Professional Documents

Culture Documents

1-SOP For Raw Mill Start

Uploaded by

vinodsnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1-SOP For Raw Mill Start

Uploaded by

vinodsnCopyright:

Available Formats

UNITED CEMENTS PVT. LTD.

JUGEDI,

NAUBESI, NEPAL DOC. NO.: PRD-SOP-001

REV NO.:

INTEGRATED MANAGEMENT SYSTEM

EFF. DATE:

PROCESS DEPARTMENT

PAGE: 1 OF 2

Title: RAW MILL GRINDING

1.0 PURPOSE- To establish a safe working procedure for Raw Mill Grinding

2.0 SCOPE- Raw Mill (Lime Stone, Sand, Clay and Steatite)

3.0 DEFINITIONS :

3.1 RBC-Rubber belt conveyor

3.2 WF –Weigh Feeder

3.3 RM-Raw Mill

3.4 Lub.-Lubrication

3.5 Start up clearance from all concerned Departments

3.6 PPE-Personal protective Equipment’s

3.7 MA-Machine Attendant

4.0 RESPONSIBILITY: HOD production is over all responsible , individual responsibility

is given below

5.0 DESCRIPTION

S. No. Activity Responsi Ref. Doc.

bility

Take Start Clearance From all concerned

1 CCR -

Departments

Proper Safety talk should hold between workman

2 CCR -

and in charge

Millers/Ma

3 Wear PPE’s before starting the work chine -

attendant

Prior to start groups, all equipment should be in

healthy condition. At the start of the shift, before

4 CCR -

running Mill thoroughly check as per

recommendations. If it is OK then only start.

5 Trail run Test of all equipment’s CCR HCIL(AMS)-PRD-F-006

6 Start to fill raw material hopper CCR -

7 Start the Transport System CCR HCIL(AMS)-PRD-F-001

8 Start the Recirculation System CCR HCIL(AMS)-PRD-F-001

9 Start the Lubrication System CCR -

UNITED CEMENTS PVT. LTD. JUGEDI,

NAUBESI, NEPAL DOC. NO.: PRD-SOP-001

REV NO.:

INTEGRATED MANAGEMENT SYSTEM

EFF. DATE:

PROCESS DEPARTMENT

PAGE: 2 OF 2

Title: RAW MILL GRINDING

10 Start the Auxiliary drive CCR -

HCIL(AMS)-PRD-F-001

11 Start the Main Drive CCR

HCIL(AMS)-PRD-F-007

Raise the Inlet Temperature by opening the Hot

12 CCR HCIL(AMS)-PRD-F-001

gas damper

Start Mill feed system , adjust feed ratio as per

13 CCR HCIL(AMS)-PRD-F-001

QC instruction

14 Check the ESP Transformer CCR HCIL(AMS)-PRD-F-001

HCIL(AMS)-PRD-F-001

15 Maintain the Daily log books of operation. CCR

HCIL(AMS)-PRD-F-006

If any abnormal sound observed from any

16 machinery, than stopped from site immediately to Miller HCIL(AMS)-PRD-F-007

avoid major break-down.

Before inspection of all the equipment take HCIL(AMS)-SAF-F-001

17 CCR

related work permit. HCIL(AMS)-SAF-F-003

Time to time interlocking to be checked, to avoid CCR/Ele.D

18 -

major accident. ept

Ideal running of the equipment to be avoided

19 CCR -

regarding and top up of grinding media timely

Pl ensures no unauthorized person is standing

20 Miller/MA -

near the mill platform/any equipment’s.

6.0 REFERENCES (Incl. External Origin Docs):

Nil

7.0 RECORDS:

7.1 HCIL(AMS)-PRD-F-001

7.2 HCIL(AMS)-PRD-F-007

You might also like

- 1.inter Lock List For Rotary KilnDocument3 pages1.inter Lock List For Rotary KilnRaji SuriNo ratings yet

- Green Co Best Practice Award 2016 PresentationDocument22 pagesGreen Co Best Practice Award 2016 PresentationSivakumaran RajuNo ratings yet

- White Paper - HolcimIEEE - AirDocument11 pagesWhite Paper - HolcimIEEE - AirKenny RuizNo ratings yet

- Inspection Check List (Raw Mill-II)Document1 pageInspection Check List (Raw Mill-II)Irfan Ahmed100% (1)

- SOP - Kiln Stopping ProcedureDocument2 pagesSOP - Kiln Stopping ProcedureJCS100% (1)

- 1.SOP-Castable Refractory Work at Pre-Heater. Kiln Inlet, TAD & CoolerDocument2 pages1.SOP-Castable Refractory Work at Pre-Heater. Kiln Inlet, TAD & CoolerJCSNo ratings yet

- Gear and equipment specification summaryDocument4 pagesGear and equipment specification summaryprashant mishraNo ratings yet

- Raw Mill Startup and Operation GuideDocument4 pagesRaw Mill Startup and Operation GuideJCS100% (1)

- Dust CollectorDocument24 pagesDust Collectorafroz ahmedNo ratings yet

- Presep Air Separator VTP enDocument6 pagesPresep Air Separator VTP enBrunoNo ratings yet

- Kiln Emergency YSDocument50 pagesKiln Emergency YSMUhammad Ishfaq Shakoor100% (1)

- Cement Mill ReportDocument13 pagesCement Mill ReportYhaneNo ratings yet

- Kiln Thruster LogicDocument3 pagesKiln Thruster LogicSameer kumar GOGOI0% (1)

- Standardize Operating Procedure for Grinding Media ChargingDocument1 pageStandardize Operating Procedure for Grinding Media ChargingJCS100% (1)

- Kiln Startup and Operation ProcedureDocument4 pagesKiln Startup and Operation ProcedureJCS100% (3)

- Presentation-Hydraulic System in VRPMDocument24 pagesPresentation-Hydraulic System in VRPMmsvprasadNo ratings yet

- Hail Cement Kiln bricks falling due to changing flame momentumDocument13 pagesHail Cement Kiln bricks falling due to changing flame momentum7atemmohNo ratings yet

- Parts list with prices under 40 charactersDocument4 pagesParts list with prices under 40 characterslibin francisNo ratings yet

- Rotary Kiln - Inst Manual English - Version 2015Document55 pagesRotary Kiln - Inst Manual English - Version 2015taghdirim100% (5)

- Phillips Kiln Kiln Alignment Gebhart 2006Document36 pagesPhillips Kiln Kiln Alignment Gebhart 2006mustaf100% (2)

- Check List Rotary Packer: Packing Plant General StatusDocument3 pagesCheck List Rotary Packer: Packing Plant General StatusTITUS YUSUF100% (1)

- Standard Operating Procedure for Kiln Brick LayingDocument3 pagesStandard Operating Procedure for Kiln Brick LayingJCSNo ratings yet

- Overview of Cement Manufacturing 09.06.21Document39 pagesOverview of Cement Manufacturing 09.06.21Abhishek Michael ChandNo ratings yet

- Training For Tensioning Hydraulic System MPS MillsDocument69 pagesTraining For Tensioning Hydraulic System MPS MillsImam SampoernoNo ratings yet

- 1568 GB 02Document7 pages1568 GB 02Andra EneNo ratings yet

- Cement Ball Mill Inspection ProcedureDocument9 pagesCement Ball Mill Inspection ProceduremahantmtechNo ratings yet

- Reverse Air Bag House PDFDocument4 pagesReverse Air Bag House PDFRanga VamshiNo ratings yet

- VDZ Cement Manufacturing Course FlyerDocument4 pagesVDZ Cement Manufacturing Course FlyerfaheemqcNo ratings yet

- Standard Operating Procedure - KilnDocument7 pagesStandard Operating Procedure - KilnJCS100% (2)

- Operation & Maintenance of Cement Ball MillDocument7 pagesOperation & Maintenance of Cement Ball MillvinodsnNo ratings yet

- Hira Ball Mill Line ReplacemenDocument2 pagesHira Ball Mill Line Replacemenananthu.uNo ratings yet

- Sop For Bag FilterDocument5 pagesSop For Bag FiltervinodsnNo ratings yet

- Unwanted False Air in Cement Plants Can Be A Big Problem and Has To Be Taken SeriouslyDocument5 pagesUnwanted False Air in Cement Plants Can Be A Big Problem and Has To Be Taken SeriouslyharyantoaditNo ratings yet

- Oil Analysis Report for VRM Hydraulic SystemDocument2 pagesOil Analysis Report for VRM Hydraulic SystemBhaskar Reddy100% (1)

- How To Ensure Safety For Castable MixingDocument4 pagesHow To Ensure Safety For Castable MixingNaelNo ratings yet

- Ultratech Kotputli CementDocument44 pagesUltratech Kotputli CementSai Sricharan ReddyNo ratings yet

- Flowchart IDocument1 pageFlowchart Ircsrm123No ratings yet

- Commissioning Guide LinesDocument53 pagesCommissioning Guide LinesthurawinNo ratings yet

- AC DC Kilns (Drives, Cement Plant)Document10 pagesAC DC Kilns (Drives, Cement Plant)RajuNo ratings yet

- TROUBLESHOOTING OF Cement Plant Mechanical and Electrical EquipmentDocument66 pagesTROUBLESHOOTING OF Cement Plant Mechanical and Electrical EquipmentCorrosion FactoryNo ratings yet

- 06-SOP For Belt Conveyor 4ABDocument14 pages06-SOP For Belt Conveyor 4ABTamil VananNo ratings yet

- 3 SOP For Cleaning of Clinker Cooler DischargeDocument3 pages3 SOP For Cleaning of Clinker Cooler DischargekakaNo ratings yet

- 15th NCB Technical PaperDocument10 pages15th NCB Technical PaperSalah RomdaniNo ratings yet

- Cast Central Pipe - EN - SmidthDocument4 pagesCast Central Pipe - EN - SmidthLuis Orlando Villarroel TorrezNo ratings yet

- Kiln Shell Specification SummaryDocument20 pagesKiln Shell Specification SummaryAnonymous p4GdtQpNo ratings yet

- Cyclone Preheater ProcedureDocument18 pagesCyclone Preheater ProcedureVisnu Sankar100% (2)

- Cement Plant Training ReportDocument26 pagesCement Plant Training ReportHimadri MahatoNo ratings yet

- Waste Heat Recovery in Cement Plant IJERTV3IS051014 PDFDocument5 pagesWaste Heat Recovery in Cement Plant IJERTV3IS051014 PDFDurjoy ChakrabortyNo ratings yet

- V P P P: Alid Ractice Roduction RocessDocument7 pagesV P P P: Alid Ractice Roduction RocessMin MCLNo ratings yet

- Running Insp Sheet NewDocument20 pagesRunning Insp Sheet NewSafrin SangiaNo ratings yet

- Cement Processing Hol CimDocument1 pageCement Processing Hol CimShailesh RaneNo ratings yet

- CTP Team Technologies: Bag Filter Vs Electrostatic PrecipitatorDocument8 pagesCTP Team Technologies: Bag Filter Vs Electrostatic PrecipitatorDaniel RicartNo ratings yet

- Operating Manual For Ammonia Unit: 1. Safety and Health 1. Purpose and ApplicationDocument55 pagesOperating Manual For Ammonia Unit: 1. Safety and Health 1. Purpose and ApplicationTeknik Kimia PLS1 Kelas B 2018No ratings yet

- Utilities Consumption Report - Module 07: TupibvDocument6 pagesUtilities Consumption Report - Module 07: TupibvRobles DreschNo ratings yet

- MD 502 3DMB Eg PR RPT 0001 - C01Document195 pagesMD 502 3DMB Eg PR RPT 0001 - C01Abdur RehmanNo ratings yet

- In-Service Aircraft Report SummaryDocument15 pagesIn-Service Aircraft Report SummaryromixrayzenNo ratings yet

- Tektronix 1502 Time Domain Reflectometer Operator ManualDocument137 pagesTektronix 1502 Time Domain Reflectometer Operator Manualkhaerul jannahNo ratings yet

- PW3D MM 71.00 PWR Plant Adj Test R45Document29 pagesPW3D MM 71.00 PWR Plant Adj Test R45FABIAN REYES TOVARNo ratings yet

- TM 11-6665-200-12Document32 pagesTM 11-6665-200-12SiviNo ratings yet

- Gain-Cell Embedded DRAMs for Low-Power VLSI Systems-on-ChipFrom EverandGain-Cell Embedded DRAMs for Low-Power VLSI Systems-on-ChipNo ratings yet

- Lime Stone Cleaning Station - Project Proposal-03Document4 pagesLime Stone Cleaning Station - Project Proposal-03vinodsnNo ratings yet

- Coal Crushing Sec. Drg. List Fo ErectionDocument1 pageCoal Crushing Sec. Drg. List Fo ErectionvinodsnNo ratings yet

- Lime Stone Cleaning Station - Project Proposal-03Document4 pagesLime Stone Cleaning Station - Project Proposal-03vinodsnNo ratings yet

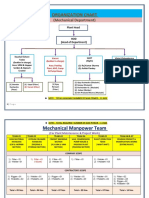

- ORGANIZATION CHARTDocument3 pagesORGANIZATION CHARTvinodsn100% (1)

- 3.20 Removal of Conveyor Belt With New BeltDocument2 pages3.20 Removal of Conveyor Belt With New Beltvinodsn100% (1)

- Pending Job of CPWDocument2 pagesPending Job of CPWvinodsnNo ratings yet

- Balaji Cement Industries Pvt. Limited: Mechanical Work Progress ReportDocument1 pageBalaji Cement Industries Pvt. Limited: Mechanical Work Progress ReportvinodsnNo ratings yet

- Nov 15 Daily MeetingDocument2 pagesNov 15 Daily MeetingvinodsnNo ratings yet

- Balaji Cement Industries Pvt. Limited: Mechanical Work Progress ReportDocument2 pagesBalaji Cement Industries Pvt. Limited: Mechanical Work Progress ReportvinodsnNo ratings yet

- Org ChartDocument1 pageOrg ChartvinodsnNo ratings yet

- Transmital of Assly. Drgs. of Equipments of Coal Crusher & Storage Sec. & Coal Mill Sec.Document2 pagesTransmital of Assly. Drgs. of Equipments of Coal Crusher & Storage Sec. & Coal Mill Sec.vinodsnNo ratings yet

- Daily Stoppage ReportDocument2 pagesDaily Stoppage ReportvinodsnNo ratings yet

- Sop Welding & Gas CuttingDocument9 pagesSop Welding & Gas CuttingvinodsnNo ratings yet

- Equip. Name:-RAW MILL Equip. TAG No. 300 RM-1Document1 pageEquip. Name:-RAW MILL Equip. TAG No. 300 RM-1vinodsnNo ratings yet

- Sop For Cleaning & HousekeepingDocument4 pagesSop For Cleaning & HousekeepingvinodsnNo ratings yet

- Sop For Safe Working at HeightDocument6 pagesSop For Safe Working at HeightvinodsnNo ratings yet

- Offer Letter-Manpower Supply & Project WorkDocument10 pagesOffer Letter-Manpower Supply & Project WorkvinodsnNo ratings yet

- Operation & Maintenance of Cement Ball MillDocument7 pagesOperation & Maintenance of Cement Ball MillvinodsnNo ratings yet

- Belt Conveyor Operation & Cleaning SOPDocument2 pagesBelt Conveyor Operation & Cleaning SOPvinodsn100% (2)

- Sop For Ls CrusherDocument5 pagesSop For Ls CrusherVinod Kumar VermaNo ratings yet

- Sop Working at High Noise AreaDocument5 pagesSop Working at High Noise AreavinodsnNo ratings yet

- Sop For Bag FilterDocument5 pagesSop For Bag FiltervinodsnNo ratings yet

- Costing Details E & I (2074-75)Document8 pagesCosting Details E & I (2074-75)vinodsnNo ratings yet

- Sop Ls CrusherDocument2 pagesSop Ls Crushervinodsn100% (1)

- Safe Lifting Guide for Chain Pulley Blocks & SlingsDocument5 pagesSafe Lifting Guide for Chain Pulley Blocks & SlingsvinodsnNo ratings yet

- HR CircularDocument2 pagesHR CircularvinodsnNo ratings yet

- Gist of Man Power in Grinding Unit: United Cements Pvt. Limited Naubise-4, Dhading, NepalDocument1 pageGist of Man Power in Grinding Unit: United Cements Pvt. Limited Naubise-4, Dhading, NepalvinodsnNo ratings yet

- HR CircularDocument4 pagesHR CircularvinodsnNo ratings yet

- Sukh Raj Sigh ResignationDocument1 pageSukh Raj Sigh ResignationvinodsnNo ratings yet

- N68C-GS FXDocument54 pagesN68C-GS FXFrancisco AmpueroNo ratings yet

- Operating System Assignment 4-Dos CommandsDocument7 pagesOperating System Assignment 4-Dos CommandsJayashree WawhalNo ratings yet

- APR48Document29 pagesAPR48ariess22009No ratings yet

- Unisonic Technologies Co., LTD: 2A, 600V N-CHANNEL Power MosfetDocument7 pagesUnisonic Technologies Co., LTD: 2A, 600V N-CHANNEL Power Mosfetjsalinas78No ratings yet

- BR-101D Technical and Applications Literature Selector Guide and Cross ReferencesDocument132 pagesBR-101D Technical and Applications Literature Selector Guide and Cross ReferencesEdward YanezNo ratings yet

- 850k Diagrama ElectricoDocument1 page850k Diagrama Electricollesli17No ratings yet

- Fuel Dilution in EnginesDocument1 pageFuel Dilution in Enginesjameel babooramNo ratings yet

- CNC Machining Vocabulary Terms ExplainedDocument2 pagesCNC Machining Vocabulary Terms ExplainedPeggopoulouNo ratings yet

- Qintern Adventures: The Untold Stories.Document10 pagesQintern Adventures: The Untold Stories.Shivangi AgrawalNo ratings yet

- OPC e PROFIBUS PDFDocument2 pagesOPC e PROFIBUS PDFChrixShines JornalNo ratings yet

- Idrac and Lifecycle Controller - A Recommended Workflow For Performing Firmware Updates On Poweredge ServersDocument17 pagesIdrac and Lifecycle Controller - A Recommended Workflow For Performing Firmware Updates On Poweredge ServersarivsNo ratings yet

- Ethereum Performance Analysis of TransactionsDocument5 pagesEthereum Performance Analysis of TransactionsShumail MohyuddinNo ratings yet

- 3521 Transair Installation Manual 20201223Document86 pages3521 Transair Installation Manual 20201223AFG AutomacaoNo ratings yet

- East Facing Model 1 PDFDocument28 pagesEast Facing Model 1 PDFCh. NarendraNo ratings yet

- Notes On Sprockets and ChainsDocument6 pagesNotes On Sprockets and Chainsjjoohhnn90No ratings yet

- Entreprenuerial Skills SurveyDocument42 pagesEntreprenuerial Skills SurveyversmajardoNo ratings yet

- Hy14-3300 Mvi PDFDocument3 pagesHy14-3300 Mvi PDFPartsGopher.comNo ratings yet

- MCQ 2Document11 pagesMCQ 2Anurag Maurya70% (27)

- Spreaderflex enDocument4 pagesSpreaderflex enARTMehr Eng. GroupNo ratings yet

- Google Chrome Operating SystemDocument9 pagesGoogle Chrome Operating Systemsmdieter0No ratings yet

- Manage Pasolink Networks with PNMTDocument53 pagesManage Pasolink Networks with PNMTIftikhar Ahmad AhmadNo ratings yet

- 16-75 BWE, Bodywork Electrical System: Overview - Sheet 1Document13 pages16-75 BWE, Bodywork Electrical System: Overview - Sheet 1lilik sukristianto100% (1)

- Diagram AsDocument46 pagesDiagram AsHector Sepulveda OrellanaNo ratings yet

- How To Prepare The SarDocument107 pagesHow To Prepare The Sargoldencomet100% (1)

- GFK-1004B CIMPLICITY HMI TCPIP Ethernet Communications For The Series 90-70 PLCDocument268 pagesGFK-1004B CIMPLICITY HMI TCPIP Ethernet Communications For The Series 90-70 PLCSam eagle goodNo ratings yet

- SAA7324Document68 pagesSAA7324vijayanand5935No ratings yet

- Islamabad PDFDocument4 pagesIslamabad PDFpradisevirtueNo ratings yet

- DMVPN TutorialDocument10 pagesDMVPN TutorialwahyuabadiNo ratings yet

- Swot Analysis of TCS FSDocument36 pagesSwot Analysis of TCS FSDanial KhanNo ratings yet