Professional Documents

Culture Documents

Unit of Learning Outcomes: Activity

Uploaded by

paulomarques22Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Unit of Learning Outcomes: Activity

Uploaded by

paulomarques22Copyright:

Available Formats

Unit of Learning Outcomes: Elaborating manufacturing programs in CNC milling machines

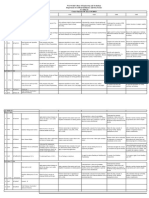

Activity Criteria of assessment – scale (1-3)

Id Designation

K-S-A 1 – Satisfactory 2 – Good 3 – Excellent

Knowledge

K1 · Drawing representation, technical terms, symbols and standards

K2 · The fundamentals of the process planning

K3

· The fundamental knowledge of machining operations and its features Is able to read and interpreter the process plan data sheet

Is able to identify errors or missing information (machining

K4 · The fundamentals of cutting technology and related information (machining process already

process already designed) and to report them. Use the appropriate technology/information systems to

· The fundamental knowledge of tool holding and work holding devices designed) but needs some guidance when face a new

K5 identify, analyse and organise data and ideas.

and theirs applications process (*) where is necessary to collect and to organize the

If a new process (*) can collect, organize and register the

K6 · The raw materials and their machining properties data to set the tasks as well as the sequence of machining

necessary data to set the tasks, the sequence of machining Takes into consideration the type of production to design

operations.

Skills operations as well as the measuring & inspection strategy. the machining process plan.

Plan the machining process

· Interpret mechanical drawing projections, cross-sections, dimensions If standard type can select the appropriate workholding

A1 (Set the operating sequences taking into account the

production type, raw material, part shape and

S1

and their related tolerances and surface markings devices, tool holders and cutting tools.

Aiming to resume production makes changes and

If standard type can select the appropriate workholding improvements in existing machining processes.

requirements) · Create the sequence of operations

S2 (in order to gather and to organize the necessary data for programming, set-up and devices, tool holders and cutting tools, but needs guidance

Is able to get the data related with the cutting tool but need

machining phases) and examples for specials. Solve problems independently.

guidance and examples to calculate the cutting parameters

Attitudes (*) Parts to be obtained from a solid block of raw material or

(*) Simple parts to be obtained from solid block of raw

C1 · Respect priorities already pre-shaped parts

material with no more than two machining faces

· Keep the workplace clean and well organized during all the process

C2 phases

C3 · Respect the times given for the execution of the tasks

· Observes occupational safety regulations and use machine safety

C4 equipment

C5 · Proactive in problems solving

C6 . Autonomous and self-orientated

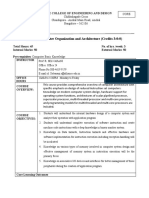

Knowledge

K1 · Drawing representation, technical terms, symbols and standards

K2 · The fundamentals of the process planning

· The fundamental knowledge of machining operations and its

K3

features

K4 · The fundamentals of cutting technology

· The fundamentals of a CNC machine

K5

(machine system, coordinate systems, references points)

Can optimize a NC programme taking into consideration the

· The fundamental knowledge of methods and techniques to generate

K6 Is able to select the best methods according to the production type.

a programme

production type and part specification.

· Program structure, preparatory function and auxiliary function (G-

K7 By using parametric programming, is able to create programs

codes and/or similar programming codes) Can generate NC programs for simple parts applying the

Can generate NC programs applying the techniques of to align the work holding devices and to set the work piece

Execute the manufacturing Skills techniques of manual programming as well as the

manual programming, the techniques of automatic reference point automatically.

techniques of automatic programming (2D and 2 ½ D), but

programs S1

· Interpret mechanical drawing projections, cross-sections, programming (3D) as well as parametric programming to

A2 (for work pieces to be obtained from a solid block, pre- dimensions and their related tolerances and surface markings needs guidance and examples to select the appropriate

create canned cycles. By using parametric programming, is able to create programs

· Interpret the work plan sheet, tooling sheet, tool data sheet programming method.

machined part, casting or forgings with simple or to check dimensions and correct the deviations

S2

complex geometry) applying the different data in the programme Takes into consideration the different technical data to automatically

S3 · Apply the techniques of manual programming create the toolpath but needs some assistance to solve

S4 · Apply the techniques of automatic programming problems. Has an independent command on program errors detection

S5 · Apply the techniques of parametric programming and resolution.

Attitudes

C1 · Respect priorities

· Keep the workplace clean and well organized during all the process

C2

phases

C3 · Respect the times given for the execution of the tasks

· Observes occupational safety regulations and use machine safety

C4

equipment

C5 · Proactive in problems solving

C6 . Autonomous and self-orientated

You might also like

- Refa Training Methods EnglishDocument16 pagesRefa Training Methods EnglishAleksandra GaberskaNo ratings yet

- 1996 GMC SAVANA Service Repair Manual PDFDocument31 pages1996 GMC SAVANA Service Repair Manual PDFjhjfnsnef0% (1)

- BCMS Information Note 1-2018 Guidance On Timber Frame WallsDocument5 pagesBCMS Information Note 1-2018 Guidance On Timber Frame WallsLiam MinogueNo ratings yet

- EPC Project Management PDFDocument28 pagesEPC Project Management PDFRuna Jully100% (1)

- Anotec 90-09 Solid Stick AnodesDocument2 pagesAnotec 90-09 Solid Stick AnodesMohsin AliNo ratings yet

- Injection Pump R&RDocument17 pagesInjection Pump R&RMahdi Besbes100% (2)

- 1.460 ATP 2023-24 GR 11 Info Tech FinalDocument5 pages1.460 ATP 2023-24 GR 11 Info Tech FinalbytesanimationstudiosNo ratings yet

- Et ZC424 Course HandoutDocument5 pagesEt ZC424 Course HandoutKUBAL MANOJ SHAMSUNDARNo ratings yet

- Cim Unit 4 PDFDocument20 pagesCim Unit 4 PDFSarthak KingerNo ratings yet

- Using Genetic Algorithms in Process Planning For Job Shop MachiningDocument12 pagesUsing Genetic Algorithms in Process Planning For Job Shop MachiningBoris MilovanovićNo ratings yet

- DBOW - Exploratory-7-Technical DraftingDocument6 pagesDBOW - Exploratory-7-Technical DraftingDannah AbatNo ratings yet

- Commissioning in DetailDocument200 pagesCommissioning in DetailmohamedovicNo ratings yet

- Pertemuan 11: Systems Analysis and Design of A Business Event Driven SystemDocument15 pagesPertemuan 11: Systems Analysis and Design of A Business Event Driven SystemCIndy SaputriNo ratings yet

- Softwrer DemoDocument4 pagesSoftwrer DemoDHARMENDRANo ratings yet

- FIDP 1 Quarter CSS1Document10 pagesFIDP 1 Quarter CSS1jonathan labajoNo ratings yet

- Intake Design Process - v1Document1 pageIntake Design Process - v1Angela RaymondNo ratings yet

- Assessment Mapping MatrixDocument3 pagesAssessment Mapping MatrixAnuu BhattiNo ratings yet

- Core Complete - Spring 24Document1 pageCore Complete - Spring 24avaayyaduraitamuNo ratings yet

- Assembly For Die MakingDocument11 pagesAssembly For Die MakingbinhleeNo ratings yet

- Developing An IAQ Profile: Appendix G and The ASHRAE Standard OnDocument11 pagesDeveloping An IAQ Profile: Appendix G and The ASHRAE Standard OnreezfyNo ratings yet

- CS8592 - Object Oriented Analysis and Design.Document312 pagesCS8592 - Object Oriented Analysis and Design.Jusu tisu86% (7)

- Enterprise Data Model - Decision TreeDocument8 pagesEnterprise Data Model - Decision Treeeat.pot33No ratings yet

- AIDS COs AY 22 23Document2 pagesAIDS COs AY 22 23shrikondaonkar2412No ratings yet

- INS Intro 2021Document65 pagesINS Intro 2021forhometvactNo ratings yet

- W 8-115 QuickDocument20 pagesW 8-115 QuicksssNo ratings yet

- Template For Chapter 4Document3 pagesTemplate For Chapter 4Michelle CasinilloNo ratings yet

- Feature Based Interoperability Between DDocument16 pagesFeature Based Interoperability Between DBAMOUROU SANOGONo ratings yet

- Lecture 1Document4 pagesLecture 1Muqaddas PervezNo ratings yet

- Unit 17 Computer Aided Manufacture CamDocument11 pagesUnit 17 Computer Aided Manufacture CamManiDeepNo ratings yet

- Building Design PDFDocument7 pagesBuilding Design PDFkbkwebsNo ratings yet

- Analysis and Design of Residential Building by Using Sap-2000Document7 pagesAnalysis and Design of Residential Building by Using Sap-2000minn ko ko kyawNo ratings yet

- What Is PLM and Why Is It Important?Document28 pagesWhat Is PLM and Why Is It Important?Sergei MozheninNo ratings yet

- VKJB HBKJDocument10 pagesVKJB HBKJAgnihothra Sarma OrugantiNo ratings yet

- Subsea Mech and Structural Engineer TemplateDocument3 pagesSubsea Mech and Structural Engineer TemplateferryfNo ratings yet

- 16-RenatoCumani Cadastre Module - FAO Presentation - V1Document18 pages16-RenatoCumani Cadastre Module - FAO Presentation - V1algassiNo ratings yet

- Annual Plan G 9Document5 pagesAnnual Plan G 9Addis Ayalew100% (1)

- The Open Group Architecture Framework (TOGAF) Version 7Document22 pagesThe Open Group Architecture Framework (TOGAF) Version 7Ashish KNo ratings yet

- Intro Ds ClassDocument46 pagesIntro Ds ClassAshitha AshiNo ratings yet

- Recognition of Features in Sheet Metal Parts Manufactured Using Progressive DiesDocument14 pagesRecognition of Features in Sheet Metal Parts Manufactured Using Progressive DiesAgostinho NoronhaNo ratings yet

- Domestic Data Entry Operator Syllabus/ CurriculumDocument4 pagesDomestic Data Entry Operator Syllabus/ CurriculumNIVI MEDIA TVNo ratings yet

- Equipment Initial Production Control SystemDocument1 pageEquipment Initial Production Control Systemsrmohapatra5086No ratings yet

- Qualifications Pack: Draughtsman - MechanicalDocument33 pagesQualifications Pack: Draughtsman - MechanicalMustafa Al Taleb BackupNo ratings yet

- System Engineering - WHY2? - Setyo PDFDocument27 pagesSystem Engineering - WHY2? - Setyo PDFSetyo SoekarsonoNo ratings yet

- RH442: Red Hat® System Monitoring and Performance Tuning: IncludesDocument1 pageRH442: Red Hat® System Monitoring and Performance Tuning: IncludesLokesh ReddyNo ratings yet

- Manufacturing Engineering-II Course Code: 4341904: Page 1 of 11Document11 pagesManufacturing Engineering-II Course Code: 4341904: Page 1 of 11Gest Account 08No ratings yet

- Infrastructure For Ict Implementation Including The Selecton of Hardware and SoftwareDocument17 pagesInfrastructure For Ict Implementation Including The Selecton of Hardware and SoftwareShiji PremNo ratings yet

- A Customizable Process Planning Approach For Rotational Parts Based On Multi-Level Machining Features and OntologyDocument23 pagesA Customizable Process Planning Approach For Rotational Parts Based On Multi-Level Machining Features and OntologyTeodoraNo ratings yet

- TRB For Print 2022Document13 pagesTRB For Print 2022Ralfh De GuzmanNo ratings yet

- The Analysis of Methods For Computer Aided Process PlanningDocument10 pagesThe Analysis of Methods For Computer Aided Process PlanningSalehNo ratings yet

- PropertyQuants - Bringing Quantitative Investment Strategies To Global Real EstateDocument5 pagesPropertyQuants - Bringing Quantitative Investment Strategies To Global Real EstateBrian ChungNo ratings yet

- CS 404 - COA Course PlanDocument8 pagesCS 404 - COA Course PlanAishwarya RajeshNo ratings yet

- T300-Training Level 2 - ScheduleDocument1 pageT300-Training Level 2 - Scheduleelmapa04No ratings yet

- Basic GD&T PDFDocument236 pagesBasic GD&T PDFVinothkumar MNo ratings yet

- Katalog enDocument12 pagesKatalog enapi-3714448100% (2)

- CAPPDocument16 pagesCAPPvirug1994No ratings yet

- Unit 3Document28 pagesUnit 3Ian Lee LugueNo ratings yet

- Applied R&M Manual For Defence Systems Part A: GeneralDocument16 pagesApplied R&M Manual For Defence Systems Part A: GeneralvedipiNo ratings yet

- Create A Whole School Plan - 7 8 Curriculum PlanningDocument2 pagesCreate A Whole School Plan - 7 8 Curriculum PlanningMary KatogianniNo ratings yet

- CNT Info and Comm Tech As 21-22Document1 pageCNT Info and Comm Tech As 21-22Aye Nyein ThuNo ratings yet

- Career OpportunitiesDocument1 pageCareer OpportunitiesWilson MondoNo ratings yet

- Dunn 1986 DRL Ops Database 15360Document13 pagesDunn 1986 DRL Ops Database 15360Mohamed Taher FechkeurNo ratings yet

- JG 5 - MMI Inspection Engineer (Facilities & Equipments)Document5 pagesJG 5 - MMI Inspection Engineer (Facilities & Equipments)bintogeorgev862No ratings yet

- Managing Buried Piping Underground Asset Integrity 2017Document24 pagesManaging Buried Piping Underground Asset Integrity 2017mouda8148No ratings yet

- The Design and Implementation of Geographic Information SystemsFrom EverandThe Design and Implementation of Geographic Information SystemsNo ratings yet

- 2016festodidacticfullcatalog PDFDocument484 pages2016festodidacticfullcatalog PDFpaulomarques22No ratings yet

- Made By: Joana Pinto Nº14 Manuela Freitas Nº19 Susana Marques n28Document12 pagesMade By: Joana Pinto Nº14 Manuela Freitas Nº19 Susana Marques n28paulomarques22No ratings yet

- StderrDocument15 pagesStderrpaulomarques22No ratings yet

- WSC2015 TP01 at A0 A4 Automation Overview Sharpener ActualDocument1 pageWSC2015 TP01 at A0 A4 Automation Overview Sharpener Actualpaulomarques22No ratings yet

- WSC2015 TP01 at 0b01 A3 Base Plate ActualDocument1 pageWSC2015 TP01 at 0b01 A3 Base Plate Actualpaulomarques22No ratings yet

- Wsc2015 Tp01 at en ActualDocument10 pagesWsc2015 Tp01 at en Actualpaulomarques22No ratings yet

- Installation and Maintenance Manual: 2 Intended Conditions of Use 3 InstallationDocument3 pagesInstallation and Maintenance Manual: 2 Intended Conditions of Use 3 Installationpaulomarques22No ratings yet

- 6 D Sub Connectors For SV Series ValvesDocument10 pages6 D Sub Connectors For SV Series Valvespaulomarques22No ratings yet

- AutoWeek ADocument2 pagesAutoWeek Apaulomarques22No ratings yet

- Porche, Four To The ForeDocument6 pagesPorche, Four To The Forepaulomarques22No ratings yet

- 70fieldbus Ex600Document59 pages70fieldbus Ex600paulomarques22No ratings yet

- Hyundai Asansor Kabin SecenekleriDocument4 pagesHyundai Asansor Kabin SecenekleriShruti PatkarNo ratings yet

- Affiliated Colleges de 2009-10Document2 pagesAffiliated Colleges de 2009-10hardikjthakkarNo ratings yet

- G3612Document12 pagesG3612Victor NunezNo ratings yet

- Processing Guide: Item Unit RepresentativeDocument2 pagesProcessing Guide: Item Unit RepresentativeTan LeNo ratings yet

- Diagnose The Vp44 Fuel System - Diesel BombersDocument10 pagesDiagnose The Vp44 Fuel System - Diesel Bombersesyjam50% (2)

- CGBDocument2 pagesCGBMauricio Oropeza CabreraNo ratings yet

- A Private Space in A Bustling City: Top of FormDocument5 pagesA Private Space in A Bustling City: Top of FormMaduwantha SilvaNo ratings yet

- Drop Raising in Underground MinesDocument20 pagesDrop Raising in Underground Minespartha das sharmaNo ratings yet

- Weldox SteelDocument2 pagesWeldox SteelHugo RodriguezNo ratings yet

- CE-333 Environmental Engineering IIDocument101 pagesCE-333 Environmental Engineering IIarif24ceNo ratings yet

- Diagrama de Guiillotina DurmaDocument18 pagesDiagrama de Guiillotina DurmaJoel VegaNo ratings yet

- 05 Geobag (Terra Sack)Document4 pages05 Geobag (Terra Sack)dixmitNo ratings yet

- Certification Docs Etso Authorisations ETSO - DevDocument47 pagesCertification Docs Etso Authorisations ETSO - Devvanmorrison69No ratings yet

- College Student PhoneDocument26 pagesCollege Student PhonesreeNo ratings yet

- Deutz - Block Load BF6M1013Document2 pagesDeutz - Block Load BF6M1013Jayaprathap NithiyanandanNo ratings yet

- Splined ShaftDocument2 pagesSplined Shaftjmpateiro1985No ratings yet

- 1-1 Computer Basics Lesson PlanDocument7 pages1-1 Computer Basics Lesson PlanArvic Omila LasacaNo ratings yet

- Re4F04A Automatic Transmission (A/T) - Will Not Shift When Placed in ReverseDocument2 pagesRe4F04A Automatic Transmission (A/T) - Will Not Shift When Placed in ReverseDaniel HernandezNo ratings yet

- Contract No. Bapex/Admin/1528: Shipping MarkDocument7 pagesContract No. Bapex/Admin/1528: Shipping MarkhaosfNo ratings yet

- 5 Smart Charge SystemDocument4 pages5 Smart Charge Systemlitieuduy100% (1)

- Wheel Chair (Spec) (R)Document1 pageWheel Chair (Spec) (R)Andri StyaNo ratings yet

- Fire AlarmDocument24 pagesFire Alarmbsh1978100% (1)

- Rule 14 - Photographic & X-Ray Films (Book Format)Document3 pagesRule 14 - Photographic & X-Ray Films (Book Format)Thea AbelardoNo ratings yet

- Mario Block Plush Sewing PatternDocument7 pagesMario Block Plush Sewing PatternOcelotl Tlili IxtlicoyuNo ratings yet

- Is 4072 1975Document15 pagesIs 4072 1975Krishnan Dandapani100% (1)

- P275HEDocument1 pageP275HENamer HajiNo ratings yet