Professional Documents

Culture Documents

Perlite Concrete Mix Designs: Materials Per Cubic Yard Based On 100% Yield

Uploaded by

MJundi0 ratings0% found this document useful (0 votes)

21 views1 pageasd

Original Title

Osborne 1999

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentasd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views1 pagePerlite Concrete Mix Designs: Materials Per Cubic Yard Based On 100% Yield

Uploaded by

MJundiasd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

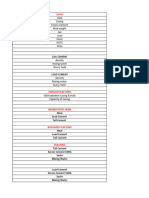

Perlite Concrete Mix Designs

Materials per Cubic Yard Based on 100% Yield

Mix Ratio Oven Air Wet

(Cement/ Dry Cement Perlite Water Entraining Density

Perlite) Density Agent Range

Volume lb./cu.ft. bags cu. ft. gal. pints lb./cu.ft

1:4 36 6.75 27 61 * 48-56

1:5 30.5 5.40 27 59.5 * 42-50

1:6 27 4.50 27 54 * 38-44

1:8 22 3.38 27 54 * 34-40

*Air Entraining Agent. Neutralized vinsol resin or other air entraining agent. Approx. 14% air

solution. Follow manufacturer’s recommendations.

Typical Physical Properties of Perlite Concrete*

Mix Typical Dry Thermal Compressive Minimum

Ration Oven Density Conductivity Strength Compressive

(cement/ Dry Range Range Range Strength

perlite) Density

Volume lb./cu.ft. lb./cu.ft. “k”^ lb./sq.in. lb./sq.in.

1:4 36 36-42 .83-.97 300-500 300

1:5 30.5 30-36 .71-.83 200-300 200

1:6 27 24-30 .58-.71 125-200 125

1:8 22 18-24 .46-.58 80-125 80

*Mixing is critical to expected properties and yields. Over-mixing or excessive water will

adversely affect results. In paddle -type mixer, mix cement, air entraining agent and water into a

slurry. Then add perlite aggregate and mix only until coated (2-5 min.).

Perlite/Sand Concrete – Typical Physical Properties & Mix Proportions

Air Dry Compressive Wet Density Air

Density Strength Range When Placed Cement Perlite Sand Water Entraining

lb./cu.ft. lb./sq.in. lb./cu.ft. cu.ft. cu.ft. cu.ft. gal. ozs.

65 800-900 82 + 5 1 3 2.2 11.2 3

75 900-1200 80 + 5 1 3 2.0 8.0 3

82 1100-1300 98 + 5 1 1.6 2.5 9.2 3

88 2300-2500 105 + 5 1 1.1 2.1 7.8 3

99 2000-2200 110 + 5 1 3 1.75 8.4 3

You might also like

- Design of Pile FoundationsDocument188 pagesDesign of Pile FoundationsSiriveri Lakshmi KanthNo ratings yet

- ACI Method of Concrete Mix DesignDocument7 pagesACI Method of Concrete Mix DesignMuhammad Ave SenaNo ratings yet

- Concrete Design MixDocument15 pagesConcrete Design MixM HAFEEZ RAJANo ratings yet

- 0.tunnel Form Technology-Case StudyDocument93 pages0.tunnel Form Technology-Case StudyP.K.MallickNo ratings yet

- Cementing Lectures 2019Document24 pagesCementing Lectures 2019Uthman Mohammed100% (1)

- Best Practice Guide For Road MaterialsDocument154 pagesBest Practice Guide For Road Materialsbruce bogwaterNo ratings yet

- Soil Improvement Techniques Lecture No. 06Document86 pagesSoil Improvement Techniques Lecture No. 06Saleh Hassan100% (2)

- CONCRETE MIX DESIGN LectureDocument32 pagesCONCRETE MIX DESIGN LectureMichael Murillo BaraquioNo ratings yet

- BOQ For Two Storage Structures in Addis UpdateDocument6 pagesBOQ For Two Storage Structures in Addis UpdateWossen DemissNo ratings yet

- ACI Method of Concrete Mix Design-C211Document6 pagesACI Method of Concrete Mix Design-C211ah ay100% (2)

- Basement Take-OffDocument11 pagesBasement Take-OffRightie CubeNo ratings yet

- Foamed Cellular Light Weight ConcreteDocument5 pagesFoamed Cellular Light Weight ConcreteIrshadNo ratings yet

- Laboratory Evaluation of Modified Bitumen Using Superpave Methodology Under Indian ConditionsDocument35 pagesLaboratory Evaluation of Modified Bitumen Using Superpave Methodology Under Indian ConditionsMd.imthiyazNo ratings yet

- Reinforced Concrete Structures R. Park T.paulayDocument783 pagesReinforced Concrete Structures R. Park T.paulayMamet Edvant89% (9)

- Residual Stress Part 1 - Measurement Techniques: P. J. Withers and H. K. D. H. BhadeshiaDocument11 pagesResidual Stress Part 1 - Measurement Techniques: P. J. Withers and H. K. D. H. Bhadeshianiraj_hwbNo ratings yet

- APTI413 PP Ch7Document67 pagesAPTI413 PP Ch7Stefanos DiamantisNo ratings yet

- Foam TypesDocument12 pagesFoam TypesRolaxNo ratings yet

- Use of Waste Plastic in Bituminous Concrete MixDocument51 pagesUse of Waste Plastic in Bituminous Concrete MixRahul KumarNo ratings yet

- Concrete Mix DesignDocument12 pagesConcrete Mix DesignGemechu100% (1)

- Staggered Truss Framing SystemsDocument49 pagesStaggered Truss Framing SystemsjorgeNo ratings yet

- Hoover DamDocument121 pagesHoover Damlcano84No ratings yet

- Bricks and Shapes 2Document6 pagesBricks and Shapes 2nay den100% (1)

- Perlite Con PDFDocument2 pagesPerlite Con PDFAfshin MahpourNo ratings yet

- Westco Carbon Black N220234326330339Document1 pageWestco Carbon Black N220234326330339Prasetia PrasetiaNo ratings yet

- High Filler Concrete Using Fly Ash - Chloride Penetration and MicrostructureDocument16 pagesHigh Filler Concrete Using Fly Ash - Chloride Penetration and MicrostructureJHON WILMAR CARDENAS PULIDONo ratings yet

- Materials and Methodology (GVNREDDY)Document21 pagesMaterials and Methodology (GVNREDDY)K VINOD KUMARNo ratings yet

- Perlite Concrete Mix DesignDocument1 pagePerlite Concrete Mix DesignHaniAminNo ratings yet

- Gulf Perlite Ready Mixed Perlite ConcreteDocument4 pagesGulf Perlite Ready Mixed Perlite Concreteosama feilatNo ratings yet

- Chapter Four: 4.0 Results and DiscussionsDocument10 pagesChapter Four: 4.0 Results and DiscussionsAyo OshoNo ratings yet

- Rpt-sales-Fundamentals of Sand ControlDocument8 pagesRpt-sales-Fundamentals of Sand ControlDidier MorenoNo ratings yet

- Mechanical Properties of High Volume Fly Ash Concrete Subjected To Elevated TemperaturesDocument29 pagesMechanical Properties of High Volume Fly Ash Concrete Subjected To Elevated TemperaturesUmer FarooqNo ratings yet

- MCM8115 Lecture 07 BITUMINOUS MATERIALS MpptasphaltDocument45 pagesMCM8115 Lecture 07 BITUMINOUS MATERIALS MpptasphaltChina AlemayehouNo ratings yet

- TDS Super Latex - Eng - Rev.02 28 08 19Document3 pagesTDS Super Latex - Eng - Rev.02 28 08 19Pallavi ChoudharyNo ratings yet

- Properties & Strength of Materials (2) CV4213: Course Instructors Dr. Waleed Fouad Tawhed Dr. Ahmad AbdelkhalikDocument20 pagesProperties & Strength of Materials (2) CV4213: Course Instructors Dr. Waleed Fouad Tawhed Dr. Ahmad AbdelkhalikMagic MasterNo ratings yet

- Polymer Waste in Road Construction Sunil Bose Sangita PDFDocument37 pagesPolymer Waste in Road Construction Sunil Bose Sangita PDFnamdev bk100% (1)

- Aging of BitumenDocument24 pagesAging of BitumenShuddhashil GhoshNo ratings yet

- Dow Water & Process SolutionsDocument11 pagesDow Water & Process SolutionsZulfikri ZulkifliNo ratings yet

- Mod 6 DRLG BasicsDocument17 pagesMod 6 DRLG BasicsMin Thant MaungNo ratings yet

- Bitumen 1 (Asphalt Cement) : Walied A. ElsaighDocument48 pagesBitumen 1 (Asphalt Cement) : Walied A. ElsaighdostjanNo ratings yet

- Materials For Making Concrete-I CementDocument40 pagesMaterials For Making Concrete-I CementJonjon BuenoNo ratings yet

- Specific Gravity & Water Absorption Test (I S 2386 Iii/63)Document11 pagesSpecific Gravity & Water Absorption Test (I S 2386 Iii/63)End EndNo ratings yet

- Primary CementingDocument63 pagesPrimary Cementingleo leoNo ratings yet

- Acid Resistant Tiles BricksDocument6 pagesAcid Resistant Tiles BricksDeboline MitraNo ratings yet

- EXAMPLE 2-Mix-PropDocument8 pagesEXAMPLE 2-Mix-PropPronab Kumar DasNo ratings yet

- Technical Data of Adtech Fluoroplastic Polymers: Servicios E Importaciones Especializadas S.A. de C.VDocument1 pageTechnical Data of Adtech Fluoroplastic Polymers: Servicios E Importaciones Especializadas S.A. de C.VEdgar LucianoNo ratings yet

- Assignment 4 PDFDocument12 pagesAssignment 4 PDFUzair MukhtarNo ratings yet

- Thebault Dop01 Teboply Ext GBDocument2 pagesThebault Dop01 Teboply Ext GBDumitrache IulianNo ratings yet

- On Fly Ash ConDocument46 pagesOn Fly Ash ConSantosh Kumar MNo ratings yet

- Chemical RraghavanDocument60 pagesChemical RraghavanjoekaledaNo ratings yet

- Plaster TestsDocument23 pagesPlaster TestsRobin SNo ratings yet

- Shubham Agrawal ProjectDocument18 pagesShubham Agrawal Projectkamlesh kumawatNo ratings yet

- HIgh Strength High-Performance Concrete For Marine EnvironmentDocument8 pagesHIgh Strength High-Performance Concrete For Marine EnvironmentdsmnnangNo ratings yet

- Mix Design by Imtisal Ahmad: Required DataDocument5 pagesMix Design by Imtisal Ahmad: Required DataAbdullahNo ratings yet

- Description: Polytetrafluoroethylene (Teflon, PTFE)Document6 pagesDescription: Polytetrafluoroethylene (Teflon, PTFE)Yaho HosNo ratings yet

- Revised Lecture by Sir JanggoDocument43 pagesRevised Lecture by Sir JanggoAriel Dela CruzNo ratings yet

- Dowex Monosphere 650C (H) Resin: DescriptionDocument3 pagesDowex Monosphere 650C (H) Resin: DescriptionZulfikri ZulkifliNo ratings yet

- Lab 3Document13 pagesLab 3ismael hashiNo ratings yet

- Effect of Viscosity On Modified BitumenDocument16 pagesEffect of Viscosity On Modified BitumenyadavameNo ratings yet

- Proportioning of Concrete MixturesDocument20 pagesProportioning of Concrete MixturesPraful MandaliyaNo ratings yet

- Soil Compaction: Standard Proctor Method & Modified Proctor Test MethodDocument32 pagesSoil Compaction: Standard Proctor Method & Modified Proctor Test MethodKenneth Peña JavierNo ratings yet

- Experiment N0. 09 Preparing A Concrete Mix and Casting Various Samples Required For Different TestsDocument5 pagesExperiment N0. 09 Preparing A Concrete Mix and Casting Various Samples Required For Different TestsAli HaiderNo ratings yet

- A Study of Self-Compacting Concrete Made With Marginal AggregatesDocument6 pagesA Study of Self-Compacting Concrete Made With Marginal AggregatesGuoqiang LiuNo ratings yet

- KeRRA Report - Week 6Document7 pagesKeRRA Report - Week 6Muthomi MunyuaNo ratings yet

- A 5 EE 437 Evaluation of Hydrated Lime EDocument8 pagesA 5 EE 437 Evaluation of Hydrated Lime Emohanadakkila1991No ratings yet

- Mix Design of Cement GroutDocument4 pagesMix Design of Cement GroutjitendraNo ratings yet

- EXAMPLE OF MIX DESIGN .R.s.Document11 pagesEXAMPLE OF MIX DESIGN .R.s.Ramkiran TalariNo ratings yet

- Soil Conditioning For Pipejacking and Tunnelling: Properties of Sand/foam MixturesDocument11 pagesSoil Conditioning For Pipejacking and Tunnelling: Properties of Sand/foam MixturesLTE002No ratings yet

- Mix Design of ConcreteDocument9 pagesMix Design of ConcreteShergul KhanNo ratings yet

- Free Chlorine Indicator Solution For CL 17 Analyzer - GHS - en - 2018 01 16Document15 pagesFree Chlorine Indicator Solution For CL 17 Analyzer - GHS - en - 2018 01 16MJundiNo ratings yet

- Coffee Husk Briquettes: A New Renewable Energy SourceDocument5 pagesCoffee Husk Briquettes: A New Renewable Energy SourceMJundiNo ratings yet

- PTWDocument3 pagesPTWMJundiNo ratings yet

- Boiler Chemical Cleaning Procedure PDFDocument17 pagesBoiler Chemical Cleaning Procedure PDFMJundiNo ratings yet

- Optimization of Fly Ash Particle Size Distribution For Cementitious Systems With High CompactnessDocument11 pagesOptimization of Fly Ash Particle Size Distribution For Cementitious Systems With High CompactnessMJundiNo ratings yet

- Boiler LayupDocument4 pagesBoiler LayupTiu TonNo ratings yet

- Characteristics of Spent Coffee Ground As A Fuel and Combustion Test in A Small Boiler PDFDocument15 pagesCharacteristics of Spent Coffee Ground As A Fuel and Combustion Test in A Small Boiler PDFMJundiNo ratings yet

- Spent Coffee Grounds As Heat Source For Coffee Roasting Plants, Experimental Validation and Case Study PDFDocument15 pagesSpent Coffee Grounds As Heat Source For Coffee Roasting Plants, Experimental Validation and Case Study PDFMJundiNo ratings yet

- Accepted Manuscript: Thermal Science and Engineering ProgressDocument21 pagesAccepted Manuscript: Thermal Science and Engineering ProgressMJundiNo ratings yet

- Using Charcoal To Increase Properties and Durability of Fired Test Briquettes PDFDocument7 pagesUsing Charcoal To Increase Properties and Durability of Fired Test Briquettes PDFMJundiNo ratings yet

- Emissions Analysis From Combustion of Eco-Fuel Briquettes For Domestic ApplicationsDocument7 pagesEmissions Analysis From Combustion of Eco-Fuel Briquettes For Domestic ApplicationsMJundiNo ratings yet

- Code of Practice Concrete Masonry CuttingDocument9 pagesCode of Practice Concrete Masonry CuttingMJundiNo ratings yet

- Energetics of Coal Substitution by Briquettes of Agricultural ResiduesDocument11 pagesEnergetics of Coal Substitution by Briquettes of Agricultural ResiduesMJundiNo ratings yet

- Direct Power Generation From Waste Coffee Grounds in A Biomass Fuel CellDocument7 pagesDirect Power Generation From Waste Coffee Grounds in A Biomass Fuel CellMJundiNo ratings yet

- Characteristics of Spent Coffee Ground As A Fuel and Combustion Test in A Small BoilerDocument15 pagesCharacteristics of Spent Coffee Ground As A Fuel and Combustion Test in A Small BoilerMJundiNo ratings yet

- Spent Coffee Grounds As Heat Source For Coffee Roasting Plants, Experimental Validation and Case Study PDFDocument15 pagesSpent Coffee Grounds As Heat Source For Coffee Roasting Plants, Experimental Validation and Case Study PDFMJundiNo ratings yet

- Recent Development On The Uses of Alternative Fuels in Cement Manufacturing ProcessDocument16 pagesRecent Development On The Uses of Alternative Fuels in Cement Manufacturing ProcessMJundi100% (1)

- Physicochemcial Characteristis of Densified Unreated and Steam Exploded Poplar Wood and Wheat Straw GrindsDocument10 pagesPhysicochemcial Characteristis of Densified Unreated and Steam Exploded Poplar Wood and Wheat Straw GrindsMJundiNo ratings yet

- An Experimental Investigation of The Roles of Water Content and Gas Decompression Rate For Outburst in Coal BriquettesDocument8 pagesAn Experimental Investigation of The Roles of Water Content and Gas Decompression Rate For Outburst in Coal BriquettesMJundiNo ratings yet

- ErsltltvlDocument12 pagesErsltltvljimsonNo ratings yet

- Feasibility Study of The Potential Use of Drill Cuttig in ConcreteDocument9 pagesFeasibility Study of The Potential Use of Drill Cuttig in ConcreteMJundiNo ratings yet

- Code Concrete MasonrDocument40 pagesCode Concrete MasonrJose AnjloNo ratings yet

- Using Perlite As A Pozzolanic Addition in BlendedDocument124 pagesUsing Perlite As A Pozzolanic Addition in BlendedMJundiNo ratings yet

- Recycling Paper Industry Ef Uent Sludge For Use in Mortars A Sustainability PerspectiveDocument13 pagesRecycling Paper Industry Ef Uent Sludge For Use in Mortars A Sustainability PerspectiveMJundiNo ratings yet

- Effect of Particlesize of Blast Furnace Slag On Properties of Portland CementDocument6 pagesEffect of Particlesize of Blast Furnace Slag On Properties of Portland CementyewNo ratings yet

- Substitution of The Natural Sand by Crystallized Slagof Blast Furnace in The Composition of Concrete PDFDocument7 pagesSubstitution of The Natural Sand by Crystallized Slagof Blast Furnace in The Composition of Concrete PDFMJundiNo ratings yet

- Investigating The Effects of High Alumina Cement and Silica Sand On The Suitability of Ikere Ekiti Clay For Refractory ApplicationsDocument6 pagesInvestigating The Effects of High Alumina Cement and Silica Sand On The Suitability of Ikere Ekiti Clay For Refractory ApplicationsMJundiNo ratings yet

- Durability of Portland Blast-Furnace Slag Cement ConcreteDocument11 pagesDurability of Portland Blast-Furnace Slag Cement ConcreteMJundiNo ratings yet

- Comparing The Pozzolanic Activity Properties of Obsidian To Those of Fly Ash and Blast Furnace SlagDocument11 pagesComparing The Pozzolanic Activity Properties of Obsidian To Those of Fly Ash and Blast Furnace SlagMJundiNo ratings yet

- Pile Test LoadingDocument10 pagesPile Test LoadingFeyisayo Ayomide OgunladeNo ratings yet

- Input Data in Green Cells: Phils. Standard Reinforcing BarsDocument10 pagesInput Data in Green Cells: Phils. Standard Reinforcing BarsreynoldNo ratings yet

- Smart Technologies For Sustainable DevelopmentDocument420 pagesSmart Technologies For Sustainable DevelopmentMaria Rafaela Bezerra de Macêdo RibeiroNo ratings yet

- Status Rfi Pie Rack & Sleeper.Document20 pagesStatus Rfi Pie Rack & Sleeper.Kurnia AryadiNo ratings yet

- RevitKeynotes NZLDocument50 pagesRevitKeynotes NZLPranshu LondaseNo ratings yet

- HOCivilSpecifications2013Volume2 PDFDocument404 pagesHOCivilSpecifications2013Volume2 PDFyash shahNo ratings yet

- Civil & Structure Design Criteria PDFDocument28 pagesCivil & Structure Design Criteria PDFcharleshutabara951No ratings yet

- Modeling and Control of Side Face Beam Cracking - FroschDocument10 pagesModeling and Control of Side Face Beam Cracking - FroschphamminhquangNo ratings yet

- Marketing Innovation Project by GRP 6Document7 pagesMarketing Innovation Project by GRP 6muskaan bhadadaNo ratings yet

- Bit BankDocument10 pagesBit BankShiva SanviNo ratings yet

- 2 Componenet Backfill Grout PDFDocument11 pages2 Componenet Backfill Grout PDFTanvirH.ChowdhuryNo ratings yet

- 4.12.080-210-004-01 Clarified Water Storage tank-Layout1-A1Document1 page4.12.080-210-004-01 Clarified Water Storage tank-Layout1-A1MohamedHussein MohamedHusseinNo ratings yet

- 278 CMS PDFDocument266 pages278 CMS PDFRecordTrac - City of OaklandNo ratings yet

- Experimental and Numerical Performance of Shear Connections in CLT-concrete Composite FloorDocument13 pagesExperimental and Numerical Performance of Shear Connections in CLT-concrete Composite FloorthusiyanthanpNo ratings yet

- Ac PlastDocument2 pagesAc Plastvinay rode100% (1)

- Sikagard Wallcoat Id Pds enDocument4 pagesSikagard Wallcoat Id Pds enodang rizkiNo ratings yet

- ECM-Transformers Guidelines For InstallingDocument24 pagesECM-Transformers Guidelines For InstallingJOSE LUIS FALCON CHAVEZNo ratings yet

- Basic Rates As Per SOR 2018-19 Escalation @5% For FY 2019-20 Unit Adopted Rate SL - No. Description of Machine Activity Output of Machine OutputDocument3 pagesBasic Rates As Per SOR 2018-19 Escalation @5% For FY 2019-20 Unit Adopted Rate SL - No. Description of Machine Activity Output of Machine Outputanon_789699787No ratings yet

- Tower Construction Detailed ProceduresDocument13 pagesTower Construction Detailed ProceduresboomarNo ratings yet

- 1.TDS Masterflow 936 AnDocument4 pages1.TDS Masterflow 936 AnRajesh ThakurNo ratings yet

- MCHW Vol 1 Series 5700 Web PDFDocument30 pagesMCHW Vol 1 Series 5700 Web PDFalejandraoy9No ratings yet