Professional Documents

Culture Documents

Pocket Hole

Uploaded by

Esteban Tena LozanoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pocket Hole

Uploaded by

Esteban Tena LozanoCopyright:

Available Formats

Wood Magazine Pocket-Hole Guide Build

Figure 1. Wood Magazine Pocket-Hole Drilling Guide. Note that this drawing may not be to scale. Copy and resize the page so

that the full size pattern matches the dimensions.

This is a lot of work for a personalized Pocket-Hole Jig (PHJ). You may

want to purchase a Kreg Mini. However, if you enjoy DIY, go for it. Build

a PHJ using the following steps.

1. The original Wood Magazine tip called for purchasing and reaming ¼’

pipe. I found it easier to purchase 1/2” OD x 3/8” ID steel pipe. A 3/8’

diameter drill fits perfectly into this size pipe. Each jig requires about 3” of

pipe.

2. Cut a wood blank to your PHJ full size plan outside dimensions. Then

apply your full size patterns. I used a scrap piece of 2x4 fir for my blanks. Figure 2. Pattern

on wood PHJ

blank

Wood Mag Pocket hole jig.docx 1 9/27/2016

Wood Magazine Pocket-Hole Guide Build

3. Drill a ½” hole through the blank. NOT 9/16” as noted on the

Wood Magazine full size pattern!! The purchased ½”pipe is

smaller. Verify the drillrd hole lines up with the pattern and that the

pipe fits in the hole.

4. Cut the wood blank to shape

prior to epoxying pipe to wood

blank. Now check your blank.

Insert a length of ½” pile and your

step drill into the blank. Align

everything with a piece of stock ¾”

wood as shown in figure 4. The Figure 3. 1/2" Hole

Figure 4. Verify jig with ¾”h step drill should point near center drilled.

stock wood. on the ¾” stock.

5. Cut the pipe to the length inside the blank hole. The pipe length

should be ~ 3”. Epoxy the pipe flush with the top of the blank as

shown in Fig. 5.

6. After the epoxy has dried, hack saw the

excess the pipe off as close to the wood as

possible. I used a hack saw as shown in Fig. 6.

7. Trim the pipe back to the wood using a

power sander. Warning - Stop often to clear

hot metal from pipe. Keep the metal pipe as

cool as possible or the wood will burn and the Figure 5. Pipe epoxied

pipe may break free from the epoxy, in wood blank.

Figure 6. Cut pipe to

wood as close as 8. Check your finished PHJ by making pocket

possible. holes and inserting pocket-hole screws into ¾”

stock wood. The final angle and distance to the

end of the jig can vary based on how accurately the blank was

drilled and cut. A set up guide in Fig. 8 is for a Kreg Mini jig. You

may wish to make a similar setup chart for your PHJ.

I hope you enjoy your DIY PHJ. It should come in handy for odd

jobs around the house and general woodworking projects where

pocket holes are used.

Figure 7. Trim pipe

to wood.

Wood Mag Pocket hole jig.docx 2 9/27/2016

Wood Magazine Pocket-Hole Guide Build

Figure 8. Kreg Mini Set up Chart based on pocket hole material thickness from

TomBuildsStuff.blogspot.com.

Wood Mag Pocket hole jig.docx 3 9/27/2016

You might also like

- Craftman Wood ChestDocument5 pagesCraftman Wood ChestIsidro CM100% (1)

- How To Make A Stopped Dado Jig For Any Router: InstructablesDocument11 pagesHow To Make A Stopped Dado Jig For Any Router: InstructablesTroy100% (1)

- Bird FeederDocument4 pagesBird FeederJayme LealNo ratings yet

- Make A Wheel Marking GaugeDocument6 pagesMake A Wheel Marking Gaugeserkan ünlü100% (1)

- Drum Sander Plans - WoodArchivistDocument9 pagesDrum Sander Plans - WoodArchivistErics100% (1)

- DIY Adjustable DeskDocument28 pagesDIY Adjustable DeskWorker0% (1)

- Wood 218 May 2013Document88 pagesWood 218 May 2013fake weinerNo ratings yet

- Work Bench 3Document4 pagesWork Bench 3- yAy3e -100% (1)

- WS23342 - Welcoming Hall Bench PDFDocument12 pagesWS23342 - Welcoming Hall Bench PDFMarianoNo ratings yet

- Workbench Magazine 315-2009Document64 pagesWorkbench Magazine 315-2009Stevan Volic100% (1)

- Table Saw LocationDocument2 pagesTable Saw LocationShane TwogoodNo ratings yet

- Tricks To Tune Up Your Table SawDocument10 pagesTricks To Tune Up Your Table SawMarko BregovecNo ratings yet

- ACMW Plans v1.0Document65 pagesACMW Plans v1.0Tanja Martinovic100% (1)

- Wood - Magazine - 259 - Mar 2019Document92 pagesWood - Magazine - 259 - Mar 2019Adam Niddrie100% (1)

- American Woodworker #144 Oct-Nov 2009Document65 pagesAmerican Woodworker #144 Oct-Nov 2009gambi100% (2)

- Pocket Hole JoineryDocument5 pagesPocket Hole JoineryJessica Sanders100% (3)

- 7.6 Control of Monitoring and Measuring DevicesDocument2 pages7.6 Control of Monitoring and Measuring Devicesejub6447No ratings yet

- Wall Storage SystemDocument5 pagesWall Storage SystemsaefulNo ratings yet

- Workshop CheatlistDocument27 pagesWorkshop CheatlistDenise York100% (1)

- Hank Ou: Get Morefromyour Tablesaw..Document9 pagesHank Ou: Get Morefromyour Tablesaw..russ310739683100% (1)

- Woodcraft Magazine - October-November 2020Document70 pagesWoodcraft Magazine - October-November 2020Adrian SeketaNo ratings yet

- 14 Circular Saw Jig Plans - Crosscut Jigs, Ripping Jigs and More!Document17 pages14 Circular Saw Jig Plans - Crosscut Jigs, Ripping Jigs and More!Ahyya100% (1)

- Adjustable Taper Ripping JigDocument6 pagesAdjustable Taper Ripping Jiggmand68No ratings yet

- MU8063 - FW Best TipsDocument13 pagesMU8063 - FW Best TipsJonas Rosa TerezaNo ratings yet

- Plans Now - Woodsmith - Pocket Hole Joinery Basics PDFDocument3 pagesPlans Now - Woodsmith - Pocket Hole Joinery Basics PDFPaweł Jamrożek100% (2)

- Shaker-Style Coat and Mitten Rack PDFDocument6 pagesShaker-Style Coat and Mitten Rack PDFEucap MdzNo ratings yet

- Build Your Own French Doors - Popular Woodworking Magazine PDFDocument1 pageBuild Your Own French Doors - Popular Woodworking Magazine PDFNei Souza100% (1)

- SN09924 - Precision Crosscut SledDocument12 pagesSN09924 - Precision Crosscut SledamelieNo ratings yet

- Modular Planter Bench: Woodworks: Intermediate ProjectDocument7 pagesModular Planter Bench: Woodworks: Intermediate ProjectEucap MdzNo ratings yet

- Dovetail Keys TutorialDocument3 pagesDovetail Keys Tutorialricheklund100% (1)

- Folding Portable WorkbenchDocument19 pagesFolding Portable WorkbenchVideoSurv SynologyNo ratings yet

- Little Table: The Woodworking Resource LibraryDocument6 pagesLittle Table: The Woodworking Resource LibraryAmanjot100% (1)

- How To Make A Wooden Bar Clamp PDFDocument13 pagesHow To Make A Wooden Bar Clamp PDFAldrin DejumoNo ratings yet

- Popular Woodworking No 76 January 1994Document100 pagesPopular Woodworking No 76 January 1994aleksandar.omasystemsNo ratings yet

- FinishDocument4 pagesFinishGsmHelpNo ratings yet

- 2021-12-01 Australian Wood Review - Sanet.st - 1-84Document227 pages2021-12-01 Australian Wood Review - Sanet.st - 1-84Muwehid Tewhid50% (2)

- A Circular Saw in The Furniture Shop-FinewoodworkingDocument4 pagesA Circular Saw in The Furniture Shop-Finewoodworkingkurt100% (1)

- Digital Patterns: Designed by Steve GoodDocument4 pagesDigital Patterns: Designed by Steve GoodEmilian Baluta100% (1)

- Build-It Starterkit ManualDocument6 pagesBuild-It Starterkit Manualrraattaarrrraattaa100% (1)

- Router LiftDocument27 pagesRouter Liftmrivero1983100% (2)

- Woodworking Plans - Entertainment CenterDocument12 pagesWoodworking Plans - Entertainment Centerapi-3822020100% (6)

- CAD Projects with Tinkercad | 3D Models Part 1: Learn how to create advanced 3D objects with Tinkercad in an easy wayFrom EverandCAD Projects with Tinkercad | 3D Models Part 1: Learn how to create advanced 3D objects with Tinkercad in an easy wayNo ratings yet

- Woodworking Journal 05-01 (February 1981)Document32 pagesWoodworking Journal 05-01 (February 1981)kiwiutNo ratings yet

- 2021-05-01 WOOD MagazineDocument88 pages2021-05-01 WOOD Magazineriver452No ratings yet

- Woodwork - PlansDocument102 pagesWoodwork - Plansaguinaldo6690No ratings yet

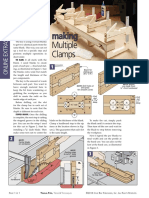

- 5 Shop Made Clamps - SSCDocument1 page5 Shop Made Clamps - SSCjuan olivaNo ratings yet

- Homemade Edge Band Clamps: InstructablesDocument4 pagesHomemade Edge Band Clamps: InstructablesJasmine VaaltynNo ratings yet

- Geoguide 1 PDFDocument155 pagesGeoguide 1 PDFExile PeachNo ratings yet

- WS22418 Dresser Top ValetDocument8 pagesWS22418 Dresser Top Valetrigono1664No ratings yet

- Basic and Principle of RelaysDocument38 pagesBasic and Principle of Relaysbijoy100% (1)

- Digital Patterns: Designed by Steve GoodDocument9 pagesDigital Patterns: Designed by Steve GoodGlodeanNo ratings yet

- Geotechnical Engineering Notes 333Document40 pagesGeotechnical Engineering Notes 333TinaNo ratings yet

- Instrumentation Pocket GuideDocument59 pagesInstrumentation Pocket Guideerwin.hindartoNo ratings yet

- American Woodworker 164 (February-March 2013)Document78 pagesAmerican Woodworker 164 (February-March 2013)Emilian Baluta100% (1)

- Shop CartDocument3 pagesShop Cartgmand68No ratings yet

- 03 PDFDocument68 pages03 PDFGeorge Vlad AndronicNo ratings yet

- WWJ #3 1990Document68 pagesWWJ #3 1990ayamNo ratings yet

- America Best Home Workshops PDFDocument10 pagesAmerica Best Home Workshops PDFIan Foreman67% (3)

- 2 - Woodworking Plans - OakplateDocument6 pages2 - Woodworking Plans - OakplatemacpatorNo ratings yet

- KDL 43W800CDocument28 pagesKDL 43W800Canup.sn5053No ratings yet

- Indoor Air QualityDocument97 pagesIndoor Air Qualitysrazaadnan100% (3)

- Design & Analysis Project BY INDIAN STUDENT (ANSYS CATIA MATLAB)Document58 pagesDesign & Analysis Project BY INDIAN STUDENT (ANSYS CATIA MATLAB)Vaibhav Soni100% (1)

- Butterfly Valves enDocument37 pagesButterfly Valves enMolitorisz AndorNo ratings yet

- Conducting PolymersDocument16 pagesConducting Polymersmanisha beheraNo ratings yet

- Public Address System: Installation Instructions SlavamplifierDocument18 pagesPublic Address System: Installation Instructions SlavamplifierMarcelo Almeida100% (1)

- WOOD Magazine Workshop Floor Plan: Mor Cla Ra W A Planer PDocument1 pageWOOD Magazine Workshop Floor Plan: Mor Cla Ra W A Planer PZERONo ratings yet

- Woodworking Plans - Tavern TableDocument2 pagesWoodworking Plans - Tavern TableBob Kowalski100% (1)

- Asi#87296 Sage#50100 DC#100329Document116 pagesAsi#87296 Sage#50100 DC#100329Roberto LeboeufNo ratings yet

- ICAM PSE CATIA Marketplace12Document11 pagesICAM PSE CATIA Marketplace12Hicham Moslim AlmorabetNo ratings yet

- PPA Application - 1310 Mission Street - 2018-017317PPA0Document8 pagesPPA Application - 1310 Mission Street - 2018-017317PPA0auweia1No ratings yet

- The Good Ventilation of Switchgear and Transformer RoomsDocument7 pagesThe Good Ventilation of Switchgear and Transformer RoomsJosé SánchezNo ratings yet

- 808 - Carbon Raschig Rings - E4 PDFDocument1 page808 - Carbon Raschig Rings - E4 PDFNada Ibtihal YumnaNo ratings yet

- AVK Power GenerationDocument21 pagesAVK Power Generationcuongnv_19No ratings yet

- IR NO CE-C 09887 Witness Test Cement Cubes (The Tests Period Is 87 Days Including Preparing Cement Cubes, Cement Compressive Strength Test With AgDocument1 pageIR NO CE-C 09887 Witness Test Cement Cubes (The Tests Period Is 87 Days Including Preparing Cement Cubes, Cement Compressive Strength Test With AgNassim SabriNo ratings yet

- Chemical EngineeringDocument7 pagesChemical EngineeringArslan AzharNo ratings yet

- PPEDocument22 pagesPPEMark Anthony Nieva RafalloNo ratings yet

- Pranav Gaur ResumeDocument2 pagesPranav Gaur ResumePranav gaurNo ratings yet

- OcvDocument4 pagesOcvIsmail SetiawanNo ratings yet

- 3-Phase Transformer ConnectionsDocument7 pages3-Phase Transformer ConnectionsAnsar AwanNo ratings yet

- Eip DraftDocument9 pagesEip Draftapi-437155888No ratings yet

- Installation Manual MSP DUCT - SLIM DUCT PDFDocument31 pagesInstallation Manual MSP DUCT - SLIM DUCT PDFutaiuliancatalinNo ratings yet

- MSC Mechatronics SyllabusDocument47 pagesMSC Mechatronics Syllabusaddy54385646100% (2)

- Physical Design Flow Challenges at 28nm On Multi-Million Gate BlocksDocument21 pagesPhysical Design Flow Challenges at 28nm On Multi-Million Gate Blockskavita4123No ratings yet

- Weight CalcDocument4 pagesWeight CalcVaniya GoelNo ratings yet

- The Various Types of EnclosuresDocument4 pagesThe Various Types of Enclosuresshan1009No ratings yet

- Past Service Award Recipient List - American Numsimatic AssociationDocument37 pagesPast Service Award Recipient List - American Numsimatic AssociationAmericanNumismatic100% (1)