Professional Documents

Culture Documents

Check List Equipment

Uploaded by

jaio880 ratings0% found this document useful (0 votes)

50 views3 pagesThis document provides a checklist for repairing electrical and mechanical equipment. It details information about a high temperature electrical pump located at the Ashok Project that broke down in June 2016 due to a failure in the rotating system from operating in rugged conditions. The cost of repairing the pump is around 10.75% of the original equipment cost. Preventative maintenance procedures will be implemented to prevent similar failures in the future.

Original Description:

checklist

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a checklist for repairing electrical and mechanical equipment. It details information about a high temperature electrical pump located at the Ashok Project that broke down in June 2016 due to a failure in the rotating system from operating in rugged conditions. The cost of repairing the pump is around 10.75% of the original equipment cost. Preventative maintenance procedures will be implemented to prevent similar failures in the future.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

50 views3 pagesCheck List Equipment

Uploaded by

jaio88This document provides a checklist for repairing electrical and mechanical equipment. It details information about a high temperature electrical pump located at the Ashok Project that broke down in June 2016 due to a failure in the rotating system from operating in rugged conditions. The cost of repairing the pump is around 10.75% of the original equipment cost. Preventative maintenance procedures will be implemented to prevent similar failures in the future.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

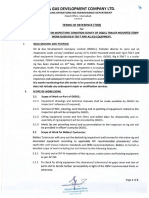

CHECK LIST FOR REPAIRING OF E&M EQUIPMENT

1) Name of Project/ Area- Ashok Project

2) Name of Equipment- HT Electrical Pump.

3) SI.No of equipment- Tag No. 3226.

4) Details of equipment- 2000 GPM, 100 mtr.

5) Date & year of installment- 2004

6) Location of installation- Pump House.

7) Life obtain from equipment/equipment in case

Of specific make is required/ OEM fitment

In case of component of specific make is required- NA

8) Date of break down- 02/06/2016.

9) Nature of break down-: Failure of rotating system.

10) Cause of break down & responsibility with complete Inspection report-:

Regular operation in

rugged condition.

11) Certificate from RWS for not undertaking the job

If being given to outside agency (in case of motor and transformer)- N.A.

Proper specification, part no & drawing of part no is not available.

12) Cost justification of repairing(Material & labor vis-à-vis

Original cost of equipment) : 10.75 %

13) Date and year when similar breakdown last- : 2014-15 partially similar breakdown.

14) Expenditure if any on the machine last 3years year wise-

2013-2014 : Nil /-

2014-2015 : 40,009 /-

2015-2016 : Nil /-

15) Action taken to prevent such recurrence of such failures- Preventive maintenance etc.

16) Provision of fund- : As per company norms.

Inspected Section Incharge Project Incharge

Signature Signature Signature

Name Name Name

Designation Designation Designation

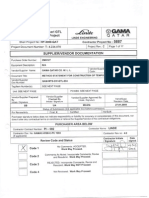

CHECK LIST FOR REPAIRING OF E&M EQUIPM

1.) Name of Project/ Area- Ashok Project

17) Name of Equipment- Sykes Pump

18) SI.No of equipment- HT Pump no-3&4

19) Details of equipment- KW-260

20) Date & year of installment- : HTE 3 – 2004 & HTE 4-2004.

21) Location of installation- Pump House “A”&”B” patch

22) Life obtain from equipment/equipment in case

Of specific make is required/ OEM fitment

In case of component of specific make is required-

23) Date of break down- HT Pump no-3-dt 18/09/2011 & HT Pump no-4-dt-25/10/2011

24) Nature of break down-: Pump body( bearing pedestal and bearing housing),shaft and impeller

repairing, gland etc

25) Cause of break down & responsibility with complete Inspection report-: Wear and tear.

26) Certificate from RWS for not undertaking the job

If being given to outside agency (in case of motor and transformer)- Not applicable

27) Proper specification, part no & drawing of part no is

not available.

28) Cost justification of repairing(Material & labour vis-à-vis

Original cost of equipment) : the present cost of new pump set of similar

Capacity is approx Rs. 24 Lakh only.

29) Date and year when similar breakdown last- Before 02 year.

30) Expenditure if any on the machine last 3years yearwise-

PUMP HTE-3:-2009-10-Rs73185, 2010-11-Rs13500

PUMP HTE-4:-2009-10-Rs73185, 2010-11-Rs16250

31) Action taken to prevent such recurrence of such failures-

32) Provision of fund-

Inspected Section Incharge Project Incharge

Signature Signature Signature

Name Name Name

Designation Designation Designation

You might also like

- DPRDocument25 pagesDPRbanavaram1No ratings yet

- SUBCO-FRM-01 Subcontractor's Prequalification FormDocument16 pagesSUBCO-FRM-01 Subcontractor's Prequalification FormMuhammad Umer100% (1)

- Soil Investigation and Topographical Works Rev ADocument5 pagesSoil Investigation and Topographical Works Rev ARiko Bin ZulkifliNo ratings yet

- Inspection and Test Plan - General Civil Works at Adr&Ruwais RefineryDocument4 pagesInspection and Test Plan - General Civil Works at Adr&Ruwais RefineryJithesh.k.sNo ratings yet

- SOP Trial StretchDocument4 pagesSOP Trial StretchashutoshpathakcivilNo ratings yet

- Compliance Documents in Respect of SOW EtcDocument4 pagesCompliance Documents in Respect of SOW EtcArun MuraliNo ratings yet

- Ogdcl Rig Tor Rm-4573Document8 pagesOgdcl Rig Tor Rm-4573Ahmed Imtiaz RaoNo ratings yet

- Standard Inspection Report of A Gas Distribution OperatorDocument21 pagesStandard Inspection Report of A Gas Distribution OperatorSaumitra Shankar GuptaNo ratings yet

- 001 - Method Statement of Site Survey and TopographyDocument9 pages001 - Method Statement of Site Survey and Topographyahmed08839494100% (1)

- 014-MS For Bolt Tightening (Piping& Equipments) PDFDocument23 pages014-MS For Bolt Tightening (Piping& Equipments) PDFKöksal PatanNo ratings yet

- MS For Street Lightning and Allied WorksDocument18 pagesMS For Street Lightning and Allied WorksDeepu Sivadas100% (1)

- System ValvesDocument18 pagesSystem ValvesSumit SinghNo ratings yet

- Replacement of Corroded Treated Waste For Water Piping From Neutralization Sump in Utility Area To Sea Water Outfall at Ruwais Refinery WestDocument8 pagesReplacement of Corroded Treated Waste For Water Piping From Neutralization Sump in Utility Area To Sea Water Outfall at Ruwais Refinery WestMirza AliNo ratings yet

- Field S.R Koomey UnitDocument3 pagesField S.R Koomey Unitaustin okoroNo ratings yet

- MS 1184 TC 311e B 1Document68 pagesMS 1184 TC 311e B 1Abanoub HakeemNo ratings yet

- Terms of Reference - Technical Due Diligence Wind Power Project - Public Private PartnershipDocument5 pagesTerms of Reference - Technical Due Diligence Wind Power Project - Public Private PartnershipJose Manuel RossodivitaNo ratings yet

- RFP - Sweeping Machines O&M PDFDocument3 pagesRFP - Sweeping Machines O&M PDFB ManoranjanNo ratings yet

- NotesheetDocument5 pagesNotesheetamitvishnoiNo ratings yet

- AMC-3311KV - For Tender FinalDocument83 pagesAMC-3311KV - For Tender FinalSANDIP ROYNo ratings yet

- SOW Medium-Voltage Equipment 2024.01.02Document7 pagesSOW Medium-Voltage Equipment 2024.01.02Christian BernalNo ratings yet

- CMIT-796-PIP-15.69-00-0008 - 0 3D Model Review ProcedureDocument10 pagesCMIT-796-PIP-15.69-00-0008 - 0 3D Model Review ProcedurenadaNo ratings yet

- Saic-N - 2013Document2 pagesSaic-N - 2013SUNIL RAJPUTNo ratings yet

- Ema 2016 01 AnnexesDocument17 pagesEma 2016 01 AnnexesZev ZekNo ratings yet

- Capex For ATFE Installation For Xylene Distillation QPDocument29 pagesCapex For ATFE Installation For Xylene Distillation QPPrathmesh GujaratiNo ratings yet

- FIDIC EPC Contract ExampleDocument18 pagesFIDIC EPC Contract ExampleNasiruddin Abdullah Hussain100% (1)

- Automobile Radiators - Cores PDFDocument8 pagesAutomobile Radiators - Cores PDFHagos AwetahegnNo ratings yet

- MS - Road and PavingDocument15 pagesMS - Road and PavingbukhoriNo ratings yet

- NM Duct 2013-14-2nd CallDocument88 pagesNM Duct 2013-14-2nd Callc2anNo ratings yet

- Uploads Job 41111Document5 pagesUploads Job 41111Anuj JainNo ratings yet

- SQF-RAMS-LIN-DR-01 - Installation of Drainage LinesDocument29 pagesSQF-RAMS-LIN-DR-01 - Installation of Drainage LinesAkshay DeepNo ratings yet

- Revised Data Buildings)Document95 pagesRevised Data Buildings)Sri Ravindra Yadav Pattapogula0% (1)

- OPGC O & M WorksDocument233 pagesOPGC O & M WorksBalkishan DyavanapellyNo ratings yet

- Solution Proposal Fleet ManagementDocument3 pagesSolution Proposal Fleet ManagementmasumidbNo ratings yet

- TI No. 97 NewDocument43 pagesTI No. 97 NewMuskmelon gamerNo ratings yet

- Request For Inspection: Client: Engineer: ContractorDocument1 pageRequest For Inspection: Client: Engineer: ContractorAouse YasinNo ratings yet

- Agromaxx 4045E ICT FTRDocument12 pagesAgromaxx 4045E ICT FTRhugo fernandezNo ratings yet

- G K P C&W H D D.I. K: Bill of QuantitiesDocument9 pagesG K P C&W H D D.I. K: Bill of QuantitiesNaveed ShaheenNo ratings yet

- 0770 W 169 Wa - 13 16 17 - 01 PDFDocument100 pages0770 W 169 Wa - 13 16 17 - 01 PDFamitkap00rNo ratings yet

- RFI FormatDocument1 pageRFI FormatVipin Kumar ParasharNo ratings yet

- Engine Inspection - "Mr. C. Gonzalez Class": "Airworthiness Directives" Assignment Study Questions 1-11Document6 pagesEngine Inspection - "Mr. C. Gonzalez Class": "Airworthiness Directives" Assignment Study Questions 1-11Luis AlonsoNo ratings yet

- Annexure-3-Commercial Terms and Condition-PKG106CDocument2 pagesAnnexure-3-Commercial Terms and Condition-PKG106CMuhammed FaheemNo ratings yet

- 004-Civil - MS Construction of Temporary Roads PDFDocument17 pages004-Civil - MS Construction of Temporary Roads PDFKöksal Patan100% (2)

- Anant Corr. MOM 7-08-18Document4 pagesAnant Corr. MOM 7-08-18Abhimanyu Singh ChundawatNo ratings yet

- MDR Manufacturers Data Report InfoDocument13 pagesMDR Manufacturers Data Report InfoSaut Maruli Tua Samosir100% (4)

- HKKJRH Foekuiùku ÇKF/KDJ.K Jkfoç : The Sr. Manager (Engg-Civil) - Ii, Aai, Raipur AirportDocument3 pagesHKKJRH Foekuiùku ÇKF/KDJ.K Jkfoç : The Sr. Manager (Engg-Civil) - Ii, Aai, Raipur AirportMitesh ShahNo ratings yet

- Insp Checklist - Piping AlignmentDocument1 pageInsp Checklist - Piping AlignmentRickesh NunkooNo ratings yet

- Request For Inspection: QC Rfi No.Document1 pageRequest For Inspection: QC Rfi No.KarthikNo ratings yet

- TPT20220806889421 RFP Part 3Document52 pagesTPT20220806889421 RFP Part 3DonovanStevensNo ratings yet

- 015-Method Statement For Painting Works (Building) PDFDocument21 pages015-Method Statement For Painting Works (Building) PDFKöksal Patan86% (21)

- Compendium On: Office of CAO (C), Central RailwayDocument145 pagesCompendium On: Office of CAO (C), Central Railwayabhaskumar68No ratings yet

- Revised Data Roadsbridges1Document404 pagesRevised Data Roadsbridges1Krishna SinghNo ratings yet

- 30-99-90-1649 Pipeline As-Built and Survey ProcedureDocument20 pages30-99-90-1649 Pipeline As-Built and Survey ProcedureEswar ReddyNo ratings yet

- Schedule B - Attachment IDocument27 pagesSchedule B - Attachment Imunna100% (2)

- viewNitPdf 2547183Document19 pagesviewNitPdf 2547183EMJAYNo ratings yet

- Cm-Mech - (73 To 74) - Send To MGPS at (03-11-2020)Document2 pagesCm-Mech - (73 To 74) - Send To MGPS at (03-11-2020)ali morisyNo ratings yet

- 20.312 D02 Rev 01 Design BriefDocument17 pages20.312 D02 Rev 01 Design BriefSarah PerezNo ratings yet

- Fire Fighting ValvesDocument399 pagesFire Fighting ValvesadamcyzNo ratings yet

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- (A Subsidiary of Coal India Limited) : Eligibility CriteriaDocument7 pages(A Subsidiary of Coal India Limited) : Eligibility Criteriajaio88No ratings yet

- Central Coalfields LimitedDocument26 pagesCentral Coalfields Limitedjaio88No ratings yet

- 180907044359hzb So Apr 2018Document8 pages180907044359hzb So Apr 2018jaio88No ratings yet

- Central Coalfields LimitedDocument26 pagesCentral Coalfields Limitedjaio88No ratings yet

- 180712122508hazaribagh So OctoberDocument15 pages180712122508hazaribagh So Octoberjaio88No ratings yet

- 09 Termsandconditions Doc CPRIBLR17 EMD14 MDocument33 pages09 Termsandconditions Doc CPRIBLR17 EMD14 Mjaio88No ratings yet

- Buy Surya Led Bulb Neo Prime 40watt Online - GemDocument1 pageBuy Surya Led Bulb Neo Prime 40watt Online - Gemjaio88No ratings yet

- 190602034531HZB So Dec 2018Document28 pages190602034531HZB So Dec 2018jaio88No ratings yet

- 120 Foot ValveDocument1 page120 Foot Valvejaio88No ratings yet

- Check List EquipmentDocument2 pagesCheck List Equipmentjaio88No ratings yet

- VDA New PDFDocument18 pagesVDA New PDFjaio88No ratings yet

- 16-ELS-Final-Module 16-08082020Document18 pages16-ELS-Final-Module 16-08082020jeseca cincoNo ratings yet

- IELTS Material Writing 1Document112 pagesIELTS Material Writing 1Lê hoàng anhNo ratings yet

- 1 s2.0 S2238785423001345 MainDocument10 pages1 s2.0 S2238785423001345 MainHamada Shoukry MohammedNo ratings yet

- Teal Motor Co. Vs CFIDocument6 pagesTeal Motor Co. Vs CFIJL A H-DimaculanganNo ratings yet

- ARTS10 Q2 ModuleDocument12 pagesARTS10 Q2 ModuleDen Mark GacumaNo ratings yet

- 2008 Kershaw CatalogDocument38 pages2008 Kershaw CatalogDANILA MARECHEKNo ratings yet

- Steve Jobs TalkDocument3 pagesSteve Jobs TalkDave CNo ratings yet

- Beng (Hons) Telecommunications: Cohort: Btel/10B/Ft & Btel/09/FtDocument9 pagesBeng (Hons) Telecommunications: Cohort: Btel/10B/Ft & Btel/09/FtMarcelo BaptistaNo ratings yet

- Reviewer in EntrepreneurshipDocument6 pagesReviewer in EntrepreneurshipRachelle Anne SaldeNo ratings yet

- Ebook Stackoverflow For ItextDocument336 pagesEbook Stackoverflow For ItextAnonymous cZTeTlkag9No ratings yet

- U2 KeyDocument2 pagesU2 KeyHằng ĐặngNo ratings yet

- 5000-5020 en PDFDocument10 pages5000-5020 en PDFRodrigo SandovalNo ratings yet

- Mini Project A-9-1Document12 pagesMini Project A-9-1santhoshrao19No ratings yet

- (Kazantzakis Nikos) Freedom or DeathDocument195 pages(Kazantzakis Nikos) Freedom or DeathTarlan FisherNo ratings yet

- Gics-In-India Getting Ready For The Digital WaveDocument81 pagesGics-In-India Getting Ready For The Digital Wavevasu.gaurav75% (4)

- Engine Stalls at Low RPM: Diagnostic CodesDocument3 pagesEngine Stalls at Low RPM: Diagnostic CodesAmir Bambang YudhoyonoNo ratings yet

- Work Permits New Guideline Amendments 2021 23.11.2021Document7 pagesWork Permits New Guideline Amendments 2021 23.11.2021Sabrina BrathwaiteNo ratings yet

- Performance Evaluation of The KVM Hypervisor Running On Arm-Based Single-Board ComputersDocument18 pagesPerformance Evaluation of The KVM Hypervisor Running On Arm-Based Single-Board ComputersAIRCC - IJCNCNo ratings yet

- 2021-01-01 - Project (Construction) - One TemplateDocument1,699 pages2021-01-01 - Project (Construction) - One TemplatemayalogamNo ratings yet

- Assignment & Case Marketing Week 1: Max Van Neerven: 1664172 Mounir Trabelsi: 1705839 Renaldas Zlatkus: 1701775Document8 pagesAssignment & Case Marketing Week 1: Max Van Neerven: 1664172 Mounir Trabelsi: 1705839 Renaldas Zlatkus: 1701775Ren ZkNo ratings yet

- Catalogo Escavadeira EC27CDocument433 pagesCatalogo Escavadeira EC27CNilton Junior Kern50% (2)

- HG32High-Frequency Welded Pipe Mill Line - Pakistan 210224Document14 pagesHG32High-Frequency Welded Pipe Mill Line - Pakistan 210224Arslan AbbasNo ratings yet

- 5G NR Essentials Guide From IntelefyDocument15 pages5G NR Essentials Guide From IntelefyUzair KhanNo ratings yet

- BS 215-2-1970-Aluminium Conductors and Aluminium Conductors Steel-Reinforced For Overhead Power TransmissionDocument16 pagesBS 215-2-1970-Aluminium Conductors and Aluminium Conductors Steel-Reinforced For Overhead Power TransmissionDayan Yasaranga100% (2)

- Rate If Iodine and PropanoneDocument3 pagesRate If Iodine and Propanoneshareef1No ratings yet

- 5 - Perception and Individual Decision Making in Organizational BehaviorDocument25 pages5 - Perception and Individual Decision Making in Organizational BehaviorJanaVrsalovićNo ratings yet

- The Impact of Personnel Behaviour in Clean RoomDocument59 pagesThe Impact of Personnel Behaviour in Clean Roomisrael afolayan mayomiNo ratings yet

- S P99 41000099DisplayVendorListDocument31 pagesS P99 41000099DisplayVendorListMazen Sanad100% (1)

- Categories of Cargo and Types of ShipsDocument14 pagesCategories of Cargo and Types of ShipsVibhav Kumar100% (1)

- WellaPlex Technical 2017Document2 pagesWellaPlex Technical 2017Rinita BhattacharyaNo ratings yet