Professional Documents

Culture Documents

Ashrae Isolation PDF

Uploaded by

uuur350 ratings0% found this document useful (0 votes)

155 views12 pagesOriginal Title

ashrae_isolation.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

155 views12 pagesAshrae Isolation PDF

Uploaded by

uuur35Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

Sound and Vibration Control

‘openings, and the room correction (27) converting the sound power lev-

els atthe ceiling to comesponding sound pressure levels in the room,

The total sound pressure levels in the receiver room from the three

paths are obtained by logarithmically adding the individval sound pres-

sure levels associated with each path. From the total sound pressure

levels for all three paths, the NC value inthe room is NC 42, and the

RC value is RC 34 (R-H), which is « combination of lower fiequency

rumble and higher feequency hiss

If the regenerated noise due to airflow through the ductwork,

silencer, and diffuser are not considered, the NC value in the room is

C42, and the RC value is RC 26 (R-H). While the calculation proce-

dure is simplified, the typically higher-frequency regenerated noise is

‘not accounted for in the overall ratings especially in the RC value,

‘whose numeric magnitude is often set by the higher frequency noise

contribution. At a minimum, the self-noise or regenerated noise ofthe

silencers and outlet or inlet devices such as giles, registers, and difus-

fxs should be considered along with the atenuation provided by the

‘duct elements and dynamic insertion oss ofthe silencers,

VIBRATION ISOLATION

AND CONTROL

‘Mechanical vibration and vibration-induced noise are often

‘major sources of occupant complaints in modern buildings. Lighter

weight construction in new buildings has made these buildings

‘more susceptible to vibration and vibration-related problems,

Increased interest in energy conservation in buildings has resulted

‘in many new buildings being designed with variable air volume sys-

tems. This often results in mechanical equipment being located in

penthouses on the roof, inthe use of roof-mounted HVAC units, and

in mechanical equipment rooms located on intermediate level

floors. These trends have resulted in an increase in the number of

pieces of mechanical equipment located in a building, and they

often have resulted in mechanical equipment being located adjacent

to or above occupied areas.

Occupant complaints associated with building vibration typi-

cally take one of three forms:

1. The level of vibration perceived by building occupants is of suf-

ficient magnitude to cause concen or alarm,

2, Vibration energy from mechanical equipment, which is transmit-

tedto the building structure is transmitted to various parts ofthe

building and then is radiated as structure-bome noise.

3. Vibration present ina building may interfere with proper opera

tion of sensitive equipment or instrumentation,

‘The following sections present basic information to properly

select and specify vibration isolators and to analyze and correct field

vibration problems. Chapter 7 in the 1997 ASHRAE Handbook—

Fundamentals and Reynolds and Bevirt (1994) provide more

detailed information.

EQUIPMENT VIBRATION

Vibration can be isolated or reduced to a fraction of the original

force with resilient mounts between the equipment and the support-

ing structure. To determine the excessive forces that must be iso-

lated or that adversely affect the performance or life of the

equipment, criteria should be established for equipment vibration,

Figures 38 and 39 show the relation between equipment vibration

levels and vibration isolators that have a fixed vibration isolation

efficiency. In this case, the magnitude of transmission to the build-

ing is a function of the magnitude of the vibration force.

VIBRATION CRITERIA

Vibration criteria can be specified relative to three areas: (1)

human response to vibration, (2) vibration levels associated

with potential damage to sensitive equipment in a building, and

(3) vibration severity of a vibrating machine. Figure 40 and

46.37

eRATORY FORCE

toe 1000 190%

90% EFFICENT ISOLATOR

“0h TRANSMISSIORITY

iY ‘ 4

te de ry

TRANSMISSION

Fig. 38 Transmission to Structure Varies as Function

of Magnitude of Vibration Fore

10000018 FORCE

S04 EFFICIENCY 30% EFFICIENCY

so Tagetssion

om TRANSMISSION

she

0018 FORCE

abe

Fig. 39 Interrelationship of Equipment Vibration, Isolation

Efficiency, and Transmission

Table 43 present recommended acceptable vibration criteria for

vibration that can exist in a building structure (Ungar et al.

1990). Vibration values associated with Figure 40 are measured

by vibration transducers (usually accelerometers) that are

placed on the building structure in the vicinity of vibrating

‘equipment or in areas of the building that contain building

‘occupants or sensitive equipment. The occupant vibration crite-

ria are based on guidelines specified by ANSI Standard $3.29,

and ISO Standard 2631-2.

‘The manufacturer's vibration criteria should be followed for sen-

sitive equipment. If acceptable vibration values are not available

from manufacturers, the values specified in Figure 41 can be used.

Figure 41 gives recommended equipment vibration severity ratings

‘based on measured RMS velocity values (IRD 1988). The vibration

values associated with Figure 41 are measured by vibration trans-

ducers (usually accelerometers) mounted directly on equipment,

equipment structures, or bearing caps. Vibration levels measured on

equipment and equipment components can be affected by unbal-

ance, misalignment of components, and resonance interaction

between a vibrating piece of equipment and the structural floor on

which itis placed. Ifa piece of equipmentis balanced within accept-

able tolerances and excessive vibration levels still exis, the equip-

‘ment and its installation should be checked for possible resonant

conditions, Table 44 gives maximum allowable RMS velocity lev-

cls for selected pieces of equipment.

With regard to maintenance and preventive maintenance

requirements, the vibration levels measured on equipment

structures should be in the “Good” region or below in Figure

41. Machine vibration levels in the “Fair” or “Slightly Rough”

regions may indicate potential problems. Machines with vibra-

tion levels in these regions should be monitored to ensure prob-

Jems do not arise. Machine vibration levels in the “Rough” and

“Very Rough” regions indicate a potentially serious problem

exists, and immediate action should be taken to identify and

correct the problem.

SPECIFICATION OF

VIBRATION ISOLATORS

‘Vibration isolators must be selected to compensate for floor stiff-

ness. Longer spans also allow the structure to be more flexible, per-

‘mitting the building to be more easily set into vibration. Building

46.38

1999 ASHRAE Applications Handbook

Table 43 Equipment Vibration Criteria

oa | Human Occupancy Time ofDay Cane?

| Workshops rT 7

Office areas ait 1

ab Residential (good environmental 0700-72000 = HA.

standards) 2200-0700" © G

Hospital operating rooms and al F

cue vetociry sitical work areas

«soa rn ne Equipment Requirements Gane

| Computer areas #

Bench microscopes up to 100% magnification; laboratory robots F

Bench microscopes upto 400% magnification; optic! and E

£ oo Sher precision balances; coordinate measuring mackins;

> metrology itboratories; optical comparstors; microelectronics

5 ‘manufacturing equipment—Ciass A

g Microsurgery eye surgery, neurosurgery: bench microscope at

5 ‘magnification greater than 400%; optical equipment on isolation

g o000 ~ tubles; microelectronic manufacturing equipmest—Ciass B®

£ 2 Electron microscopes up to 30,000x magnification; microtomes;

magnetic resonance imagers; microelectronics mansfacturing

e 7 equipment—ClassC

00 F Electron microscopes at magnification greater than 30,000%; B

tase spectrometers; ell mplant equipment; microelectronics

eee ‘manufacturing equipment—Class D®

Unisolated laser and optical esearch systems; microelectronics A

00a | A oe ‘manufacturing equipment—Class E®

See Figur 0 forconespndiag carves.

Sim eas wher indvidoae are sensitive to vibraon, we cure H.

A 000125 Cases of microsecwescs manufacture equipment:

fast I Css A: Inspection, probe est, an ther manufetrng suppor equipment.

Pea ee ao gg 100 | Clas B: Aline teppern and oer eral qupment for phoiogrnky

‘with ie wits of 3 un o mor.

FREQUENCY, Hz

Fig. 41 Equipment Vibration Severity Rating for Vibration

Measured on Equipment Structure or Bearing Caps

asc: Kignes ae, tl ee cea equipment or alibi

oie of um

coud: Mig er ee si pet x hte

Fig. 40. Building Vibration Criteria for ce, iin wi of 05 nc onan ee

Vibration Measured on Building Structure CE SE ecto um ine iceertean geen

f ~ ‘Table 44 Equipment Vibration Criteria

10° “Alowable raw

Equipment Tot.

E cw na ao

vervrousn Yuet =~ sc

Centrifugal compresors a

RouGH 0.202 Fans (vent sets, centrifugal, axial) 0.09

SUGHTEY ROUGH a ya,

i wk spans, equipment operating speeds, equipment power, damping,

2° Fran oo thd tet factors have been considered in te Vibration isolator

z selection gui in Table 45.

§ Ficcoo oar? By specifying isolator deflection rather than isolation efficiency

| é caneaiges ater bee pre, 2 espero

5 veRY GOOD fn ‘compensate for floor stiffness and building resonances by selecting

8 Cocom | fsolsiors that provide minimum vibration transmission and thal

mc 0.0069 1 have more deflection than the supporting floor. To apply the infor-

| aay SOT 4 | mation from Table 45, base type, isolator type, and minimum

E 2.0036 deflection columns are added to the equipment schedule. These iso-

F-sancwewouoomm 4 lator specification ae then incorporated into mechanical specifi

f tons forthe project

| : "The minimum deflections listed in Table 45 are based on the

ot 7 a experience of acoustical and mechanical consultants and vibration

control manufacturers. Recommended isolator type, base type, and

‘minimum static deflection are reasonable and safe recommenda

tions for 70% to 80% of HVAC equipment installations. The selec

tions are based on concrete equipment room floors 4 to 12 in. thick

with typical floor stiffness. The type of equipment, proximity t0

noise-sensitive areas, and the type of building construction may

alter these choices.

sound and Vibration Control 46.39

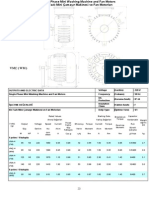

Table 45 Selection Guide for Vibration Isolation

‘Equipment Location Note)

Upe20n 2010308 oan

SlabonGrade_ Floor Span Floor Span. Floor Span

Te Min Tho: Mia, 1s- Ma. Tso Min.

Horsepower Base lator Defl, Base lator Defl, Base intor Defl, Base lator Dell, Reference

Equipment Type and Other Rom_Type Type_in.’ Type Type_n.” Type Type in.” Type Type_ in. Notes,

‘Refrigeration Machines and Chillers

Bure compressors a al A 2 025 C3 os C3 ts 4 250 zat

Reciprocating a al A 20025 A 4 ors A 3 IS A 8 25023

Ceatifugat a al A 1 035 A 4 07 A 3 175 Stas ada

Open centrifugal al ale G1 035 C4 07s C3 as tts Ba

Absorption al alo A 1 035 Ae OS KTS LS

‘Air Commpresors and Vacuum Pumps

Taakemounted| Upwe10 au A 3075 A 3 OS A 3 SA 31s tas

1Sand over all € 3 075 G3 os C8 as tts SSS

Base-nouned "All al 043 075 G3 om CO TS GS tas sata

Large reciprocating al alo G3 075 C3 0m C3 ts C3 19s SaaS

Pumps

Closed coupled upto7s al B20 «C3 os C3 Os C3 Os

10d over al 3 075 «C3 os CG 3 Is 6 3 18 ib

Laz nine 51025 al A 3 075 A 3 18K 3 13s 3

30and over al A 3 495 A 3 SA 318 SD

Bad suction and spit cate Upto alo € 3 ors G3 om 6G 3 ns C3 Ls

$00 125 al 3 075 3 os 3 1s 3 80

150 and over ai «3 oS C3 1s 3 1s G8 a0

Cooling Towers au Upto A 1 025 A 4 350 A 4 350 A 4 350

sors A 1 025 A 4 25 A 4 250 A 4 250

sOmdovr A 1 025 A 4 O75 A 4 O95 A 4 LIS

Bollers—Fre-tabe au aul A 1 025 B44 oS Be SB 4 mg

‘Axial Fans, Fan leds, Cabinet Fans, and Fan Sections

Upto 22in di. al al, A 2 0 A 3 075 A 3 07 © 3 095

2a, du aod over Uptotinsp Upto0. B38 250 C 3 350 C 3 35 © 3 350

300500 B43 075 «BS 17s C3 28 © 3 280

SOlmdover B 3 07 B 3 175 B 3 178 B 3 198

2iinsp.and “Ups C3 2 CF SDC «C3 3 3 48

ove soowso) C3 175 C 3 17 C 3 250 6 3 230

sOlmdor C 3 07 C 3 175 C 3 175 © 3 290

(Contigal Fans

Upto 22in dia. All al B2 035 B 3 os BR 3 Os C3 1s

2a da tad over Uptoso Ups BF 230 BS 55 BS 3 BOS 30

3000500 B33 17S BOS 17S BOS 250 «BOS 280

SOlmdover B 3 075 B 3 O75 B 3 O75 B 3 178

SOandower —Upwo30C «3 «28 «COS 30 COS 850 8D

soowso0 C3 175 Cc 3 1s C3 2% C3 280

SOimdover C 3 10 C 3 175 C 3 17 © 3 250

Propeller Fens

Wallmnted a al A 1 035 A 102s A 0s A ns

Roof mounted au au A 1 025 A 1 ons Bs Ls Dk 8

leat Pumps a al A 3 07S A 3 07S A 3 07S AD 3 8

Condensing Units au Al A 1 035 A 4 0S A SD 4s

‘Packaged AH, AC, Hand’ Unite

Al Upte10 Al A 3075 A 3 OS A 3 OS 3 os

1Smdove, “Upio300 A 3 OS A 3 350 A 3 350 «CS S80 2akID

wpiodinsp. 3010500 A 3078 A 3 202028 aD

sOladovr A 3 075 A 3 178 A 3 its A 3 195 4D

ISandove, Upw300 B43 075 C3380 CO 350 CO 380 2s ha9

‘imspandover 30110500 B 3 07 C 3 17S C 3 250 C 3 230 a3Kd

SOlmdover B 3 07 C 3 175 C 3 17s © 3 290 2349

Packaged Rooftop Equipment al Al WD 1 025 D3 ars See Note 17 568.17

Ducted Rotating Equipment

‘Smal fans, fan powered Upto 6006fm al A 3050 A 3 080 A 3 050 A 3 ODT

‘bores COleimandover = Al.—«s SAS O7S OTS ATS 3 OST

Engine Driven Generators All Al A 3 os cs sc 3 20 C3 350 a8

Base Tbolator Types:

‘A. No bse, isolators attached direty to equipment (Note 27)

Structural ste ral or base (Noes 28 and 29)

C. Conceinertia bate (Note 30)

.Curbmounted bese (Not 31),

[Pad uber, glass ber (Note 20 and 21)

2. Rubber flor iselator or hangee (Notes 20 and 25)

3 Spring flor issator or banger (Note 22,23, and 25)

4 Reswained spring isolator (Notes 2 and 24)

5. Thrust estat (Note 26)

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 1 Fazlı Mini Fan MotorlarıDocument1 page1 Fazlı Mini Fan Motorlarıuuur35No ratings yet

- FirestoneDocument108 pagesFirestoneEduardoNo ratings yet

- Vibration IsolationDocument14 pagesVibration IsolationYogesh100% (7)

- Design of AbsorberDocument11 pagesDesign of Absorberuuur35No ratings yet

- VVDDocument2 pagesVVDuuur35No ratings yet

- Elektrikli Ve Hibrit Elektrikli Araç Tahrik Sistemleri Için Elektrik Motor-Jeneratör Ve Sürücü SistemlerininDocument3 pagesElektrikli Ve Hibrit Elektrikli Araç Tahrik Sistemleri Için Elektrik Motor-Jeneratör Ve Sürücü Sistemlerininuuur35No ratings yet

- BZ 8002953Document15 pagesBZ 8002953uuur35No ratings yet

- 250 300 HP 2 Stage Variable Drive Air CompresorDocument12 pages250 300 HP 2 Stage Variable Drive Air Compresoruuur35No ratings yet

- 521Gasket521Gasketing - 1005 - GB - Pdfing 1005 GBDocument8 pages521Gasket521Gasketing - 1005 - GB - Pdfing 1005 GBuuur35No ratings yet

- 1 H-52734-1 Brithinee Case StudyDocument4 pages1 H-52734-1 Brithinee Case Studyuuur35No ratings yet

- Rotor Cage Fault Detection in Induction MotorsDocument26 pagesRotor Cage Fault Detection in Induction Motorsuuur35No ratings yet

- Measurement and Simulation of The Vibroacoustic Performance of An Electric MotorDocument10 pagesMeasurement and Simulation of The Vibroacoustic Performance of An Electric Motoruuur35No ratings yet

- Motor bearings: understanding common problems and proper handlingDocument8 pagesMotor bearings: understanding common problems and proper handlinghozipek5599100% (1)

- Vem Ic 418 En12101 3Document5 pagesVem Ic 418 En12101 3uuur35No ratings yet

- Bedienungs-Und Wartungsanleitung: Operating and Maintenance InstructionsDocument17 pagesBedienungs-Und Wartungsanleitung: Operating and Maintenance Instructionsuuur35No ratings yet

- High Temperature Bearing - 14961 EN - TCM - 12-171071Document64 pagesHigh Temperature Bearing - 14961 EN - TCM - 12-171071uuur35No ratings yet

- Sound Power Measurements Noise Workshop Oxford 2012-3-2 Thomas HansenDocument21 pagesSound Power Measurements Noise Workshop Oxford 2012-3-2 Thomas Hansenuuur35No ratings yet

- Rotating Machinery Rotor BalancingDocument15 pagesRotating Machinery Rotor Balancingprajash007100% (1)

- Iso 2372Document10 pagesIso 2372WulaNda Rika75% (4)

- ISO 10816-1 Normativa VibracionesDocument10 pagesISO 10816-1 Normativa Vibracionesumendibil100% (1)

- Bolted Flange ConnectionDocument6 pagesBolted Flange Connectiondip_maanNo ratings yet

- Balance Quality Requirements of Rigid Rotors - The Practical Application of ISO 1940-1Document11 pagesBalance Quality Requirements of Rigid Rotors - The Practical Application of ISO 1940-1FabbroxNo ratings yet

- Mekanik BALANS PDFDocument9 pagesMekanik BALANS PDFuuur35No ratings yet

- Vibration Monitoring For Fault Motors Diagnosis PDFDocument8 pagesVibration Monitoring For Fault Motors Diagnosis PDFuuur35100% (1)

- Doğal Frekans Dene PDFDocument10 pagesDoğal Frekans Dene PDFuuur35No ratings yet

- Rulman Tekni̇k Bi̇lgi̇Document71 pagesRulman Tekni̇k Bi̇lgi̇Sinan Aslan92% (12)

- Vibration AnalysisDocument12 pagesVibration AnalysistheealokNo ratings yet

- Sinter Burç PDFDocument6 pagesSinter Burç PDFuuur35No ratings yet

- Analisis de Falla en ReductoresDocument20 pagesAnalisis de Falla en Reductores24ava100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)