Professional Documents

Culture Documents

NDT Pile Test

Uploaded by

Ali RazaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NDT Pile Test

Uploaded by

Ali RazaCopyright:

Available Formats

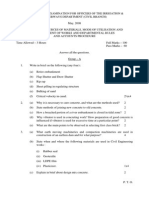

Geotechnical Safety and Risk V 597

T. Schweckendiek et al. (Eds.)

© 2015 The authors and IOS Press.

This article is published online with Open Access by IOS Press and distributed under the terms

of the Creative Commons Attribution Non-Commercial License.

doi:10.3233/978-1-61499-580-7-597

Non-Destructive Quality Check on Cast In-Situ

Piles

Victor HOPMAN, Paul HÖLSCHER

Deltares, the Netherlands

Abstract. A test field with 20 cast in-situ piles has been built. Flaws (necks, bulges and cracks) are built in. Existing and newly

developed detecting methods have been tested. They show interpretable signals and also some challenges to improve the results.

The final phase e.g. excavation of a representative number of piles will lead to final conclusions of the usability of these meas-

urement techniques.

Keywords. Non-destructive techniques, cast in-situ piles, quality control

1. Introduction five experimental techniques for the determina-

tion of pile integrity has been deployed.

On the grounds of Deltares in Delft a foundation The field test is part of Geo-Impuls (Geo-

was made with cast in-situ piles. After one year, Impuls, 2014), a research program that aims to

the piles are still there and with the same quality reduce 50% of the cost of failure. A reliable pile

as they were made: too poor to build something test method will reduce the discussion in the

on it. But… we are happy with it! short term as well as the unnecessary placement

Every year hundreds of thousands cast in- of additional piles. On the long term the profit is

situ piles are made. By default, all cast in-situ much bigger: a reliable test method will give rise

piles are acoustically measured with the 'Pile to a 'natural' selection of the most reliable instal-

Integrity Test’ (PIT) to determine whether the lation techniques. This will greatly reduce the

pile shaft meets the requirements. In a significant costly waste of placing additional piles and will

amount of cases, the current measuring technique lead to a general improvement of pile founda-

does not give a satisfactory answer: the signal tions.

cannot be interpreted unambiguously. The cause

of this shortcoming of the technique is related to

the heterogeneity of the soil surrounding the 2. Setup test field

piles: especially to the irregular structure of the

individual layers. It is not possible to determine The test field exists of 20 cast in-situ piles

whether cracks arose after making the pile or that (length 10 meter, diameter 460 mm) with artifi-

the pile has a neck and is locally too thin. This cial flaws, such as cracks, necks and bulges.

uncertainty leads to delay in the construction With a mutual pile distance of 5 m, the ability to

process and entails additional costs with it. An pull out a number of piles afterwards is taken

additional non-destructive measurement technic into account. The test is performed with so-called

to solve this quandary is required. ‘Hek-piles’ (Gebr. van 't Hek, 2015). These are

In the Netherlands, a joint research project concrete cast in-situ piles with a lost tip. A

has started to answer the question which tech- smooth casing is screwed down by axial pressure

niques are available to get an accurate picture and a considerable torque. Once the required

whether the foundation pile meets all require- depth is reached, the reinforcement is placed and

ments. The field test described in this paper is the casing is filled with concrete. Then the casing

part of this project. Twenty cast in situ piles are is pulled out with an oscillating motion. In the

installed. The piles has a number of intended field test, the reinforcement in the pile is used as

flaws. Besdes the traditional Pile Integrity Test, a frame that supports the equipment needed for

598 V. Hopman and P. Hölscher / Non-Destructive Quality Check on Cast In-Situ Piles

the creation of flaws and the installation of vari- starts. An asymmetric construction is made by

ous sensors. filling a half tire with bentonite (Figure 3).

Crack: at the location of the intended frac-

ture two adjacent reinforcement bars were sawn

3. Flaws through (Figure 4). During placement of the

reinforcement cage in the casing, a steel cable

In total five different flaws are identified as replaces temporarily the missing piece of rein-

relevant to the pile integrity: a crack, a neck forcement, in order to keep the cage straight.

(symmetric and asymmetric) and a bulge (shal- After placement of the reinforcement, but before

low and deep) (see Figure 1). pouring the concrete, the steel cables were dis-

connected. After hardening of the concrete, a

crack is made by driving cautious against the pile.

Figure 1: Piles with selected flaws. From left to right: no

flaw; symmetrical neck; bulge (deep); crack; bulge (shallow);

asymmetrical neck.

An important requirement for the defects is

that their location and size are reasonably well

defined. Special measures are needed. The fol-

lowing technics are created:

Bulge: special injection channels are in-

stalled to the reinforcement. After pouring the

concrete, additional concrete is injected into the Figure 2: Structural adjustment to create flaws. Protection

pile. To force the concrete to move into the soil, ring and injection tube for bulge.

a PVC protection ring has been installed in the

pile. During injection the volume and pressure

are carefully monitored. The creation of a bulge

is a delicate process: if the additional grout injec-

tion starts too early the cast in-situ pile is not

hardened and the injected grout will mix with the

concrete instead of creating a bulge. If the grout

injection starts too late the concrete of the cast

in-situ pile is hardened and the injection tube for

the grout injection will be clogged (Figure 2).

Neck: a rubber tire is placed around the rein- Figure 3: Structural adjustment to create flaws. Rubber tire

forcement. It is injected with bentonite after and a filled injection tube for neck (bottom right). Top:

installation of the cast in-situ pile. Creation of symmetric neck. Bottom left: asymmetric neck.

the neck must be carried out quickly after pour-

ing the pile, before the curing of the concrete

V. Hopman and P. Hölscher / Non-Destructive Quality Check on Cast In-Situ Piles 599

the pile (e.g. Hertlein and Davies, 2006; Amir,

2002). This measuring channel can be created

during the manufacturing process by including a

PVC tube into the pile. The signal emitted from

the source will run through the concrete to the

receiver. There are several possible paths (see

Figure 5b). When the pile has a flaw, one or

more paths differs from the paths in the situation

without a flaw. This will be visible in the re-

ceived signals. E.g. a bad spot in the concrete

leads to a later arrival time of the signals and

usually a smaller signal strength, while a neck

Figure 4: Structural adjustment to create a crack. Sawn leads to an earlier arrival time and a higher signal

reinforcement bias for a crack. strength.

A clear picture of the wave propagation

around this instrument is still missing. This caus-

4. Methods and results es problems in the interpretation of the type and

size of a flaw.

This chapter briefly explains the principles of the In order to clarify the complexity of the

measurements and the first preliminary results. wave paths a new device has been build: the

This article deals specifically with the develop- seismic tube. The seismic tube is one string with

ment of the experimental techniques. Figure 5 sources and recievers, so it can be lowered in one

shows sketches of the measurement techniques tube, like the single hole sonic logging device.

used. The seismic tube consists of two sources (one at

each end) and eight receivers in between. The

mutual distance between the receivers is 15 cm.

The eight receivers measure simultaneously

response on the signal of one of the two sources.

This device gives an image of the spatial wave

patterns. The Seismic tube is built for this study,

but may later also be used in practice.

Figure 5: Overview of acoustic measurement techniques:

(a) on top, left: fibre optics and single hole sonic logging; (b)

on top right: detail of possible wave paths for single hole

sonic logging, (c) below, left: parallel seismics (d) below,

right: deep acoustic check. Figure 6: Seismogram of seismic tube. The source is on top

of the receivers.

4.1. Single Hole Sonic Logging

Figure 6 shows a measurement result in the

In a standard single hole sonic logging, an form of a seismogram: the measured signal in a

acoustic source with one acoustic receiver is sensor is drawn on the place where the sensor is

slowly moved through a measuring channel in situated. The active source is located above the

600 V. Hopman and P. Hölscher / Non-Destructive Quality Check on Cast In-Situ Piles

receivers. The source gives a short signal. The 4.3. Parallel Seismics

measured signals are amplified so that a clear

signal is visible on each line, with always the Parallel seismics is performed by pushing an

same maximum. In reality, the signal falls sharp- acoustic sensor (installed in a cone) in the soil

ly with distance from the source. close to the pile (Figure 5c) (e.g. Niederleithing-

The dashed line indicates the arrival time of er 2012; de Groot, 2014). It is a technique that

the first vibration. However, in the third sensor can be performed without any preparation during

for example, a very strong vibration is visible, the installation of the cast in-situ pile.

which arrives significantly later. This amplifica- After the pile head has been hit with a ham-

tion may have been caused by interference of mer, waves are travelling through the pile and

different waves in the pile, caused by e.g. a bulge the soil to the acoustic sensor in the cone. After

in the pile: if the wall is further away, the reflec- each measurement the cone is pushed about 25

tion will arrive later. By carrying out measure- cm deeper. This produces a seismogram with

ments at more depths in the pile, the reason of depth.

such an anomaly can be analysed more specific.

4.2. Deep Acoustic Check

The deep acoustic measurement uses a cheap

acoustic acceleration sensor which is attached to

the reinforcement halfway the pile (Figure 5d). It

is a lost transducer.

Figure 7 shows the measured signals in the

pile head (upper plot) and deep transducer. In the

upper plot, the hammer blow is clearly visible. In

the deep sensor registration (lower plot), the

passage of the wave in the downward direction is

clearly visible. This means that the wave velocity

in the pile can be determined. Thus the reflection

of the pile tip can be better determined in both Figure 8: Seismogram of parallel seismics. Cone- pile dis-

tance about 2 meter [de Groot 2014]).

the deep sensor and the pile head sensor. A major

problem of the standard acoustic is resolved by

this. Figure 8 shows an example of the seismo-

The measurements in the deep transducer gram of the measured horizontal vibrations in the

can be interpreted like a transducer in the pile bottom immediately next to the pile (de Groot

head to check the quality of the pile below the 2014). The wave radiation from the pile tip is

transducer. clearly visible at 10 m. The reflection of the

stress wave in the pile at the pile tip gives a large

force on the soil. This force radiates in all direc-

tions. A similar radiation pattern is visible at 6 m

depth. This is exactly the depth of the transition

from clay to peat. This pile has a flaw at approx-

imately 3.8 m. There is a change in the wave

radiation, but this effect is too much dominated

by the waves of the transition at 3.8 m (or an

unknown defect at 6 m depth). This means that

for a correct interpretation the waves due to the

layer transitions must be removed from the

measurements.

Figure 7: Result of acoustic test with a sensor at the pile head

(top) and at 5 m depth (below).

V. Hopman and P. Hölscher / Non-Destructive Quality Check on Cast In-Situ Piles 601

4.4. Fibre optics 5. Future research

Distributed Temperature Sensing (DTS) This paper has described the test field and

(DeCusatis, 2006) can be used to monitor the the complexity of constructing piles with various

curing of concrete in cast in-situ piles. The fibre flaws. Methods to obtain piles with well-defined

optic cable is directly attached to the reinforce- defects were shown. The tested measurement

ment. The fibre optics measures the temperature techniques are explained theoretically.

in the pile, that is influenced by the hydration A prerequisite for the application of a tech-

heat from the curing concrete. The measurement nique is that the reliability in the field is known.

starts directly after the pouring of the concrete, Nevertheless, the selection of a technique also

and stops after a few days when the hydration depends on other aspects such as costs, availabil-

heat is fully dissipated. ity and manageability. The final phase e.g. exca-

The measurement is based on a change in vation of a representative number of piles will

temperature profile if a deviating diameter (e.g. lead to final conclusions of the usability of these

bulge or neck) occurs. This leads to a lower or measurement techniques.

higher dissipation of generated heat. The influ-

ence of the surrounding soil has to be taken in

account (see Figure 9). This is less complex if 6. Conclusions

more piles are equipped with fibre optic cables

(with little additional costs). The temperature In the framework of Geo-Impuls, a test field

measurement can, in addition to classical pile has been built. Existing and newly developed

integrity tests, be used to estimate the magnitude techniques meant to check the quality of cast in-

of the deviation. situ piles have been tested. All new techniques

show interpretable signals and also some chal-

lenges to improve the results.

This research has been initiated by the Geo-

Impuls programme in the Netherlands. Geo-

Impuls is a five year long, joint industry pro-

gramme which aims at reducing geotechnical

failure substantially in 2015.

References

Amir, J. M. (2002). Single-Tube Ultrasonic Testing of Pile

Integrity, ASCE Deep Foundation Congress, Orlando,

US, Vol 1 pp. 836–850

DeCusatis, C.J.S. (2006). Handbook fiber optic essentials,

Academic Press Elsevier

Gebr. van ’t Hek. (2014). http://www.vanthek.com/en-

GB/79/hekpile.html, visited June 2015

Geo-Impuls. (2014). http://www.geoimpuls.org/

Groot, P.H. de. (2014). Evaluation of the Parallel Seismic

Figure 9: Fibre optics: influence of surrounding soil. detection of defects in pile foundations. MSc theses,

TU-Delft, afd. CiTG. oktober 2014.

Hertlein B., Davies A. (2006). Non-destructive testing of

deep foundations, John Willey and sons Ltd, 2006

Niederleithinger, E. (2012). Improvement and extension of

the parallel seismic method for foundation depth meas-

urement. Soils and Foundations, (52):1093{1101} 2012

You might also like

- Pile Integrity Test2 PDFDocument3 pagesPile Integrity Test2 PDFSima Datta Deb100% (1)

- An Investigation On Distressed Concrete Piles by Pit and Their Repair and RetrofittingDocument9 pagesAn Investigation On Distressed Concrete Piles by Pit and Their Repair and RetrofittinglingamkumarNo ratings yet

- 2009 Geot Model 2 RefDocument6 pages2009 Geot Model 2 RefSudhakar GeoNo ratings yet

- Chapter IDocument15 pagesChapter IFernando LopezNo ratings yet

- Numerical Simulation of Prestressed Precast Concrete Bridge Deck Panels Using Damage Plasticity ModelDocument10 pagesNumerical Simulation of Prestressed Precast Concrete Bridge Deck Panels Using Damage Plasticity ModelAnand RajNo ratings yet

- Epoxy Insertion: Repair of Cracked Structural Concrete by Injection and RebarDocument3 pagesEpoxy Insertion: Repair of Cracked Structural Concrete by Injection and RebarMain TenorioNo ratings yet

- Method Statement For Pile Integrity Test ProcedureDocument3 pagesMethod Statement For Pile Integrity Test ProcedureDeny Cahyo N100% (2)

- Comparative_study_of_pile_quality_control_techniquDocument9 pagesComparative_study_of_pile_quality_control_techniqumacjonan745No ratings yet

- KEM.691.321Document13 pagesKEM.691.321alpegambarliNo ratings yet

- Concrete Anchoring Q&A: Measuring Embedment Depth Through Cold JointsDocument2 pagesConcrete Anchoring Q&A: Measuring Embedment Depth Through Cold JointsFredie UnabiaNo ratings yet

- Evaluation of Pile Intergrity Using Cross Hole Sonic Logging TestDocument5 pagesEvaluation of Pile Intergrity Using Cross Hole Sonic Logging TestDayah MahadiNo ratings yet

- Seismic Behavior of Hollow Masonry WallsDocument11 pagesSeismic Behavior of Hollow Masonry WallsCarlos NBNo ratings yet

- Punching Shear PDFDocument13 pagesPunching Shear PDFmohamedadel100No ratings yet

- Adan Luft Parking-Structure-DamageDocument4 pagesAdan Luft Parking-Structure-Damagemrzap5007No ratings yet

- Recent Development in Pile Instrumentation Technology For Driven, Jacked-In and Bored Cast-In-Place PilesDocument25 pagesRecent Development in Pile Instrumentation Technology For Driven, Jacked-In and Bored Cast-In-Place Pileszzz_monsterNo ratings yet

- Computers and Structures: Adam Wosatko, Jerzy Pamin, Maria Anna PolakDocument13 pagesComputers and Structures: Adam Wosatko, Jerzy Pamin, Maria Anna Polakno_milk_todayNo ratings yet

- Castelleted BeamsDocument15 pagesCastelleted Beamsbasavasdmcet0% (1)

- 1 s2.0 S1687404814000996 Main PDFDocument16 pages1 s2.0 S1687404814000996 Main PDFgeorgeispasoiuNo ratings yet

- 2005 (A Colori) TAHER - Strenghtening of Critically Designed Girders With Dapped EndsDocument31 pages2005 (A Colori) TAHER - Strenghtening of Critically Designed Girders With Dapped EndsEleonora InghelleriNo ratings yet

- Retrofitting of Reinforced Concrete BuildingsDocument36 pagesRetrofitting of Reinforced Concrete BuildingsKalmesh U PeerannavarNo ratings yet

- Bai Bao Xac Dinh ModulDocument9 pagesBai Bao Xac Dinh ModulThái Trân LêNo ratings yet

- Failures During and After Construction - tcm45-340882Document6 pagesFailures During and After Construction - tcm45-340882Uvie M. PtwolanNo ratings yet

- Concrete capacity design of Cazaly hangers in shallow membersDocument26 pagesConcrete capacity design of Cazaly hangers in shallow membersOliver LopezNo ratings yet

- Lifting Eyes Ara Paper 8mayDocument14 pagesLifting Eyes Ara Paper 8mayiuliandurdureanuNo ratings yet

- 34-Base, C.D., Beeby, A.W., Taylor, P.J. (1966) - An Investigation of The Crack Control Characteristics ofDocument45 pages34-Base, C.D., Beeby, A.W., Taylor, P.J. (1966) - An Investigation of The Crack Control Characteristics ofJan Van MiddendorpNo ratings yet

- Pile Integrity Test Pile Integrity Test (Low Strain Impact Integrity Testing)Document5 pagesPile Integrity Test Pile Integrity Test (Low Strain Impact Integrity Testing)Mahinda100% (1)

- Fatigue in The Shell of A Conveyor Drum: Ch. Affolter, G. Piskoty, R. Koller, M. Zgraggen, T.F. Ru TtiDocument15 pagesFatigue in The Shell of A Conveyor Drum: Ch. Affolter, G. Piskoty, R. Koller, M. Zgraggen, T.F. Ru TtiSamir KulkarniNo ratings yet

- Geotechnical Model For Pipe Roof Supports in TunneDocument7 pagesGeotechnical Model For Pipe Roof Supports in TunneSudhakar GeoNo ratings yet

- Method Statement For Pile Integrity Test ProcedureDocument3 pagesMethod Statement For Pile Integrity Test ProcedureDharma Pratap Lamgade100% (1)

- Ijet16 08 06 198Document8 pagesIjet16 08 06 198Apm FoumilNo ratings yet

- Reliability Assessment of International Design Concepts For Punching Shear Retrofitting by Use of Post-Installed Shear LinksDocument8 pagesReliability Assessment of International Design Concepts For Punching Shear Retrofitting by Use of Post-Installed Shear LinksPanos SpNo ratings yet

- Vision Based Monitoringfor Tunnelling Induced Damage MasonryDocument6 pagesVision Based Monitoringfor Tunnelling Induced Damage MasonrymsinanacikgozNo ratings yet

- Optimal Design of A High Slope For Ice World & Water Park (IWWP) Built Over An Abandoned Quarry A Case Study in Changsha of ChinaDocument22 pagesOptimal Design of A High Slope For Ice World & Water Park (IWWP) Built Over An Abandoned Quarry A Case Study in Changsha of ChinaDiego fernando polania liscanoNo ratings yet

- Fib 61 Strut and TieDocument4 pagesFib 61 Strut and TieSardar0% (4)

- Soft Soils Improved by Prefabricated Vertical Drains: Performance and PredictionDocument25 pagesSoft Soils Improved by Prefabricated Vertical Drains: Performance and PredictionAlep AzizNo ratings yet

- Institute of Civil EngineerinDocument7 pagesInstitute of Civil Engineerinheherson juanNo ratings yet

- Axial Deformation of Column in Tall Structuresfinal1Document22 pagesAxial Deformation of Column in Tall Structuresfinal1pradeepjoshi007No ratings yet

- Industrial Fiber Concrete FlooDocument5 pagesIndustrial Fiber Concrete FlooMarial MbzNo ratings yet

- Fernandez 10 ADocument14 pagesFernandez 10 AalpegambarliNo ratings yet

- Soil Nailing With Flexible Structural Facing - Design and ExpDocument6 pagesSoil Nailing With Flexible Structural Facing - Design and ExptehNo ratings yet

- Evaluations of The Depth of A Root-Pile and A Caisson Foundations Using The Parallel Seismic TestDocument8 pagesEvaluations of The Depth of A Root-Pile and A Caisson Foundations Using The Parallel Seismic TestVinicius Zamai SevaNo ratings yet

- 3.3-Design of Shallow FoundationDocument32 pages3.3-Design of Shallow FoundationSamson YonasNo ratings yet

- Design of jet grouting cut-offs for damsDocument13 pagesDesign of jet grouting cut-offs for damsThaung Myint OoNo ratings yet

- The Effect of Anchorage On The Effectiveness of The Shear Reinforcement in The Punching ZoneDocument11 pagesThe Effect of Anchorage On The Effectiveness of The Shear Reinforcement in The Punching ZoneVinh LENo ratings yet

- Tunnelling and Underground Space Technology: Leonardo M. Massone, Francisco NazarDocument13 pagesTunnelling and Underground Space Technology: Leonardo M. Massone, Francisco NazarnishantNo ratings yet

- Calibration of Methods For Designing Large-Diameter Bored Piles: Ultimate Limit StateDocument13 pagesCalibration of Methods For Designing Large-Diameter Bored Piles: Ultimate Limit StateBalajiNo ratings yet

- A New Post Tensioned Continuity Detail For Super Tees BGE David MolloyDocument11 pagesA New Post Tensioned Continuity Detail For Super Tees BGE David MolloyTamaduianu IoanNo ratings yet

- Flange Paper Final PDFDocument11 pagesFlange Paper Final PDFRutikNo ratings yet

- Al Maryah CentralDocument19 pagesAl Maryah CentralKaram JaradatNo ratings yet

- Soil-Nailed Retaining Wall Case Study for Hotel in KodaikanalDocument4 pagesSoil-Nailed Retaining Wall Case Study for Hotel in KodaikanalB Divya jyothiNo ratings yet

- Retrofitting Presentation by Dds - 19.10.2020Document78 pagesRetrofitting Presentation by Dds - 19.10.2020store filesNo ratings yet

- Development of Large Diameter V-Belt Pulley Using Coreless Drag and Wire-Reinforced CheekDocument9 pagesDevelopment of Large Diameter V-Belt Pulley Using Coreless Drag and Wire-Reinforced CheekAna MayumiNo ratings yet

- Cross Hole Sonic Logging APPLICATION WORD FORMATDocument3 pagesCross Hole Sonic Logging APPLICATION WORD FORMATQc C7No ratings yet

- DURABLE POST-TENSIONED BRIDGESDocument4 pagesDURABLE POST-TENSIONED BRIDGESKiran MadhaviNo ratings yet

- Application of Elastic Wave Tomography Method For Damage Evaluation in A Large-Scale Reinforced Concrete StructureDocument7 pagesApplication of Elastic Wave Tomography Method For Damage Evaluation in A Large-Scale Reinforced Concrete StructureUHNo ratings yet

- PC PenetrationDocument36 pagesPC PenetrationSalvatore Salvatore100% (1)

- Is 14893 2001Document14 pagesIs 14893 2001Ashokan KelothNo ratings yet

- Low Strain Pile Integrity TestingDocument6 pagesLow Strain Pile Integrity TestingWaqas SadiqNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Some Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910From EverandSome Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910No ratings yet

- 08 PB Civil Servants Conduct Rules 1966Document61 pages08 PB Civil Servants Conduct Rules 1966Syed Ubaid ur RehmanNo ratings yet

- Codu To Yeung Kitch Cover 2011Document2 pagesCodu To Yeung Kitch Cover 2011Ali RazaNo ratings yet

- 4 - Projections of Crop Water Requirement in Pakistan Under Global Warming PDFDocument7 pages4 - Projections of Crop Water Requirement in Pakistan Under Global Warming PDFikhlas65No ratings yet

- UET Taxila PhD admissions sample paperDocument18 pagesUET Taxila PhD admissions sample paperAli RazaNo ratings yet

- Santosh K Garg Mcqs SolvedDocument11 pagesSantosh K Garg Mcqs SolvedAli RazaNo ratings yet

- Sub Divisional Officer Recruitment TestDocument3 pagesSub Divisional Officer Recruitment TestAli RazaNo ratings yet

- 01 Sialkot 2014Document10 pages01 Sialkot 2014Ali RazaNo ratings yet

- Standard Proctor TestDocument5 pagesStandard Proctor TestAli RazaNo ratings yet

- All CompleteDocument16 pagesAll CompleteMohammad RehanNo ratings yet

- Evaluation of Options For Remodelling of Upper Jhelum Canal, PakistanDocument7 pagesEvaluation of Options For Remodelling of Upper Jhelum Canal, PakistanAli Raza100% (1)

- Evaluation of Options For Remodelling of Upper Jhelum Canal, PakistanDocument7 pagesEvaluation of Options For Remodelling of Upper Jhelum Canal, PakistanAli Raza100% (1)

- Indicators of Institutional PerformanceDocument37 pagesIndicators of Institutional PerformanceAli RazaNo ratings yet

- Advertisement PHD Fall-2015Document1 pageAdvertisement PHD Fall-2015Ali RazaNo ratings yet

- MSC Mid Semester AOCH 2013Document2 pagesMSC Mid Semester AOCH 2013Ali RazaNo ratings yet

- Development Length Hook Splice of ReinforcementsDocument14 pagesDevelopment Length Hook Splice of ReinforcementsmailmaverickNo ratings yet

- NTS Book For GAT General Free Download PDFDocument142 pagesNTS Book For GAT General Free Download PDFMuhammad Ramzan100% (3)

- Marshall Mix Design (Nptel - ceTEI - L26 (1) )Document7 pagesMarshall Mix Design (Nptel - ceTEI - L26 (1) )andrewcwng0% (1)

- 4 - Projections of Crop Water Requirement in Pakistan Under Global Warming PDFDocument7 pages4 - Projections of Crop Water Requirement in Pakistan Under Global Warming PDFikhlas65No ratings yet

- RebarDocument32 pagesRebarMustafa UzyardoğanNo ratings yet

- Consolidation of Soil For Foundation by Using Sand DrainsDocument7 pagesConsolidation of Soil For Foundation by Using Sand DrainsAulia Nurul AnnisaNo ratings yet

- MCQ Gate 2015Document34 pagesMCQ Gate 2015Bedatrayee0550% (2)

- Diversion Headworks: CEL351: Design of Hydraulic StructuresDocument78 pagesDiversion Headworks: CEL351: Design of Hydraulic StructuresAlvaro Rodrigo Chavez Viveros100% (1)

- Manual of Order Irrigation PunjabDocument256 pagesManual of Order Irrigation PunjabAli Raza100% (3)

- Impact of irrigation reforms on rice productivity in Punjab, PakistanDocument5 pagesImpact of irrigation reforms on rice productivity in Punjab, PakistanAli RazaNo ratings yet

- DPE ExamDocument3 pagesDPE ExamAli RazaNo ratings yet

- Chapter 7Document10 pagesChapter 7Ali RazaNo ratings yet

- Top 150 Soil Mechanics and Foundation Engineering QuestionsDocument16 pagesTop 150 Soil Mechanics and Foundation Engineering QuestionsAli Raza100% (1)

- Crop Calendar PakistanDocument48 pagesCrop Calendar PakistanAli RazaNo ratings yet

- Owner Manual - AVR 158 (English EU)Document42 pagesOwner Manual - AVR 158 (English EU)Romeo MoranoNo ratings yet

- Regaining Wholeness Through The Subtle DimensionsDocument226 pagesRegaining Wholeness Through The Subtle DimensionsChuy Soto Naranjo100% (4)

- DS9 Trials and Tribble-AtionsDocument68 pagesDS9 Trials and Tribble-AtionsBobNo ratings yet

- Addams Audition PrepDocument4 pagesAddams Audition PrepChristina Johnson100% (5)

- 2019-10-11 Proof of Licensing For Luis Miguel Matta Rios (LPL194494) PDFDocument2 pages2019-10-11 Proof of Licensing For Luis Miguel Matta Rios (LPL194494) PDFLuis Matta RiosNo ratings yet

- Eng Communicative PaperDocument3 pagesEng Communicative PaperRoja SankarNo ratings yet

- Acoustic Blues Guitar StylesDocument76 pagesAcoustic Blues Guitar StylesJob Navarrete Plasencia86% (7)

- sky-sender-liste-01-2024-pdfDocument2 pagessky-sender-liste-01-2024-pdfvedri11No ratings yet

- Rohde Schwarz SMIQ6GHZ R Service Manual 6 GHZ Extension PDFDocument56 pagesRohde Schwarz SMIQ6GHZ R Service Manual 6 GHZ Extension PDFgonnos28106No ratings yet

- Wifi - BDCom WAP2100-T22DDocument5 pagesWifi - BDCom WAP2100-T22DFeby AndyNo ratings yet

- Hercules Super BEC PRO: Item# Wrl-HbecspDocument1 pageHercules Super BEC PRO: Item# Wrl-HbecspdanielNo ratings yet

- Statement RobinsonDocument3 pagesStatement RobinsonDuy Tran100% (1)

- Search IndexDocument23 pagesSearch IndexMaria SpitzerNo ratings yet

- Tape scripts for English listening practiceDocument24 pagesTape scripts for English listening practicebảo trân lê100% (1)

- The Girl From IpanemaDocument1 pageThe Girl From IpanemaLeon Onn67% (3)

- Music of John Ford ColeyDocument3 pagesMusic of John Ford Coleyparopilook100% (1)

- NetplanDocument19 pagesNetplanNyankoye Apollinaire LouaNo ratings yet

- Antonín Dvorak - Piano Quintet No. 2 (Violín I) PDFDocument12 pagesAntonín Dvorak - Piano Quintet No. 2 (Violín I) PDFDaniel PérezNo ratings yet

- MATLAB Implementation of Multiuser Code Division Multiple AccessDocument6 pagesMATLAB Implementation of Multiuser Code Division Multiple AccessAshish D PatelNo ratings yet

- Lutebot 3Document21 pagesLutebot 3Mau AlvaradoNo ratings yet

- 3S3 PhilipsDocument18 pages3S3 PhilipswiroNo ratings yet

- 【H102】方竹西语社Happy Spanish 1 - ExerciseDocument64 pages【H102】方竹西语社Happy Spanish 1 - ExerciseAdriana NaomyNo ratings yet

- Ukulele ThursdaysDocument10 pagesUkulele ThursdaysIlmar FerreiraNo ratings yet

- Mindanao's Indigenous Music and Musical InstrumentsDocument11 pagesMindanao's Indigenous Music and Musical InstrumentsElaine Mae Guillermo Esposo100% (2)

- Kendor Volume 31 Jazz BookletDocument13 pagesKendor Volume 31 Jazz BookletIngvar Leerimaa50% (2)

- Amplifiers Using FETsDocument6 pagesAmplifiers Using FETsabdullah samdi100% (4)

- Grammar - Be Past Simple: Affirmative and Negative: 10 / 11 Points (90%)Document19 pagesGrammar - Be Past Simple: Affirmative and Negative: 10 / 11 Points (90%)Sheyla Armas FloresNo ratings yet

- IVCS3 User GuideDocument19 pagesIVCS3 User GuideJimmy Watt AbarcaNo ratings yet

- Li 2019Document22 pagesLi 2019Fervian VersatyNo ratings yet