Professional Documents

Culture Documents

Standard Operating Procedure For Boiler Circulation Pump (BCP)

Uploaded by

PabitraMandalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standard Operating Procedure For Boiler Circulation Pump (BCP)

Uploaded by

PabitraMandalCopyright:

Available Formats

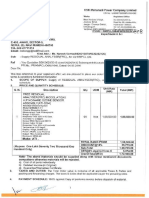

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL / CRITICAL/BOILER / BCP/

19

SOP FOR BOILER CIRCULATING PUMP (BCP)

Power from Knowledge

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 1 of 4

STANDARD OPERATING PROCEDURE FOR BOILER CIRCULATION PUMP (BCP)

OBJECTIVE: For Smooth Operation of Boiler Circulation Pump.

SCOPE: This SOP is applicable for 03 BCP.

INTRODUCTION: Boiler Water Circulation Pump used in high capacity boiler (super critical or sub critical),

it assisted the circulation of water to overcome friction losses in pipe lines.

In this power plant unit is designed on the basis that the boiler can operate in the full load only by using two

of three pumps. In order of flexibly, three pumps can be operate at same time. If only one pump put into

service, boiler load must decrease to 60 % of MCR. If continuous operating load is 60 % MCR, it is allowed

one pump in service. During light up, it is suggested that at least two pumps should be in service.

RESPONSIBILITY: Unit Control Engineer, Field Engineer and Desk Engineer.

SAFETY PRECAUTIONS:

Ensure no permit to work is pending on this system.

Use proper PPE where necessary.

Ensure all Manual Call Points, Public Address System and Fire Alarms in working condition.

Ensure housekeeping and proper area lighting.

Ensure all electrical connections to be tight.

Proper tools to be used for field operation.

Leakages to be informed and barricading the same should be ensured.

Area should be clear of any material.

Ensure proper approach to instruments for maintenance.

Ensure all measuring instruments working properly.

SPECIAL TOOLS/ EQUIPMENTS: NIL

OPERATING PROCEDURE –

RESPONSIBILITY

Sr. No. Description

UCE DE FE EE

PRE- START CHECKS:

1. All permits and cross permits have been returned. √ √ √

2. Area is clear of any other material. √

1|Page

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Bhupendra Sahu Name: Subrata Kumar Mishra Name:

Designation: AM Designation: GM Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL / CRITICAL/BOILER / BCP/

19

SOP FOR BOILER CIRCULATING PUMP (BCP)

Power from Knowledge

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 2 of 4

3. Power supply and control power supply available. √ √

4. All C & I instruments such as temperature gauge, pressure gauges,

√ √

DP transmitter & Flow meter of the BCP & Cooling water system

have been put into operation.

5. Check the CCCW pressure ≥ 0.7 Mpa and Low pressure cooling

√ √

water flow of the BCP’s motor cooler, heat barrier and purge

cooler is normal.

6. Drum water level should be normal ± 100mm. √ √ √

7. Left and right outlet valves of the BCP are fully opened. √ √

8. Temperature difference between the BCP housing and inlet header √

boiler water is less than 55 ° C

9. Check the Cavity water temperature <60 ° C √

NOTE

02 BCP are strictly prohibited to start at the same time

In case if BCP starts to fail in 5 sec, it should be stopped

immediately and start again after identifying the cause of failure

RESPONSIBILITY

Sr. No. Description

UCE DE FE EE

Cavity filling ,Flushing and Venting of BCP

1 Flush the heat barrier line and do the proper venting of the line. √

2 Flush the cavity filling line √

3 Cavity filling can be done from CEP OR BFP √

Drain valve of first strainer kept open to ensure purge cooler line √

4

and strainer get flushed

Than charge up to second strainer and open its drain and keep √

5

first strainer drain close

Flushed continued till water reaches following parameters:- √ √ √

PH › 6.5

6

Halogen (specially CI) ≤ 50 ppm

Solid content ≤ 5 PPM

2|Page

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Bhupendra Sahu Name: Subrata Kumar Mishra Name:

Designation: AM Designation: GM Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL / CRITICAL/BOILER / BCP/

19

SOP FOR BOILER CIRCULATING PUMP (BCP)

Power from Knowledge

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 3 of 4

7 Ensure pump vent open and line drain kept closed √

8 Start Cavity filling with a rate of 5 L/Min √ √

9 Do cavity air venting through pump vent √

10 Once cavity filled, ensure water comes through vent √

11 Stop cavity filling √

12 Do the venting of Motor cooler √

13 Do the venting of purge water cooler √

Do the priming and close all the drain and vent after priming of the √

14

pump

After closing all the drain and vent ,don’t touch the valve while √

15

pump is in service

START UP SEQUENCE :

1 Start the BCP

POST START UP CHECK

1 Ensure pump draws normal amps

2 Maintain the drum level since it will drop drastically, maintain

normal drum level

3 Check the inlet and outlet DP is normal

4 Check the low pressure cooling water Flow, Temperature &

Pressure

5 Check the BCP vibration is normal

6 Inspect BCP & Check for no leakage

SHUTDOWN SEQUENCE

HOT STATE OF BOILER

1 Shutdown the BCP

2 The outlet valve of BCP is open

3 The low pressure cooling water system of the BCP is maintained

the normal operation

4 Open the outlet and inlet bypass valve of BCP and drain valve of

the pump body

5 After BCP is shutdown, closely monitor the pump motor chamber

temperature to prevent damaging the motor coil insulation.

3|Page

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Bhupendra Sahu Name: Subrata Kumar Mishra Name:

Designation: AM Designation: GM Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL / CRITICAL/BOILER / BCP/

19

SOP FOR BOILER CIRCULATING PUMP (BCP)

Power from Knowledge

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 4 of 4

COLD STATE OF BOILER

1 When the boiler water temperature ≤150 ° C, Shutdown the BCP

2 The outlet valve of BCP is maintain to open

3 The low pressure cooling water system of the BCP is maintained

the normal operation and after shell temperature ≤ 80° C, stop the

low pressure cooling water

PROTECTIONS

1 Temperature of motor cavity>=66℃ {Temp. S/W}

2 Anyone outlet valve is not fully opened after pump running 60s

with 3 sec delay

3 Lost LP cooling water {Flow S/W } <287lit./min with 300 S delay

4 Differential pressure<60kPa between inlet and outlet

INTERLOCK START-UP CONDITION OF THE BCP

1 The interlock of boiler circulation pump put into operation, if any

running pump tripped.

2 The interlock of boiler circulation pump put into operation, if

differential pressure<148.3kPa between inlet and outlet of any

running pump with 3 sec delay

Do’s & Don’ts

Do’s:

Ensure adequate flow of cooling water for Motor Cooler and heat barrier.

Test safety controls and devices on a periodic basis.

Ensure local operators are adequately trained to assure safe and efficient operation.

Inspect the equipment daily for proper operation, and/or adverse conditions.

4|Page

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Bhupendra Sahu Name: Subrata Kumar Mishra Name:

Designation: AM Designation: GM Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL / CRITICAL/BOILER / BCP/

19

SOP FOR BOILER CIRCULATING PUMP (BCP)

Power from Knowledge

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 5 of 4

Maintain a log of incidents and parameters that effect equipment operation.

Allow only authorized person to work and attend any leakages.

Regular maintenance and calibration of instruments to be ensured.

Don’ts

Avoid operating BCP without getting required motor cavity cooling water parameters.

Avoid bypassing permissive/protection logics.

Permit unqualified personnel to operate the equipment.

REFERENCE DOCUMENTS:

Boiler Operation Manual

CURVES & CHARTS

NA

ABBREVIATIONS / NOTATIONS:-

o SOP: Standard Operating Procedure

o UCE: Unit Control Engineer

o DE: Desk Engineer

o FE: Field Engineer

o DCS: Distributed Control System

o EE: Electrical Shift Engineer

o MFT: Main Fuel Trip.

o RB : Run Back

5|Page

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Bhupendra Sahu Name: Subrata Kumar Mishra Name:

Designation: AM Designation: GM Designation:

You might also like

- Sop For Vacuum PumpDocument7 pagesSop For Vacuum PumpSonratNo ratings yet

- Turbine Drains SOPDocument6 pagesTurbine Drains SOPSonratNo ratings yet

- BCWDocument13 pagesBCWRohit100% (2)

- CCCWDocument7 pagesCCCWSonratNo ratings yet

- SOP For Turbine ChecklistDocument11 pagesSOP For Turbine Checklistpradeep.selvarajanNo ratings yet

- Stg-1 TDBFP Isolation NormalisationDocument4 pagesStg-1 TDBFP Isolation Normalisationnetygen1No ratings yet

- Standard Operating Procedure FOR Oil Gun Light-UpDocument5 pagesStandard Operating Procedure FOR Oil Gun Light-Upsambhu100% (3)

- Line TraceDocument84 pagesLine TraceSam100% (1)

- Line Up Turbine Aux. SystemDocument42 pagesLine Up Turbine Aux. SystemAmit Chauhan100% (2)

- Presentation OnDocument28 pagesPresentation OnAnonymous umnT4ZZcuNo ratings yet

- Seal Oil SopDocument18 pagesSeal Oil SopSonrat100% (1)

- Turbine Emergency - Thermal Power Plant A-ZDocument5 pagesTurbine Emergency - Thermal Power Plant A-ZSiva Kulanji100% (1)

- AGM & Sr. Faculty Member (PMI) NTPC LTD.: Dr. K. V. VidyanandanDocument46 pagesAGM & Sr. Faculty Member (PMI) NTPC LTD.: Dr. K. V. VidyanandanPraveen PeethambaranNo ratings yet

- Sop For Gauge Glass ChargingssDocument2 pagesSop For Gauge Glass ChargingssKUSH SHARMANo ratings yet

- 31-Station Acwp - SopDocument3 pages31-Station Acwp - SopSiddhant Satpathy100% (1)

- 018-SOP of Gland Steam ChargingDocument6 pages018-SOP of Gland Steam Chargingsambhu100% (1)

- Turbine Start Up ProcedureDocument3 pagesTurbine Start Up ProcedureShameer Majeed100% (1)

- 500MW Boiler Fans and ProtectionsDocument5 pages500MW Boiler Fans and Protectionsshashank100% (1)

- Problem Faced in Turbine Governing System During Commissioning of TDBFPDocument5 pagesProblem Faced in Turbine Governing System During Commissioning of TDBFPCharu ChhabraNo ratings yet

- TDBFP Start Up Procedure 600 MWDocument1 pageTDBFP Start Up Procedure 600 MWmayukh_mitra_2No ratings yet

- Power Plant Operation Turbine & Auxiliaries: 18 February 2013 PMI Revision 00 1Document43 pagesPower Plant Operation Turbine & Auxiliaries: 18 February 2013 PMI Revision 00 1Alok Ranjan Tripathi100% (1)

- Hydraulic Low Vacuum Trip Device FailureDocument3 pagesHydraulic Low Vacuum Trip Device Failuretsrinivasan5083No ratings yet

- Cep Startup and ShutdownDocument5 pagesCep Startup and ShutdownAnonymous W9VINoTzaNo ratings yet

- Standard Operating Procedure: Adhunik Power & Natural Resources LTDDocument1 pageStandard Operating Procedure: Adhunik Power & Natural Resources LTDApnrl maincontrolroomNo ratings yet

- Turbine Trip LogicDocument2 pagesTurbine Trip Logicdilbagh_scribd50% (2)

- P Chandankhede Dy. Supdt, OperationDocument59 pagesP Chandankhede Dy. Supdt, Operationsitaramaes2009No ratings yet

- TG Ele Hydro Oil PumpDocument8 pagesTG Ele Hydro Oil PumpsambhuNo ratings yet

- MDBFP TO TDBFP Change OverDocument4 pagesMDBFP TO TDBFP Change OversambhuNo ratings yet

- 200mw Volume 2Document316 pages200mw Volume 2Sam100% (2)

- Station Black Out Handling and Restoration St1Document8 pagesStation Black Out Handling and Restoration St1Shift Incharge BrbclNo ratings yet

- Cold Start Up ProcedureDocument18 pagesCold Start Up ProcedurerahulNo ratings yet

- 020-SOP of H2 CYLINDER Room ChargingDocument4 pages020-SOP of H2 CYLINDER Room ChargingsambhuNo ratings yet

- CEP PresentatioDocument14 pagesCEP PresentatioVinod Mahajan100% (1)

- Furnace Safeguard Supervisory System: 8th March 2015 FsssDocument9 pagesFurnace Safeguard Supervisory System: 8th March 2015 FsssSiva KumarNo ratings yet

- Cold Start Up Procedure: - NTPC, SimhadriDocument29 pagesCold Start Up Procedure: - NTPC, SimhadriAhemadNo ratings yet

- Governing System WriteUp TDBFPDocument4 pagesGoverning System WriteUp TDBFPArnab PalNo ratings yet

- Boiler Hydro Test by R K JaintDocument9 pagesBoiler Hydro Test by R K JaintRajeevAgrawalNo ratings yet

- SESI-TSPL-OPN-SOP-BTG-074 (MDBFP & TDBFP Paralleling)Document5 pagesSESI-TSPL-OPN-SOP-BTG-074 (MDBFP & TDBFP Paralleling)sourav mahapatraNo ratings yet

- Stage 2 TDBFPDocument56 pagesStage 2 TDBFPvijaykrishnatenneti100% (2)

- Emergency Procedure For Total Station Power FailureDocument4 pagesEmergency Procedure For Total Station Power FailureSelva Manian100% (1)

- One PA Fan TrippingDocument3 pagesOne PA Fan TrippingSubrahmanyam100% (1)

- Sop TurbineDocument4 pagesSop TurbinesambhuNo ratings yet

- Presentation On Steam Turbine Operation by S ChandDocument36 pagesPresentation On Steam Turbine Operation by S Chandsomyaranjan das100% (1)

- Case Study On BFP Mod.Document18 pagesCase Study On BFP Mod.rajan_me08350% (2)

- Mill Interlocks: Start PermissivesDocument6 pagesMill Interlocks: Start PermissivesNikhilNo ratings yet

- Tripping of Turbine On High Differential PressureDocument3 pagesTripping of Turbine On High Differential Pressureatulbhogare7No ratings yet

- TDBFP Over Speed ProtocolDocument2 pagesTDBFP Over Speed ProtocolAnoop Kumar AllankiNo ratings yet

- FSSS PresentationDocument28 pagesFSSS Presentationjp mishra100% (2)

- Cep Sop KSKDocument11 pagesCep Sop KSKSonratNo ratings yet

- Unit Start Up Sequence ActivitiesDocument6 pagesUnit Start Up Sequence ActivitiesranjanNo ratings yet

- Automatic Turbine TestorDocument26 pagesAutomatic Turbine TestorSam100% (2)

- 057 - SOP of Boiler Circulating Pump FlushingDocument6 pages057 - SOP of Boiler Circulating Pump FlushingsambhuNo ratings yet

- BFP Hyd CouplingDocument21 pagesBFP Hyd CouplingAditya Nandula100% (2)

- Standard Operating Instruction: Sop For CT FanDocument5 pagesStandard Operating Instruction: Sop For CT FanSonratNo ratings yet

- Sop For Flushing Water PumpDocument6 pagesSop For Flushing Water PumpSonratNo ratings yet

- OCCW Pump SOP-1Document7 pagesOCCW Pump SOP-1SonratNo ratings yet

- Condenser Ball Cleaning SystemDocument6 pagesCondenser Ball Cleaning SystemSonratNo ratings yet

- Turbine Drains SOPDocument6 pagesTurbine Drains SOPSonratNo ratings yet

- Sop For LP Pump (R1)Document6 pagesSop For LP Pump (R1)SonratNo ratings yet

- Gland Sealing Systeam011Document6 pagesGland Sealing Systeam011SonratNo ratings yet

- MMD AphDocument8 pagesMMD AphPabitraMandalNo ratings yet

- Aph SopDocument5 pagesAph SopPabitraMandalNo ratings yet

- MMD Barring GearDocument6 pagesMMD Barring GearPabitraMandalNo ratings yet

- AHP Clinker GrinderDocument5 pagesAHP Clinker GrinderPabitraMandalNo ratings yet

- CHP ImpactorDocument8 pagesCHP ImpactorPabitraMandalNo ratings yet

- Guarantee Certificate: TO, M/S. KSK Mahanadi Power Co LTDDocument1 pageGuarantee Certificate: TO, M/S. KSK Mahanadi Power Co LTDPabitraMandalNo ratings yet

- #4 Cep Motor-ADocument4 pages#4 Cep Motor-APabitraMandalNo ratings yet

- Verb-Ed Modifier - How Is It DerivedDocument5 pagesVerb-Ed Modifier - How Is It DerivedPabitraMandalNo ratings yet

- 878 BSK EnggDocument2 pages878 BSK EnggPabitraMandalNo ratings yet

- Digital Modulation PDFDocument41 pagesDigital Modulation PDFPabitraMandalNo ratings yet

- Shatrudhan Lal Kushwaha: Add:-Navjeevan Vihar Sec No.-2 Post-Vindhyanagar, Singrauli (MP) Pin Code-486885 Mob: - 8982119149Document2 pagesShatrudhan Lal Kushwaha: Add:-Navjeevan Vihar Sec No.-2 Post-Vindhyanagar, Singrauli (MP) Pin Code-486885 Mob: - 8982119149PabitraMandalNo ratings yet

- SSC SSC: Instructions For SBI Branches: Instructions For SBI BranchesDocument1 pageSSC SSC: Instructions For SBI Branches: Instructions For SBI BranchesPabitraMandalNo ratings yet

- Levelstate EDLIDocument11 pagesLevelstate EDLIPabitraMandalNo ratings yet

- Shatrudhan's ResumeDocument2 pagesShatrudhan's ResumePabitraMandalNo ratings yet

- ALCOA Plus 9 Principles For Data IntegrityDocument24 pagesALCOA Plus 9 Principles For Data IntegrityMd Amdadul HoqueNo ratings yet

- SPLK-1002 Splunk Core Certified Power User DumpsDocument11 pagesSPLK-1002 Splunk Core Certified Power User Dumpskevin jackyNo ratings yet

- Medical Devices Training For Medical StaffDocument3 pagesMedical Devices Training For Medical StafffatematareefNo ratings yet

- Ford Ranger Spare PartsDocument2 pagesFord Ranger Spare PartsNgila João AndréNo ratings yet

- Granta Note Installation GuidelinesDocument11 pagesGranta Note Installation GuidelinesAshwary Sheel Wali Research Scholar, Dept of Mech Engg., IIT (BHU)No ratings yet

- Capstone Project Proposal COMP 10076 Capstone Prep: ApprovedDocument7 pagesCapstone Project Proposal COMP 10076 Capstone Prep: ApprovedJohanthan SputkaovNo ratings yet

- Detailing GuidelinesDocument23 pagesDetailing GuidelinesWayne Garner100% (2)

- 3 - Practical Benefit of Risk Assessment-Zone Determination by Layout Analysis PDFDocument29 pages3 - Practical Benefit of Risk Assessment-Zone Determination by Layout Analysis PDFrafecar100% (1)

- Dwnload Full Visual C 2012 How To Program 5th Edition Deitel Test Bank PDFDocument35 pagesDwnload Full Visual C 2012 How To Program 5th Edition Deitel Test Bank PDFresigner.nudicaul7k1p3100% (8)

- LNC-T510i Operator's Manual-V04.00.000 (4408110053) ENGDocument94 pagesLNC-T510i Operator's Manual-V04.00.000 (4408110053) ENGEduardo Gonzalez OleaNo ratings yet

- Pmg5317-T20B: Wireless N Gpon Hgu With 4-Port Gbe SwitchDocument4 pagesPmg5317-T20B: Wireless N Gpon Hgu With 4-Port Gbe SwitchppancxooNo ratings yet

- Graduate Aptitude Test in EngineeringDocument48 pagesGraduate Aptitude Test in Engineeringsomsubhra_1988No ratings yet

- DatabaseDocument18 pagesDatabaseSyed SalmanNo ratings yet

- Cloud Pathology Demo TRXDocument3 pagesCloud Pathology Demo TRXshubham redlawarNo ratings yet

- UniTartuCS Poster Template PortraitDocument1 pageUniTartuCS Poster Template PortraitManuel ZumbadoNo ratings yet

- Davao Maps, Informations, Datas and SourcesDocument89 pagesDavao Maps, Informations, Datas and SourcesGenny Aubrey Ramos CarcedoNo ratings yet

- A Primer On ROADM ArchitecturesDocument17 pagesA Primer On ROADM ArchitecturesSathish Kumar100% (1)

- Brochure Overall Thermal Transfer Value 1Document2 pagesBrochure Overall Thermal Transfer Value 1ShahidHamkarNo ratings yet

- Tech Guide: PC LAN Setup: XP Operating SystemsDocument3 pagesTech Guide: PC LAN Setup: XP Operating SystemsRobinson SanchezNo ratings yet

- Face DetectionDocument23 pagesFace Detectionnimarose 1175% (4)

- Very Simple 9v Tesla Coil - Instructables PDFDocument16 pagesVery Simple 9v Tesla Coil - Instructables PDFpolikarpaNo ratings yet

- Appendix 1.1 - Ethylene DetectorDocument5 pagesAppendix 1.1 - Ethylene DetectorMarkNo ratings yet

- AQ12FANDocument9 pagesAQ12FANhdave32No ratings yet

- 13 Transformer ContDocument12 pages13 Transformer ContHusseinZyoudNo ratings yet

- Change of HSE Management ProcedureDocument15 pagesChange of HSE Management ProcedureEldhose VargheseNo ratings yet

- A Beginners Guide To Building An Electric Go-Kart.Document9 pagesA Beginners Guide To Building An Electric Go-Kart.Kabir Singh BhaiNo ratings yet

- Leica Nova MS50 White Paper: September 2013Document13 pagesLeica Nova MS50 White Paper: September 2013kurd99No ratings yet

- Recording Spirit M8 ReviewDocument4 pagesRecording Spirit M8 ReviewPriscilla Bajomo100% (2)

- Command To Sun Server V240Document5 pagesCommand To Sun Server V240Henrique SemedoNo ratings yet

- Change Management in Office 365Document6 pagesChange Management in Office 365TomNo ratings yet