Professional Documents

Culture Documents

900-1800 HP Boiler Specs

Uploaded by

sebaversaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

900-1800 HP Boiler Specs

Uploaded by

sebaversaCopyright:

Available Formats

Model CBL 900-1800 HP Boilers

open until pilot flame has been established. The pilot train shall include one

manual shut-off valve, solenoid valve, pressure regulator and pressure gauge

and one (1) plugged leakage test (Canada only).

3. Oil Pump - An oil pump set with a capacity of approximately twice the maximum

burning rate shall be included.

• The motor driven pump set, shipped loose, to be installed in a location

favorable to the oil storage tank shall be provided.

4. Oil Burner Piping - Fuel oil piping on the unit shall include oil pressure regulating

devices, oil metering controls, low oil pressure switch, two (2) motorized oil

valves and pressure gauges all integrally mounted on the unit.

5. Low Pressure Air-Atomizing - Separate air compressor module, “shipped loose”

with the burner-mounted low-atomizing air pressure switch.

6. Oil Preheat

The oil shall be preheated by a steam heater and electric heater, each with

thermostatic control. Both heaters shall be installed in a single compact shell;

mounted, piped, and wired. The thermostatic controls shall be set to cut-out the

electric heater when steam is available.

7. Burner Turndown - Turndown range will be 4:1 when firing No. 6 oil on standard

burners with uncontrolled emissions. Consult Cleaver-Brooks representative

regarding turndown capability for low NOx burners.

E. Fuel Series 400 - No. 6 Oil or Gas-Fired

1. Burner Type - The burner shall be mounted at the front the boiler and shall be a

combination of the low pressure atomizing type for oil and multi-port type for gas.

The burner shall be approved for operation with either CS12-48 Commercial No.

6 oil or natural gas.

2. Gas Pilot - The gas pilot shall be a premix type with automatic electric ignition.

An electronic detector shall monitor the pilot so that the primary fuel valve cannot

open until pilot flame has been established. The pilot train shall include one

manual shut-off valve, solenoid valve, pressure regulator and pressure gauge,

and one (1) plugged leakage test connection. (Canada only.)

3. Oil Burner

a. Oil Pump - An oil pump with a capacity of approximately twice the maximum

burning rate shall be included. The motor driven pump set, shipped loose,

shall be provided to be installed in a location favorable to the oil storage tank.

b. Oil Burner Piping - Fuel oil piping on the unit shall include oil pressure

regulating devices, oil metering controls, low oil pressure switch, two (2)

motorized oil valves, and pressure gauges all integrally mounted on the unit.

c. Low Pressure Air-Atomizing: Separate air compressor module “shipped

loose” with burner mounted low atomizing air pressure switch.

d. Oil Preheat - The oil shall be preheated by a steam heater and electric

heater, each with thermostatic control. Both heaters shall be installed in a

single compact shell mounted, piped, and wired. The thermostatic controls

shall be sent to cut-out the electric heater when steam is available.

e. Burner Turndown - Turndown range will be 4:1 when firing No. 6 oil on

standard burners with uncontrolled emissions. Consult Cleaver-Brooks

representative regarding turndown capability for low NOx burners.

f. Gas Burner

1) Gas Burner Piping - Gas burner piping on all units shall include a gas

pressure regulator, and a primary gas shutoff valve, motor-operated with

proof-of-closure switch and plugged leakage test connection. The main

Section A5-26 Rev. 03-08

Model CBL 900-1800 HP Boilers

gas valves shall be wired to close automatically in the event of power

failure, flame failure, low water or any safety shutdown condition. A

lubricating plug cock shall be provided as means for a tightness check of

the primary shutoff valve. An additional plug cock shall be furnished at

entrance to gas train. High and low gas pressure switches shall be

provided. A second motorized safety shutoff valve, plus an additional

plugged leakage test connection shall be provided. A vent valve shall be

located between the safety shutoff valves.

2) Burner Turndown - Turndown range shall be 6:1 when firing natural gas

on standard burners with uncontrolled emissions (100 ppm NOx).

Consult Cleaver- Brooks representative regarding turndown capability for

low NOx burners 30 ppm and less.

2.5 Boiler Flame Safeguard Controller and Control Panel

A. CB100E Flame Safeguard

1. Each boiler shall be factory-equipped with flame safeguard controller providing

technology and functions equal to the Cleaver-Brooks Model CB100E.

Flame safeguard shall be a Cleaver-Brooks Model CB 100E microprocessor-

based control to monitor all critical boiler and burner interlocks, control and

supervise burner light-off sequence, and initiate an orderly safety procedure in

the event of interlock or flame failure. The system shall provide status, fault

history, and diagnostic information by means of a BACKLIT LCD display. The

system shall be approved by UL, FM, and CSA, and shall be acceptable by IRI.

B. Control Panel

A factory prewired control panel shall be supplied with the boiler/burner package.

Panel may be mounted on the burner or boiler.

1. The panel will have a NEMA 1A rating and contain the flame safeguard

controller, burner motor starter, air compressor motor starter, oil-metering

pump motor starter, control circuit transformer and fuses, selector switches,

indicating lights and terminal strips. Lights shall indicate load demand, flame

failure, low water, and fuel valve open.

2. The panel shall contain over-current protection for the burner motor, air

compressor motor, and oil metering pump.

2.6 Efficiency Guarantee

A. The boiler must be guaranteed to operate at a minimum fuel-to-steam efficiency of

_____ percent at 100 percent of rating when burning natural gas and _____ fuel-to-

steam efficiency at 100% firing rate when burning oil (Contact your local Cleaver-

Brooks authorized representative for efficiency details).

PART 3 EXECUTION

3.1 Warranty

A. All equipment is to be guaranteed against defects in materials and/or workmanship

for a period of 12 months from date of start-up, or 18 months from date of shipment;

whichever comes first.

3.2 Shop Tests

A. The packaged boiler must receive factory tests to check the construction, controls,

and operation of the unit. All tests may be witnessed by the purchaser, if desired.

Section A5-27 Rev. 03-08

Model CBL 900-1800 HP Boilers

B. Start-up Service

1. After boiler installation is completed, the manufacturer shall provide the services

of a field representative for starting the unit and training the operator at no

additional costs.

a. A factory-approved and authorized start-up report shall be submitted to the

customer/user at the time of start-up.

Section A5-28 Rev. 03-08

Model CB 15-100 HP Boilers

MODEL CB

15 - 100 HP

Steam and Hot Water

Dryback Integral Burner

CONTENTS

FEATURES AND BENEFITS ............................................................................................................................... A6-3

PRODUCT OFFERING ........................................................................................................................................ A6-4

Boiler Options ................................................................................................................................................... A6-4

Burner/Control Options ..................................................................................................................................... A6-4

Fuel Options ..................................................................................................................................................... A6-5

DIMENSIONS AND RATINGS ............................................................................................................................. A6-5

PERFORMANCE DATA ..................................................................................................................................... A6-14

Efficiency......................................................................................................................................................... A6-14

Emissions........................................................................................................................................................ A6-15

ENGINEERING DATA ........................................................................................................................................ A6-17

Blowdown Water Requirements ..................................................................................................................... A6-17

Sound Level .................................................................................................................................................... A6-18

Units ................................................................................................................................................................ A6-18

Test Method .................................................................................................................................................... A6-21

Sound Level Meter.......................................................................................................................................... A6-21

Sound Pressure .............................................................................................................................................. A6-21

Typical Values ................................................................................................................................................ A6-21

Octave Band ................................................................................................................................................... A6-21

Gas-Fired Burners .......................................................................................................................................... A6-21

Oil-Fired Burners ............................................................................................................................................ A6-21

No. 6 Oil Piping, Storage Tank Heating.......................................................................................................... A6-22

Boiler Room Information ................................................................................................................................. A6-30

Stack Support Capabilities.............................................................................................................................. A6-30

Stack/Breeching Size Criteria ......................................................................................................................... A6-30

Boiler Room Combustion Air .......................................................................................................................... A6-30

SAMPLE SPECIFICATIONS - STEAM .............................................................................................................. A6-35

SAMPLE SPECIFICATIONS - HOT WATER ..................................................................................................... A6-47

Section A6-1 Rev. 07-10

Model CB 15-100 HP Boilers

ILLUSTRATIONS

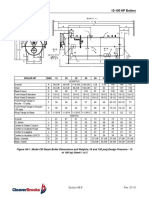

Figure A6-1. Model CB Steam Boiler Dimensions and Weights (15 and 150 psig Design Pressure -

15 to 100 hp) Sheet 1 of 2 ....................................................................................................................... A6-8

Figure A6-2. Model CB Hot Water Boiler Dimensions (30 psig and 125 psig Design Press. -

15 to 100 hp) Sheet 1 of 2 ..................................................................................................................... A6-10

Figure A6-3. Space Required to Open Rear Head on Model CB Boilers Equipped with Davits ........................ A6-12

Figure A6-4. Model CB Boiler Mounting Piers .................................................................................................... A6-12

Figure A6-5. Lifting Lug Locations, Model CB Boilers ........................................................................................ A6-13

Figure A6-6. Predicted Stack Temperature Increase for Pressure Greater Than 125 psig ............................... A6-16

Figure A6-7. Standard Gas Train Connection Size and Location ...................................................................... A6-23

Figure A6-8. Typical Gas Piping Layout ............................................................................................................. A6-24

Figure A6-9. Model CB Gas Train Components ................................................................................................. A6-25

Figure A6-10. No. 2 Oil Connection Size, Location and Recommended Line Sizes ......................................... A6-26

Figure A6-11. No. 6 Oil Connection Size, Location and Recommended Line Sizes, Model CB Boiler ............. A6-26

Figure A6-12. No. 2 Oil Piping, Single Boiler Installation, Remote Oil Pump..................................................... A6-27

Figure A6-13. No. 2 Oil Piping, Multiple Boiler Installation, Remote Oil Pumps ................................................ A6-27

Figure A6-14. No. 2 Oil Piping, Multiple Boiler Installation ................................................................................. A6-28

Figure A6-15. No. 2 Oil Piping ............................................................................................................................ A6-29

Figure A6-16. Typical Fuel Storage Tank Arrangement ..................................................................................... A6-29

Figure A6-17. Boiler Room Length (Typical Layout) .......................................................................................... A6-32

Figure A6-18. Boiler Room Width (Typical Layout) ............................................................................................ A6-32

Figure A6-19. Breeching Arrangement ............................................................................................................... A6-33

TABLES

Table A6-1. Model CB Steam Boiler Ratings (15 - 100 hp) ................................................................................. A6-6

Table A6-2. Model CB Hot Water Boiler Ratings (15 - 100 hp) ............................................................................ A6-6

Table A6-3. Steam Boiler Safety Valve Openings................................................................................................ A6-7

Table A6-4. Hot Water Boiler Relief Valve Openings ........................................................................................... A6-7

Table A6-5. Predicted Fuel-to-Steam Efficiencies (%), Model CB Boilers - 10 psig, Natural Gas ..................... A6-15

Table A6-6. Predicted Fuel-to-Steam Efficiencies (%), Model CB Boilers - 125 psig, Natural Gas ................... A6-15

Table A6-7. Predicted Fuel-to-Steam Efficiencies (%), Model CB Boilers - 10 psig, No. 6 Oil .......................... A6-16

Table A6-8. Predicted Fuel-to-Steam Efficiencies (%), Model CB Boilers - 125 psig, No 6 Oil ......................... A6-16

Table A6-9. Predicted Fuel-to-Steam Efficiencies (%), Model CB Boilers - 10 psig, No. 2 Oil .......................... A6-16

Table A6-10. Predicted Fuel-to-Steam Efficiencies (%), Model CB Boilers - 125 psig, No 2 Oil ......................... A6-16

Table A6-11. Model CB Boiler Emission Data .................................................................................................... A6-17

Table A6-12. Heating Surface, Model CB Boilers .............................................................................................. A6-17

Table A6-13. Steam Volume and Disengaging Area.......................................................................................... A6-18

Table A6-14. Water Circulation Rate and Temperature Drop for Hot Water Boiler ........................................... A6-18

Table A6-15. Recommended Steam Nozzle Size (To Maintain 4000 to 5000 fpm Nozzle Velocity) ................. A6-19

Table A6-16. Model CB Blowdown Tank Sizing Information .............................................................................. A6-19

Table A6-17. Sound Pressure Level Summary (50-100 hp) .............................................................................. A6-19

Table A6-18. Model CB Boiler Sound Pressure Level Details (40 hp) ............................................................... A6-20

Table A6-19. Model CB Boiler Sound Pressure Level Details (50 - 100 hp)...................................................... A6-20

Table A6-20. Minimum Required Gas Pressure at Entrance To Gas Train ....................................................... A6-22

Table A6-21. Minimum Required Gas Pressure Altitude Conversion ................................................................ A6-22

Table A6-22. Maximum Gas Consumption (CFH) for Natural Gas and Propane Vapor.................................... A6-23

Table A6-23. Gas Pilot Data ............................................................................................................................... A6-23

Section A6-2 Rev. 07-10

You might also like

- Model CBR 125-800 HP BoilersDocument5 pagesModel CBR 125-800 HP BoilerssebaversaNo ratings yet

- 60 PPM Nox Operation Natural Gas: CBEX Elite 100-800 HPDocument4 pages60 PPM Nox Operation Natural Gas: CBEX Elite 100-800 HPsebaversaNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- CBEX Elite 100-800 HPDocument4 pagesCBEX Elite 100-800 HPsebaversaNo ratings yet

- CBEX Elite 100-800 HPDocument4 pagesCBEX Elite 100-800 HPsebaversaNo ratings yet

- CBEX 350 To 800 HorsepowerDocument4 pagesCBEX 350 To 800 HorsepowersebaversaNo ratings yet

- Model CBLE 100-800 HP BoilersDocument4 pagesModel CBLE 100-800 HP BoilerssebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model 4WI Boiler Warranty, Tests and StartupDocument4 pagesModel 4WI Boiler Warranty, Tests and StartupsebaversaNo ratings yet

- High-efficiency boiler specifications for 100-800 HP modelsDocument4 pagesHigh-efficiency boiler specifications for 100-800 HP modelssebaversaNo ratings yet

- Efficient 15-100 HP Boilers for BuildingsDocument5 pagesEfficient 15-100 HP Boilers for BuildingssebaversaNo ratings yet

- Series 500 Water SpecDocument5 pagesSeries 500 Water SpecChristhofer Arroyo ChacónNo ratings yet

- Boiler SpecificationsDocument25 pagesBoiler Specificationspaul kioiNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Hurst Boiler & Welding Co., IncDocument4 pagesHurst Boiler & Welding Co., IncChristian Veliz CamargoNo ratings yet

- Series 4vt Steam SpecificationsDocument5 pagesSeries 4vt Steam Specificationsagusti24No ratings yet

- Hurst Boiler & Welding Company, Inc.: SERIES 500 STEAM BOILER (100-1500 HP, STEAM 15-300 Psig) Sample SpecificationsDocument5 pagesHurst Boiler & Welding Company, Inc.: SERIES 500 STEAM BOILER (100-1500 HP, STEAM 15-300 Psig) Sample SpecificationsDaniel GonzalezNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- General: Model ICB 100-800 HP BoilersDocument4 pagesGeneral: Model ICB 100-800 HP BoilerssebaversaNo ratings yet

- SPEC ModelCBR Steam Mar4Document10 pagesSPEC ModelCBR Steam Mar4Jason PoloNo ratings yet

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDocument5 pagesModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaNo ratings yet

- 9 IriDocument2 pages9 IriEnrique PauliniNo ratings yet

- SPEC Model CB Steam Jan11Document12 pagesSPEC Model CB Steam Jan11Stanford BrownNo ratings yet

- Spec Modelcble Steam Mar4Document12 pagesSpec Modelcble Steam Mar4Jason PoloNo ratings yet

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 pagesModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaNo ratings yet

- Section A5: Model CBL 900-1800 HP BoilersDocument5 pagesSection A5: Model CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Gs 18ms 1pdDocument11 pagesGs 18ms 1pdRitesh JhaNo ratings yet

- 1.0 Specification of Equipment / Material and Installation Standards 1.1 Specifications For Water Cooled Centrifugal Chiller Performance ParametersDocument8 pages1.0 Specification of Equipment / Material and Installation Standards 1.1 Specifications For Water Cooled Centrifugal Chiller Performance Parametersعامر شیخNo ratings yet

- 100-800 HP Model CB-LE Boilers SpecificationsDocument11 pages100-800 HP Model CB-LE Boilers SpecificationsDiogenes Rafael TorresNo ratings yet

- Section A1 Model Cb-Le Steam Boiler Specifications (125-800 HP, STEAM 15-300 PSIG)Document4 pagesSection A1 Model Cb-Le Steam Boiler Specifications (125-800 HP, STEAM 15-300 PSIG)sebaversaNo ratings yet

- Section A1 Model Cb-Le Hot Water Specifications (125-800 HP, 30 PSIG, 125 PSIG)Document4 pagesSection A1 Model Cb-Le Hot Water Specifications (125-800 HP, 30 PSIG, 125 PSIG)sebaversaNo ratings yet

- Hot Water Boilers ControlDocument13 pagesHot Water Boilers ControlMunir RasheedNo ratings yet

- Model CBLE Steam Boilers from 100-800 HPDocument12 pagesModel CBLE Steam Boilers from 100-800 HPDiogenes Rafael TorresNo ratings yet

- Section 9 Oil Burners and Oil Firing Equipment: A. General 1. Scope 1.1Document4 pagesSection 9 Oil Burners and Oil Firing Equipment: A. General 1. Scope 1.1Muh Kurniawan SNo ratings yet

- Eca Day Tank SpecDocument3 pagesEca Day Tank Specenlightened1718No ratings yet

- Normas de seguridad para sistemas de combustibleDocument10 pagesNormas de seguridad para sistemas de combustibleRonnyNo ratings yet

- Technical Specifications Valve Actuators ScopeDocument6 pagesTechnical Specifications Valve Actuators ScopeBilalPervezNo ratings yet

- Fire Pump, Motor and ControllerDocument3 pagesFire Pump, Motor and Controllerعامر شیخNo ratings yet

- Model 4WG 100 - 800 HP BoilersDocument4 pagesModel 4WG 100 - 800 HP BoilerssebaversaNo ratings yet

- Fire Protection and Suppression SystemDocument4 pagesFire Protection and Suppression Systemamrit90320No ratings yet

- Gas detection and safety systems overviewDocument4 pagesGas detection and safety systems overviewinfo5922No ratings yet

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaNo ratings yet

- Manual Powerflame C PDFDocument56 pagesManual Powerflame C PDFRoberto MnedezNo ratings yet

- 2MW Turbine EnquiryDocument7 pages2MW Turbine EnquiryRamu MaddiNo ratings yet

- 100-800 HP Boiler Control System PLC HMI Safety FunctionsDocument4 pages100-800 HP Boiler Control System PLC HMI Safety FunctionssebaversaNo ratings yet

- Replacement of Boiler ControlsDocument7 pagesReplacement of Boiler Controlscam0917No ratings yet

- Burner Logic System PDFDocument5 pagesBurner Logic System PDFshiviitd02No ratings yet

- Hurst Boiler & Welding Company, IncDocument7 pagesHurst Boiler & Welding Company, IncChristian Veliz CamargoNo ratings yet

- Gas Train Requirements For Gas or Dual Fired Steam Boiler PDFDocument2 pagesGas Train Requirements For Gas or Dual Fired Steam Boiler PDFringo limNo ratings yet

- Fi 6-Fi 81F2Omf22: Burner Instruction ManualDocument36 pagesFi 6-Fi 81F2Omf22: Burner Instruction ManualMaurice Lachaud100% (1)

- Model 4WI 100 - 800 HP BoilersDocument4 pagesModel 4WI 100 - 800 HP BoilerssebaversaNo ratings yet

- Chapter 2 Single Burner Boilers: Boiler and Combustion Systems Hazards CodeDocument12 pagesChapter 2 Single Burner Boilers: Boiler and Combustion Systems Hazards CodeJosé Olivier RománNo ratings yet

- HVAC Guide Specifications Commercial Air-Cooled Condensing UnitsDocument4 pagesHVAC Guide Specifications Commercial Air-Cooled Condensing UnitsHazemNo ratings yet

- Tech Spec of Nitrogen InjectionDocument5 pagesTech Spec of Nitrogen InjectionJustin MyersNo ratings yet

- CFS31 Day Tanks and Return Pump 4-7-20Document10 pagesCFS31 Day Tanks and Return Pump 4-7-20Getahun AmareNo ratings yet

- Turn Key Steam Boilers System Section 1 1.00 - GENERAL 1.01 Related DocumentsDocument18 pagesTurn Key Steam Boilers System Section 1 1.00 - GENERAL 1.01 Related DocumentsKarim Galal IsmailNo ratings yet

- Controlling Fired HeatersDocument20 pagesControlling Fired HeatersArjun Shantaram ZopeNo ratings yet

- Ball Tube Mill Fire Fighting SystemDocument9 pagesBall Tube Mill Fire Fighting SystemRajesh SirsathNo ratings yet

- Engineer'S Specification Fuel Oil Day Tank 1.0 1.1Document4 pagesEngineer'S Specification Fuel Oil Day Tank 1.0 1.1Ladapo OladipupoNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Efficient 15-100 HP Boilers for BuildingsDocument5 pagesEfficient 15-100 HP Boilers for BuildingssebaversaNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Sound LevelDocument5 pagesModel CB 15-100 HP Boilers: Sound LevelsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDocument5 pagesModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocument5 pagesModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Engineering DataDocument5 pagesModel CBL 900-1800 HP Boilers: Engineering DatasebaversaNo ratings yet

- Section A5: Model CBL 900-1800 HP BoilersDocument5 pagesSection A5: Model CBL 900-1800 HP BoilerssebaversaNo ratings yet

- 15-100 HP Boilers Dimensions SpecsDocument5 pages15-100 HP Boilers Dimensions SpecssebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizeDocument5 pagesModel CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizesebaversaNo ratings yet

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDocument5 pagesModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaNo ratings yet

- Features and Benefits: Model CB 15-100 HP BoilersDocument5 pagesFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaNo ratings yet

- 900-1800 HP Steam Boilers: Features, Dimensions and Engineering DataDocument5 pages900-1800 HP Steam Boilers: Features, Dimensions and Engineering DatasebaversaNo ratings yet

- 125-800 HP Model CBR Boilers Technical Specs & Performance DataDocument5 pages125-800 HP Model CBR Boilers Technical Specs & Performance DatasebaversaNo ratings yet

- 75Document5 pages75sebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 pagesModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaNo ratings yet

- 81Document5 pages81sebaversaNo ratings yet

- General: Model ICB 100-800 HP BoilersDocument4 pagesGeneral: Model ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDocument5 pagesModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaNo ratings yet

- 78Document5 pages78sebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocument5 pagesModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaNo ratings yet

- 125-800 HP Model CBR Boilers Technical Specs & Performance DataDocument5 pages125-800 HP Model CBR Boilers Technical Specs & Performance DatasebaversaNo ratings yet

- High-efficiency boiler specifications for 100-800 HP modelsDocument4 pagesHigh-efficiency boiler specifications for 100-800 HP modelssebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Document6 pagesModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaNo ratings yet

- Konica 7020 Error Codes: Code DescriptionDocument3 pagesKonica 7020 Error Codes: Code Descriptionsaito36No ratings yet

- Fast, Fast VP : FAST: Features, Drawbacks, Applications and Some QuestionsDocument13 pagesFast, Fast VP : FAST: Features, Drawbacks, Applications and Some QuestionsSraVanKuMarThadakamallaNo ratings yet

- Line Differential Protection and Control RED615: Product GuideDocument32 pagesLine Differential Protection and Control RED615: Product GuidebrahimNo ratings yet

- VW Golf Diagnostic Scan Reveals Multiple Fault CodesDocument17 pagesVW Golf Diagnostic Scan Reveals Multiple Fault Codeskikin strongNo ratings yet

- Abb CatDocument9 pagesAbb CatMukesh Kumar MeenaNo ratings yet

- Stresses, Loads, and Factors of Safety in Structural ElementsDocument6 pagesStresses, Loads, and Factors of Safety in Structural ElementsMark Louies Mago VillarosaNo ratings yet

- Ztree 2 StataDocument3 pagesZtree 2 StataDaniel Felipe ParraNo ratings yet

- 1 Hyperion Essbase Interview QuestionsDocument2 pages1 Hyperion Essbase Interview Questionssen2natNo ratings yet

- Sni+03 6868 2002Document3 pagesSni+03 6868 2002abanghasanNo ratings yet

- Part 3B - Energy Balance - Open SystemDocument23 pagesPart 3B - Energy Balance - Open SystemHarold SumagaysayNo ratings yet

- Notice: Applications, Hearings, Determinations, Etc.: Southern Star Central Gas Pipeline, Inc.Document2 pagesNotice: Applications, Hearings, Determinations, Etc.: Southern Star Central Gas Pipeline, Inc.Justia.comNo ratings yet

- SuperStr 14Document1 pageSuperStr 14Poshan DhunganaNo ratings yet

- A Study On Customer Satisfaction Towards Online Banking ServicesDocument12 pagesA Study On Customer Satisfaction Towards Online Banking ServicesEditor IJTSRD100% (1)

- Boeco Mantas de CalentamientoDocument2 pagesBoeco Mantas de CalentamientoJhon VallejoNo ratings yet

- IEEEtran HOWTO PDFDocument28 pagesIEEEtran HOWTO PDFMario CruzNo ratings yet

- Fuels and Chemicals - Auto Ignition TemperaturesDocument5 pagesFuels and Chemicals - Auto Ignition TemperaturesyoesseoyNo ratings yet

- Design of Water Cooled Electric Motors Using CFD and Thermography TechniquesDocument6 pagesDesign of Water Cooled Electric Motors Using CFD and Thermography TechniquesNicolas JerezNo ratings yet

- 0751 VICTAULIC in Mechanical PipingDocument17 pages0751 VICTAULIC in Mechanical PipingsyafiqNo ratings yet

- MASTERSEAL 755 SPF v1 PDFDocument2 pagesMASTERSEAL 755 SPF v1 PDFJaga Nath100% (1)

- ALFA 4000 - Peru 2 PDFDocument2 pagesALFA 4000 - Peru 2 PDFErick MaderoNo ratings yet

- Project Report - FormatsDocument7 pagesProject Report - Formatsfazela shaukatNo ratings yet

- Classful IP Addressing (Cont.) : Address Prefix Address SuffixDocument25 pagesClassful IP Addressing (Cont.) : Address Prefix Address SuffixGetachew ShambelNo ratings yet

- Nov-23 Main Fcom QRH FCTM Changes A320Document17 pagesNov-23 Main Fcom QRH FCTM Changes A320Joe FalchettoNo ratings yet

- Exam 1 With SolutionsDocument11 pagesExam 1 With SolutionsSsebass PozzoNo ratings yet

- Camden CM-30EE-LED Data SheetDocument2 pagesCamden CM-30EE-LED Data SheetJMAC SupplyNo ratings yet

- What is a Gear Motor? - An In-Depth GuideDocument15 pagesWhat is a Gear Motor? - An In-Depth GuidePuneet KumarNo ratings yet

- Staggered Truss System - Wikipedia, The Free EncyclopediaDocument3 pagesStaggered Truss System - Wikipedia, The Free EncyclopediashawnideaNo ratings yet

- PQA824 ManualDocument100 pagesPQA824 ManualElkin AguasNo ratings yet

- Al Washali2016Document17 pagesAl Washali2016tomi wirawanNo ratings yet

- TM 1001 AVEVA Plant 12 1 PDMS Foundations Rev 3 0 PDFDocument153 pagesTM 1001 AVEVA Plant 12 1 PDMS Foundations Rev 3 0 PDFPolarogramaNo ratings yet