Professional Documents

Culture Documents

Single, Unbalanced, Multi-Spring Pusher Seal For General Purpose Applications

Uploaded by

Sulaiman Kadher KOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Single, Unbalanced, Multi-Spring Pusher Seal For General Purpose Applications

Uploaded by

Sulaiman Kadher KCopyright:

Available Formats

RO

Single, unbalanced, multi-spring pusher

seal for general purpose applications

A simple, proven and dependable design features an open, rotating

compression unit that imparts a turbulent flow of the process fluid

which helps keep solids away from the seal faces and removes

seal generated heat. The flexibly mounted insert compensates for

misalignment to ensure seal face contact. Off-the-shelf availability

in standard configurations for most chemical pumps.

Features and Benefits

• Rotating Seal Ring

Self centers around the shaft independent of compression unit. Designed

to withstand the harsh physical demands of cyclic operation or continuous

duty. Multiple springs and drive pins evenly distribute the load. Available

in a wide range of materials; in fact, this part can be built to stand up to

nearly any known chemical.

• Compression Unit

Sturdy, robust design. Built to perform in

aggressive, even abrasive, fluids.

Available in any machinable metallurgy.

• Shaft Packing

Completely interchangeable materials

without changing other components.

Available in a wide range of configurations

and materials for compatibility with all process

fluids and process temperatures.

• Stationary Insert

Flexibly mounted to prevent distortion.

• Insert Mounting

Dimensionally interchangeable for versatility in secondary seal

material selections.

Available Materials of Construction

Metal Seal Rings Secondary Seals

Components or Inserts (shaft packing and insert mounting)

304, 316 or 20 Stainless Steel Tungsten Carbide Fluoroelastomer

Alloy 400 Silicon Carbide Buna N

Alloy C-276 or B-2 Peramic Ethylene Propylene

Titanium Durchrome Rubber (EPR)

Nickel Bronze Perfluoroelastomer

Tantalum No. 5 Carbon Ethylene Propylene

Terpolymer (EPT)

Neoprene

Operating Parameters PTFE

• Maximum Pressure: Up to 20 bar (300 psi)

• Temperature: cryogenics to 260°C (500°F)

• Speed: Up to 23 mps (4500 fpm)

Here’s how the RO seal self-compensates for any installation misalignment or gland irregularities

With a clamped insert, a cocked gland ring can cause With Flowserve’s flexibly mounted insert, the gland ring can be

seal faces to misalign (angle A) and leakage can occur. cocked and the insert remains square with the axis of the shaft.

O-ring - Effectively

O-ring - Effectively

isolated insert

isolated insert

Cocked gland

Cocked

ringgland ring from any mechanical,

from any mechanical,

thermal orthermal or Cocked Cocked

hydraulic hydraulic

distortiondistortion

of the gland

of the gland gland ringgland ring

Clamp Clamp

points points

Shaft Shaft Shaft Shaft

Angle A Angle A 90° 90°

Insert (stationary

Insert (stationary

face) face) Insert (stationary

Insert (stationary

face) face)

Rotating seal

Rotating

ring seal ring Rotating seal

Rotating

ring seal ring

FSD155eng REV 10/09 Printed in USA

USA and Canada

Kalamazoo, Michigan USA

To find your local Flowserve representative

Telephone: 1 269 381 2650

and find out more about Flowserve Corporation

Telefax: 1 269 382 8726

visit www.flowserve.com

Europe, Middle East, Africa

Roosendaal, The Netherlands

Telephone: 31 165 581400

Telefax: 31 165 554590

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this

Flowserve product is designed to perform its intended function safely during its useful life. However, the purchaser or user of Flowserve Asia Pacific

products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial service

conditions. Although Flowserve can provide general guidelines, it cannot provide specific data and warnings for all possible applications. The Singapore

purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance

of Flowserve products. The purchaser/user should read and understand the Installation Instructions included with the product, and train its Telephone: 65 6544 6800

employees and contractors in the safe use of Flowserve products in connection with the specific application.

Telefax: 65 6214 0541

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes

only and should not be considered certified or as a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to

be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve is Latin America

continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to

change without notice. Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation Mexico City

at any one of its worldwide operations or offices.

Telephone: 52 55 5567 7170

© 2011 Flowserve Corporation Telefax: 52 55 5567 4224

You might also like

- Gas Filters: FC SeriesDocument4 pagesGas Filters: FC SeriesHeryanto SyamNo ratings yet

- Catalog Series 551 553 Ss Namur 1 4 Et 1 2 3 2 5 2 Asco en 6316858Document9 pagesCatalog Series 551 553 Ss Namur 1 4 Et 1 2 3 2 5 2 Asco en 6316858Jeyson BueraNo ratings yet

- Anti-Seize Compound TdsDocument3 pagesAnti-Seize Compound TdskorayNo ratings yet

- MS 01 54Document6 pagesMS 01 54fagundds2No ratings yet

- High Performance BFV's Buterfly ValveDocument2 pagesHigh Performance BFV's Buterfly ValverajNo ratings yet

- Document 5Document1 pageDocument 5leoNo ratings yet

- I-Tork PDS CatalogDocument12 pagesI-Tork PDS CatalogAnisVisuNo ratings yet

- Rotary Joint: SeriesDocument19 pagesRotary Joint: SeriesSUBHAMOY BASUNo ratings yet

- ML - Valve ActuatorDocument8 pagesML - Valve ActuatorGabrielNo ratings yet

- FLO DS 0006 Wafer Butterfly ValvesDocument4 pagesFLO DS 0006 Wafer Butterfly ValvesShubhajit ChakrabortyNo ratings yet

- Fig-970-970G-NEW DESIGNDocument1 pageFig-970-970G-NEW DESIGNAsmaaNo ratings yet

- EXP Series - : Standard Chemical Process PumpsDocument6 pagesEXP Series - : Standard Chemical Process PumpsMohsen ParpinchiNo ratings yet

- Tekno Valves Ton ContainerDocument14 pagesTekno Valves Ton ContainerFrancisco Hevia FariaNo ratings yet

- O RingDocument50 pagesO RingPRASHANT KANTE100% (1)

- J6 Series, MS-02-214 R1Document2 pagesJ6 Series, MS-02-214 R1herysyam1980No ratings yet

- BTVDocument12 pagesBTVJuan HernandezNo ratings yet

- Needle Valves GU Series (MS-02-312-E) R1Document6 pagesNeedle Valves GU Series (MS-02-312-E) R1herysyam1980No ratings yet

- s Fsd165 TurboDocument4 pagess Fsd165 Turbobillel limaneNo ratings yet

- Fero Strata Product Profiles Combined - Zezt - Com.auDocument19 pagesFero Strata Product Profiles Combined - Zezt - Com.auSplitset TürkiyeNo ratings yet

- Spiral Wound GaskeDocument1 pageSpiral Wound GasketogentongNo ratings yet

- Anti-Seize Stainless GBDocument3 pagesAnti-Seize Stainless GBKarinaNo ratings yet

- iRSVP 3100 Data Sheet.Document2 pagesiRSVP 3100 Data Sheet.Gỗ MộcNo ratings yet

- Antico HE SeriesDocument6 pagesAntico HE SeriesSandipNo ratings yet

- Dixon HT SeriesDocument2 pagesDixon HT SeriesAngelina JunioNo ratings yet

- Dvenbr0020 en A4Document14 pagesDvenbr0020 en A4Ulises MurielNo ratings yet

- Flush Bottom Valve Steam IMI PBM - PB-FD5 - 2020Document2 pagesFlush Bottom Valve Steam IMI PBM - PB-FD5 - 2020Mauricio Villanova Do AmaralNo ratings yet

- Profile - JINWOO KOREA (GASKET)Document19 pagesProfile - JINWOO KOREA (GASKET)김성호No ratings yet

- Argus IntroDocument12 pagesArgus IntroJuan HernandezNo ratings yet

- Severe service, bubble-tight Ball Valves for high performance applicationsDocument12 pagesSevere service, bubble-tight Ball Valves for high performance applicationskuraimundNo ratings yet

- Parker Piston T-Seal for Improved StabilityDocument4 pagesParker Piston T-Seal for Improved StabilityGriphold PlantNo ratings yet

- Effortless tubing connections with Quick Star push-in fittingsDocument14 pagesEffortless tubing connections with Quick Star push-in fittingsNo HopeNo ratings yet

- Swivel Joint SRL825: Ptfe-LinedDocument1 pageSwivel Joint SRL825: Ptfe-Linedady vNo ratings yet

- PW SeriesDocument8 pagesPW SeriesMt GrNo ratings yet

- Keystone f990 920 CatalogoDocument4 pagesKeystone f990 920 CatalogoGino Chavez ValenciaNo ratings yet

- KS-SR & KS-SRM Parts PDFDocument4 pagesKS-SR & KS-SRM Parts PDFYusuf Bumi PuteraNo ratings yet

- Systemair Fans KVO Data Sheet Eng PDFDocument4 pagesSystemair Fans KVO Data Sheet Eng PDFErnesto OtazuNo ratings yet

- Trim DetailsDocument15 pagesTrim DetailsDilip VaradharajanNo ratings yet

- Series PR40/60: Heavy-Duty Repairable Stainless GaugeDocument4 pagesSeries PR40/60: Heavy-Duty Repairable Stainless GaugelaurayrNo ratings yet

- Industrial Excess Flow Valves: SEFV SeriesDocument4 pagesIndustrial Excess Flow Valves: SEFV SeriesToty DzNo ratings yet

- Imd PDFDocument8 pagesImd PDFPati KasaNo ratings yet

- Single PPM QUALITY INNOVATION Butterfly ValvesDocument23 pagesSingle PPM QUALITY INNOVATION Butterfly Valveshuutan12345No ratings yet

- DSM-0274.0 Bronze AlloysDocument5 pagesDSM-0274.0 Bronze AlloyskerbaubiruNo ratings yet

- Wear Rings: Product DescriptionDocument11 pagesWear Rings: Product DescriptionMehdi SoltaniNo ratings yet

- RA Rotary Actuators - Technical Catalogue-UKDocument4 pagesRA Rotary Actuators - Technical Catalogue-UKDanilo AugustoNo ratings yet

- Series: Insert FittingsDocument7 pagesSeries: Insert FittingsDiogo CarameloNo ratings yet

- EO & EO 2: Metric Bite Type FittingsDocument10 pagesEO & EO 2: Metric Bite Type FittingsHenri Flavio NalineNo ratings yet

- Masoneilan 31000 Series Rotary Control ValvesDocument12 pagesMasoneilan 31000 Series Rotary Control ValvesJuan Manuel AcebedoNo ratings yet

- TT OpVEE V-Notch Ball-Valve-BrochureDocument16 pagesTT OpVEE V-Notch Ball-Valve-BrochureSergio Gana GonzalezNo ratings yet

- GPT 1-15 LineBackerDocument4 pagesGPT 1-15 LineBackerazadeazNo ratings yet

- Starflange 1701Document4 pagesStarflange 1701Wilber ChavezNo ratings yet

- Mechanical Seal Stirling GNZ - CatalogDocument4 pagesMechanical Seal Stirling GNZ - Catalogsiera100% (2)

- ABS Dry Installed Sewage Pump FR: ApplicationsDocument2 pagesABS Dry Installed Sewage Pump FR: ApplicationsIR MA Al AzharNo ratings yet

- O RingsDocument10 pagesO RingsFernando Padilla100% (1)

- Válvulas Agulha InoxDocument4 pagesVálvulas Agulha InoxNoUserNameNo ratings yet

- F10 Series, MS-02-215 R2Document6 pagesF10 Series, MS-02-215 R2herysyam1980No ratings yet

- ProValve Knife Gate ValveDocument12 pagesProValve Knife Gate ValveHarry HonchoNo ratings yet

- ANTI-SEIZE Stainless - GBDocument3 pagesANTI-SEIZE Stainless - GBHasan RazaNo ratings yet

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363No ratings yet

- Bolt Depot - Machine Screw Diameter TableDocument1 pageBolt Depot - Machine Screw Diameter TableSulaiman Kadher KNo ratings yet

- Technical - Info SealsDocument9 pagesTechnical - Info SealsSulaiman Kadher KNo ratings yet

- Leakage Wear and Friction in The Mechanical Face SDocument9 pagesLeakage Wear and Friction in The Mechanical Face SSulaiman Kadher KNo ratings yet

- Sealing Extreme Cold Application - FSADocument3 pagesSealing Extreme Cold Application - FSASulaiman Kadher KNo ratings yet

- Elastomer Tech - FSADocument4 pagesElastomer Tech - FSASulaiman Kadher KNo ratings yet

- Fresh View On Containment Seals AESSEALDocument18 pagesFresh View On Containment Seals AESSEALSulaiman Kadher KNo ratings yet

- Containment Seals For Api 682 Second Edition: by Peter E. BowdenDocument18 pagesContainment Seals For Api 682 Second Edition: by Peter E. BowdenMichael J. BaneNo ratings yet

- 53C - FsaDocument5 pages53C - FsaSulaiman Kadher KNo ratings yet

- Unusual Application - FSADocument4 pagesUnusual Application - FSASulaiman Kadher KNo ratings yet

- Thermal Attack - FSADocument2 pagesThermal Attack - FSASulaiman Kadher KNo ratings yet

- Failure and Corrective Action - FSADocument2 pagesFailure and Corrective Action - FSASulaiman Kadher KNo ratings yet

- IoTReliability - FSADocument2 pagesIoTReliability - FSASulaiman Kadher KNo ratings yet

- SmallDeedsBigRewards PDFDocument23 pagesSmallDeedsBigRewards PDFsheik mohamedNo ratings yet

- AESSEAL Case Study 2Document1 pageAESSEAL Case Study 2Sulaiman Kadher KNo ratings yet

- AESSEAL Sustainability ReportDocument30 pagesAESSEAL Sustainability ReportSulaiman Kadher KNo ratings yet

- Curc™: Range of Single Cartridge Mechanical SealsDocument8 pagesCurc™: Range of Single Cartridge Mechanical SealsSulaiman Kadher KNo ratings yet

- Catalog Systems PDFDocument36 pagesCatalog Systems PDFWong DaNo ratings yet

- LABTECTA BrochureDocument12 pagesLABTECTA BrochureSulaiman Kadher KNo ratings yet

- Aesseal Capi Dual SealDocument2 pagesAesseal Capi Dual SealSulaiman Kadher KNo ratings yet

- Rolling Bearings - 17000 EN - TCM - 12-121486Document1,152 pagesRolling Bearings - 17000 EN - TCM - 12-121486Abhinav SaiNo ratings yet

- Edwards Model-80 ManualDocument39 pagesEdwards Model-80 ManualSulaiman Kadher KNo ratings yet

- M0GCH™/M0GCE™ Series: Plug-In Seals To Suit Grundfos PumpsDocument2 pagesM0GCH™/M0GCE™ Series: Plug-In Seals To Suit Grundfos PumpsSulaiman Kadher KNo ratings yet

- Kalrez Oring IdentificationDocument1 pageKalrez Oring IdentificationSulaiman Kadher KNo ratings yet

- Curc™: Range of Single Cartridge Mechanical SealsDocument8 pagesCurc™: Range of Single Cartridge Mechanical SealsSulaiman Kadher KNo ratings yet

- 1B Seal IomDocument4 pages1B Seal IomSulaiman Kadher KNo ratings yet

- Aesseal Capi Dual SealDocument2 pagesAesseal Capi Dual SealSulaiman Kadher KNo ratings yet

- Mechanical Seal StudyDocument16 pagesMechanical Seal StudySulaiman Kadher KNo ratings yet

- Bulk Fill Composites For Class II Restorations by DentistryDocument12 pagesBulk Fill Composites For Class II Restorations by Dentistryddmorar486No ratings yet

- 2011 04 11 Biomass GasificationDocument48 pages2011 04 11 Biomass GasificationHotib PerwiraNo ratings yet

- MO-114D/104D: Instruction ManualDocument32 pagesMO-114D/104D: Instruction Manualmikail2008No ratings yet

- Mindanao State University Iligan Institute of TechnologyDocument9 pagesMindanao State University Iligan Institute of TechnologynikkihipulanNo ratings yet

- Caterpillar Connecting Rod Bearings Service TrainingDocument5 pagesCaterpillar Connecting Rod Bearings Service Trainingaudrey100% (40)

- Lista MateriałówDocument7 pagesLista MateriałówVanessa KowalskaNo ratings yet

- Ficha SWEP M10 - 2Document2 pagesFicha SWEP M10 - 2lilymaulenNo ratings yet

- Supply and Fixing Ultralite 10mm Multiwall Polycarbonate SheetDocument3 pagesSupply and Fixing Ultralite 10mm Multiwall Polycarbonate SheetRaghvendra AgarwalNo ratings yet

- Directional SolidificationDocument2 pagesDirectional SolidificationTeka KamNo ratings yet

- Heavy-Duty Lubricant: FeaturesDocument2 pagesHeavy-Duty Lubricant: Featuresarjun vsNo ratings yet

- Astm A333-Gr3 PDFDocument14 pagesAstm A333-Gr3 PDFIkhsan SiratNo ratings yet

- QC Check ListDocument1 pageQC Check ListshwayeNo ratings yet

- UCM Masters Research Topics 2018Document1 pageUCM Masters Research Topics 2018Trisha Gaile MoscosoNo ratings yet

- Low Impact Woodland HouseDocument7 pagesLow Impact Woodland HouseABHISHNo ratings yet

- Unit 1 Question Bank Welding EngineeringDocument5 pagesUnit 1 Question Bank Welding EngineeringSayiram GNo ratings yet

- Surface Preparation and Protective Coating Procedure (R03) CivilDocument116 pagesSurface Preparation and Protective Coating Procedure (R03) CivilMogul KhanNo ratings yet

- NADCA Standards 2015Document272 pagesNADCA Standards 2015mr.nguyenkNo ratings yet

- Casting Material Carbon Steel A27 GR 65 35Document8 pagesCasting Material Carbon Steel A27 GR 65 35Abdul RozaqNo ratings yet

- Training Activity Matrix SMAW NC I-COREDocument52 pagesTraining Activity Matrix SMAW NC I-COREEugenio Mates Jr.No ratings yet

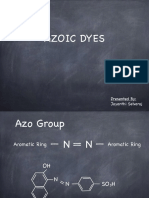

- Azoic Dyes: Presented By: Jayanthi SelvarajDocument13 pagesAzoic Dyes: Presented By: Jayanthi Selvarajdona biswasNo ratings yet

- Patent Application Publication (10) Pub - No .: US 2021/0351455 A1Document58 pagesPatent Application Publication (10) Pub - No .: US 2021/0351455 A1JagenNo ratings yet

- Manual Cleaning and Disinfection of General Instruments in Cleaning and Disinfection BathDocument4 pagesManual Cleaning and Disinfection of General Instruments in Cleaning and Disinfection BathEGHNo ratings yet

- Prevent Water Penetration Brick WallsDocument4 pagesPrevent Water Penetration Brick WallscarmeloNo ratings yet

- Fichas Tecnicas TIXOGEL EZ-100 (Ingles)Document2 pagesFichas Tecnicas TIXOGEL EZ-100 (Ingles)fatimallNo ratings yet

- Installation Guidance For Cement Rotary Kiln (LKB)Document20 pagesInstallation Guidance For Cement Rotary Kiln (LKB)Waka OngetiNo ratings yet

- Comparing Effect of Adding LDPE, PP, PMMA On The Mechanical Properties of Polystyrene (PS)Document12 pagesComparing Effect of Adding LDPE, PP, PMMA On The Mechanical Properties of Polystyrene (PS)Jawad K. OleiwiNo ratings yet

- ICA Electrochemical finaLLLLLLLLLDocument8 pagesICA Electrochemical finaLLLLLLLLLTehmasipNo ratings yet

- PLSC0017 Requirements For Welder Qualifications in Accordance With ASME Section IXDocument13 pagesPLSC0017 Requirements For Welder Qualifications in Accordance With ASME Section IXBhavin ParekhNo ratings yet

- Chapter 1-3Document25 pagesChapter 1-3Janley AresNo ratings yet

- Compelete CEP ReportDocument16 pagesCompelete CEP ReportAhmer EjazNo ratings yet