Professional Documents

Culture Documents

Volute

Uploaded by

M Ferry AnwarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Volute

Uploaded by

M Ferry AnwarCopyright:

Available Formats

P R O D U C T D A T A S H E E T

CORNELL PUMP COMPANY

Double Volute System

DOUBLE VOLUTE SYSTEM Single Cutwater

To minimize the radial thrust loads common with

high capacity, high head centrifugal pumps, Cornell

has developed a Double Volute System (DVS)

design. With this feature the radial forces around the

impeller are balanced, eliminating shaft flexing and

fatigue. This greatly extends the life of the packing,

wear rings, and bearings.

Cornell’s double volute system, with our statically

and dynamically balanced enclosed impellers

and superior hydraulic design, enables our single

stage, end-suction centrifugal pumps to effectively

and efficiently meet high pressure, high volume,

requirements.

On single volute pumps, increasing pressure acts

against the impeller area creating unbalanced

radial forces. In contrast, the double volute system

effectively balances these forces by dividing the Conventional Single Volute

flow into two comparable parts with two cutwaters (unbalanced radial thrust causes

located directly across from each other. The shaft deflection)

resulting two opposing forces, balance each other

and hold the shaft in proper alignment. Thus the Cutwater #1

combined radial forces remain low throughout the

operating range of the pump regardless of load

variance, shut-off or run-out conditions.

Cornell’s “DVS” design keeps the shaft from breaking;

extends the life of the packing, mechanical seals,

wear rings, and bearings; and helps maintains high

hydraulic efficiency.

RADIAL FORCE

Shut-Off

Percentage of Force at Shut-Off

100

80 Run-Out

60

Si

n

gl

Vo

Cutwater #2

e

40 lu

te

20 Double Vo

lute Cornell Double Volute

(radial thrust is offset and balanced

0 25 50 75 100 125 150

by the double volute design)

Percentage of Design Capacity

Cornell Pump Company

P.O. Box 6334 • Portland, Oregon 97228-6334

Phone: (503) 653-0330 • Fax: (503) 653-0338

web site: www.cornellpump.com • e-mail: info@cornellpump.com

You might also like

- Hydraulic Design CriteriaDocument171 pagesHydraulic Design CriteriaMartinFelipeRamirezMuñozNo ratings yet

- Ehc SovDocument16 pagesEhc SovDSGNo ratings yet

- Petrofisika TM2209 W10Document25 pagesPetrofisika TM2209 W10Hafiizhoh HanafiaNo ratings yet

- Armorlite: Type MC PVC Jacketed Neutral Per PhaseDocument3 pagesArmorlite: Type MC PVC Jacketed Neutral Per PhaseHector MoraNo ratings yet

- Bosch - Dados Bicos InjetoresDocument25 pagesBosch - Dados Bicos InjetoresClaudio GibeiliNo ratings yet

- SW Long NhiDocument6 pagesSW Long NhiVICTOR LOPEZNo ratings yet

- FCV 1200 - ErhardDocument3 pagesFCV 1200 - Erhardrizkboss8312No ratings yet

- Fracturing Design 1Document32 pagesFracturing Design 1gandhihetamiNo ratings yet

- 02 - SIM DN150 PN160 Valve 2 PDFDocument4 pages02 - SIM DN150 PN160 Valve 2 PDFunnicyriacNo ratings yet

- SPE 154567 Polymer Flooding A 500-cp OilDocument13 pagesSPE 154567 Polymer Flooding A 500-cp OilBichara DjimetNo ratings yet

- Extrusion Process and Die Design ConsiderationDocument62 pagesExtrusion Process and Die Design ConsiderationMun JiwonNo ratings yet

- Little - Giant LSP-150-C Lawn Sprinkler Pump - OverviewDocument2 pagesLittle - Giant LSP-150-C Lawn Sprinkler Pump - OverviewjuliusttNo ratings yet

- Wsro-T500 (Ris)Document5 pagesWsro-T500 (Ris)Ahmad JundullahNo ratings yet

- Optimization of Multiple Hydraulically F PDFDocument17 pagesOptimization of Multiple Hydraulically F PDFMiguel Angel Vidal ArangoNo ratings yet

- Cornell - AgricultureDocument8 pagesCornell - AgricultureSBM LagunaNo ratings yet

- Bearing Water PumpDocument17 pagesBearing Water PumpHenni TanNo ratings yet

- All Products Brochure 2018 - 14Document4 pagesAll Products Brochure 2018 - 14Adriana Meet MarkNo ratings yet

- Asd6 Asd18lDocument1 pageAsd6 Asd18lsinggih prasetiyoNo ratings yet

- Injection and Disposal Wells: - What Is Different - How To Convert Producers To InjectorsDocument49 pagesInjection and Disposal Wells: - What Is Different - How To Convert Producers To Injectorsdriller22No ratings yet

- 01 - SIM DN150 PN16 Valve 1 PDFDocument4 pages01 - SIM DN150 PN16 Valve 1 PDFunnicyriacNo ratings yet

- Lenkkraenze FLY BPW EN 20201001 PDFDocument10 pagesLenkkraenze FLY BPW EN 20201001 PDFNguyễn ĐạiNo ratings yet

- SPE 154567 Polymer Flooding A 500-cp OilDocument13 pagesSPE 154567 Polymer Flooding A 500-cp OilfuatNo ratings yet

- Kirloskar Electric Co LTD.: Price List For Ac MotorsDocument20 pagesKirloskar Electric Co LTD.: Price List For Ac MotorsAshishNo ratings yet

- Wankel Engines As Steam Expanders: Design ConsiderationsDocument14 pagesWankel Engines As Steam Expanders: Design ConsiderationsbanstalaNo ratings yet

- ResistorDocument9 pagesResistorSakahi SharmaNo ratings yet

- ResistorDocument9 pagesResistordennis0611237No ratings yet

- Duplomatic md1d s4Document40 pagesDuplomatic md1d s4Artari RNo ratings yet

- Brosur Pompa Submersible EbaraDocument4 pagesBrosur Pompa Submersible EbaraBudi RahmadiNo ratings yet

- Kobold - DSV - Datasheet DSV-2105HDocument4 pagesKobold - DSV - Datasheet DSV-2105HEstefania ZamoraNo ratings yet

- Victor Gustavo Domingos Chen Bera 11.10.21Document2 pagesVictor Gustavo Domingos Chen Bera 11.10.21Liliana ChenNo ratings yet

- Dynaflo 6220 / 6230 Model Numbers: 62201, 62203 & 62303: Transfer PumpsDocument2 pagesDynaflo 6220 / 6230 Model Numbers: 62201, 62203 & 62303: Transfer PumpsMohammad ZeeshanNo ratings yet

- 450G PDFDocument2 pages450G PDFSean Torrefranca LopezNo ratings yet

- 意大利casappa(凯斯帕)股份公司 Strada 定量斜轴式柱塞泵选型样本Document4 pages意大利casappa(凯斯帕)股份公司 Strada 定量斜轴式柱塞泵选型样本walk111No ratings yet

- HNF Lagc Datasheet en PDFDocument16 pagesHNF Lagc Datasheet en PDFMira RedaNo ratings yet

- 10 - Formation - ResistivityDocument24 pages10 - Formation - ResistivityAtheer HadiNo ratings yet

- 5e8367a7ae7e0 20200331065415Document8 pages5e8367a7ae7e0 20200331065415AnaNo ratings yet

- Bombas Kawasaky PDFDocument11 pagesBombas Kawasaky PDFRoberth Alexander Ríos NievesNo ratings yet

- Radial Eductor VortexDocument6 pagesRadial Eductor Vortexyamid muñozNo ratings yet

- Pot 5K Bourns 3362P-1-502LFDocument2 pagesPot 5K Bourns 3362P-1-502LFJoão Oliveira BentesNo ratings yet

- MD 20100218Document76 pagesMD 20100218Scribd_TorontoNo ratings yet

- 12 Rot Valve SizeDocument9 pages12 Rot Valve Sizecesar yair soto hernandezNo ratings yet

- Cable Schedule - ST OXD - RP Rev 1Document2 pagesCable Schedule - ST OXD - RP Rev 1mukesh_kht1No ratings yet

- MC InjectionDocument3 pagesMC InjectionMordo GordoNo ratings yet

- Rock Type Course - Rev2Document225 pagesRock Type Course - Rev2Mario Mallaviabarrena100% (4)

- Performance of MOV Stem Lubricants at Elevated TemperatureDocument11 pagesPerformance of MOV Stem Lubricants at Elevated TemperatureVittorio FacchettiNo ratings yet

- New Approach To Improve The Horizontal Drilling ReachDocument7 pagesNew Approach To Improve The Horizontal Drilling Reachraj kumarNo ratings yet

- Overview of Industrial and Rocket Turbopump Inducer Design: Cav2001:Sessionb7.001Document12 pagesOverview of Industrial and Rocket Turbopump Inducer Design: Cav2001:Sessionb7.001EssienNo ratings yet

- Wahlberg 2003Document20 pagesWahlberg 2003squivviaNo ratings yet

- S2111-600-005JS Ele - Load Analysis A0Document10 pagesS2111-600-005JS Ele - Load Analysis A0Cornea IonutNo ratings yet

- Brosur DL Dan DF 1Document4 pagesBrosur DL Dan DF 1nandaNo ratings yet

- Aula2 Turb in Fluids VorticityDocument50 pagesAula2 Turb in Fluids VorticityTomás CarreiraNo ratings yet

- Screen and Cyclones in Concentrators PDFDocument11 pagesScreen and Cyclones in Concentrators PDFAnonymous C0lBgO24iNo ratings yet

- t6cc t6ccw Denison Vane Pumps IndustrialDocument5 pagest6cc t6ccw Denison Vane Pumps IndustrialSamuel Lopez BenitesNo ratings yet

- Pipe Ready Engine Drives: Cross Country 300 SAE - 300 MP Classic 300 MPDocument1 pagePipe Ready Engine Drives: Cross Country 300 SAE - 300 MP Classic 300 MPJorge CarrascoNo ratings yet

- Ycua Ydf (Tech. Guide) 2Document20 pagesYcua Ydf (Tech. Guide) 2Elmer80% (5)

- Natco Dual Polarity PsDocument2 pagesNatco Dual Polarity PsajostosNo ratings yet

- Adobe Scan 19-Feb-2021Document17 pagesAdobe Scan 19-Feb-2021Sharma P PNo ratings yet

- Yamaha ps-10 Keyboard SMDocument21 pagesYamaha ps-10 Keyboard SMLuigiNo ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

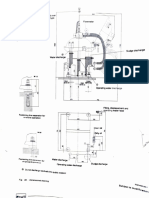

- PC3000-1 S - N 06174 - Idler AssyDocument2 pagesPC3000-1 S - N 06174 - Idler AssyM Ferry AnwarNo ratings yet

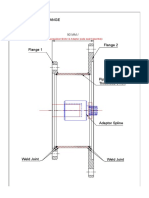

- 04 Assembly Adaptor MotorDocument1 page04 Assembly Adaptor MotorM Ferry AnwarNo ratings yet

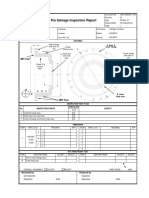

- Inspection Test Plan Post-Salvage Inspection: Part Name: Retainer MODEL: 777 PART NO.: 106-2624 / 354-7988Document7 pagesInspection Test Plan Post-Salvage Inspection: Part Name: Retainer MODEL: 777 PART NO.: 106-2624 / 354-7988M Ferry AnwarNo ratings yet

- 03 Adaptor SplineDocument1 page03 Adaptor SplineM Ferry AnwarNo ratings yet

- 02 Flange 2Document1 page02 Flange 2M Ferry AnwarNo ratings yet

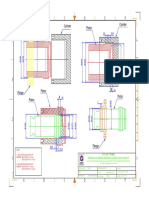

- Cat Duo Cone Seal 01Document1 pageCat Duo Cone Seal 01M Ferry AnwarNo ratings yet

- Adaptor Flange 1: Pt. SSC WorksDocument1 pageAdaptor Flange 1: Pt. SSC WorksM Ferry AnwarNo ratings yet

- Bucket CAT 6015BDocument1 pageBucket CAT 6015BM Ferry AnwarNo ratings yet

- ULTAGE Spherical Roller Bearings 23 PDFDocument20 pagesULTAGE Spherical Roller Bearings 23 PDFM Ferry AnwarNo ratings yet

- Caterpillar 320D2 PDFDocument1 pageCaterpillar 320D2 PDFM Ferry AnwarNo ratings yet

- 381-4190 Frame Gp-Telescoping Recoil - R... 666 Undercarriage Ar An Attachment D9RDocument1 page381-4190 Frame Gp-Telescoping Recoil - R... 666 Undercarriage Ar An Attachment D9RM Ferry AnwarNo ratings yet

- QAR-QD405-1373 Catridge Tumbler I EX2500 HitachiDocument1 pageQAR-QD405-1373 Catridge Tumbler I EX2500 HitachiM Ferry AnwarNo ratings yet

- SSCSMD Yoke & Piston PC1250 PDFDocument1 pageSSCSMD Yoke & Piston PC1250 PDFM Ferry AnwarNo ratings yet

- N 10001-UP Komatsu Part Catalog PC1600-1Document4 pagesN 10001-UP Komatsu Part Catalog PC1600-1M Ferry AnwarNo ratings yet

- 60 Ton 950 MMDocument13 pages60 Ton 950 MMM Ferry AnwarNo ratings yet

- 40 Ton 300 MMDocument13 pages40 Ton 300 MMM Ferry AnwarNo ratings yet

- Cylinder Piston Piston Cylinder: Pt. SSC WorkDocument1 pageCylinder Piston Piston Cylinder: Pt. SSC WorkM Ferry AnwarNo ratings yet

- Air-Conditioning Module Slides-FinalDocument37 pagesAir-Conditioning Module Slides-FinalMorgan HengNo ratings yet

- Propulsion - I: B.E. (Aeronautical Engineering) Semester Fifth (C.B.S.)Document2 pagesPropulsion - I: B.E. (Aeronautical Engineering) Semester Fifth (C.B.S.)Preshit SamNo ratings yet

- Light Commercial ACDocument52 pagesLight Commercial ACFerdinand FernandezNo ratings yet

- BHR 35 - 30 4 Stg.Document3 pagesBHR 35 - 30 4 Stg.Maknan SteelNo ratings yet

- FFS 0217 2015 Franklin Fueling Systems Price ListDocument208 pagesFFS 0217 2015 Franklin Fueling Systems Price ListpogisimpatikoNo ratings yet

- Axial Fans PDFDocument10 pagesAxial Fans PDFFahad KhanNo ratings yet

- F19460 RB 4700 GB 07-007 LowDocument8 pagesF19460 RB 4700 GB 07-007 LowJuan JuanNo ratings yet

- ITR B StatusDocument8 pagesITR B StatusPazhamalai RajanNo ratings yet

- Installation, Operation & Maintenance Manual: Model 72 Simplex Basket Strainer, Sizes 3/8" - 8"Document5 pagesInstallation, Operation & Maintenance Manual: Model 72 Simplex Basket Strainer, Sizes 3/8" - 8"Arvnd VckyNo ratings yet

- How A Refrigeration Compressor WorksDocument9 pagesHow A Refrigeration Compressor WorksYasir ButtNo ratings yet

- Volume (11) Issue (3) 362-382Document21 pagesVolume (11) Issue (3) 362-382e.vicente.caballeroNo ratings yet

- Ansi B 16.104 (Fci)Document8 pagesAnsi B 16.104 (Fci)jshadwanNo ratings yet

- W 11 Study MaterialDocument9 pagesW 11 Study MaterialebbasinghNo ratings yet

- 2SP Series Twin Screw Pump EnglishDocument17 pages2SP Series Twin Screw Pump EnglishDurrani SonsNo ratings yet

- VSMC Compressor Unit Installation Operation Maintenance Manual 35391vc Rev 0 en Us 1580320 PDFDocument156 pagesVSMC Compressor Unit Installation Operation Maintenance Manual 35391vc Rev 0 en Us 1580320 PDFSEFRIGUA NH3No ratings yet

- 2 Valve Manifold 3 Way g2vm1Document1 page2 Valve Manifold 3 Way g2vm1srk_mit111No ratings yet

- Bahasa Inggris Teknik - Controlling The Plant InstrumentationDocument15 pagesBahasa Inggris Teknik - Controlling The Plant InstrumentationIka Mustika WatiNo ratings yet

- Manual de Partes RFADocument140 pagesManual de Partes RFALeonardo Benitez100% (1)

- Laminar FlowDocument48 pagesLaminar Flowtimothyatambo383No ratings yet

- Tank SizeDocument6 pagesTank SizeNghiaNo ratings yet

- Dimensionless NumbersDocument15 pagesDimensionless NumbersHaider Ali100% (1)

- Sullair Air Compressor Parts CatalogDocument88 pagesSullair Air Compressor Parts CatalogМихайло ЗахаркоNo ratings yet

- SCMS 7035Document5 pagesSCMS 7035Jose Manuel CastroNo ratings yet

- Pressure Reducing Valve - Test and AdjustDocument4 pagesPressure Reducing Valve - Test and AdjustHendra MonoNo ratings yet

- Emergency Stop Valve-V5i352 PDFDocument4 pagesEmergency Stop Valve-V5i352 PDFmahesh waliNo ratings yet

- Module 04 Water System in A BuildingDocument112 pagesModule 04 Water System in A BuildingbiancabelvismochiNo ratings yet

- IC-000113Document23 pagesIC-000113hiralronny100% (1)

- CTHS430-02 SPC R223.1394-01Document82 pagesCTHS430-02 SPC R223.1394-01Patricio Tamayo100% (1)

- Pump Basic Types & OperationDocument1 pagePump Basic Types & Operationmark navarreteNo ratings yet

- Hydraulics and PneumaticsDocument6 pagesHydraulics and PneumaticslardominicNo ratings yet