Professional Documents

Culture Documents

Bearing Failure Analysis 180629053850 SKF

Uploaded by

angelsalinasbaltazarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bearing Failure Analysis 180629053850 SKF

Uploaded by

angelsalinasbaltazarCopyright:

Available Formats

Bearing Failure Analysis

2013-09-13 ©SKF Slide 1 [Code]

SKF [Organisation]

Bearing failure analysis

Overview:

•Load path patterns

•Failure mode classification

•How to secure evidence

•Hands-on exercises

2013-09-13 ©SKF Slide 2 [Code]

SKF [Organisation]

Bearing failure analysis

The best way to become expert is to examine damaged bearings. Evidence will emerge

to allow root cause analysis and hence corrective action. Many of ball and roller bearings

never attain their calculated life expectancy. .

The calculated life expectancy of any bearing is based on four assumptions:

1.Good lubrication in proper quantity will always be available to the bearing.

2.The bearing will be mounted without damage.

3.Dimensions of parts related to the bearing will be correct.

4.There are no defects inherent in the bearing.

2013-09-13 ©SKF Slide 3 [Code]

SKF [Organisation]

Bearing failure analysis

Even if all the four conditions are met, the bearing may still

fail due to fatigue of bearing material.

Three major classifications of premature spalling are

lubrication, mechanical damage, and material defects.

2013-09-13 ©SKF Slide 4 [Code]

SKF [Organisation]

Bearing failure analysis

Most bearing failures can be attributed to one or more of the

following causes:

1. Defective bearing seats on shafts and in housings.

2. Misalignment.

3. Faulty mounting practice

4. Incorrect shaft and housing fits.

5. Inadequate lubrication.

6. Ineffective sealing.

7. Vibration while the bearing is not rotating

8. Passage of electric current through the bearing.

9. Transportation, storage and handling.

2013-09-13 ©SKF Slide 6 [Code]

SKF [Organisation]

Load paths

2013-09-13 ©SKF Slide 7 [Code]

SKF [Organisation]

Normal radial load zones…

2013-09-13 ©SKF Slide 8 [Code]

SKF [Organisation]

Normal radial load zones…

Stationary outer ring

Rotating inner ring

Constant unidirectional loads

2013-09-13 ©SKF Slide 9 [Code]

SKF [Organisation]

Normal radial load zones

Stationary inner ring

Rotating outer ring

Constant unidirectional load

2013-09-13 ©SKF Slide 10 [Code]

SKF [Organisation]

Combined (radial and axial) load

Stationary outer ring

Rotating inner ring

Constant unidirectional radial and axial loads

2013-09-13 ©SKF Slide 11 [Code]

SKF [Organisation]

Pure Axial load

2013-09-13 ©SKF Slide 12 [Code]

SKF [Organisation]

Misalignment of outer ring

2013-09-13 ©SKF Slide 13 [Code]

SKF [Organisation]

Ovalised outer ring

2013-09-13 ©SKF Slide 15 [Code]

SKF [Organisation]

Out of round housing

2013-09-13 ©SKF Slide 16 [Code]

SKF [Organisation]

Tight fit - preloading

2013-09-13 ©SKF Slide 17 [Code]

SKF [Organisation]

Eccentric radial load

2013-09-13 ©SKF Slide 18 [Code]

SKF [Organisation]

Imbalance

2013-09-13 ©SKF Slide 19 [Code]

SKF [Organisation]

Failure mode classification

• Causes of failures have identifiable characteristics

• Failure mechanisms have identifiable failure modes

• Observed damage can identify failure causes

2013-09-13 ©SKF Slide 20 [Code]

SKF [Organisation]

Failure modes

Subsurface fatigue

Fatigue

Surface initiated fatigue

Abrasive wear

Wear

Adhesive wear

Moisture corrosion

Corrosion

Fretting corrosion

Excessive voltage

Electrical erosion

Current leakage

Overload Indents from debris

Plastic deformation

Indentation

Indents by handling

Forced fracture

Fracture Fatigue fracture

Thermal cracking

2013-09-13 ©SKF Slide 21 [Code]

SKF [Organisation]

Subsurface fatigue

Subsurface fatigue

Fatigue

Surface initiated fatigue

Wear

Corrosion

Electrical erosion

Plastic deformation

Fracture

• Repeated stress changes

• Material structural

• Micro cracks under the surface changes

• Crack propagation

• Flaking and peeling

2013-09-13 ©SKF Slide 22 [Code]

SKF [Organisation]

Fatigue spall

2013-09-13 ©SKF Slide 23 [Code]

SKF [Organisation]

Edge loading

2013-09-13 ©SKF Slide 24 [Code]

SKF [Organisation]

True brinelling

2013-09-13 ©SKF Slide 25 [Code]

SKF [Organisation]

Surface initiated fatigue

Subsurface fatigue

Fatigue

Surface initiated fatigue

Wear

Corrosion

• Surface distress 40 µm

Electrical erosion • Reduced lubrication

• Sliding motion

Plastic deformation • Severity micro cracks

Fracture

2013-09-13 ©SKF Slide 26 [Code]

SKF [Organisation]

Abrasive wear

• Progressive removal of material

• Accelerating process

• Inadequate lubrication

• Ingress of dirt particles Fatigue

Abrasive wear

Wear

Adhesive wear

Corrosion

Electrical erosion

Plastic deformation

Fracture

2013-09-13 ©SKF Slide 29 [Code]

SKF [Organisation]

Wear

2013-09-13 ©SKF Slide 30 [Code]

SKF [Organisation]

Adhesive wear

Fatigue

Abrasive wear

Wear

Adhesive wear

Corrosion

• Smearing / skidding / galling

Electrical erosion • Material transfer / friction heat

• Tempering / rehardening with stress

Plastic deformation concentrations and cracking or flaking

• Low loads

Fracture • Accelerations

2013-09-13 ©SKF Slide 32 [Code]

SKF [Organisation]

Adhesive wear

Fatigue

Abrasive wear

Wear

Adhesive wear

Corrosion

• It is a material transfer from one

Electrical erosion surface to another high temperature

resulting in tempering and

Plastic deformation rehardening of material

Fracture

2013-09-13 ©SKF Slide 33 [Code]

SKF [Organisation]

Temperature discoloration

150° - 177° C (300° - 350° F)

177° - 205° C (350° - 400° F)

205° - 260° C (400° - 500° F)

+ 260° C (+ 500° F)

+ 540° C (+ 1000° F)

• SKF Bearings can be used at temperatures up to

125° C (~ 250° F)

• Higher temperatures may cause loss of Hardness

• Loss of 2-4 points of Rockwell Hardness reduces life 50%

2013-09-13 ©SKF Slide 34 [Code]

SKF [Organisation]

Corrosion

Rust will form if water or corrosive agents reach the in side of the bearing In

Fatigue such quantities that the lubricant can not provide adequate protection.

Wear

Moisture corrosion

Corrosion

Fretting corrosion

Electrical erosion

Plastic deformation • Oxidation / rust

• Chemical reaction

Fracture • Etching (water / oil

mixture)

2013-09-13 ©SKF Slide 35 [Code]

SKF [Organisation]

Ineffective sealing

2013-09-13 ©SKF Slide 36 [Code]

SKF [Organisation]

False brinelling…

Fatigue

Wear

Moisture corrosion

Corrosion

Fretting corrosion

Electrical erosion

Plastic deformation

• Rolling element / raceway

Fracture • Micro movements / elastic deformations

• Vibrations

• Corrosion / wear: shiny or reddish depressions

• Stationary: Damage at rolling element spacing

• Rotating: Damage exhibits parallel flutes

2013-09-13 ©SKF Slide 37 [Code]

SKF [Organisation]

Fretting corrosion

Fatigue

Wear

Moisture corrosion

Corrosion

Fretting corrosion

Electrical erosion

Plastic deformation

• Rolling element / raceway

Fracture • Micro movements / elastic deformations

• Vibrations

• Corrosion / wear: shiny or reddish depressions

• Stationary: Damage at rolling element spacing

• Rotating: Damage exhibits parallel flutes

2013-09-13 ©SKF Slide 38 [Code]

SKF [Organisation]

Advanced fretting…

2013-09-13 ©SKF Slide 39 [Code]

SKF [Organisation]

Advanced fretting

2013-09-13 ©SKF Slide 40 [Code]

SKF [Organisation]

Electrical erosion

Fatigue

• High current = sparking

• Instant localized heating Wear

leads to melting and/or

welding Corrosion

Excessive voltage

• Craters up to 100 µm Electrical erosion

Current leakage

Plastic deformation

Fracture

2013-09-13 ©SKF Slide 41 [Code]

SKF [Organisation]

Electrical erosion – excessive voltage

2013-09-13 ©SKF Slide 42 [Code]

SKF [Organisation]

Electrical erosion

Fatigue

• Low current intensity

Wear

• Shallow craters

Corrosion closely positioned

Excessive voltage

Electrical erosion

Current leakage

• Development of

flutes on raceways

Plastic deformation

and rollers, parallel

Fracture to rolling axis

• Dark gray

discoloration

2013-09-13 ©SKF Slide 43 [Code]

SKF [Organisation]

Vibration

2013-09-13 ©SKF Slide 44 [Code]

SKF [Organisation]

Current leakage

2013-09-13 ©SKF Slide 45 [Code]

SKF [Organisation]

Electric current passage solutions

Hybrid deep groove Insocoat

ball bearing

2013-09-13 ©SKF Slide 46 [Code]

SKF [Organisation]

Overload

Fatigue • Static or shock loads

Wear

• Plastic deformations

• Depressions at rolling element spacing

Corrosion • Handling damage

Electrical erosion

Overload

Plastic deformation Indents from debris

Indentation

Fracture Indents by handling

2013-09-13 ©SKF Slide 47 [Code]

SKF [Organisation]

Installation damage

2013-09-13 ©SKF Slide 48 [Code]

SKF [Organisation]

Debris denting

Fatigue • Localized overloading

Wear • Over-rolling of particles = dents

Corrosion • Caused by soft / hardened steel / hard mineral

particles

Electrical erosion

Overload

Plastic deformation Indents from debris

Indentation

Fracture Indents by handling

2013-09-13 ©SKF Slide 49 [Code]

SKF [Organisation]

Handling damage…

• Localized overloading

• Nicks caused by hard /

sharp objects

Fatigue

Wear

Corrosion

Electrical erosion

Overload

Plastic deformation Indents from debris

Indentation

Fracture Indents by handling

2013-09-13 ©SKF Slide 50 [Code]

SKF [Organisation]

Handling damage

2013-09-13 ©SKF Slide 51 [Code]

SKF [Organisation]

CRB roller damage

2013-09-13 ©SKF Slide 52 [Code]

SKF [Organisation]

Forced fracture…

Fatigue

Wear

• Stress concentration exceeds tensile strength

Corrosion • Impact / overstressing

Electrical erosion

Plastic deformation Forced fracture

Fracture Fatigue fracture

Thermal cracking

2013-09-13 ©SKF Slide 53 [Code]

SKF [Organisation]

Forced fracture…

2013-09-13 ©SKF Slide 54 [Code]

SKF [Organisation]

Fatigue fracture

Fatigue • Exceeding fatigue

strength under

Wear bending

Corrosion

• Crack initiation /

Electrical erosion

propagation

Plastic deformation Forced fracture • Finally forced fracture

Fracture Fatigue fracture

• Rings and Cages

Thermal cracking

2013-09-13 ©SKF Slide 55 [Code]

SKF [Organisation]

Thermal cracking

Fatigue • High sliding and / or

insufficient lubrication

Wear • High friction heat

• Cracks at right angle to

Corrosion sliding direction

Electrical erosion

Plastic deformation Forced fracture

Fracture Fatigue fracture

Thermal cracking

2013-09-13 ©SKF Slide 56 [Code]

SKF [Organisation]

Securing evidence

• Collect operating data, monitoring data

• Collect lubricant samples

• Check bearing environment(s)

• Assess bearing(s) in mounted condition

• Mark mounting position(s)

• Remove, mark and bag bearing(s) and parts

• Check bearing seats

2013-09-13 ©SKF Slide 58 [Code]

SKF [Organisation]

Conducting the analysis

Examine Bearing(s) and Parts

• Record visual observations

• Use the Failure Modes to eliminate improbable possible causes and

determine the original cause of the failure.

• Contact external resources for assistance, if needed

• Initiate corrective action, if desired

2013-09-13 ©SKF Slide 59 [Code]

SKF [Organisation]

False brinelling

2013-09-13 ©SKF Slide 60 [Code]

SKF [Organisation]

You might also like

- p-7770-sv Svendborg BrakeDocument1 pagep-7770-sv Svendborg BrakeangelsalinasbaltazarNo ratings yet

- Manual 1 Lightnin Mixer Model X6Q100 Line 10.PRECOATDocument34 pagesManual 1 Lightnin Mixer Model X6Q100 Line 10.PRECOATangelsalinasbaltazar50% (2)

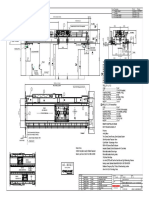

- H12303 002 (3) As - BuiltDocument1 pageH12303 002 (3) As - BuiltangelsalinasbaltazarNo ratings yet

- Instruction Manual - Automatic Grease Lubrication System For Decanters - ES - 8175-9005-008Document14 pagesInstruction Manual - Automatic Grease Lubrication System For Decanters - ES - 8175-9005-008angelsalinasbaltazarNo ratings yet

- Series 9000 y 8000Document4 pagesSeries 9000 y 8000angelsalinasbaltazarNo ratings yet

- El Abra Conveyor CV205 Test ReportDocument22 pagesEl Abra Conveyor CV205 Test ReportangelsalinasbaltazarNo ratings yet

- El Abra Conveyor CV205 Test ReportDocument22 pagesEl Abra Conveyor CV205 Test ReportangelsalinasbaltazarNo ratings yet

- A 108 - 99 Qtewoc05oq - PDFDocument4 pagesA 108 - 99 Qtewoc05oq - PDFangelsalinasbaltazarNo ratings yet

- A 372 - A 372M - 99 Qtm3mi05oqDocument4 pagesA 372 - A 372M - 99 Qtm3mi05oqangelsalinasbaltazarNo ratings yet

- EM 1110-1-4008 Engineer Manual, Design Liquid Process Piping (US Army 1999)Document244 pagesEM 1110-1-4008 Engineer Manual, Design Liquid Process Piping (US Army 1999)Bogdan BulgariuNo ratings yet

- A 291 - 02 Qti5ms1sruqDocument7 pagesA 291 - 02 Qti5ms1sruqangelsalinasbaltazarNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Pizza Restaurant PowerPoint TemplatesDocument49 pagesPizza Restaurant PowerPoint TemplatesAindrila BeraNo ratings yet

- Aex-Kissan KeralaDocument25 pagesAex-Kissan Keralabsh08070No ratings yet

- Volcanoes Sub-topic:Volcanic EruptionDocument16 pagesVolcanoes Sub-topic:Volcanic EruptionVhenz MapiliNo ratings yet

- Gigabyte Ga b85m Ds3h A r10 PDFDocument30 pagesGigabyte Ga b85m Ds3h A r10 PDFMartha Lorena TijerinoNo ratings yet

- MATH 304 Linear Algebra Lecture 9 - Subspaces of Vector Spaces (Continued) - Span. Spanning Set PDFDocument20 pagesMATH 304 Linear Algebra Lecture 9 - Subspaces of Vector Spaces (Continued) - Span. Spanning Set PDFmurugan2284No ratings yet

- Hand Winches 122 Load Sheaves 126 Gear-And Worm Gear Winches 127 Electric Worm Gear Winches 131 Snatch Blocks 133Document14 pagesHand Winches 122 Load Sheaves 126 Gear-And Worm Gear Winches 127 Electric Worm Gear Winches 131 Snatch Blocks 133Rajaram JayaramanNo ratings yet

- All About TarlacDocument12 pagesAll About TarlacAnonymous uLb5vOjXNo ratings yet

- Iso Iec 25030 2007 eDocument44 pagesIso Iec 25030 2007 eAngélica100% (1)

- Kursus Jabatan Kejuruteraan Mekanikal Sesi Jun 2014Document12 pagesKursus Jabatan Kejuruteraan Mekanikal Sesi Jun 2014ihsanyusoffNo ratings yet

- On The Wings of EcstasyDocument79 pagesOn The Wings of Ecstasygaya3mageshNo ratings yet

- The Limits of The Sectarian Narrative in YemenDocument19 pagesThe Limits of The Sectarian Narrative in Yemenهادي قبيسيNo ratings yet

- The Determinants of Corporate Dividend PolicyDocument16 pagesThe Determinants of Corporate Dividend PolicyRutvikNo ratings yet

- Materials Management - 1 - Dr. VP - 2017-18Document33 pagesMaterials Management - 1 - Dr. VP - 2017-18Vrushabh ShelkarNo ratings yet

- Rare Watches (Christie's) 16. 05. 2016.Document236 pagesRare Watches (Christie's) 16. 05. 2016.Simon LászlóNo ratings yet

- Hackerearth Online Judge: Prepared By: Mohamed AymanDocument21 pagesHackerearth Online Judge: Prepared By: Mohamed AymanPawan NaniNo ratings yet

- Teaching PowerPoint Slides - Chapter 5Document19 pagesTeaching PowerPoint Slides - Chapter 5Azril ShazwanNo ratings yet

- An Introduction To Routine and Special StainingDocument13 pagesAn Introduction To Routine and Special StainingBadiu ElenaNo ratings yet

- RS-All Digital PET 2022 FlyerDocument25 pagesRS-All Digital PET 2022 FlyerromanNo ratings yet

- 3E Hand Over NotesDocument3 pages3E Hand Over NotesAshutosh MaiidNo ratings yet

- EDAG0007Document5 pagesEDAG0007krunalNo ratings yet

- ANTINEOPLASTICSDocument21 pagesANTINEOPLASTICSGunjan KalyaniNo ratings yet

- Masking Conventional Metallic Cast Post For Enhancing EstheticsDocument5 pagesMasking Conventional Metallic Cast Post For Enhancing EstheticsleilyanisariNo ratings yet

- 2023 2024 Syllabus PDFDocument23 pages2023 2024 Syllabus PDFRika DianaNo ratings yet

- Class 1 KeyDocument3 pagesClass 1 Keyshivamsingh.fscNo ratings yet

- FIGMADocument22 pagesFIGMACessNo ratings yet

- 2021 Individual 20546 (Lawrence, Stephen R. and Bette F.) ClientDocument18 pages2021 Individual 20546 (Lawrence, Stephen R. and Bette F.) ClientVANDA MOORENo ratings yet

- Reinforced Concrete Design PDFDocument1 pageReinforced Concrete Design PDFhallelNo ratings yet

- Chemical & Biological Depopulation (By Water Floridation and Food Additives or Preservatives) PDFDocument178 pagesChemical & Biological Depopulation (By Water Floridation and Food Additives or Preservatives) PDFsogunmola100% (2)

- Nursing Assessment in Family Nursing PracticeDocument22 pagesNursing Assessment in Family Nursing PracticeHydra Olivar - PantilganNo ratings yet

- AN44061A Panasonic Electronic Components Product DetailsDocument3 pagesAN44061A Panasonic Electronic Components Product DetailsAdam StariusNo ratings yet