Professional Documents

Culture Documents

Installation Guide Fabrications, Safety & Lighting Solutions

Uploaded by

AThaddeusAntonioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Guide Fabrications, Safety & Lighting Solutions

Uploaded by

AThaddeusAntonioCopyright:

Available Formats

1

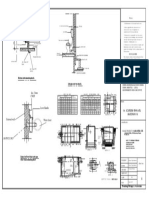

Boundary Wall Gutter Detail

Fabrications, Safety Installation Note: Ensure steel work is suitably Gutter Joint Detail

LPCB certified PIR insulation Parapet flashing Valley Gutter Detail

& Lighting Solutions Guide

lined, levelled and within tolerance.

Each gutter length must be fully

board with site applied fire

rated canister insulation

to fill any gaps if

with 150mm

sealed butt straps Alternate Parapet Wall Detail

Membrane Lined Maximum recommended

2 g

c

installed prior to access, once each required to Insulated Gutter sole 700mm, additional

It is important that

maintain continuity support necessary for

the edge of the

length is fully installed it can be of insulation

panel is over the larger sole dimension Gutter joints and ends

considered non fragile if Kingspan Fasten gutter at max

d

base of the gutter

as shown

to be fixed at maximum

installation recommendations have 6mm Ø butyl 1500mm centres with Site applied fire rated 75mm centres, 25mm

rubber sealant

been followed and falls within our minimum 2 no. stainless steel canister insulation

from gutter edge 50

m

Profiled filler sealed

8mm Ø butyl 50mm overlap on of

silv m ov

maximum sizing. rubber sealant rivets (grip range 1.5mm - er er

top and bottom with Membrane Lined external membrane 25m foi lap

l ta

9mm) per gutter wing

G2

gun-grade sealant 100mm wide

Guidance on rainwater drainage Insulated Gutter

silver foil tape

m pe

calculations is available from Membrane Lined

Insulated Gutter m

the Kingspan Technical Services 75mtres

cen

Department. Maximum

recommended sole One line of

stainless steel

Any drilling swarf and redundant 868mm, additional

fixings must be removed from gutter G1 support necessary for

larger sole dimension

rivets 25mm from

edge at max.

75mm centres

surface as works progress to prevent

damage to the membrane.

Gutter joints should be kept clean G1

and dry prior to welding. Should dirt

and moisture contaminate a joint

prior to welding, it should be cleaned

with a mild detergent solution and Note: The gutter proportions shown are purely

indicative and the actual size required will be

thoroughly dried with a linen cloth. subject to steelwork zone available

Should a joint be contaminated

with oil or grease prior to welding

it should be cleaned with either

alcohol, acetone or white spirit

a

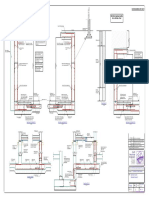

Locate stop end/mitred corner/

(ensure compliance with any safety

recommendations) and thoroughly

tee junction and work away from

section, ensuring correctly aligned f

dried.

To prevent contamination, membrane

and direction of lay. Continue

pattern with gutters

Direc

tion o

f lay e

Position gutter (G2) ensuring 50mm

Fasten gutter at max 1500mm

centres with minimum 2 no.

stainless steel rivets (grip range

gutter joints to be fully welded across

full girth of gutter as works progress, external and 50mm internal laps are 1.5mm - 9mm) per gutter wing

Direc

April 2016

prior to panel installation. correctly engaged tion o

f lay

Membrane Lined

Insulated Gutter

Syphonic and other outlets can be

factory fitted on request.

50mm lap on internal liner

b

The gutter welding should only be denotes direction of lay

carried out by those experienced in

the welding of PVC membranes.

Bespoke Outlet (Metal) Standard Outlet (PVC)

Bespoke Outlet (Metal) Standard Outlet (PVC)

Peel back membrane

collar around

perimeter of 50mm PVC membrane

outlet flange weld strip heat welded

for 50mm with a 50mm weld Fix at max.

all round 75mm centres

25mm from the

m

Outlet edge

flange PVC membrane

m

Components

Push fit outlet

ax

75

Boundary Wall Gutter Heat Gun

k

.

m

into position. For

m

Plastic outlet

Fixings at

metal and bespoke

n

max. 75mm

When cooled, test the finished centres outlets, rivet flange

weld with a seam probe and

re-weld where necessary

Membrane

bonded to

outlet flange

to the gutter sole

at maximum

75mm centres

Hot air weld PVC collar 5 Repeat process as previous to complete gutter run

to gutter membrane as

h j Note: The ‘metal outlet’ is a bespoke item and can

be provided in several different ways. This method of

per joint welding method

o Valley Gutter

Apply 100mm wide silver installation is also used for syphonic and Trocal outlets Fasten gutter at max 1500mm

foil tape centrally over joint Lay cover strip centrally over centres with minimum 2 no.

gutter joint, and hot air tack-weld

to hold in position. Pre-weld the 50

mm

25

0m

m 4 stainless steel rivets (grip range

1.5mm - 9mm) per gutter wing

3 cover strip, approx. 50mm from

the edge and then fully weld the

50

mm

Metal Gutter Outlet Seam Probe

strip 50mm along both edges

whilst applying silicone pressure

roller or penny roller (corners and 50mm of

membrane hot G1

detailing) to ensure good weld - air welded at

G1 indicated by visible edges

Silicone Roller Penny Roller

fusion line Adhesion

Note: Hot air welding should be carried out by an

G2

experienced membrane welding contractor using

PVC Gutter Outlet

G2 electric heat gun. Refer to Kingspan Field Services

for recommendations

1.5mm PVC

Membrane Cover

Strip 250mm wide

Direc

tion o

f lay Silver Foil Tape

Direc

tion o

f lay

Direc

tion o

f lay

l p This installation guide should be read in conjunction

i

with the ‘project specific’ design drawings and method

Identify outlet position and cut Stop end or overflow statements.

required diameter hole weirs can be factory fitted

PVC membrane cover strip roll is provided 250mm x Although this ‘installation guide’ is deemed to be correct

1.5mm. Material to be cut to length using scissors at the time of publication, Kingspan Limited reserve the

right to amend the information at any time in the future.

Note: Membrane must always be of same membrane Installation guides are available for the full range of

as gutter, and installed facing correct way up Kingspan insulated roof, wall and façade systems.

Please call Kingspan Limited on:

UK: +44 (0) 1352 716100

Ire: +353 (0) 42 96 98500

You might also like

- Drawing 3.Document1 pageDrawing 3.tiyaniNo ratings yet

- C.H. - 0+465.5 Section No5Document1 pageC.H. - 0+465.5 Section No5Fran LuqueNo ratings yet

- 30° roof galvanized IBR sheetsDocument1 page30° roof galvanized IBR sheetsanzaniNo ratings yet

- Castillejos WELL DataDocument3 pagesCastillejos WELL DataJohn Christopher BaquingNo ratings yet

- Ramothibe T - Stage 4-Acuv300Document2 pagesRamothibe T - Stage 4-Acuv300Monde Tidimalo Lunathi MbaluNo ratings yet

- Ridge Installation GuideDocument1 pageRidge Installation GuideGeorgios PNo ratings yet

- Acuv Stage 5-PlansDocument1 pageAcuv Stage 5-PlansMonde Tidimalo Lunathi MbaluNo ratings yet

- Mark Up L2 Slab (Zone 2)Document7 pagesMark Up L2 Slab (Zone 2)Emon SahNo ratings yet

- East Elevation South Elevation: Church HallDocument1 pageEast Elevation South Elevation: Church HallanzaniNo ratings yet

- Drawing 2.Document1 pageDrawing 2.tiyaniNo ratings yet

- Ground Floor: Back Elevation Side ElevationDocument1 pageGround Floor: Back Elevation Side ElevationanzaniNo ratings yet

- Second Floor Isometric Sewer Line Layout Plan: For PermitDocument1 pageSecond Floor Isometric Sewer Line Layout Plan: For PermitChristine Joyce RoseteNo ratings yet

- 06020101_DTF Structural drawingsDocument35 pages06020101_DTF Structural drawings宋海波No ratings yet

- R.C Wall Block Wall Vent Pipe Low Level CisternDocument1 pageR.C Wall Block Wall Vent Pipe Low Level CisternAmadi HenryNo ratings yet

- Installation Guide: KS1000 XD Longspan X-Dek® Roof Panel Multiple Panels Eaves To RidgeDocument1 pageInstallation Guide: KS1000 XD Longspan X-Dek® Roof Panel Multiple Panels Eaves To RidgeGlavanRafaelNo ratings yet

- GENERAL NOTES FOR CONCRETE PAVEMENT SUBDRAINAGEDocument4 pagesGENERAL NOTES FOR CONCRETE PAVEMENT SUBDRAINAGEIbrahimNo ratings yet

- Chi Ti T D2/ D2 Details Chi Ti T Seno D1/ Seno D1 DetailsDocument1 pageChi Ti T D2/ D2 Details Chi Ti T Seno D1/ Seno D1 DetailsPhanLạcKhanhNo ratings yet

- Mefort Marondera ModelDocument1 pageMefort Marondera Modelbryan mutariNo ratings yet

- Fpa101249 BR (D) 001-003Document3 pagesFpa101249 BR (D) 001-003chriscundyNo ratings yet

- S-2 RDocument1 pageS-2 Rविवेक कुमारNo ratings yet

- Architectural Drawings 1Document13 pagesArchitectural Drawings 1Manish PandeyNo ratings yet

- Sgebste1 21Document3 pagesSgebste1 21Ronnie1478No ratings yet

- C.H. - 0+407 Section No1 C.H. - 0+835 Section No3Document1 pageC.H. - 0+407 Section No1 C.H. - 0+835 Section No3Fran LuqueNo ratings yet

- Drawing - BasementDocument1 pageDrawing - BasementCanny EngineerNo ratings yet

- Nfef 60 87 Ci DR TD 001 - d1 - 000Document1 pageNfef 60 87 Ci DR TD 001 - d1 - 000Abid AyubNo ratings yet

- Mark Up L2 Slab (Zone 1)Document6 pagesMark Up L2 Slab (Zone 1)Emon SahNo ratings yet

- MRT M&E Drawing3Document1 pageMRT M&E Drawing3qinxuekunNo ratings yet

- Maa Manasa Pole ShedulesDocument69 pagesMaa Manasa Pole Shedulesmuralipower1986No ratings yet

- 2.2.02 Schedule of Components: L D SD S PIR DN L/P P Rtls Code Description TotalDocument1 page2.2.02 Schedule of Components: L D SD S PIR DN L/P P Rtls Code Description TotalVinay PallivalppilNo ratings yet

- MFE Shell Plan - Signed OffDocument2 pagesMFE Shell Plan - Signed OffJuly FermiaNo ratings yet

- General Notes:: DIVISION 4: Masonry DIVISION 7: Thermal & Moisture DIVISION 9: FinishesDocument5 pagesGeneral Notes:: DIVISION 4: Masonry DIVISION 7: Thermal & Moisture DIVISION 9: FinishesKarim TarekNo ratings yet

- 9946Z - 0657-SP-SL-DE-C-G77-451-P3 - Private Construction Details (Sheet 2 of 2)Document1 page9946Z - 0657-SP-SL-DE-C-G77-451-P3 - Private Construction Details (Sheet 2 of 2)jmdavies.isNo ratings yet

- Floor Pattern Layout 1: Masterpiece Asia Properties IncDocument7 pagesFloor Pattern Layout 1: Masterpiece Asia Properties Incerwin leeNo ratings yet

- CEILING LEGEND AND COMPONENT SCHEDULEDocument1 pageCEILING LEGEND AND COMPONENT SCHEDULEVinay PallivalppilNo ratings yet

- Cable Trench and Road Banka Combine PDFDocument3 pagesCable Trench and Road Banka Combine PDFManas MondalNo ratings yet

- Insulated roof panel installation guideDocument2 pagesInsulated roof panel installation guideGabi DanutNo ratings yet

- GH22148 0100D TD Gen A 50001 Rev0Document1 pageGH22148 0100D TD Gen A 50001 Rev0felix sowah-laryeaNo ratings yet

- UPTŽ (G.15.11) - Nacrt Armature Kampade CC G.002 - K2Document1 pageUPTŽ (G.15.11) - Nacrt Armature Kampade CC G.002 - K2Kenan BegagicNo ratings yet

- 1077 - Floor PlanDocument1 page1077 - Floor PlanErmin TralješićNo ratings yet

- 3202 - Changing W Sub Waiting Accessible - Rls PDFDocument1 page3202 - Changing W Sub Waiting Accessible - Rls PDFVinay PallivalppilNo ratings yet

- BW Tok JiringDocument4 pagesBW Tok JiringHakimi ZulkifliNo ratings yet

- DFDFDDocument1 pageDFDFDPrince RanaNo ratings yet

- Design and construction details for attaching span wires and ground wires to concrete and strain polesDocument1 pageDesign and construction details for attaching span wires and ground wires to concrete and strain polesrifkynetNo ratings yet

- Gambar Concrete PoleDocument1 pageGambar Concrete PolerifkynetNo ratings yet

- Ilide - Info Caterpillar Gas Engine 3516 Schematic Diagram PRDocument2 pagesIlide - Info Caterpillar Gas Engine 3516 Schematic Diagram PRTamNo ratings yet

- Warehouse DrawingsDocument6 pagesWarehouse DrawingsnokoNo ratings yet

- 98 140656 A01 Installation Guide Sailor 6588 Dgnss ReceiverDocument2 pages98 140656 A01 Installation Guide Sailor 6588 Dgnss ReceiverAnonymous XnufDzrpoNo ratings yet

- Benja PlanDocument1 pageBenja Planmasumba patrickNo ratings yet

- 310-Navtex Cobham Sailor 6390 QuickRef ManualDocument2 pages310-Navtex Cobham Sailor 6390 QuickRef ManualAbdoulKarimiFatihiNo ratings yet

- Shaft-F: Ceiling PenetrationDocument1 pageShaft-F: Ceiling PenetrationisraelNo ratings yet

- Type CDocument1 pageType Creal riderNo ratings yet

- 12.7kV SWER 2Document1 page12.7kV SWER 2Mosa Elnaid ElnaidNo ratings yet

- Concrete Storage Tanks Rev 1 Structurals 171102-1Document9 pagesConcrete Storage Tanks Rev 1 Structurals 171102-1Chancedaniels EmunaNo ratings yet

- Inclined Tower Level Unita - Block Wall SectionDocument1 pageInclined Tower Level Unita - Block Wall SectionHirushan MenukaNo ratings yet

- Michael Romeo - Paganini Concerto in B Minor (Ver 2 by Marvin Zemanate)Document7 pagesMichael Romeo - Paganini Concerto in B Minor (Ver 2 by Marvin Zemanate)Labis Pop FlorentinNo ratings yet

- Elevations and SchedulesDocument1 pageElevations and SchedulesMackson NkhomaNo ratings yet

- R O A D SITE PLAN Scale 1: 500Document1 pageR O A D SITE PLAN Scale 1: 500Mercyline MaworereNo ratings yet

- As Revised - R2-A-101Document1 pageAs Revised - R2-A-101Farhan AhamedNo ratings yet

- Rear Elevation Front Elevation: MercadoDocument1 pageRear Elevation Front Elevation: MercadoLADY NICOLE STA. MARIANo ratings yet

- Component Spray Tool V1.4.2 For Sketchup V6 and Higher (Free and Pro)Document21 pagesComponent Spray Tool V1.4.2 For Sketchup V6 and Higher (Free and Pro)Daniel Alexander AlvarezNo ratings yet

- Kitchen 1901 Rev1 PDFDocument1 pageKitchen 1901 Rev1 PDFAThaddeusAntonioNo ratings yet

- 05 Checkmate - WikipediaDocument10 pages05 Checkmate - WikipediaAThaddeusAntonioNo ratings yet

- Mikhail Kobalia - Wikipedia PDFDocument1 pageMikhail Kobalia - Wikipedia PDFAThaddeusAntonioNo ratings yet

- 01 Viktor Korchnoi - WikipediaDocument8 pages01 Viktor Korchnoi - WikipediaAThaddeusAntonioNo ratings yet

- Chigorin Memorial - WikipediaDocument3 pagesChigorin Memorial - WikipediaAThaddeusAntonioNo ratings yet

- 03 Paul Keres - WikipediaDocument10 pages03 Paul Keres - WikipediaAThaddeusAntonioNo ratings yet

- British Dance Band - WikipediaDocument3 pagesBritish Dance Band - WikipediaAThaddeusAntonioNo ratings yet

- 02 Alexander Beliavsky - WikipediaDocument2 pages02 Alexander Beliavsky - WikipediaAThaddeusAntonioNo ratings yet

- 04 Chess Puzzle - WikipediaDocument2 pages04 Chess Puzzle - WikipediaAThaddeusAntonioNo ratings yet

- USSR Chess Championship - WikipediaDocument3 pagesUSSR Chess Championship - WikipediaAThaddeusAntonioNo ratings yet

- Lev Polugaevsky - WikipediaDocument2 pagesLev Polugaevsky - WikipediaAThaddeusAntonioNo ratings yet

- Chigorin Memorial - WikipediaDocument3 pagesChigorin Memorial - WikipediaAThaddeusAntonioNo ratings yet

- Mikhail Kobalia - WikipediaDocument1 pageMikhail Kobalia - WikipediaAThaddeusAntonioNo ratings yet

- Grandmaster (Chess) - WikipediaDocument5 pagesGrandmaster (Chess) - WikipediaAThaddeusAntonioNo ratings yet

- Nona Gaprindashvili - WikipediaDocument2 pagesNona Gaprindashvili - WikipediaAThaddeusAntonioNo ratings yet

- Rogelio Antonio Jr. - WikipediaDocument1 pageRogelio Antonio Jr. - WikipediaAThaddeusAntonioNo ratings yet

- Alexandra Kosteniuk - WikipediaDocument3 pagesAlexandra Kosteniuk - WikipediaAThaddeusAntonioNo ratings yet

- Eugenio Torre - WikipediaDocument5 pagesEugenio Torre - WikipediaAThaddeusAntonioNo ratings yet

- Anatoly Karpov - WikipediaDocument6 pagesAnatoly Karpov - WikipediaAThaddeusAntonioNo ratings yet

- 1.roof Build Up-IsometricDocument1 page1.roof Build Up-IsometricAThaddeusAntonioNo ratings yet

- PR Application Guide for ProfessionalsDocument5 pagesPR Application Guide for ProfessionalsGuan LiNo ratings yet

- Tengbom, Felix Gerlach The Temporary Market Hall DivisareDocument16 pagesTengbom, Felix Gerlach The Temporary Market Hall DivisareAThaddeusAntonioNo ratings yet

- Lot Miv PDFDocument1 pageLot Miv PDFAThaddeusAntonioNo ratings yet

- Floor PlanDocument1 pageFloor PlanAThaddeusAntonioNo ratings yet

- 1 Hour Fire Rated Timber Doors 1Document27 pages1 Hour Fire Rated Timber Doors 1AThaddeusAntonioNo ratings yet

- Occupancy Load CalculationDocument20 pagesOccupancy Load CalculationAThaddeusAntonioNo ratings yet

- Membrane Lined Insulated Gutter - BrochureDocument8 pagesMembrane Lined Insulated Gutter - BrochureAThaddeusAntonioNo ratings yet

- Membrane Lined Insulated Gutter - BrochureDocument8 pagesMembrane Lined Insulated Gutter - BrochureAThaddeusAntonioNo ratings yet

- Filter DesignDocument4 pagesFilter Designhassan11783No ratings yet

- 1 s2.0 S0038080612000790 Main PDFDocument16 pages1 s2.0 S0038080612000790 Main PDFJuanSebastianGamezNo ratings yet

- Determining The Redundancy FactorDocument6 pagesDetermining The Redundancy FactorEdris Salehi GolsefidiNo ratings yet

- 06 HVAC Plumbing PDFDocument727 pages06 HVAC Plumbing PDFTamNo ratings yet

- The Causes and Prevention of Crowd DisastersDocument10 pagesThe Causes and Prevention of Crowd DisastersVarun SwaminathanNo ratings yet

- GD&T Training Levels and ServicesDocument1 pageGD&T Training Levels and ServicesdramiltNo ratings yet

- SDCK CD Ies 01 (Rev B)Document125 pagesSDCK CD Ies 01 (Rev B)Narada HerathNo ratings yet

- ESAB Welding HandbookDocument31 pagesESAB Welding Handbookhooky1100% (4)

- PVT Correlations McCain - ValkoDocument17 pagesPVT Correlations McCain - ValkoAlejandra Maleja RivasNo ratings yet

- Huawei EHuawei - Erelay - Solution - OverviewRelay Solution OverviewDocument31 pagesHuawei EHuawei - Erelay - Solution - OverviewRelay Solution Overviewtariq8283% (6)

- Calculate heating and cooling loads for buildingsDocument8 pagesCalculate heating and cooling loads for buildingsdpadrianNo ratings yet

- Iraqi Code for Reinforced Concrete StructuresDocument71 pagesIraqi Code for Reinforced Concrete Structuresmamandawe50% (2)

- Hit-Re 500 With Hit-V Has RodsDocument3 pagesHit-Re 500 With Hit-V Has RodsMKNo ratings yet

- Analysis, Specification and Estimate On Road WorksDocument71 pagesAnalysis, Specification and Estimate On Road WorksAnonymous BACdUNvPZ280% (5)

- 3.17. Creep EquationsDocument10 pages3.17. Creep Equationsruchit solankiNo ratings yet

- Catálogo King LaiDocument144 pagesCatálogo King LaiJason Salas FloresNo ratings yet

- Calgon Tech SpecDocument4 pagesCalgon Tech SpecDanStratoNo ratings yet

- Microsoft Word - Transistor Models and The Feedback Amp - Docmicrosoft Word - Transistor Models and The Feedback Amp - Doctransistor - Models - and - The - FbaDocument14 pagesMicrosoft Word - Transistor Models and The Feedback Amp - Docmicrosoft Word - Transistor Models and The Feedback Amp - Doctransistor - Models - and - The - FbashubhamformeNo ratings yet

- 13 - Principles of Flight - QuestionsDocument80 pages13 - Principles of Flight - QuestionsEdgar Muñoz Fernández50% (4)

- INTERCOMP Pt300 Users Manual Rev GDocument44 pagesINTERCOMP Pt300 Users Manual Rev GCTN2010No ratings yet

- Tabla 1 Engine ControlDocument2 pagesTabla 1 Engine Controljulio montenegroNo ratings yet

- UI Sample ResumeDocument6 pagesUI Sample ResumenazeerNo ratings yet

- Wire Rope Maintenance enDocument12 pagesWire Rope Maintenance ensriabolfazlNo ratings yet

- Support Orca3D HelpDocument281 pagesSupport Orca3D Helplavrik100% (1)

- CompoundingDocument5 pagesCompoundingMajester RigsNo ratings yet

- ApaveMare Training 2013Document41 pagesApaveMare Training 2013fbarakaNo ratings yet

- Unit Conversion Heat TransferDocument5 pagesUnit Conversion Heat TransferFamela GadNo ratings yet

- Apache Oozie - A workflow scheduler to manage Hadoop jobsDocument5 pagesApache Oozie - A workflow scheduler to manage Hadoop jobsarjuncchaudharyNo ratings yet

- Sad Thesis Guidelines FinalsDocument13 pagesSad Thesis Guidelines FinalsJes RamosNo ratings yet

- Grounding and JumperingDocument16 pagesGrounding and Jumperingferreiramarco56No ratings yet