Professional Documents

Culture Documents

Model CBL 900-1800 HP Boilers

Uploaded by

sebaversaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model CBL 900-1800 HP Boilers

Uploaded by

sebaversaCopyright:

Available Formats

Model CBL 900-1800 HP Boilers

Table A5-3. CBL Input Ratings (4-Pass Boilers)

Boiler Square Foot

4000 4500 5000 5500 6000 6500 7000 7500

Heating Surface

Approximate Fuel ConsumptionD

Horsepower

800 900 1000 1100 1200 1300 1400 1500

(5 sq.ft./bhp)

Natural GasA (cfh) 32659 36741 40824 44906 48989 53071 57153 61236

B

No. 2 Oil (gph) 233.3 262.4 291.6 320.8 349.9 379.1 408.2 437.4

No. 6 OilC (gph) 217.7 244.9 272.2 299.4 326.6 353.8 381.0 408.2

Horsepower

1000 1100 1200 1300 1500 1600 1700 1800

(4 sq.ft./bhp)

Natural GasA (cfh) 40824 44906 48989 53071 57153 65317 69399 73481

No. 2 OilB (gph) 291.6 320.8 349.9 379.1 437.4 466.6 495.7 524.9

C

No. 6 Oil (gph) 272.2 299.4 326.6 353.8 408.2 435.4 462.6 489.9

Note:

A. Natural gas based on heating value of 1000 BTU/cu.ft

B. No. 2 oil based on heating value of 140,000 BTU/gal.

C. No. 6 oil based on heating value of 150,000 BTU/gal.

D. Ratings based on nominal 82% efficiency.

Section A5-6 Rev. 03-08

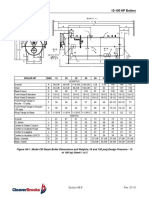

Model CBL 900-1800 HP Boilers

BOILER SQUARE FOOT HEATING

DIM 4000 4500 5000 5500 6000 6500 7000 7500

SURFACE

Boiler Horsepower@ 5 ft2/bhp 800 900 1000 1100 1200 1300 1400 1500

2

Boiler Horsepower @ 4 ft /bhp 1000 1100 1200 1300 1500 1600 1700 1800

LENGTHS

B

Overall * A 367 394 386 411 434 387 406 425

Shell B 293 323 288 312 335 304 323 342

Base Frame * C 285 317 282 304 327 296 315 334

Base Frame to Rear Flange H 26 26 26 26 26 26 26 26

Flange to Steam Nozzle E 148 148 148 148 148 148 148 148

WIDTHS

Overall With Trim I 144 144 156 156 156 168 168 168

I. D. Boiler J 114 114 126 126 126 138 138 138

Center to Water Column K 72 72 78 78 78 84 84 84

Center to Lagging L 59-1/2 59-1/2 65-3/4 65-3/4 65-3/4 71 3/4 71 3/4 71 3/4

Base Outside M 96 96 96 96 96 96 96 96

Base Inside N 80 80 80 80 80 80 80 80

* Approximate - varies with burner selection

2

Boiler Horsepower@ 5 ft /bhp 800 900 1000 1100 1200 1300 1400 1500

2

Boiler Horsepower @ 4 ft /bhp 1000 1100 1200 1300 1500 1600 1700 1800

Figure A5-1. CBL Steam Boiler Dimensions, 4-Pass (Page 1 of 2)

Section A5-7 Rev. 03-08

Model CBL 900-1800 HP Boilers

BOILER SQUARE FOOT HEATING

DIM 4000 4500 5000 5500 6000 6500 7000 7500

SURFACE

HEIGHTS

Base to piping connections F 149 149 161 161 161 168-1/8 168-1/8 168-1/8

Base to Boiler Centerline D 77-1/2 77-1/2 83-3/4 83-3/4 83-3/4 86-1/2 86-1/2 86-1/2

Base to Vent Outlet O 141 141 153-1/2 153-1/2 153-1/2 162-1/8 162-1/8 162-1/8

Base to Steam Outlet P 141 141 153-1/2 153-1/2 153-1/2 162-1/8 162-1/8 162-1/8

Base Frame Q 12 12 12 12 12 12 12 12

Base to Bottom Boiler R 20 20 20 20 20 17 17 17

CONNECTIONS

Chemical Feed G 3/4 3/4 3/4 3/4 3/4 3/4 3/4 3/4

Feedwater Inlet (Both Sides) S 3 33 3 3 3 33

A

Steam Nozzle (150 psig) Y 10 10 10 12 12 12 12 12

Blowdown - Front & Rear W 2 2 2 2 2 2 2 2

Surface Blowoff T 1 11 1 1 1 11

Vent Stack Diameter (Flanged) BB 32 32 36 36 36 42 42 42

Flange to Center Vent CC 17-1/2 17-1/2 19-1/2 19-1/2 19-1/2 24 24 24

MISCELLANEOUS

C

Rear Door Swing AA - - - -- - - -

Tube Removal - Front Only GG 246 276 217 241 264 233 252 271

Min. Boiler Room Length For

RF 537 597 538 586 632 665 703 741

Tube Removal Front

Min. Boiler Room Length For

RD 484 514 489 513 536 528 547 566

Tube Removal Thru Door

Normal Water Weight (Lbs) 43800 49400 49300 54000 60000 61000 66000 71000

Flooded Water Weight (Lbs) 54500 61300 65300 71900 78300 83000 89000 96000

Approx. Wt. 15/30 psig (Lbs.) 58000 63000 73100 77200 82200 87000 91700 96600

Approx. Wt. 150 psig (Lbs.) 65000 71000 79600 85300 90900 97300 102600 108200

Approx. Wt. 200 psig (Lbs.) 73500 82200 88600 95000 101500 107800 115500 121000

Approx. Wt. 250 psig (Lbs.) 81300 89000 97200 104000 110000 118000 124000 132000

NOTES:

Accompanying dimensions, while sufficiently accurate for layout purposes, must be confirmed for actual option requirements.

A. 300 psig Flange. See recommended steam nozzle size chart for operating pressure greater than 125 psig.

B. Add 11 1/2 inches to dimension “B” for a three pass boiler.

C. Reference Figure A11-2.

Figure A5-1. CBL Steam Boiler Dimensions, 4-Pass (Page 2 of 2)

Section A5-8 Rev. 03-08

Model CBL 900-1800 HP Boilers

DIMENSION (INCHES)

BOILER ID

A B C D E

114" 60 72 39 82 22

126" 66 78 52 93 33

138" 72 84 66 105 45

Figure A5-2. Space Required to Open Rear Doors on CBL Boilers

BOILER SQUARE BHP

FOOT OF HEATING A B C D E

SURFACE 4 sq.ft. 5 sq.ft.

4000 1000 800 138 47 205 12 3

4500 1100 900 138 47 238 12 3

5000 1200 1000 150 47 200 12 3

5500 1300 1100 150 47 222 12 3

6000 1500 1200 150 47 247 12 3

6500 1600 1300 162 47 216 12 3

7000 1700 1400 162 47 235 12 3

7500 1800 1500 162 47 254 12 3

Figure A5-3. CBL Boilers Lifting Lug Location

Section A5-9 Rev. 03-08

Model CBL 900-1800 HP Boilers

BOILER SQUARE FOOT BHP

A B C D E F G H

OF HEATING SURFACE 4 sq-ft 5 sq-ft

4000 1000 800 6 12 * 76 100 8 80 12

4500 1100 900 6 12 * 76 100 8 80 12

5000 1200 1000 6 12 * 76 100 8 80 15

5500 1300 1100 6 12 * 76 100 8 80 15

6000 1500 1200 6 12 * 76 100 8 80 15

6500 1600 1300 6 12 * 76 100 8 80 15

7000 1700 1400 6 12 * 76 100 8 80 15

7500 1800 1500 6 12 * 76 100 8 80 15

NOTE: All numbers in table are in inches.

6-inch high mounting piers recommended for beneath the boiler frame. The use of these piers provides increased inspection

accessibility to the piping beneath the boiler and added height for washing down the area beneath the boiler.

The (*) varies with horsepower rating and burner selection, see Dimension Diagram for job-specific mounting pier length.

Figure A5-4. CBL Boiler Mounting Piers

PERFORMANCE DATA

Efficiency

Tables A5-4, A5-5, A5-6, A5-7, A5-8, and A5-9 show predicted fuel-to-steam efficiencies

(including radiation and convection losses) for Cleaver-Brooks CBL Firetube boilers. For

specific efficiencies on firetube boiler offerings not listed here, contact your local Cleaver-

Brooks authorized representative.

Cleaver-Brooks offers an industry leading fuel-to-steam boiler efficiency guarantee for

CBL Firetube Boilers. The guarantee is based on the fuel-to-steam efficiencies shown in

the efficiency tables and the following conditions. The efficiency percent number is only

meaningful if the specific conditions of the efficiency calculations are clearly stated in the

specification (see Cleaver-Brooks publication CB-7767 for a detailed description of

efficiency calculations).

The boiler manufacturer shall guarantee that, at the time of startup, the boiler will achieve

fuel-to-steam efficiency (as shown in the tables listed above) at 100% firing rate (add

efficiency guarantees at 25%, 50%, and 75% of rating, if required). If the boiler(s) fail to

Section A5-10 Rev. 03-08

You might also like

- Model 4WG 100 - 800 HP Boilers: Burner/Control OptionsDocument4 pagesModel 4WG 100 - 800 HP Boilers: Burner/Control OptionssebaversaNo ratings yet

- Thermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualFrom EverandThermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualNo ratings yet

- Φούρνος Electrolux παλιός διασκορπισηDocument14 pagesΦούρνος Electrolux παλιός διασκορπισηΠαναγιώτης ΚοκκίνηςNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Boiler SpecificationsDocument3 pagesBoiler Specificationssimonatics08No ratings yet

- GHHDocument28 pagesGHHRanit MukherjeeNo ratings yet

- Model CB Boilers 15-100 HP: Dimensions and RatingsDocument10 pagesModel CB Boilers 15-100 HP: Dimensions and Ratingsleonel lopezNo ratings yet

- Model CB Boilers 15-100 HP: Dimensions and RatingsDocument9 pagesModel CB Boilers 15-100 HP: Dimensions and RatingsMauricio RojasNo ratings yet

- E 5 Appendix "A"Document48 pagesE 5 Appendix "A"Braulio CvNo ratings yet

- DR ModelCBR May09Document8 pagesDR ModelCBR May09scax25No ratings yet

- NEF67 TE5 - 202kW - 217kWDocument3 pagesNEF67 TE5 - 202kW - 217kWMatheus TonetaNo ratings yet

- R410 Units SpecificationsDocument2 pagesR410 Units SpecificationsKello jamesNo ratings yet

- Service Manual Air ConditionDocument63 pagesService Manual Air ConditionespagnitaNo ratings yet

- Boiler - Tech Guide - Dimensions Ratings - CB - CB Hot WaterDocument88 pagesBoiler - Tech Guide - Dimensions Ratings - CB - CB Hot WaterzacccccNo ratings yet

- Blast Furnace OverviewDocument26 pagesBlast Furnace OverviewProfMVSNo ratings yet

- Tma FC: MiserDocument15 pagesTma FC: MiserJim JonesjrNo ratings yet

- Dual Fuel Gas/Light-Oil Burners at Two Stages: SK073506 - C - enDocument4 pagesDual Fuel Gas/Light-Oil Burners at Two Stages: SK073506 - C - ensteam mastersNo ratings yet

- Manual Servicios LG Aruv PDFDocument42 pagesManual Servicios LG Aruv PDFHERIBERTONo ratings yet

- Condensing Unit: ASE-18AH, ASE-24AH, ASE-36AH, ASE-48AH, ASE-60AHDocument41 pagesCondensing Unit: ASE-18AH, ASE-24AH, ASE-36AH, ASE-48AH, ASE-60AHMilton UrrozNo ratings yet

- Model ICB 100-800 HP Boilers: Table A4-3. Model ICB Hot Water Boiler Ratings, 4-PassDocument4 pagesModel ICB 100-800 HP Boilers: Table A4-3. Model ICB Hot Water Boiler Ratings, 4-PasssebaversaNo ratings yet

- Fiche Split Mural InverterDocument2 pagesFiche Split Mural InverterOULDITTOU MohamedNo ratings yet

- Blast Furnace OverviewDocument26 pagesBlast Furnace OverviewResego PhiriNo ratings yet

- Thermal Fluid Heaters (Fulton)Document16 pagesThermal Fluid Heaters (Fulton)Martín Diego MastandreaNo ratings yet

- City Multi Catalogpart 108Document1 pageCity Multi Catalogpart 108Enak CenirNo ratings yet

- Furnace: A Division of Crown Boiler CoDocument4 pagesFurnace: A Division of Crown Boiler Cokamran shahNo ratings yet

- JGK-T ArielDocument4 pagesJGK-T Arielrsilayen951No ratings yet

- Parameters of Different Heat ExchangersDocument2 pagesParameters of Different Heat ExchangersCuando la dictadura es un hecho, la Revolución es un derechoNo ratings yet

- OACOACHMANUAL05282008Document29 pagesOACOACHMANUAL05282008G MartinNo ratings yet

- Copeland Hermetic CS & Scrolls ZF, ZP, ZODocument3 pagesCopeland Hermetic CS & Scrolls ZF, ZP, ZOCirstea Nicoleta50% (2)

- Model: C2250 D5 Frequency: 50 HZ Fuel Type: Diesel: Generator Set Data SheetDocument3 pagesModel: C2250 D5 Frequency: 50 HZ Fuel Type: Diesel: Generator Set Data Sheetarshadtabassum782No ratings yet

- Dimensions and Ratings: Watertube BoilerDocument10 pagesDimensions and Ratings: Watertube Boilerfauzi endraNo ratings yet

- Ship Info MRV and Seemp and Basic Vessel Info.1Document4 pagesShip Info MRV and Seemp and Basic Vessel Info.1Sachin SikkaNo ratings yet

- Boiler Design Data: GT-3620 GT-3621 GT-5307Document1 pageBoiler Design Data: GT-3620 GT-3621 GT-5307Gaurav SinghNo ratings yet

- Boi e BF Mod. 100 - 150 - 200 - 300 - 500Document4 pagesBoi e BF Mod. 100 - 150 - 200 - 300 - 500Beatrix BtxNo ratings yet

- 3828A24006XDocument51 pages3828A24006XMarco KersulNo ratings yet

- Lennox - Split Pared R-22Document2 pagesLennox - Split Pared R-22Saidy Jimena Plazas MarlesNo ratings yet

- Semen Rate 5Document8 pagesSemen Rate 5wretchNo ratings yet

- TP BravusDocument2 pagesTP Bravussloba68No ratings yet

- Operation 490BDocument60 pagesOperation 490BYe Min Htike100% (1)

- Vecv Diesel GeneratorsDocument1 pageVecv Diesel GeneratorsHariNo ratings yet

- ), 1$/ DRAWINGS FOR Centrifugal SeparatorDocument2,113 pages), 1$/ DRAWINGS FOR Centrifugal SeparatorCvetelin TodorovNo ratings yet

- 1 Ficha Tecnica Piso CieloDocument1 page1 Ficha Tecnica Piso CieloFranklinIgorLeytonMoragaNo ratings yet

- High Wall Unit: 42KHF / 42QHFDocument2 pagesHigh Wall Unit: 42KHF / 42QHFAhmed ElsayedNo ratings yet

- Series: High Pressure BoilerDocument4 pagesSeries: High Pressure Boilerjohn torresNo ratings yet

- Series: High Pressure BoilerDocument4 pagesSeries: High Pressure BoilerHeide Liseth Salazar VegaNo ratings yet

- Despiece Fanworld fw2Document49 pagesDespiece Fanworld fw2jesus rodriguezNo ratings yet

- Press-T G Ts0038uk03Document20 pagesPress-T G Ts0038uk03Berhanu GebreyohannesNo ratings yet

- Katalog Defro - en 01 - 2022Document36 pagesKatalog Defro - en 01 - 2022Octavian MrejeruNo ratings yet

- C13TE2A DatasheetDocument3 pagesC13TE2A DatasheetPowerTechNo ratings yet

- Dokumen - Tips - Tabla de Especificaciones Tcnicas Condensador de Especificaciones Tcnicas CondensadorDocument1 pageDokumen - Tips - Tabla de Especificaciones Tcnicas Condensador de Especificaciones Tcnicas CondensadorMisael EstevezNo ratings yet

- Triangle Tube SME Hybrid Solar/Geothermal DHW Storage Tanks BrochureDocument4 pagesTriangle Tube SME Hybrid Solar/Geothermal DHW Storage Tanks Brochuree-ComfortUSANo ratings yet

- 3700 Tech DataDocument2 pages3700 Tech DataMohamed BadranNo ratings yet

- AsdDocument26 pagesAsdJawed JdNo ratings yet

- GE Gas Turbine Generator Spare Parts For PG 5341 P, PG 5361 P 1ST STAGE BUCKET KIT 314B 7158 G003Document3 pagesGE Gas Turbine Generator Spare Parts For PG 5341 P, PG 5361 P 1ST STAGE BUCKET KIT 314B 7158 G003ajo zinzoNo ratings yet

- Spesifikasi Teknis Heat PumpDocument16 pagesSpesifikasi Teknis Heat Pumpcrisma tariNo ratings yet

- Bentoflex ST 133 Ka/K: Providing Sustainable Energy Solutions WorldwideDocument24 pagesBentoflex ST 133 Ka/K: Providing Sustainable Energy Solutions Worldwidesameeh919No ratings yet

- Multi V Air Conditioner: SVC MANUAL (Exploded View)Document21 pagesMulti V Air Conditioner: SVC MANUAL (Exploded View)José ArgüelloNo ratings yet

- Wascomat Flatwork Ironer Specifications IC5019 LF OC5021 R LF IC5025 R LF IC5028 R LF IC5032 R LFDocument2 pagesWascomat Flatwork Ironer Specifications IC5019 LF OC5021 R LF IC5025 R LF IC5028 R LF IC5032 R LFmairimsp2003No ratings yet

- 1939-1964 Ford Tractor Specifications & DataDocument12 pages1939-1964 Ford Tractor Specifications & Datajleo250% (1)

- Model CB 15-100 HP Boilers: LightsDocument5 pagesModel CB 15-100 HP Boilers: LightssebaversaNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)Document5 pagesModel CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)sebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDocument5 pagesModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocument5 pagesModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizeDocument5 pagesModel CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizesebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDocument5 pagesModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Sound LevelDocument5 pagesModel CB 15-100 HP Boilers: Sound LevelsebaversaNo ratings yet

- Features and Benefits: Model CB 15-100 HP BoilersDocument5 pagesFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDocument5 pagesModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaNo ratings yet

- Section A5: Model CBL 900-1800 HP BoilersDocument5 pagesSection A5: Model CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CBL: 900 - 1800 HP Steam Wet-Back Package BurnerDocument5 pagesModel CBL: 900 - 1800 HP Steam Wet-Back Package BurnersebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Engineering DataDocument5 pagesModel CBL 900-1800 HP Boilers: Engineering DatasebaversaNo ratings yet

- 81Document5 pages81sebaversaNo ratings yet

- Model CBR 125-800 HP BoilersDocument5 pagesModel CBR 125-800 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EDocument5 pagesModel CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EsebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocument5 pagesModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 pagesModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaNo ratings yet

- 78Document5 pages78sebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- General: Model ICB 100-800 HP BoilersDocument4 pagesGeneral: Model ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EDocument5 pagesModel CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EsebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Document6 pagesModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaNo ratings yet

- 75Document5 pages75sebaversaNo ratings yet

- Model ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimDocument4 pagesModel ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimsebaversaNo ratings yet

- VII Steam Generator Rev1Document24 pagesVII Steam Generator Rev1tap isko006No ratings yet

- MAAE 2400 Lab Manual PDFDocument49 pagesMAAE 2400 Lab Manual PDFVincent LiNo ratings yet

- rt80 95 115 BrochureDocument9 pagesrt80 95 115 BrochurerabihharizNo ratings yet

- Idi Excavator: Net Horsepower SAE J1349Document8 pagesIdi Excavator: Net Horsepower SAE J1349alexns84No ratings yet

- SAE Metric Users GuideDocument39 pagesSAE Metric Users GuidehaharameshNo ratings yet

- MDSP Mastery Part 2-Answer KeyDocument2 pagesMDSP Mastery Part 2-Answer KeyLorence Cardenas100% (1)

- Fiat Kobelko Ex135 Shop ManualDocument20 pagesFiat Kobelko Ex135 Shop Manualkaren100% (44)

- C89A Service Kits and Parts ListDocument32 pagesC89A Service Kits and Parts ListrobertNo ratings yet

- CompAir SolenoidValvesDocument8 pagesCompAir SolenoidValvesSam JoseNo ratings yet

- Yanmar Engine For ShipDocument20 pagesYanmar Engine For ShipM Sholikhul Muhdi Syams75% (4)

- M45LSE-100034T8 運転構造編(英)Document207 pagesM45LSE-100034T8 運転構造編(英)Tansu Mavunacı100% (4)

- 6CTA (430,2600,2172, HO, Dec 00, M-90215)Document2 pages6CTA (430,2600,2172, HO, Dec 00, M-90215)Gonzalo FioriloNo ratings yet

- Wirtgen W 2000 DatasheetDocument8 pagesWirtgen W 2000 DatasheetBeltazor HellboyNo ratings yet

- AHUsDocument43 pagesAHUsAudric Ralph TuppilNo ratings yet

- HD1500-7 Operation & Mainenance Manual PDFDocument162 pagesHD1500-7 Operation & Mainenance Manual PDFanggieNo ratings yet

- Manual Kubota d1105Document142 pagesManual Kubota d1105Eduardo Neivas100% (6)

- Unit Conversions: Appendix BDocument6 pagesUnit Conversions: Appendix BMehul RabariNo ratings yet

- PC350 8 - PC350LC 8 - Cen00222 03 PDFDocument8 pagesPC350 8 - PC350LC 8 - Cen00222 03 PDFLU YONo ratings yet

- Dozer Comparison DatabaseDocument20 pagesDozer Comparison DatabaseJoshwa SimamoraNo ratings yet

- Pumps: Key ConceptsDocument8 pagesPumps: Key ConceptsJadeAsurtoNo ratings yet

- Unit 7 Ic Engine Testing: StructureDocument39 pagesUnit 7 Ic Engine Testing: Structurevishal kumarNo ratings yet

- Hydraulic Motors: T E C H N I C A L C A T A L O GDocument20 pagesHydraulic Motors: T E C H N I C A L C A T A L O Gdinny blanco rojasNo ratings yet

- Detroit DD15 Engine: Horsepower LB-FT Torque LitersDocument10 pagesDetroit DD15 Engine: Horsepower LB-FT Torque Litersramsi17100% (1)

- Applying Adjustable Frequency Drives: What Does Applying A Drive Mean?Document25 pagesApplying Adjustable Frequency Drives: What Does Applying A Drive Mean?jiguparmar20094903No ratings yet

- D475a, D475asd 5e0Document18 pagesD475a, D475asd 5e0João MariaNo ratings yet

- Gang SawDocument55 pagesGang SawAstri NgentNo ratings yet

- Quantum Engine Series: Ower AtingsDocument2 pagesQuantum Engine Series: Ower AtingsAlbertoNo ratings yet

- CP 7760 PC9650 - 01mar15Document1,260 pagesCP 7760 PC9650 - 01mar15Clodoaldo100% (2)

- Contender Series Manual Motor Starters and Contactors: Explosionproof, Dust-IgnitionproofDocument2 pagesContender Series Manual Motor Starters and Contactors: Explosionproof, Dust-Ignitionproofpr_oilNo ratings yet

- Manual Datos Tecnicos ZetorDocument127 pagesManual Datos Tecnicos ZetoredhuamNo ratings yet