Professional Documents

Culture Documents

Cast Iron Weld Repair

Uploaded by

ssCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cast Iron Weld Repair

Uploaded by

ssCopyright:

Available Formats

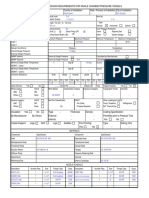

Date 30-Oct-18

REPAIR WELDING PROCEDURE FOR Owner

Turbocharger Class

Ship name ---

Scope of Repair: Welding repair Cast Iron

Material Grade: Cast Iron

1. NDE before welding

• LPT shall be perform after thorough cleaning

• Length of crack shall be marked from tip to tip.

• Traces of all penetrant shall be removed after completion

2 Crack Removal

• Drill at least 1/8” hole at the both end of the crack.

• Thoroughly Clean surrounding area of at least 2" with grind.

• Grind the crack to create a bevel of atleast 60°, Make sure crack is entirely removed, Check with LPT.

• Root of bevel shall be of radius of at least 3-5 mm.

3. Preheat

• 360°C - 650°C, Preheat the entire casting, not just the area to be welded for at least 1 hour (Heating coils are strictly

recommended)

• Must preheat the part slowly and uniformly.

• Make sure to maintain the preheat temperature of the casting from start to finish.

4. Welding process (WPS is not qualified)

• SMAW

• AWS/SFA 5.15 ENiFe-CI, 2.4mm, Current- 50-80 A (shall be kept at min. 80°C)

• Restrict the welds run, approximately 3”-4” long segments.

• Weld using low currents for minimum penetration, Min. dilution of parent metal.

• Immediately peen the face (gently) of each weld with a small ball-peen hammer to relieve stresses in weld.

• Use Skip welding technique (not continues)

• Always re-strike the arc on the previously deposited weld metal.

• Do not keep heating the same area. finish one layer then second and so on.

• After welding, allow the part to cool very very slowly. Wrapping the casting in an insulating blanket thoroughly or furnace

cooling

• LPT shall be carried out after completion and thoroughly clean the part after test.

Notes:

• Welders are requested to strictly follow above instruction and part shall not be allowed to go below preheat temp. until weld completed.

• All safety precautions for hot work shall be taken care of.

FILLER METAL BASE METAL

WELDING

POSITION Current Heat Input ASME P-

PROCESS Rod Size AWS Class AWS Spec. TYPE THICKNESS

A KJ/mm NO.

SMAW 1G,2G 2.4 mm ENiFe-CI A 5.15 50-80 1.0 Max. -- CAST IRON --

Q.C ENGR. SUPERINTENDENT CLASS REMARKS:

You might also like

- Welding A Cast IronDocument9 pagesWelding A Cast Ironjatin jainNo ratings yet

- Cast Iron Welding AlloysDocument4 pagesCast Iron Welding AlloysKhin Aung ShweNo ratings yet

- Welding Cast Iron PDFDocument15 pagesWelding Cast Iron PDFAmr Mohamed SolimanNo ratings yet

- Stainless Steel Welding by Weld RealityDocument50 pagesStainless Steel Welding by Weld RealitylightwinterdayNo ratings yet

- Repairing A Crack in CastingDocument2 pagesRepairing A Crack in CastingpriaNo ratings yet

- Duplex Stainless Steel 2d Edition PracticalDocument64 pagesDuplex Stainless Steel 2d Edition Practicalmahmoud_allam3No ratings yet

- Filler Metal Selection GuideDocument2 pagesFiller Metal Selection GuideMehta Mehul100% (1)

- Thermanit 17-06 (Boehler)Document1 pageThermanit 17-06 (Boehler)queno1No ratings yet

- Heat Treatment ProcessesDocument44 pagesHeat Treatment Processesmesa142No ratings yet

- Select Arc Catalogue Part 1Document10 pagesSelect Arc Catalogue Part 1lionheartedNo ratings yet

- BOC 216295 GeneralGasesBrochure AUS v12Document28 pagesBOC 216295 GeneralGasesBrochure AUS v12idontlikeebooksNo ratings yet

- All Materials DocumentsDocument1 pageAll Materials DocumentsHarnish BariaNo ratings yet

- Weld Rod SelectionDocument2 pagesWeld Rod SelectionRads53100% (1)

- Cast IronDocument43 pagesCast IronThulasi Ram100% (1)

- Stellite Hardfacing AlloysDocument28 pagesStellite Hardfacing Alloysromanosky11No ratings yet

- Welding CalculatorDocument18 pagesWelding CalculatorKhamdi AfandiNo ratings yet

- SMAW GTAW Guide Filler Metal SelectionDocument3 pagesSMAW GTAW Guide Filler Metal SelectionBipin SinghNo ratings yet

- Thermal Barrier Coatings Material Selection, Method of Preparation and Applications - ReviewDocument8 pagesThermal Barrier Coatings Material Selection, Method of Preparation and Applications - ReviewAbdelkader TayebiNo ratings yet

- Chemical Analysis of Ductile Iron With Spectrometer - ProblemsDocument8 pagesChemical Analysis of Ductile Iron With Spectrometer - ProblemsSiriusNo ratings yet

- Hardfacing PDFDocument56 pagesHardfacing PDFIrshad HussainNo ratings yet

- Heat Treatments for Optimizing Steel Microstructure and PropertiesDocument32 pagesHeat Treatments for Optimizing Steel Microstructure and PropertiesSrushti MNo ratings yet

- How To Calculate Filler Metal Consumption For Welding ProjectsDocument3 pagesHow To Calculate Filler Metal Consumption For Welding ProjectsEdgar Coavas PérezNo ratings yet

- Agarwal Fastners Pvt. Ltd.Document1 pageAgarwal Fastners Pvt. Ltd.satyam nagaichNo ratings yet

- Stainless Steel Grade Composition ChartDocument8 pagesStainless Steel Grade Composition Chart23OtterNo ratings yet

- 50 Casting DefectsDocument49 pages50 Casting DefectsmohammadNo ratings yet

- Weld Filler Metal SelectionDocument7 pagesWeld Filler Metal SelectionsusanwebNo ratings yet

- Comparative Chart: AWS Advani Esab D & H GEE NucorweldDocument4 pagesComparative Chart: AWS Advani Esab D & H GEE NucorweldAnik Desai100% (2)

- Final Welding of Ti Alloys and MG AlloysDocument32 pagesFinal Welding of Ti Alloys and MG AlloysArjyajyoti GoswamiNo ratings yet

- Welding and Cutting ProcessDocument60 pagesWelding and Cutting Processquiron2010100% (1)

- Use of Alloy 718 and 725 in Oil and Gas IndustryDocument9 pagesUse of Alloy 718 and 725 in Oil and Gas IndustryEddyWangNo ratings yet

- Welding Consumables-Cast IronDocument9 pagesWelding Consumables-Cast Ironshabbir626No ratings yet

- AlokJain JindalDocument76 pagesAlokJain JindalArunprasad Murugesan100% (1)

- Lecture 1-Fundamentals of Welding MetallurgyDocument46 pagesLecture 1-Fundamentals of Welding MetallurgyHamiduNo ratings yet

- KMT Stellite Alloys Brochure FINALDocument15 pagesKMT Stellite Alloys Brochure FINALIkhsan LyNo ratings yet

- Tabla de Referencia de Materiales: Material Reference ChartDocument2 pagesTabla de Referencia de Materiales: Material Reference Chartsateesh chandNo ratings yet

- Fatigue Performance of Repair WeldsDocument197 pagesFatigue Performance of Repair WeldszhangjlNo ratings yet

- Type 347-347H Stainless SteelDocument2 pagesType 347-347H Stainless SteelPravin PawarNo ratings yet

- 2 HeatTreatment-1Document43 pages2 HeatTreatment-1PrakashNo ratings yet

- Dissimilar Metal WeldingDocument30 pagesDissimilar Metal Weldingdselvakuu100% (1)

- Passivation Treatment of Stainless Steel AcomDocument10 pagesPassivation Treatment of Stainless Steel Acomvijayarangam1984No ratings yet

- Steel Plates For Offshore StructuresDocument8 pagesSteel Plates For Offshore StructuresYiengeChanYeeNo ratings yet

- AWS specifications for selecting electrodes for welding various material gradesDocument1 pageAWS specifications for selecting electrodes for welding various material gradesmohammedetaNo ratings yet

- Weld RepireDocument91 pagesWeld RepireالGINIRAL FREE FIRENo ratings yet

- Welding Metallurgy: Solidification of Weld Metal and Modes of SolidificationDocument23 pagesWelding Metallurgy: Solidification of Weld Metal and Modes of SolidificationbassemNo ratings yet

- Development of New Etchant For High Manganese Steel CastingDocument9 pagesDevelopment of New Etchant For High Manganese Steel CastingShankhaPathakNo ratings yet

- Surface Defects in Steel ProductsDocument41 pagesSurface Defects in Steel ProductsShilaj PNo ratings yet

- ASME Section IX Materials List GuideDocument186 pagesASME Section IX Materials List GuideDavid Macatangay100% (1)

- Welding Hardox and Weldox PDFDocument4 pagesWelding Hardox and Weldox PDFEnoc AndradeNo ratings yet

- Welding AISI 4130 PDFDocument5 pagesWelding AISI 4130 PDFDarioNo ratings yet

- Intergard 345 - DatasheetDocument4 pagesIntergard 345 - DatasheetmanuthomasNo ratings yet

- Welding of Nickel AlloysDocument12 pagesWelding of Nickel Alloysaj87_goswamiNo ratings yet

- ASTM A106 Data SheetDocument4 pagesASTM A106 Data Sheetmarcelomaster88No ratings yet

- WPS PQR XLSXDocument4 pagesWPS PQR XLSXMd Sahabul IslamNo ratings yet

- ARL-AL-WPS-001 welding procedureDocument2 pagesARL-AL-WPS-001 welding procedurerajuajiNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- Wps Gt-9b-Cvn90 Rev 1Document6 pagesWps Gt-9b-Cvn90 Rev 1HAKANNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- Manual Standard WeldingDocument192 pagesManual Standard WeldingGEORGE IVAN0% (1)

- Manual Overlay WeldingDocument8 pagesManual Overlay Weldingcarlmac6183% (6)

- Paper 1 2015Document6 pagesPaper 1 2015pradeepNo ratings yet

- Noise Measurement Procedures Manual: Second Edition July 2008Document85 pagesNoise Measurement Procedures Manual: Second Edition July 2008barun1977No ratings yet

- Material Receiving Report FormDocument2 pagesMaterial Receiving Report FormssNo ratings yet

- TWI UT Level IIDocument7 pagesTWI UT Level IIssNo ratings yet

- Inspection Report for Incoming MaterialsDocument1 pageInspection Report for Incoming MaterialsssNo ratings yet

- Odc VT RevDocument1 pageOdc VT RevssNo ratings yet

- LPT ParikshaDocument6 pagesLPT ParikshaKlusnerKlusnerKlusnerNo ratings yet

- 190301SKD S2Document2 pages190301SKD S2ssNo ratings yet

- DRP001 Ouf Pro U 000 001 B4Document58 pagesDRP001 Ouf Pro U 000 001 B4ss50% (2)

- 190301SKD S2Document2 pages190301SKD S2ssNo ratings yet

- DRP001 Ouf Pro U 000 001 B4Document58 pagesDRP001 Ouf Pro U 000 001 B4ss50% (2)

- Odc ND RevDocument1 pageOdc ND RevssNo ratings yet

- Aws Preheat Calculations From HardnessDocument6 pagesAws Preheat Calculations From HardnessElias KapaNo ratings yet

- 35% Reduction in Welding Costs PDFDocument4 pages35% Reduction in Welding Costs PDFssNo ratings yet

- Odc-Sh-Rev 0Document1 pageOdc-Sh-Rev 0ssNo ratings yet

- DFG GTRFCDocument38 pagesDFG GTRFCssNo ratings yet

- PWHTDocument57 pagesPWHTssNo ratings yet

- Visualacuityform PDFDocument1 pageVisualacuityform PDFP BNo ratings yet

- Form U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsDocument3 pagesForm U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsssNo ratings yet

- Astm G48Document11 pagesAstm G48thedreampower100% (4)

- Odc-Vt-Rev 0 - 14.02.19Document2 pagesOdc-Vt-Rev 0 - 14.02.19ssNo ratings yet

- Odc-Sh-Rev 0 - 14.02.19Document1 pageOdc-Sh-Rev 0 - 14.02.19ssNo ratings yet

- AUdit Schedule 2018Document1 pageAUdit Schedule 2018ssNo ratings yet

- Form U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsDocument3 pagesForm U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsssNo ratings yet

- Hull and Machinery Steel Castings W8Document6 pagesHull and Machinery Steel Castings W8ssNo ratings yet

- Aws Preheat Calculations From HardnessDocument6 pagesAws Preheat Calculations From HardnessElias KapaNo ratings yet

- Icc1 Sample Material Work at HeightDocument7 pagesIcc1 Sample Material Work at HeightsaeeddhclNo ratings yet

- Inco-Weld 725NDUR Filler MetalDocument1 pageInco-Weld 725NDUR Filler MetalssNo ratings yet

- ASME Standards Benefits Case StudyDocument33 pagesASME Standards Benefits Case StudyssNo ratings yet

- Checklist for WPS-PQR certification requirementsDocument1 pageChecklist for WPS-PQR certification requirementsssNo ratings yet

- Batch 10 TimetableDocument1 pageBatch 10 TimetableMarcoNo ratings yet

- C1990-EH(HC)ver 1 0英文Document6 pagesC1990-EH(HC)ver 1 0英文顏健軒No ratings yet

- Duplex and Superduplex Stainless Steel Fittings (Amendments/Supplements To Astm A 815)Document11 pagesDuplex and Superduplex Stainless Steel Fittings (Amendments/Supplements To Astm A 815)Mathew CherianNo ratings yet

- Rishab IntroDocument4 pagesRishab IntroDeborsha DekaNo ratings yet

- CNT Neutron Porosity ToolDocument2 pagesCNT Neutron Porosity ToolAurora Duran LiraNo ratings yet

- Barazan® D Plus™: Viscosifier/Suspension AgentDocument1 pageBarazan® D Plus™: Viscosifier/Suspension AgentMarcoAntonioSerranoBazanNo ratings yet

- Coal Preparation Technologies Sep 2019 Indpnesia (JCOAL)Document23 pagesCoal Preparation Technologies Sep 2019 Indpnesia (JCOAL)ErwinLBudiNo ratings yet

- Carbonate Acidizing Design PDFDocument15 pagesCarbonate Acidizing Design PDFNelson PuentsNo ratings yet

- Thermal Properties of Aggregates ExplainedDocument6 pagesThermal Properties of Aggregates ExplainedAditya AdityaNo ratings yet

- Molecular Imaging Modalities and ApplicationsDocument42 pagesMolecular Imaging Modalities and ApplicationsSheila KwokNo ratings yet

- Wellness Finish With Vitamin EDocument3 pagesWellness Finish With Vitamin EMohammed Atiqul Hoque ChowdhuryNo ratings yet

- LecturesNotes (MEE122) 88Document1 pageLecturesNotes (MEE122) 88mhd slmnNo ratings yet

- Cascade Aeration Lecture 6 Environmental Engineering Unit Operations Spring 2014Document16 pagesCascade Aeration Lecture 6 Environmental Engineering Unit Operations Spring 2014Song Nguyen NguyenNo ratings yet

- Onshore Pipeline Engineering: Challenges: Oliver Sokoll - Pipeline Lead EngineerDocument25 pagesOnshore Pipeline Engineering: Challenges: Oliver Sokoll - Pipeline Lead EngineerdanielNo ratings yet

- KK Rao IndustriesDocument1 pageKK Rao IndustriesSainath AmudaNo ratings yet

- Efficient H2S Scavenger Glyoxal Outperforms TriazineDocument8 pagesEfficient H2S Scavenger Glyoxal Outperforms TriazineMo OsNo ratings yet

- Mineral PropertiesDocument3 pagesMineral PropertiesAji SuhadiNo ratings yet

- The Neurohistological TechniquesDocument4 pagesThe Neurohistological Techniquesapi-3846255100% (2)

- Awwa C218 2008Document36 pagesAwwa C218 2008Moito Carvalho100% (1)

- 3M™ Novec™ 1230 Fire Protection Fluid: PerformanceDocument1 page3M™ Novec™ 1230 Fire Protection Fluid: PerformanceAntonio Guillermo CruzNo ratings yet

- RMS 6th 2019Document14 pagesRMS 6th 2019angelgupta2303No ratings yet

- Air PollutionDocument19 pagesAir PollutionMika Hakimie100% (1)

- Temperature Compensation in PH Meter-A Survey: April 2015Document10 pagesTemperature Compensation in PH Meter-A Survey: April 2015Deepakrao Bornare PatilNo ratings yet

- Lecture 10: Nucleic Acids (DNA & RNA)Document13 pagesLecture 10: Nucleic Acids (DNA & RNA)Binoni Laja EndongNo ratings yet

- Spe 1266 G PDFDocument6 pagesSpe 1266 G PDFDarayt Jimenez100% (1)

- Dielectric Constants Chart: How To Use This GuideDocument10 pagesDielectric Constants Chart: How To Use This GuideDewet VirmondNo ratings yet

- Unit III Engine Exhaust Emission ControlDocument49 pagesUnit III Engine Exhaust Emission ControlMani Karthi100% (1)

- Why LPG Is Stored in Sphere or Cylindrical BulletDocument1 pageWhy LPG Is Stored in Sphere or Cylindrical BulletBNH Gas TanksNo ratings yet

- Unit 1.5 - Stress and Strain in Lifting EquipmentDocument14 pagesUnit 1.5 - Stress and Strain in Lifting EquipmentnitharsunNo ratings yet

- Process For Recovering Molybdenum and Tungsten From MoS3/WS3 PrecipitatesDocument4 pagesProcess For Recovering Molybdenum and Tungsten From MoS3/WS3 PrecipitatesMike MilovanovNo ratings yet