Professional Documents

Culture Documents

Paint Data Sheet

Uploaded by

didiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Paint Data Sheet

Uploaded by

didiCopyright:

Available Formats

CHEM-O-GARD PRIMER GRAY

High Solids Epoxy Polyamide Coating

Technical Data Thinner

Airless Spray......................... Not required

Conventional Spray............... Not required

Brush/Roll.............................. Not required

PRODUCT DESCRIPTION Clean Up................................... Xylene, MEK, 21092 or 21064 thinner

A two-component, high solids, high film build epoxy polyamide The above product and application data for this technical data

primer or intermediate designed for application over steel sheet are based on product 33522/33523.

and for application over self-cured inorganic zinc coatings.

Primer offers excellent adhesion and corrosion protection. CURED FILM PERFORMANCE

FEATURES Description Test Method Results

Adhesion to Steel ASTM D4541 1,200 psi

• High solids Hardness ASTM D2240 60

• Excellent corrosion resistance

Impact Resistance ASTM D2794 24 in. lbs - reverse

• Excellent sag resistance

70 in. lbs - direct

• Excellent adhesion

Corrosion Resistance ASTM B117 No face blistering

• Can be over coated with wide range of topcoats

3,000 hours salt spray

• High-performance general maintenance coating for new

and old steel Tensile Strength ASTM D638 1,317 psi

• Successful use of the light coat - full coat application Tensile Elongation ASTM D638 39%

techniques over inorganic zinc

EQUIPMENT RECOMMENDATIONS

PRODUCT DATA

Listed below are general equipment guidelines for the

Description Results application of this product. Job site conditions may require

Vehicle Type ............................. Epoxy / Polyamide modifications to these guidelines to achieve the desired

Color ����������������������������������������� Gray

results.

Gloss ������������������������������������������10 - 20

VOC (mixed w/33523)............... 227 g/L (1.9 lbs/gal)

Weight/Gallon (mixed)............... 12.9 pounds BRUSH: Use a good quality solvent resistant, natural or

Solids by Weight (mixed)........... 84.13% synthetic.

Solids by Volume (mixed).......... 71.37% ROLLER: Use a good quality natural or synthetic 1/4" short-

Viscosity (mixed)....................... 1,500 cps

nap roller cover with phenolic core.

Flash Point................................ 84oF Hardener, 92oF Resin

Dry Heat Resistance................. 250oF continuous, 350oF intermittent SPRAY APPLICATION (General): The following spray

Packaging.................................. 2 gallons unit, 10 gallons unit equipment has been found suitable and is available from

manufacturers such as Binks, DeVilbiss and Graco.

APPLICATION DATA AIR ATOMIZED SPRAY:

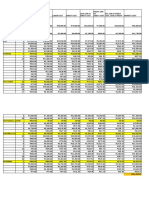

Fluid Atomizing

Model Air Cap Fluid Head

Delivery Pressure

Description Results

Application �������������������������������� Conventional and Airless Spray, Brush Binks 18 68 PB 68 20 oz/min 65 - 75 psi

or Roll DeVilbiss MBC-510 MB-4039-62HD AV-650-AC 20 oz/min 65 - 75 psi

Mix Ratio................................... 1:1 by Volume

Resin......................................... 33522 AIRLESS SPRAY:

Hardener................................... 33523 Model Pump Ratio Fluid Tip Fluid Pressure Filter Mesh

Recommended Thickness......... 4 - 6 mils/coat (dry) Graco 30:1 or Larger 0.017 - 0.021 1,800 - 2,400 psi 60

Dry Time @ 77oF and 50% R.H.

Binks 30:1 or Larger 0.017 - 0.021 1,800 - 2,400 psi 60

No Accelerator Spray/Brush/Roll

Recoat................................... 5 hours min., 3 months max.

Tack Free............................... 3 hours

Handle................................... 7 - 8 hours

GENERAL SURFACE PREPARATION

With 3 fl oz/gal

Recoat................................... 3 hours min., 3 months max. All surfaces must be sound, dry, clean and free of oil, dirt,

Tack Free............................... 1.5 hours grease, wax, mildew, loose or flaking paint and other surface

Handle................................... 4 - 5 hours contaminants.

Pot Life @ 75oF, 50% R.H.

No Accelerator Remove loose, peeling, flaking or scaling paint by scraping,

2X Viscosity........................... 3 hours

Gel Time................................ 5 hours

sanding or wire brush.

With 3 fl oz/gal

2X Viscosity........................... 2 hours For good results, an SSPC-SP 5 (NACE No. 1) white metal

Gel Time................................ 3.5 hours blast with a 3 - 4 mils profile or SSPC-SP 10 (NACE No.

Coverage ���������������������������������� 1145 sf/gal at 1 mil DFT 2) near-white metal blast with a 2 - 4 mils dense, sharp

anchor profile free of peening. For moderate exposure, an

SSPC-SP 6 (NACE No. 3) commercial blast should be used.

DIRECTIONS FOR USE

TINTING: Do not tint.

THINNING: None required.

Note: Always know local VOC restrictions for coatings

applications in your area before thinning this product.

Thinning recommendations meet Federal VOC restrictions

for architectural coatings. This product and other referenced

products may not meet VOC restrictions for your application

and may not be available in your area. Carefully read and

observe warning thinner labels.

APPLICATION: Apply by spray, brush or roller. APPLY

ONLY when air and surface temperatures are between

50 - 110°F and the surface temperature of the steel substrate

is at least 5oF above dew point.

For use over inorganic zinc, apply unthinned at wet film

thickness of 5 - 6 mils. Allow to flash-off solvents 10 - 15

minutes, then apply a full wet coat to achieve specified dry

film thickness.

DRYING TIME: Under normal conditions, dries to touch in

5 - 8 hours. Recoat time is 5 hour minimum and 3 months

maximum. Low temperature, high humidity, poor ventilation

and thick films will retard drying time. Recoating time

is highly dependent upon actual surface temperatures.

Higher surface temperature will shorten the maximum

recoat window. Surface temperature should be monitored,

especially on heated surfaces.

CLEAN UP: Clean up skin, clothing, paint tools or spills

immediately with recommended thinner or cleaner, carefully

observing cautions on paint, thinner and cleaner labels.

Dried paint may be removed by scraping.

HEALTH AND SAFETY

Read the Material Safety Data Sheet (MSDS) and contain-

er labels for detailed health and safety information. This

product is intended for industrial use by properly trained

professional applicators only.

The information, data and suggestions contained herein are believed to be reliable, based upon our knowledge and experience; however, it is expressly declared that Seller does not

guarantee the result to be obtained in Buyer’s process. SELLER HEREBY EXPRESSLY DISCLAIMS ANY IMPLIED WARRANTY OF MERCHANTABILITY FOR FITNESS FOR A

PARTICULAR PURPOSE AND/OR ANY OTHER WARRANTY, EXPRESS OR IMPLIED as to any and all products and/or suggestions described herein, whether such products are

used alone or in combination with other materials. Buyer must make its own determination of the suitability of any product for its use, and the completeness of any information contained

herein. Nothing contained herein shall be construed to constitute inducement or recommendation to practice any invention covered by any patent without authority from the owner of

the patent. 02162010 Chem-O-Gard Primer Gray.indd

JONES-BLAIR®/NEOGARD®

2728 Empire Central - Dallas, TX 75235 - Telephone (214) 353-1600 - Fax (214) 350-7624 - www.jones-blair.com - www.neogard.com

You might also like

- Specifications: Schedule of Materials and FinishesDocument11 pagesSpecifications: Schedule of Materials and FinishesAmyr AmyrNo ratings yet

- C.H. - 0+465.5 Section No5Document1 pageC.H. - 0+465.5 Section No5Fran LuqueNo ratings yet

- Pag Asa Steel - ReinforcementDocument2 pagesPag Asa Steel - Reinforcementjremptymak100% (1)

- Structural FujiDocument6 pagesStructural Fujichris100% (1)

- Electrical Budget For 4 Flats of of 1-BHKDocument18 pagesElectrical Budget For 4 Flats of of 1-BHKhazihappyNo ratings yet

- Itp - Rebar & Concrete-UploadDocument4 pagesItp - Rebar & Concrete-UploadMohammad Arif RasheedNo ratings yet

- Tac Company Profile 2012Document33 pagesTac Company Profile 2012vista_serverNo ratings yet

- Productivity Output For PreliminariesDocument2 pagesProductivity Output For PreliminariesAmalina YaniNo ratings yet

- Material Tracking ListDocument2 pagesMaterial Tracking Listsmart_onyx17No ratings yet

- RFI FORMAT 06 RC Grade Beam For Invoice No 6Document1 pageRFI FORMAT 06 RC Grade Beam For Invoice No 6محمد باتعNo ratings yet

- Particular Specifications Plumbing and Sanitary Work: 1.0 GeneralDocument19 pagesParticular Specifications Plumbing and Sanitary Work: 1.0 GeneralCherryl Chrissie JamesNo ratings yet

- Safety Data Sheet SDS For HIT-RE 500 V3 Epoxy Adhesive Documentation ASSET DOC LOC 5384987Document24 pagesSafety Data Sheet SDS For HIT-RE 500 V3 Epoxy Adhesive Documentation ASSET DOC LOC 5384987Librany RioNo ratings yet

- Aecon Construction Company CanadaDocument22 pagesAecon Construction Company CanadaSrinivasa MurthyNo ratings yet

- PRICE SCHEDULE FOR CIVIL WORKDocument18 pagesPRICE SCHEDULE FOR CIVIL WORKMukesh Jangid100% (1)

- Compliance StatementDocument2 pagesCompliance Statementshajeer1982No ratings yet

- Personal Protective Equipment Matrix Per Person Per Scope of WorkDocument1 pagePersonal Protective Equipment Matrix Per Person Per Scope of Worklouie_mapuanNo ratings yet

- Construction Planning & ManagementDocument39 pagesConstruction Planning & ManagementAnkur SrivastavaNo ratings yet

- Structural Steel: Steel Shape Profile Cross Section Chemical Composition Standards I-Beams Second Moments of AreaDocument5 pagesStructural Steel: Steel Shape Profile Cross Section Chemical Composition Standards I-Beams Second Moments of AreaIshwarya SrikanthNo ratings yet

- Norguard Eagle - Horizontal and Vertical Lifeline SystemsDocument4 pagesNorguard Eagle - Horizontal and Vertical Lifeline SystemsnorguardNo ratings yet

- Building Specification ProposalDocument9 pagesBuilding Specification ProposalEngr SwapanNo ratings yet

- As Built ManagerDocument141 pagesAs Built ManagerRatan MaheshwaramNo ratings yet

- KnaufDocument28 pagesKnaufprokaNo ratings yet

- Architect & Engineer Instruction Variation OrderDocument4 pagesArchitect & Engineer Instruction Variation OrderaimiNo ratings yet

- Lead Estimator for Oil & Gas Operator in DubaiDocument2 pagesLead Estimator for Oil & Gas Operator in DubaiManoj SinghNo ratings yet

- Suzlon payment schedules for wind turbine sitesDocument4 pagesSuzlon payment schedules for wind turbine sitesvaibhavsinha55No ratings yet

- Ancoring RebarsDocument44 pagesAncoring Rebarsrvsingh17gmailcomNo ratings yet

- Notes, Standard Forms and Preliminaries: Proposed Renovation and Extension of The Agriculture Laboratory BuildingDocument65 pagesNotes, Standard Forms and Preliminaries: Proposed Renovation and Extension of The Agriculture Laboratory Buildingkasiva cindyNo ratings yet

- Gas FurnaceDocument8 pagesGas FurnaceCoco GalindoNo ratings yet

- Record of HandoverDocument1 pageRecord of Handoverlkra006No ratings yet

- Steel DeckDocument4 pagesSteel DeckTeodoro Miguel Carlos IsraelNo ratings yet

- Vacuum de - Watered Flooring Method Statement: ActivitiesDocument1 pageVacuum de - Watered Flooring Method Statement: Activitiesவினோத் குமார்No ratings yet

- I. Summary of WorksDocument55 pagesI. Summary of WorksKaye Kathlene BasubasNo ratings yet

- BOQ RCC Septic Tank For AFOH Offices PDFDocument7 pagesBOQ RCC Septic Tank For AFOH Offices PDFxalid AbdulrahmanNo ratings yet

- Davies Rust ConverterDocument1 pageDavies Rust ConverterMichael TolboNo ratings yet

- Civil specifications for Cut & Bend Processing Building projectDocument10 pagesCivil specifications for Cut & Bend Processing Building projectLuis Gabriel BautistaNo ratings yet

- Pre-Qualification DocumentDocument49 pagesPre-Qualification DocumentNaveen NagisettiNo ratings yet

- Sikadur 732Document2 pagesSikadur 732Hafidh Roiy100% (1)

- Final-Corrected Calculation (Concrete)Document6 pagesFinal-Corrected Calculation (Concrete)ChungHuiPingNo ratings yet

- Company ProfileDocument2 pagesCompany ProfileGrace EuniceNo ratings yet

- Concrete Slump TestDocument19 pagesConcrete Slump TestGhayas Ud-din DarNo ratings yet

- Lavatex 2000...Document2 pagesLavatex 2000...ArifNo ratings yet

- Concrete Pre-Placement Checklist BackupDocument1 pageConcrete Pre-Placement Checklist Backuphermano balbonNo ratings yet

- Work Inspection Request Form (WIR) APPROVEDDocument1 pageWork Inspection Request Form (WIR) APPROVEDImran ZamanNo ratings yet

- Welder 2Document1 pageWelder 2Fahad AhmadNo ratings yet

- BOQ FormatExcelDocument2 pagesBOQ FormatExcelHomeSolutions Iloilo100% (2)

- CV Prem Singh Geneal ForemanDocument3 pagesCV Prem Singh Geneal ForemanpremNo ratings yet

- Floor Plan Floor Plan: Line of Canopy AboveDocument4 pagesFloor Plan Floor Plan: Line of Canopy AboveRonin GoraNo ratings yet

- Garden DSR Civil 2016-17 FinalDocument218 pagesGarden DSR Civil 2016-17 FinalShruti DamgirNo ratings yet

- Lalitpur Super Thermal Power Project Technical SpecificationsDocument370 pagesLalitpur Super Thermal Power Project Technical SpecificationsapsNo ratings yet

- Shop Fabrication of Structural SteelDocument12 pagesShop Fabrication of Structural SteelAris WicaksonoNo ratings yet

- Natsteel RebarsDocument12 pagesNatsteel RebarsjoebriffaNo ratings yet

- MAF For Ceramic TilesDocument1 pageMAF For Ceramic TilesAyman Al Hasaar100% (1)

- Department of Public Works and Highways: DPWH Standard Specification For Carbon Fiber, Item 416Document8 pagesDepartment of Public Works and Highways: DPWH Standard Specification For Carbon Fiber, Item 416jay_medrano_1No ratings yet

- Improving Oman Airport With Stone ColumnsDocument6 pagesImproving Oman Airport With Stone ColumnsMAJ1980No ratings yet

- 1 PDF Revised National Plumbing Code of The Philippinespdf El Niña Jude B PDFDocument141 pages1 PDF Revised National Plumbing Code of The Philippinespdf El Niña Jude B PDFKevinDataHilaNo ratings yet

- Fort Bliss Job Order ContractDocument446 pagesFort Bliss Job Order ContractNick AndrewsNo ratings yet

- AMG Pre-Qualification Catalogue 2015Document119 pagesAMG Pre-Qualification Catalogue 2015jegz diazNo ratings yet

- Residential Buildings BOQDocument11 pagesResidential Buildings BOQkevoroyalprinzNo ratings yet

- Standards Pertaining To ValvesDocument3 pagesStandards Pertaining To ValvesdidiNo ratings yet

- Standards Pertaining To ValvesDocument8 pagesStandards Pertaining To Valveselangopi89No ratings yet

- Material Safety Data Sheet: Product No.: 5512Document12 pagesMaterial Safety Data Sheet: Product No.: 5512didiNo ratings yet

- Weld Imperfections and Preventive MeasuresDocument25 pagesWeld Imperfections and Preventive Measuresecaph244100% (1)

- Surface CoatingDocument18 pagesSurface Coatingaaftab ahmed100% (1)

- Surface CoatingDocument18 pagesSurface Coatingaaftab ahmed100% (1)

- Establishing Scientifically Justified Acceptance Criteria For The Cleaning Validation of Apis (Active Pharmaceutical Ingredients) (Le Blanc)Document6 pagesEstablishing Scientifically Justified Acceptance Criteria For The Cleaning Validation of Apis (Active Pharmaceutical Ingredients) (Le Blanc)jorgeNo ratings yet

- D3376-14 Standard Test Methods of Sampling and Testing Pulps To Be Used in The Manufacture of Electrical InsulationDocument10 pagesD3376-14 Standard Test Methods of Sampling and Testing Pulps To Be Used in The Manufacture of Electrical Insulationastewayb_964354182No ratings yet

- Ceng204P Separation Processes I Coursework 1: 1. Problem DescriptionDocument3 pagesCeng204P Separation Processes I Coursework 1: 1. Problem DescriptionKaren Chong Yap100% (1)

- Concrete Repair and Protection System1 - CeresitDocument12 pagesConcrete Repair and Protection System1 - CeresitJill Jim LivestockNo ratings yet

- Introduction To Chemical Reactor Engineering - Problems PDFDocument75 pagesIntroduction To Chemical Reactor Engineering - Problems PDFJojie-Ann Alabarca100% (1)

- Clean Light-Colored Bricks SafelyDocument1 pageClean Light-Colored Bricks SafelymutazsalihNo ratings yet

- PPT1 Plastics Product DesignDocument7 pagesPPT1 Plastics Product DesignLalitya KrishnanNo ratings yet

- 0 - Rot DesizingDocument5 pages0 - Rot DesizingRajatNo ratings yet

- Infill-Wall CalculationDocument10 pagesInfill-Wall CalculationPrakash Singh RawalNo ratings yet

- FM Lab ManualDocument70 pagesFM Lab ManualRishi PatilNo ratings yet

- Redox 2Document366 pagesRedox 2Ana Emily Prentiss100% (1)

- Organic Chemistry: Basic Principles & TechniquesDocument4 pagesOrganic Chemistry: Basic Principles & TechniquesHasan shaikhNo ratings yet

- Chemistry and Technology of Honey Production PDFDocument47 pagesChemistry and Technology of Honey Production PDFsedianpo100% (1)

- A2 Biology Nerve Impulse ExamDocument16 pagesA2 Biology Nerve Impulse ExamDeborah HenniganNo ratings yet

- DX 2010 0625 EngDocument12 pagesDX 2010 0625 EngguillermorettoNo ratings yet

- A-3 LM Sol (Pulley)Document28 pagesA-3 LM Sol (Pulley)rockingjoeNo ratings yet

- Coil SelectionDocument5 pagesCoil SelectionMohsin Shaikh100% (1)

- Liquid-Liquid Equilibria For The Systems Water-Alcohols-Acetic AcidDocument10 pagesLiquid-Liquid Equilibria For The Systems Water-Alcohols-Acetic AcidAleska Guzman SantamariaNo ratings yet

- Dubai Municipality G+12 Concrete & Shoring QuestionsDocument7 pagesDubai Municipality G+12 Concrete & Shoring QuestionsMohammed Nasih Vettathur100% (2)

- FIITJEE ALL INDIA TEST SERIES FULL TEST – XI PHYSICS ANSWERS AND SOLUTIONSDocument19 pagesFIITJEE ALL INDIA TEST SERIES FULL TEST – XI PHYSICS ANSWERS AND SOLUTIONSVoxNo ratings yet

- Aucet 2014 BrochureDocument43 pagesAucet 2014 BrochurebtvlnarayanaNo ratings yet

- Demand Defrost Strategies in Supermarket Refrigeration SystemsDocument33 pagesDemand Defrost Strategies in Supermarket Refrigeration SystemsHoàngViệtAnhNo ratings yet

- Fatty Acids: Avid NnekenDocument44 pagesFatty Acids: Avid NnekenCory AmeliaNo ratings yet

- ME 331 Thermodynamics II Lecture 3cDocument31 pagesME 331 Thermodynamics II Lecture 3cJosell CaipangNo ratings yet

- Drilling Formulas Calculation Sheet Verson 1.4Document190 pagesDrilling Formulas Calculation Sheet Verson 1.4Adedire FisayoNo ratings yet

- Barett PDFDocument20 pagesBarett PDFlnadolskiNo ratings yet

- Physics I ProblemsDocument1 pagePhysics I ProblemsbosschellenNo ratings yet

- 3404 10153 1 PBDocument6 pages3404 10153 1 PBSergio Fabian NavarroNo ratings yet

- Design of Fatigue StrengthDocument21 pagesDesign of Fatigue StrengthRaviteja VgaNo ratings yet

- Qualitative Analysis of Groups 3-5 CationsDocument45 pagesQualitative Analysis of Groups 3-5 CationsMerrene Bright Divino JudanNo ratings yet