Professional Documents

Culture Documents

AMBERJET, AMBERLITE Industrial Water Treatment

Uploaded by

Riski Nalendra SukmaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AMBERJET, AMBERLITE Industrial Water Treatment

Uploaded by

Riski Nalendra SukmaCopyright:

Available Formats

Ion Exchange Resins

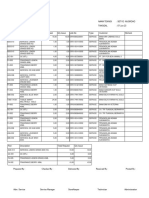

SUMMARY CHART

Resins for industrial water treatment

Min. total Mean size Temp.

Trademark Name Matrix Porosity Functionality Moisture %

cap (eq/L) µm °C max

Amberjet 1000 H Styrenic Gel SAC 53 - 58 1.8 630 120

Amberjet 1000 Na Styrenic Gel SAC 44 - 49 2.0 630 120

Amberjet 1200 H Styrenic Gel SAC 49 - 55 1.8 630 120

Amberjet 1200 Na Styrenic Gel SAC 43 - 47 2.0 630 120

Amberjet 1300 H Styrenic Gel SAC 45 - 51 2.0 650 130

Amberjet 1300 Na Styrenic Gel SAC 38 - 44 2.1 650 130

Amberjet 1500 H Styrenic Gel SAC 45 - 51 2.0 650 130

Amberjet 1600 H Styrenic Gel SAC 46 - 50 2.4 660 130

Amberjet 4200 Cl Styrenic Gel SBA, type 1 49 - 55 1.3 650 60

Amberjet 4400 Cl Styrenic Gel SBA, type 1 40 - 48 1.4 600 60

Amberjet 4400 OH Styrenic Gel SBA, type 1 54 - 60 1.1 600 60

Amberjet 4600 Cl Styrenic Gel SBA, type 2 45 - 51 1.3 670 35

Amberjet 9000 OH Styrenic Macro SBA, type 1 66 - 75 0.8 640 60

Amberlite 200C Na Styrenic Macro SAC 46 - 52 1.7 700 130

Amberlite 252 Na Styrenic Macro SAC 47 - 54 1.8 700 130

Amberlite 252RF H Styrenic Macro SAC 52 - 58 1.7 700 130

Amberlite IR120 H Styrenic Gel SAC 53 - 58 1.8 700 120

Amberlite IR120 Na Styrenic Gel SAC 44 - 49 2.0 650 120

Amberlite IRA402 Cl Styrenic Gel SBA, type 1 50 - 56 1.3 650 60

Amberlite IRA405 Cl Styrenic Gel SBA 54 - 58 1.3 600 60

Amberlite IRA410 Cl Styrenic Gel SBA, type 2 45 - 51 1.3 640 35

Amberlite IRA458 Cl Acrylic Gel SBA 57 - 62 1.25 750 35

Amberlite IRA458RF Cl Acrylic Gel SBA 57 - 62 1.25 850 35

Amberlite IRA478RF Cl Acrylic Gel WBA/SBA 58 - 63 1.15 850 25

Amberlite IRA67 Acrylic Gel WBA 56 - 64 1.6 650 60

Amberlite IRA67RF Acrylic Gel WBA 56 - 64 1.6 800 60

Amberlite IRA70RF Acrylic Gel WBA 56 - 64 1.4 810 60

Amberlite IRA743 Styrenic Macro Chelating (boron) 49 - 56 0.7 580 40

Amberlite IRA900 Cl Styrenic Macro SBA, type 1 58 - 64 1.0 730 60

Amberlite IRA900RF Cl Styrenic Macro SBA, type 1 58 - 64 1.0 760 60

Amberlite IRA910 Cl Styrenic Macro SBA, type 2 46 - 55 1.0 690 35

Amberlite IRA958 Cl Acrylic Macro SBA 66 - 72 0.8 720 80

Amberlite IRA92 Styrenic Macro WBA 40 - 50 1.60 640 100

Amberlite IRA96 Styrenic Macro WBA 57 - 63 1.25 620 100

Amberlite IRA96RF Styrenic Macro WBA 57 - 63 1.25 720 100

Amberlite IRA96SB Styrenic Macro WBA 57 - 63 1.25 510 100

Amberlite IRC747 Styrenic Macro Chelating (metals) 64 - 69 1.75 600 80

Amberlite IRC748 Styrenic Macro Chelating (metals) 60 - 65 1.35 600 90

Amberlite IRC86 Acrylic Gel WAC 47 - 53 4.1 640 120

Amberlite IRC86RF Acrylic Gel WAC 47 - 53 4.1 720 120

Amberlite IRC86SB Acrylic Gel WAC 47 - 53 4.1 530 120

Amberlite MB20 Styrenic Gel MB, regenerable 35

Amberlite MB9L Styrenic Gel MB, non-regenerable 35

Amberlite MB6113 Styrenic Gel MB, with colour indicator 35

Amberlite RF12 Polyethylene Gel Inert 2500 90

Amberlite RF14 Polypropylene Gel -

Inert 1400 90

-

Ambersep 252 H Styrenic Macro SAC 52 - 58 1.7 960 130

Ambersep 200 H Styrenic Macro SAC 50 - 57 1.7 960 130

Ambersep 349 Acrylic Gel Inert 540 80

Ambersep 900 OH Styrenic Macro SBA, type 1 66 - 75 0.7 640 60

Ambersep 900 SO4 Styrenic Macro SBA, type 1 58 - 65 1.0 620 60

| © 2010 Rohm and Haas Company | ALP IWT A – Apr 10 - 1/2

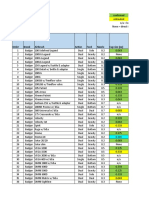

ULTRAPURE WATER

Min. total Mean size Temp.

Trademark Name Matrix Porosity Functionality Moisture %

cap (eq/L) µm °C max

Amberjet UP1400 Styrenic Gel SAC 45 - 51 2.0 650 60

Amberjet UP4000 Styrenic Gel SBA type 1 54 - 60 1.1 610 40

Amberjet UP6040 Styrenic Gel MB, Non-regenerable 40

Amberjet UP6150 Styrenic Gel MB, Regenerable 40

Amberlite UP252 Styrenic Macro SAC 52 – 58 1.7 700 60

Amberlite UP900 Styrenic Macro SBA type 1 66 - 75 0.7 640 40

INDUSTRIAL WATER TREATMENT SELECTION MAP

CFR RFR Packed Bed Stratabed Mixed Bed Triobed

WAC IRC86 IRC86RF IRC86SB

SAC IR120 Na IR120 Na Amberjet 1000 Na Amberjet 1300 H Amberjet 1200 H Amberjet 1500 H

IR120 H IR120 H Amberjet 1000 H Amberjet 1300 Na Amberjet 1300 H Ambersep 252 H

Amberjet 1000 Na Amberjet 1200 Na

Amberjet 1000 H Amberjet 1200 H

252 Na 252 Na 252RF H Amberjet 1500 H Ambersep 200 H

252RF H

WBA IRA96 IRA96RF IRA96SB

IRA67 IRA67RF

IRA70RF IRA70RF

SBA IRA402 Cl IRA402 Cl Amberjet 4200 Cl Amberjet 4400 Cl Amberjet 4200 Cl Amberjet 4200 Cl

Amberjet 4400 Cl Amberjet 4400 OH

IRA410 Cl IRA410 Cl Amberjet 4600 Cl Amberjet 4600 Cl

IRA458 Cl IRA458 Cl IRA458RF Cl IRA458RF Cl IRA458 Cl Ambersep 900 SO4

IRA478RF Cl IRA478RF Cl IRA478RF Cl IRA900 Cl Ambersep 900 OH

SCAVENGER IRA900 Cl IRA900RF Cl

IRA958 Cl

INERT RF12 RF12 RF12 Ambersep 349

RF14 RF14

Abbreviations CFR Co-flow regeneration Other resins are available for

RFR Reverse flow (counterflow) regeneration drinking water, condensate

SAC Strongly Acidic Cation exchange resin polishing, radioactive waste

SBA Strongly Basic Anion exchange resin decontamination, food processing,

WAC Weakly Acidic Cation exchange resin chemical processes, catalysis,

WBA Weakly Basic Anion exchange resin pharmaceutical applications.

MB Mixed Bed (mixture of SAC & SBA)

Macro Macroreticular (macroporous)

All resin products are manufactured in ISO 9001 certified facilities.

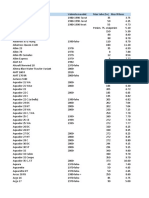

Rohm and Haas/Ion Exchange Resins - Philadelphia, PA - Tel. (800) RH AMBER - Fax: (215) 537-4157

Rohm and Haas/Ion Exchange Resins - 75579 Paris Cedex 12 - Tel. (33) 1 40 02 50 00 - Fax : 1 43 45 28 19

http://www.amberlite.com

AMBERLITE, AMBERJET AMBERSEP and TRIOBED are trademarks of Rohm and Haas Company, Philadelphia, U.S.A.

Ion exchange resins and polymeric adsorbents, as produced, contain by-products resulting from the manufacturing process. The user must determine the extent to which

organic by-products must be removed for any particular use and establish techniques to assure that the appropriate level of purity is achieved for that use. The user must

ensure compliance with all prudent safety standards and regulatory requirements governing the application. Except where specifically otherwise stated, Rohm and Haas

Company does not recommend its ion exchange resins or polymeric adsorbents, as supplied, as being suitable or appropriately pure for any particular use. Consult your Rohm

and Haas technical representative for further information. Acidic and basic regenerant solutions are corrosive and should be handled in a manner that will prevent eye and skin

contact. Nitric acid and other strong oxidising agents can cause explosive type reactions when mixed with Ion Exchange resins. Proper design of process equipment to prevent

rapid buildup of pressure is necessary if use of an oxidising agent such as nitric acid is contemplated. Before using strong oxidising agents in contact with Ion Exchange Resins,

consult sources knowledgeable in the handling of these materials.

Rohm and Haas Company makes no warranties either expressed or implied as to the accuracy or appropriateness of this data and expressly excludes any liability upon Rohm and Haas

arising out of its use. We recommend that the prospective users determine for themselves the suitability of Rohm and Haas materials and suggestions for any use prior to their adoption.

Suggestions for uses of our products or the inclusion of descriptive material from patents and the citation of specific patents in this publication should not be understood as recommending

the use of our products in violation of any patent or as permission or license to use any patents of the Rohm and Haas Company. Material Safety Data Sheets outlining the hazards and

handling methods for our products are available on request.

© 2010 Rohm and Haas Company ALP IWT A – Apr 10 - 2/2

You might also like

- Cross ReferenceDocument3 pagesCross ReferenceABDUL MUZAMMILNo ratings yet

- Stock Material Per TGL 29 Nov 2021Document14 pagesStock Material Per TGL 29 Nov 2021Reza AlfiansyahNo ratings yet

- Qazi & Sons Group of CompaniesDocument1 pageQazi & Sons Group of CompaniesNadeem AhmedNo ratings yet

- Kester - Catalogue - Kester - Consommables Pour L'électronique - 2010Document18 pagesKester - Catalogue - Kester - Consommables Pour L'électronique - 2010ZorbanfrNo ratings yet

- 20.02 Huancayo 3 ActDocument2 pages20.02 Huancayo 3 Act02-CF-HU-ELVIS CAPCHA ORIHUELANo ratings yet

- Bidco-COCA COLA PRICE LIST 11TH JULY 23Document2 pagesBidco-COCA COLA PRICE LIST 11TH JULY 23nicole wanjaNo ratings yet

- Approved Rates of Plant Protection Chemicals 2011Document209 pagesApproved Rates of Plant Protection Chemicals 2011C.G. CropCareNo ratings yet

- Pricelist 2020 Bahan Farmasi - 1Document7 pagesPricelist 2020 Bahan Farmasi - 1ningsih rezekiNo ratings yet

- No Description COO Qty Pack Brand Model Unit Price/USD: Thermo Scientific OV/100/SS/F/DIG INC/100/SS/DIGDocument4 pagesNo Description COO Qty Pack Brand Model Unit Price/USD: Thermo Scientific OV/100/SS/F/DIG INC/100/SS/DIGlusoegyi 1919No ratings yet

- DefomerDocument37 pagesDefomerKassahun LeykunNo ratings yet

- Chemical ListDocument3 pagesChemical ListNooranisa SsgyNo ratings yet

- Inventario PinturasDocument8 pagesInventario Pinturaseddy vilcaNo ratings yet

- Lampiran SHSR 3. (Bahan Kimia) FinalDocument5 pagesLampiran SHSR 3. (Bahan Kimia) FinalyayansudiantoNo ratings yet

- Stok Dan Estimasi Pemakaian Chemical Jan 2024Document43 pagesStok Dan Estimasi Pemakaian Chemical Jan 2024slamet supriyadiNo ratings yet

- List of Registered Agricultural PesticidesDocument56 pagesList of Registered Agricultural Pesticidespo83% (6)

- Pages From International Price List 90.3 4Document1 pagePages From International Price List 90.3 4dunglxNo ratings yet

- JKDocument4 pagesJKdana setiawanNo ratings yet

- Control de Materias Primas - Enero 2024Document28 pagesControl de Materias Primas - Enero 2024ftony.santosNo ratings yet

- EIS MARITIMO Price List Bonded StoresDocument1 pageEIS MARITIMO Price List Bonded Storesvodoley634No ratings yet

- Musim Tanam Sumbar Tahun - 2022Document3 pagesMusim Tanam Sumbar Tahun - 2022Admin8 DalzonNo ratings yet

- Produk Kode Ruah Nama Produk Bs Mixing (Liter) Bs Filling (Botol)Document2 pagesProduk Kode Ruah Nama Produk Bs Mixing (Liter) Bs Filling (Botol)Andy FauziNo ratings yet

- Lista de Precios Agosto 2022Document9 pagesLista de Precios Agosto 2022RuvigleidysDeLosSantosNo ratings yet

- Certified Wood Stove Manufacturers: 2014Document33 pagesCertified Wood Stove Manufacturers: 2014Vimarsha HSNo ratings yet

- Stok 10novDocument195 pagesStok 10novNando AswinNo ratings yet

- Chemical StockDocument20 pagesChemical StockTsegaye Mokonen TsmNo ratings yet

- Maximum Retail Price: 2T Specification 20 40 60 250 500 1 5Document2 pagesMaximum Retail Price: 2T Specification 20 40 60 250 500 1 5Nitansh GuptaNo ratings yet

- Tradução Artigo - EstéticaInDocument14 pagesTradução Artigo - EstéticaInMls RTNo ratings yet

- Inflamable 2Document4 pagesInflamable 2isabelaNo ratings yet

- Medicine Price List MPL Acute and Chronic November 2020Document123 pagesMedicine Price List MPL Acute and Chronic November 2020karar hussainNo ratings yet

- Stok 23 JanDocument196 pagesStok 23 JanNando AswinNo ratings yet

- Noka Drink NewDocument8 pagesNoka Drink NewOch gerelNo ratings yet

- So Rawan Hilang Pnm3 Update NovDocument6 pagesSo Rawan Hilang Pnm3 Update Novahaekal81No ratings yet

- BAQ Report-RPT - MtlReq (Printout Material Request) - 73655Document2 pagesBAQ Report-RPT - MtlReq (Printout Material Request) - 73655Altorik Syah putraNo ratings yet

- Nuevo Microsoft Excel WorksheetDocument1 pageNuevo Microsoft Excel WorksheetLaura Villegas jimenezNo ratings yet

- AMBERLITE™ Ion Exchange Resins For Industrial Water Treatment and Power GenerationDocument2 pagesAMBERLITE™ Ion Exchange Resins For Industrial Water Treatment and Power GenerationMandiriNo ratings yet

- Spectra 977 Process: Technical Data SheetDocument2 pagesSpectra 977 Process: Technical Data SheetLuuThiThuyDuongNo ratings yet

- Daftar Stok 27-7-23-1Document58 pagesDaftar Stok 27-7-23-1klinik olasviNo ratings yet

- Master Opname Update 11 Nov 2019 Zoya BanjarDocument206 pagesMaster Opname Update 11 Nov 2019 Zoya BanjarIndra HermansyahNo ratings yet

- November PricelistDocument5 pagesNovember PricelistGeoffrey Vin GumatayNo ratings yet

- Screenshot 2023-03-30 at 20.17.14Document1 pageScreenshot 2023-03-30 at 20.17.14Divan LouwNo ratings yet

- DAFTAR HARGA NurjayaDocument4 pagesDAFTAR HARGA NurjayabadriNo ratings yet

- Chemical Stock DataDocument18 pagesChemical Stock DataTsegaye Mokonen TsmNo ratings yet

- Order Brand Airbrush Action Feed Nozzle Cup Size (Oz)Document6 pagesOrder Brand Airbrush Action Feed Nozzle Cup Size (Oz)Stephen WhiteNo ratings yet

- Vanhemmat Venemallit Ja KonetehotDocument268 pagesVanhemmat Venemallit Ja KonetehotAllu AhoNo ratings yet

- Agma Ep Gear OilDocument2 pagesAgma Ep Gear OilMauricioNo ratings yet

- Microbiology Available Equipments Data As Per NABL FormatDocument8 pagesMicrobiology Available Equipments Data As Per NABL FormatKrishna ChaitanyaNo ratings yet

- NA 2015 DEM-Demulsifiers-251403Document8 pagesNA 2015 DEM-Demulsifiers-251403Fabian ArboledaNo ratings yet

- No. Jenis Reel Satuan Harga Jumlah: Ranumila Fishing Tackle - SidarejaDocument2 pagesNo. Jenis Reel Satuan Harga Jumlah: Ranumila Fishing Tackle - SidarejaMavic osssNo ratings yet

- FG ConvertorDocument39 pagesFG ConvertorNabeelNo ratings yet

- Barberking: Price List Hair Care & Styling ProductDocument5 pagesBarberking: Price List Hair Care & Styling ProductAhza DanishNo ratings yet

- 2 Talcor ProductsDocument27 pages2 Talcor ProductsAymanSayedElantableeNo ratings yet

- Codigos de BarraDocument12 pagesCodigos de BarraJonathan Vasquez BuzonNo ratings yet

- Catálogo SuplementosDocument55 pagesCatálogo SuplementosMarcilio BrunoNo ratings yet

- Lplpo Pasilambena 2023Document177 pagesLplpo Pasilambena 2023idahNo ratings yet

- RM Pricelist 170101Document13 pagesRM Pricelist 170101Dumitru MariusNo ratings yet

- New Updated Rate List 28-05-20 PDFDocument3 pagesNew Updated Rate List 28-05-20 PDFZubairBinYounasNo ratings yet

- 72315390biosash Order Form Sep-19Document2 pages72315390biosash Order Form Sep-19Deepak Naik100% (2)

- Balmatech Greases Compiled VersionsDocument2 pagesBalmatech Greases Compiled VersionsAnalista De CalidadNo ratings yet

- Informe Mensual de Precios de Venta de Plaguicidas - Agencias Agrarias Precio Casas Comerciales (S/. X Unidad de Medida)Document12 pagesInforme Mensual de Precios de Venta de Plaguicidas - Agencias Agrarias Precio Casas Comerciales (S/. X Unidad de Medida)Mike MillaNo ratings yet

- h4 Presure Vessels and Water Storage TanksDocument69 pagesh4 Presure Vessels and Water Storage TanksRakesh Ranjan100% (1)

- Cooling System ArticleDocument16 pagesCooling System ArticleRiski Nalendra SukmaNo ratings yet

- Prepare Your Cooling System Before Startup - CEP - Jul 2012 PDFDocument5 pagesPrepare Your Cooling System Before Startup - CEP - Jul 2012 PDFonizuka-t2263No ratings yet

- Resin LewatitDocument15 pagesResin LewatitRiski Nalendra SukmaNo ratings yet

- Turbidity, (FAU), Method 8237, 02-2009, 9th EdDocument4 pagesTurbidity, (FAU), Method 8237, 02-2009, 9th EdRiski Nalendra SukmaNo ratings yet

- Grade Thresholds - November 2018: Cambridge International AS & A Level Mathematics (9709)Document3 pagesGrade Thresholds - November 2018: Cambridge International AS & A Level Mathematics (9709)redwanNo ratings yet

- Philippine College of Science and Technology: Assignment For Module 1 Nge6 (Art Appreciation)Document1 pagePhilippine College of Science and Technology: Assignment For Module 1 Nge6 (Art Appreciation)Mark Brendon Jess VargasNo ratings yet

- October 2016 2Document16 pagesOctober 2016 2Tanvika AroraNo ratings yet

- Sheree Hendersonresume 2Document3 pagesSheree Hendersonresume 2api-265774249No ratings yet

- One-Dimensional Unconstrained Optimization: Example 1 Golden Section MethodDocument5 pagesOne-Dimensional Unconstrained Optimization: Example 1 Golden Section MethodMohamed MuayidNo ratings yet

- 30 Tips For Indesign Users enDocument38 pages30 Tips For Indesign Users enMoo MNo ratings yet

- Original PDF Biological Psychology 1st Edition by Kelly G Lambert PDFDocument41 pagesOriginal PDF Biological Psychology 1st Edition by Kelly G Lambert PDFclarence.barcia711100% (35)

- Employee Engagement - Korn - Ferry InternationalDocument2 pagesEmployee Engagement - Korn - Ferry InternationalЯрослава ЛояничNo ratings yet

- Class-5 Unit-5 (Prose) Shabale (Sabala)Document16 pagesClass-5 Unit-5 (Prose) Shabale (Sabala)GKHPS B HOSAHALLINo ratings yet

- Reducing Streetism: A Neglected Cause of Social Anxiety and Delinquency in Adama CityDocument25 pagesReducing Streetism: A Neglected Cause of Social Anxiety and Delinquency in Adama CityKorie ArsieNo ratings yet

- ADM - DIASS 11 Q4 Weeks 1-8 - LatestDocument28 pagesADM - DIASS 11 Q4 Weeks 1-8 - LatestjoyceNo ratings yet

- Ministry of Health and Family Welfare Pregnancy GuidelinesDocument173 pagesMinistry of Health and Family Welfare Pregnancy GuidelinesKhushi GuptaNo ratings yet

- Alexander Lowen - The Language of The Body (Physical Dynamics of Character Structure) (1958, Psychology, Freud)Document404 pagesAlexander Lowen - The Language of The Body (Physical Dynamics of Character Structure) (1958, Psychology, Freud)Barbara Kubiec75% (4)

- Breathwork Fundamentals GuidebookDocument148 pagesBreathwork Fundamentals GuidebookJuliana RennerNo ratings yet

- Weekly Home Learning Plan (Q3) Self-Learning Module 4 (Week 5)Document2 pagesWeekly Home Learning Plan (Q3) Self-Learning Module 4 (Week 5)Richie MacasarteNo ratings yet

- EDUC 7 Detailed Lesson Plan in Science VIDocument8 pagesEDUC 7 Detailed Lesson Plan in Science VIRosemarie Garing100% (2)

- RA-080202 - PROFESSIONAL TEACHER - Secondary (Mathematics) - KORONADAL CITY - 10-2022Document39 pagesRA-080202 - PROFESSIONAL TEACHER - Secondary (Mathematics) - KORONADAL CITY - 10-2022Fretzie CambiadoNo ratings yet

- A Peer Reviewed Research Journal On Language, Literature & Culture'sDocument8 pagesA Peer Reviewed Research Journal On Language, Literature & Culture'sTRISANGAM INTERNATIONAL REFEREED JOURNAL (TIRJ) EDITOR - MR. PRASENJIT ROYNo ratings yet

- Session Nos. 26 - 31: Cities of Mandaluyong and PasigDocument25 pagesSession Nos. 26 - 31: Cities of Mandaluyong and PasigLego AlbertNo ratings yet

- Problem Set Math Day 1-4Document15 pagesProblem Set Math Day 1-4vince rian legaspi100% (3)

- Genomic and CDNA LibrariesDocument15 pagesGenomic and CDNA LibrariesPrabhleen KaurNo ratings yet

- Natal Chart ReportDocument22 pagesNatal Chart ReportIngridNo ratings yet

- DLL-All Subjects - Week 7 Day 1Document5 pagesDLL-All Subjects - Week 7 Day 1Windel Beth Quimat ZafraNo ratings yet

- Basic Science AssigDocument5 pagesBasic Science AssigdomromeoNo ratings yet

- Research Methodology and Biostatistics - Syllabus & Curriculum - M.D (Hom) - WBUHSDocument5 pagesResearch Methodology and Biostatistics - Syllabus & Curriculum - M.D (Hom) - WBUHSSumanta KamilaNo ratings yet

- Generative NLP Robert Dilts PDFDocument11 pagesGenerative NLP Robert Dilts PDFCristina LorinczNo ratings yet

- Curriculam Vitae OF MD - Nazmus Sakib Khan: Career ObjectivesDocument4 pagesCurriculam Vitae OF MD - Nazmus Sakib Khan: Career ObjectivesRubayetNo ratings yet

- Wre MCQDocument136 pagesWre MCQsurendranath jadhavNo ratings yet

- Research ProposalDocument2 pagesResearch ProposalAnika AroviNo ratings yet

- Astm D2777 Determinacion de La Precision y El Sesgo PDFDocument21 pagesAstm D2777 Determinacion de La Precision y El Sesgo PDFAlvaro Pérez PérezNo ratings yet