STANDARD 100 Tipe 010 MW - C250Dadang KurniaNo ratings yet

- Iec Codes PDFDocument257 pagesIec Codes PDFAkhil AnumandlaNo ratings yet