Professional Documents

Culture Documents

GM 6180M - Condição de Superfície de Chapas de Aço e Alumínio (Inglês)

Uploaded by

Natan1912Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GM 6180M - Condição de Superfície de Chapas de Aço e Alumínio (Inglês)

Uploaded by

Natan1912Copyright:

Available Formats

Material

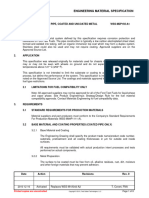

Specification GM6180M

Metals

Surface Condition Requirements – Steel and Aluminum Sheet

1 Scope Surface Type Surface Roughness

Exposed, E 0.5 – 1.3 µm

This standard covers the surface condition require-

ments for aluminum and steel sheet normally used Semi-exposed, Z 0.5 – 1.3 µm

for automobile and truck bodies. This standard does

Unexposed, U Not Required

not include any other requirements normally specified

in GMNA or GMW specifications for aluminum, cold

3.1.3.2 Peak Count. Exposed and Semi-exposed

rolled steel, or hot rolled steel.

surfaces (E and Z grade) with an Ra roughness

1.1 Material Description. Subparagraphs were not within the above range are acceptable if the observed

applicable. Peak Count (PC) exceeds 40 using a 1.25 µm mea-

surement band for determining peaks per centimeter

1.2 Cross-Reference of Replaced Specifications. (PCcm).

Subparagraphs were not applicable.

3.1.3.3 Test Method. SAE J911-98 Surface Rough-

1.3 Symbol. Not applicable. ness and Peak Count Measurement of Cold Rolled

1.4 Typical Application. Not applicable. Steel Sheet shall be used to determine arithmetic av-

erage surface roughness (Ra) and peak frequency

1.5 Remarks. Not applicable. (PC). Ra and PC shall be measured using a 0.8 mm

filter cutoff with the appropriate traverse length as

2 References listed in SAE J911-98 for the type of instrument used

for the measurement.

2.1 Normative.

3.1.3.4 Exposed (E) surface shall be free from

SAE J911-98 scratches, mill marks, dross, and any other steel

making or processing defects detrimental to a Class

2.2 GM. None.

A finish. This finish is applicable to bare and coated

products.

3 Requirements

3.1 Requirements on Delivery. 3.1.3.5 Semi-exposed (Z) surface cannot contain

scratches, dross, or any other steel making or pro-

3.1.1 Chemical Requirements. cessing defects detrimental to Class B finish. This

surface is only applicable for a temper rolled, spangle

3.1.1.1 Surface Carbon. The total surface carbon free, hot dip free zinc product.

on cold rolled exposed (E) shall not exceed 10 mg/m2

(milligrams per square meter) on uncleaned sheet. 3.1.3.6 Unexposed (U) surface may be bare or

The measurement method used shall show accept- coated and is to be used for Class C and/or Class

able R&R as agreed between supplier and purchaser, B finishes. Surface defects detrimental to the part

with the referee method being weigh-strip-weigh. No (lamination, flaking of zinc, excessive surface carbon,

evidence of carbon or snake edge is allowed on E fin- etc.) are not allowed. The maximum spangle size for

ish. hot dip free zinc product is 6 mm.

3.1.2 Mechanical Requirements. Not applicable. 3.1.4 Additional Requirements. Not applicable.

3.1.3 Physical Requirements. 3.2 Processing Requirements. Subparagraphs

were not applicable.

3.1.3.1 Surface Roughness. The arithmetic aver-

age (Ra) surface roughness shall be as follows: 3.3 Performance Requirements.

© Copyright 2000 General Motors Corporation All Rights Reserved

Originating Department: North American Engineering Standards, Records and Documentation

October 2000 Page 1 of 2

COPYRIGHT General Motors Corporation, North America

Licensed by Information Handling Services

GM6180M GM ENGINEERING STANDARDS

3.3.1 Chemical Requirements. Not applicable. incoming shipments and checked for conformance to

this specification, the supplier shall accept the respon-

3.3.2 Mechanical Requirements. Not applicable.

sibility for incoming shipments meeting this specifi-

3.3.3 Physical Requirements. cation without dependence upon purchaser’s inspec-

tion.

3.3.3.1 Reappearance of the former tandem mill fin-

ish on the surface of the fabricated part is not permit- 5.5 Initial Source Approval. No shipments shall be

ted. made by any supplier until representative initial pro-

duction samples have been approved by Materials

3.3.3.2 All products shall be free from stretcher

Engineering as meeting the requirements of this spec-

strains for six months unless otherwise agreed upon

between purchaser and supplier. ification.

3.3.4 Additional Requirements. Not applicable. 5.6 Safety Data Sheets. Not applicable.

3.4 Requirements on other Stages during Life Cy-

cle. Subparagraphs were not applicable.

6 Approved Sources

Not applicable.

4 Manufacturing Process

Not applicable. 7 Coding System

This material specification shall be called up in other

5 Rules and Regulations documents, drawings, VTS, CTS, etc. as follows:

5.1 Legal Regulations. For use of this material the GM6180M

valid laws and other regulations and recommenda-

tions in the country of usage have to be followed.

8 Release and Revisions

5.2 Language. Not applicable.

8.1 Release. This specification was first approved

5.3 Restricted and Reportable Substances for and published in August 1976.

Parts. Not applicable.

8.2 Revisions.

5.4 Inspection and Rejection. All shipments of ma-

terials or parts under contract or purchase order man- Rev. Date Description (Org.)

ufactured to this specification shall be equivalent in

every respect to the initial samples approved by engi- B JUL 1991 Revised title (GM)

neering. There shall be no changes in formulation or

manufacturing process permitted without prior notifi- C OCT 2000 Total revision; reformatted, revised

cation and approval by engineering. Lack of notifica- title, Z-grade defined, converted to

tion by the supplier constitutes grounds for rejection metric, SAE test method and addi-

of any shipment. While samples may be taken from tional requirements added. (GM)

© Copyright 2000 General Motors Corporation All Rights Reserved

Page 2 of 2 October 2000

COPYRIGHT General Motors Corporation, North America

Licensed by Information Handling Services

You might also like

- Nominal Sheet Steel Thicknesses and Thickness Tolerances: Worldwide Engineering StandardsDocument5 pagesNominal Sheet Steel Thicknesses and Thickness Tolerances: Worldwide Engineering StandardsMarcos FerreiraNo ratings yet

- GM 4350M-2004 部件涂层性能要求Document7 pagesGM 4350M-2004 部件涂层性能要求KESAVANNo ratings yet

- Worldwide Engineering Standards: Material Specification Finish GMW14664Document8 pagesWorldwide Engineering Standards: Material Specification Finish GMW14664Akmal NizametdinovNo ratings yet

- Worldwide Engineering Standards: Material Specification Finish GMW4700Document4 pagesWorldwide Engineering Standards: Material Specification Finish GMW4700Miguel Queiros100% (4)

- GMNA9981833Document3 pagesGMNA9981833Felipe De la cruzNo ratings yet

- GMW14672 ProfileID - 000070128Document15 pagesGMW14672 ProfileID - 000070128Muthu Ganesh100% (1)

- GMW 8-2008Document9 pagesGMW 8-2008Clauco Tiago Seno RoqueNo ratings yet

- GMW 3044 Zinc Plating TrivalentDocument5 pagesGMW 3044 Zinc Plating TrivalentRaymond100% (1)

- GM4348 MJun 2005Document12 pagesGM4348 MJun 2005Uday SharmaNo ratings yet

- Worldwide Engineering Standards: Low Carbon Sheet SteelDocument14 pagesWorldwide Engineering Standards: Low Carbon Sheet SteelKyle H100% (1)

- ASTM B580 Anodic Oxide Coating For Aluminum PDFDocument3 pagesASTM B580 Anodic Oxide Coating For Aluminum PDFeka putriNo ratings yet

- Ford ABS Plating Spec.Document7 pagesFord ABS Plating Spec.Pieter100% (2)

- Es 12003Document37 pagesEs 12003turgutNo ratings yet

- GMW14668Document20 pagesGMW14668Carlos LanzillottoNo ratings yet

- Electrodeposition Primer - Cathodic ELPO For Small Parts: Engineering StandardsDocument3 pagesElectrodeposition Primer - Cathodic ELPO For Small Parts: Engineering StandardsMuthu GaneshNo ratings yet

- 42 % Nickel-6 % Chromium-Iron Sealing Alloy: Standard Specification ForDocument4 pages42 % Nickel-6 % Chromium-Iron Sealing Alloy: Standard Specification ForROHITNo ratings yet

- Material Specification Metals Gmw4: Impressão Não ControladaDocument17 pagesMaterial Specification Metals Gmw4: Impressão Não ControladaLucas MlbNo ratings yet

- Astm F1941-2015 PDFDocument14 pagesAstm F1941-2015 PDFBryan ChengNo ratings yet

- GM 7111Document2 pagesGM 7111Felipe De la cruzNo ratings yet

- Astm A897 - A897m-22Document11 pagesAstm A897 - A897m-22anant11235No ratings yet

- Minimum Performance Requirements For Decorative Chromium Plated Plastic PartsDocument20 pagesMinimum Performance Requirements For Decorative Chromium Plated Plastic PartsJefferson CruzNo ratings yet

- Decorative Electroplating On Steel, Black or Low Gloss Black Interior Parts 1. ScopeDocument4 pagesDecorative Electroplating On Steel, Black or Low Gloss Black Interior Parts 1. ScopeAleks SenaNo ratings yet

- A848 PDFDocument6 pagesA848 PDFEduardoNo ratings yet

- Asme Section Ii A-2 Sa-1010 Sa-1010mDocument4 pagesAsme Section Ii A-2 Sa-1010 Sa-1010mAnonymous GhPzn1xNo ratings yet

- A742a742m-18 1.06 PDFDocument4 pagesA742a742m-18 1.06 PDFist93993No ratings yet

- GMW14057Document19 pagesGMW14057Felipe De la cruzNo ratings yet

- Sec. II A - SA - 202Document4 pagesSec. II A - SA - 202RamuAlagappanNo ratings yet

- ASTM A848-01 (Reapproved 2011)Document6 pagesASTM A848-01 (Reapproved 2011)amh.fpdNo ratings yet

- ASTM-F1941-F1941M Standard Specification For Electrodeposited Coatings On Mechanical Fasteners, Inch and MetricDocument14 pagesASTM-F1941-F1941M Standard Specification For Electrodeposited Coatings On Mechanical Fasteners, Inch and MetricSinan Chen100% (1)

- A153 PDFDocument4 pagesA153 PDFfernandoraiasaNo ratings yet

- ASME SECTION II A SA-202 SA-202MDocument4 pagesASME SECTION II A SA-202 SA-202Mksd2No ratings yet

- Astm A827-14Document3 pagesAstm A827-14Артем Титов100% (1)

- General Requirements For Wire Rods and Coarse Round Wire, Alloy Steel (Metric)Document9 pagesGeneral Requirements For Wire Rods and Coarse Round Wire, Alloy Steel (Metric)Paulo GalvãoNo ratings yet

- Fine Aluminum-1 % Magnesium Wire For Semiconductor Lead-BondingDocument3 pagesFine Aluminum-1 % Magnesium Wire For Semiconductor Lead-BondingROHITNo ratings yet

- A153a153m 16Document5 pagesA153a153m 16Ralf JonesNo ratings yet

- F 1178 - 01 RjexnzgDocument8 pagesF 1178 - 01 Rjexnzgmiguel perezNo ratings yet

- Specification For Pressure Vessel Plates, Alloy Steel, Chromium-Manganese-SiliconDocument4 pagesSpecification For Pressure Vessel Plates, Alloy Steel, Chromium-Manganese-SiliconMauricio FernándezNo ratings yet

- Astm A153Document5 pagesAstm A153Hanzel RodriguezNo ratings yet

- Cobalt-28Chromium-6Molybdenum Alloy Forgings For Surgical Implants (UNS R31537, R31538, R31539)Document3 pagesCobalt-28Chromium-6Molybdenum Alloy Forgings For Surgical Implants (UNS R31537, R31538, R31539)Adrian GonzalezNo ratings yet

- Stainless Steel Spring Wire: Standard Specification ForDocument8 pagesStainless Steel Spring Wire: Standard Specification Forsharon blushteinNo ratings yet

- A 533 - A 533M - 93 R99 Qtuzmy9bntmztqDocument4 pagesA 533 - A 533M - 93 R99 Qtuzmy9bntmztqdelta lab sangliNo ratings yet

- Abstract of ASTM F1136 1998Document3 pagesAbstract of ASTM F1136 1998Jesse ChenNo ratings yet

- ASTM A153-03 - Zinc Coating (Hot-Dip) On Iron and Steel HardwareDocument4 pagesASTM A153-03 - Zinc Coating (Hot-Dip) On Iron and Steel HardwareMelissa SammyNo ratings yet

- Electrodeposited Coatings On Threaded Fasteners (Unified Inch Screw Threads (UN/UNR) )Document11 pagesElectrodeposited Coatings On Threaded Fasteners (Unified Inch Screw Threads (UN/UNR) )Darwin DarmawanNo ratings yet

- Astm F1941-F1941MDocument14 pagesAstm F1941-F1941MShawn Deol100% (2)

- WSB M1P78 B1Document6 pagesWSB M1P78 B1JorgeNo ratings yet

- GMW14671 - Organic Coating UnderbodyDocument4 pagesGMW14671 - Organic Coating UnderbodyYosua Dimas Agus SriyantoNo ratings yet

- Ferritic Ductile Iron Castings Suitable For Low-Temperature ServiceDocument3 pagesFerritic Ductile Iron Castings Suitable For Low-Temperature ServiceBalasahebNo ratings yet

- F2730F2730MDocument7 pagesF2730F2730MMARCELO DOS SANTOS BARRETOSNo ratings yet

- A153a153m - 16 PDFDocument5 pagesA153a153m - 16 PDFHéctor BrunaNo ratings yet

- Astm A493-16Document4 pagesAstm A493-16Eugene DerkachNo ratings yet

- Zinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForDocument5 pagesZinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForMariela BelénNo ratings yet

- A 874 - A 874M - 98 - Qtg3nc9bodc0tqDocument3 pagesA 874 - A 874M - 98 - Qtg3nc9bodc0tqQaisir MehmoodNo ratings yet

- WSS-M2P192-A1 THE FILL PIPE SPECDocument8 pagesWSS-M2P192-A1 THE FILL PIPE SPECcer.qualityNo ratings yet

- Pressure Vessel Plates, Alloy Steel, Manganese-Molybdenum and Manganese-Molybdenum-NickelDocument3 pagesPressure Vessel Plates, Alloy Steel, Manganese-Molybdenum and Manganese-Molybdenum-Nickelsharon blushteinNo ratings yet

- Carbon Steel Plate Properties and SpecificationsDocument13 pagesCarbon Steel Plate Properties and Specificationsanhtho100% (1)

- F1136F1136M 11Document3 pagesF1136F1136M 11Manuel Antonio Santos Vargas0% (1)

- Astm A 986 - 2016 PDFDocument3 pagesAstm A 986 - 2016 PDFEmmanuel BoquetNo ratings yet

- Astm A240 A240m 07Document12 pagesAstm A240 A240m 07Elena ValienteNo ratings yet

- Meet Your TeamDocument2 pagesMeet Your TeamAyushman MathurNo ratings yet

- British Universal Steel Columns and Beams PropertiesDocument6 pagesBritish Universal Steel Columns and Beams PropertiesjagvishaNo ratings yet

- Felizardo C. Lipana National High SchoolDocument3 pagesFelizardo C. Lipana National High SchoolMelody LanuzaNo ratings yet

- Paradigms of ManagementDocument2 pagesParadigms of ManagementLaura TicoiuNo ratings yet

- PEDs and InterferenceDocument28 pagesPEDs and Interferencezakool21No ratings yet

- Gapped SentencesDocument8 pagesGapped SentencesKianujillaNo ratings yet

- Google Earth Learning Activity Cuban Missile CrisisDocument2 pagesGoogle Earth Learning Activity Cuban Missile CrisisseankassNo ratings yet

- Technical Specification of Heat Pumps ElectroluxDocument9 pagesTechnical Specification of Heat Pumps ElectroluxAnonymous LDJnXeNo ratings yet

- Rapport DharaviDocument23 pagesRapport DharaviUrbanistes du MondeNo ratings yet

- Evil Days of Luckless JohnDocument5 pagesEvil Days of Luckless JohnadikressNo ratings yet

- Brochure en 2014 Web Canyon Bikes How ToDocument36 pagesBrochure en 2014 Web Canyon Bikes How ToRadivizija PortalNo ratings yet

- Learning Activity Sheet: 3 Quarter Week 1 Mathematics 2Document8 pagesLearning Activity Sheet: 3 Quarter Week 1 Mathematics 2Dom MartinezNo ratings yet

- Checklist of Requirements For OIC-EW Licensure ExamDocument2 pagesChecklist of Requirements For OIC-EW Licensure Examjonesalvarezcastro60% (5)

- THE DOSE, Issue 1 (Tokyo)Document142 pagesTHE DOSE, Issue 1 (Tokyo)Damage85% (20)

- U2 All That You Can't Leave BehindDocument82 pagesU2 All That You Can't Leave BehindFranck UrsiniNo ratings yet

- Journals OREF Vs ORIF D3rd RadiusDocument9 pagesJournals OREF Vs ORIF D3rd RadiusironNo ratings yet

- Link Ratio MethodDocument18 pagesLink Ratio MethodLuis ChioNo ratings yet

- Embryology-Nervous System DevelopmentDocument157 pagesEmbryology-Nervous System DevelopmentGheavita Chandra DewiNo ratings yet

- LegoDocument30 pagesLegomzai2003No ratings yet

- Managerial EconomicsDocument3 pagesManagerial EconomicsGuruKPONo ratings yet

- Meet Joe Black (1998) : A Metaphor of LifeDocument10 pagesMeet Joe Black (1998) : A Metaphor of LifeSara OrsenoNo ratings yet

- 7 Aleksandar VladimirovDocument6 pages7 Aleksandar VladimirovDante FilhoNo ratings yet

- CFO TagsDocument95 pagesCFO Tagssatyagodfather0% (1)

- Wheeled Loader L953F Specifications and DimensionsDocument1 pageWheeled Loader L953F Specifications and Dimensionssds khanhNo ratings yet

- Paper 4 (A) (I) IGCSE Biology (Time - 30 Mins)Document12 pagesPaper 4 (A) (I) IGCSE Biology (Time - 30 Mins)Hisham AlEnaiziNo ratings yet

- Level 10 Halfling For DCCDocument1 pageLevel 10 Halfling For DCCQunariNo ratings yet

- Correlation Degree Serpentinization of Source Rock To Laterite Nickel Value The Saprolite Zone in PB 5, Konawe Regency, Southeast SulawesiDocument8 pagesCorrelation Degree Serpentinization of Source Rock To Laterite Nickel Value The Saprolite Zone in PB 5, Konawe Regency, Southeast SulawesimuqfiNo ratings yet

- An Introduction To Ecology and The BiosphereDocument54 pagesAn Introduction To Ecology and The BiosphereAndrei VerdeanuNo ratings yet

- BIT 4107 Mobile Application DevelopmentDocument136 pagesBIT 4107 Mobile Application DevelopmentVictor NyanumbaNo ratings yet