Professional Documents

Culture Documents

Aus Steel

Uploaded by

MichenerparkCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aus Steel

Uploaded by

MichenerparkCopyright:

Available Formats

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 1 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

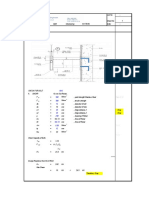

SHEAR CONNECTION: W BEAM WITH DOUBLE ANGLE (BOLTED/BOLTED)

ONE-WAY SHEAR CONNECTION TO W GIRDER WEB

Description:Detailed Report Created by: Giza 17

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 2 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

I. DESIGN DATA AND LOADS (ASD-14th Edition)

GIRDER PROPERTIES: W12X40 - A992

Depth, d = 11.9 in Web Thickness, tw = 0.295 in

Flange Width, bf = 8.01 in Flange Thickness, tf = 0.515 in

Distance k, k = 1.375 in Distance k1, k1 = 0.875 in

Area, Ag = 11.7 in² Distance k kdes = 1.02 in

(Design),

Minimum Yield Fy = 50 ksi Minimum Tensile Fu = 65 ksi

Stress, Stress,

Modulus of E = 29000 ksi

Elasticity,

Top of Steel Elev = 9 ft + 10 in Gage, g = 5.25 in

Elevation,

BEAM PROPERTIES: W16X26 - A992

Depth, d = 15.7 in Web Thickness, tw = 0.25 in

Flange Width, bf = 5.5 in Flange Thickness, tf = 0.345 in

Distance k, k = 1.063 in Distance k1, k1 = 0.75 in

Area, Ag = 7.68 in² Distance kdes = 0.747 in

k(Design),

Minimum Yield Fy = 50 ksi Minimum Tensile Fu = 65 ksi

Stress, Stress,

Modulus of E = 29000 ksi

Elasticity,

Top of Steel Elev = 10 ft + 0 in

Elevation,

Span Length, L = 15 ft Erection gap = 0.5 in

Clearance,

Slope, θsl = 0 deg Skew, θsk = 0 deg

Depth of Top dcT = 3 in Depth of Bottom dcB = 2.75 in

Cope, Cope,

Length of Top cT = 4 in Length of Bottom cB = 4 in

Cope, Cope,

CONNECTION ANGLE PROPERTIES: 2L4X3-1/2X5/16 SLBB - A36

Girder Side leg1 = 4 in Thickness, t = 0.313 in

Leg Size,

Beam Side Leg leg2 = 3.5 in Number of n = 2

Size, Connection Angles,

Minimum Yield Fy = 36 ksi Modulus of E = 29000 ksi

Stress, Elasticity,

Description:Detailed Report Created by: Giza 17

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 3 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

Minimum Tensile Fu = 58 ksi

Stress,

Girder Side g1 = 2.5 in Beam Side Bolt g2 = 2.25 in

Bolt Gage, Gage,

HORIZONTAL STIFFENER PLATE PROPERTIES: A572-50

Thickness, t = 0.375 in Number of n = 2

Plates,

Width, b = 2.625 in Length, L = 10.5 in

Minimum Yield Fy = 50 ksi Minimum Tensile Fu = 65 ksi

Stress, Stress,

Modulus of E = 29000 ksi

Elasticity,

BOLTS PROPERTIES: 3/4" - ø - A325-N

For Connection Angle to Beam Web Connection:

Bolt Diameter, db = 0.75 in

Bolt Shear Λrv = 11.928 kips Bolt Tensile Λrn = 19.88 kips

Strength, Strength,

Bolt Type, Bolt_Type = A325-N Connection Type, Conn_type = Bearing

Type

Number of nr = 3 Bolt Vertical s = 3 in

Bolt Rows, Spacing,

Number of Bolt nv = 1 Bolt Horizontal sv = 0 in

Column Lines, Spacing,

Total Number nb = 3

of Bolts

(nr·nv),

Holes at Beam Web, Holes at Connection Angle,

Vertical Hole hdv = 0.875 in Vertical Hole hdv = 0.875 in

Dimension, Dimension,

Horizontal Hole hdh = 0.875 in Horizontal Hole hdh = 0.875 in

Dimension, Dimension,

Bolt First Down D = 5.438 in

from Top of

Beam,

Vertical Edge Lev = 2.438 in Vertical Edge Lev = 1.25 in

Distance(D-dcT), Distance,

Horizontal Edge Leh = 1.75 in Horizontal Edge Leh = 1.25 in

Distance, Distance

(leg2-g2-(nv-1)·(sv)),

BOLTS PROPERTIES: 3/4" - ø - A325-N

Description:Detailed Report Created by: Giza 17

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 4 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

For Connection Angle to Girder Web Connection:

Bolt Diameter, db = 0.75 in

Bolt Shear Λrv = 11.928 kips Bolt Tensile Λrn = 19.88 kips

Strength, Strength,

Bolt Type, Bolt_Type = A325-N Connection Type, Conn_type = Bearing

Type

Number of nr = 3 Bolt Vertical s = 3 in

Bolt Rows, Spacing,

Number of Bolt nv = 1 Bolt Horizontal sv = 0 in

Column Lines, Spacing,

Total Number of nb = 3

Bolts (nr·nv),

Adjacent Number nr2 = 0

of Bolt Rows

(if any),

Holes at Girder Web, Holes at Connection Angle,

Vertical Hole hdv = 0.875 in Vertical Hole hdv = 0.875 in

Dimension, Dimension,

Horizontal Hole hdh = 0.875 in Horizontal Hole hdh = 1.063 in

Dimension, Dimension,

Bolt First Down D = 5.438 in

from Top of Beam,

Vertical Edge Lev = 1.25 in

Distance,

Horizontal Edge Leh = 1.5 in

Distance

(leg1-g1-(nv-1)·(sv)),

WELDS PROPERTIES: E70xx LH

Minimum Tensile Fu = 70 ksi

Stress,

For Horizontal Stiffener Plate to Beam Web Connection (As Req'd):

Prefered Weld w = 0.25 in

Size (w13),

SAFETY AND RESISTANCE FACTORS:

Safety Factor, Ω(ASD) Resistance Factor, f(LRFD)

Modification Factor,

Λ = 1

(if ASD) Λ = f (if LRFD)

W

safety factor resistance factor modification factor

Description:Detailed Report Created by: Giza 17

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 5 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

For Member in Wbrg = 2.00 fbrg = 0.75 Λbrg = 0.50

Bearing/Bolt

Bearing(brg),

For Block Shear(bs), Wbs = 2.00 fbs = 0.75 Λbs = 0.50

For Fillet Weld Wvw = 2.00 fvw = 0.75 Λvw = 0.50

Shear(vw),

For Flexural Local W b = 1.67 fb = 0.90 Λb = 0.60

Buckling/Flexural

Strength(b),

For Flexural Wfr = 2.00 ffr = 0.75 Λfr = 0.50

Rupture(fr),

For Member Shear for Wv = 1.67 fv = 0.90 Λv = 0.60

C, WT, L(v),

For Shear Wvr = 2.00 fvr = 0.75 Λvr = 0.50

Rupture(vr),

For Shear Wvy = 1.50 fvy = 1.00 Λvy = 0.67

Yielding(vy),

APPLIED LOADS:

Beam:

50% Uniform Distributed Load

Shear Load, V = 29.5 kips

Adjacent Shear V2 = 0 kips

Load (if any),

Description:Detailed Report Created by: Giza 17

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 6 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

II. CALCULATIONS

A. BEAM WEB CHECK

1. Bolt Capacity

(AISC 14th Ed. Specifications, Chapter J, Section J3.10, pages 16.1-127 to

16.1-128)

a. Bolt Capacity due to Shear Load

Bearing Area,

Abrg = db·tw Abrg = 0.187 in²

Bolt Centerline Distance from Face of Support,

ab = g2 + 0.5·(nv - 1)·sv ab = 2.25 in

Eccentricity Distance of End Reaction from Bolt Line,

ab ≤ 3.0in ˄ nv = 1

ebv = 0 in ebv = 0 in

Load Inclination from Vertical,

θ = 0 deg

Eccentric Load Coefficient,

(AISC 14th Ed. Manual Part 7, Instantaneous Center of Rotation Method, pages

7-6 to 7-8)

C = 3

Allowable Bearing Strength Using Edge Distance, (J3-6a, J3-6c)

hdh < hdls

Fbe = Λbrg·Fu· 1.2·(Lev-0.5·hdv)·tw

1.2·(Leh-0.5·hdh)·tw

2.4·Abrg

ebv ≤ 0in

Fbe = min(Fbe₀, Fbe₂) Fbe = 14.625 kips

Allowable Bearing Strength Using Bolt Spacing, (J3-6a, J3-6c)

hdh < hdls

Fbs = Λbrg·Fu·min[1.2·(s - hdv)·tw,2.4·Abrg]

Fbs = 14.625 kips

Number of Areas in Consideration,

n1 = 1

Connection Angle,

n2 = n

Bolt Capacity,

ebv ≤ 0in

Description:Detailed Report Created by: Giza 17

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 7 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

Rbrg = nv·[min(n1·Fbe,n2·Λrv) + min(n1·Fbs,n2·Λrv)·(nr - 1)]

Rbrg = 43.875 kips V = 29.5 kips

Bolt Capacity > Applied Force, UCV = 0.672, OK

2. Coped Beam Capacity

a. Capacity if Beam Web is Double Coped with Same Cope length at Both Flanges

(AISC 14th Ed. Manual Part 9, page 9-8)

Depth of Cope,

Top Cope,

dcT = 3 in

Bottom Cope,

dcB = 2.75 in

Maximum Cope,

dc = max(dcT,dcB) dc = 3 in

depth of cope < 0.2 of depth of beam, OK

Length of Cope,

Top Cope,

cT = 4 in

Bottom Cope,

cB = 4 in

Maximum Cope,

c = max(cT,cB) c = 4 in

length of cope < twice the depth of beam, OK

Reduced Beam Depth,

ho = d - dcT - dcB

ho = 9.95 in

Adjustment Factor of Lateral-Torsional Buckling Model,

dcT

fd = 3.5 - 7.5 fd = 2.067

d

Allowable Flexural Local Buckling Stress or Yielding Stress,

2

tw

Fcr =min 0.62·π·E·fd· , Fy Fcr = 50 ksi

c·ho

Net Section Modulus,

2

tw·ho

Snet = Snet = 4.125 in³

6

Eccentricity,

Description:Detailed Report Created by: Giza 17

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 8 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

e = c + gap e = 4.5 in

Flexural Local Buckling Capacity or Yielding Capacity,

Fcr·Snet

Rbc = Λb· Rbc = 27.446 kips

e

Flexural Rupture Capacity,

Fu·Snet

Rfr = Λfr· Rfr = 29.792 kips

e

Shear Capacity of Reduced Section,

Vwg = Λvy·0.6·Fy·ho·tw Vwg = 49.75 kips

Coped Beam Capacity,

Rcb = min(Rbc,Rfr,Vwg)

Rcb = 27.446 kips V = 29.5 kips

Please refer to Design of Coped Beam with Reinforcement, OK

3. Coped Beam Capacity with Horizontal Stiffener Plate

Allowable Flexural Local Buckling Stress/Yielding Stress,

Fcr = 50 ksi

Location of Neutral Axis on the Reduced Section,

xb = 6.952 in

xt = 2.998 in

Moment of Inertia,

I = 42.553 in⁴

Slenderness of Horizontal Stiffener Plate,

Net Section Modulus at Compression Area,

I

SxC = SxC = 14.194 in³

xt

Net Section Modulus at Tension Area,

I

SxT = SxT = 6.121 in³

xb

Flexural Yield Stress, (Table B4.1b)

SxT

< 0.7

SxC

SxT

FL = Fy1 FL = 21.562 ksi

SxC

Clear Distance Between Flanges of Beam Less the Fillet or Corner Radii,

h = ho h = 9.95 in

Web Plate Buckling Coefficient,

Description:Detailed Report Created by: Giza 17

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 9 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

4

> 0.35

h 0.5

tw

4

0.76,

0.5 kc = 0.634

kc = min h

tw

Limiting Slenderness Parameter for Noncompact Element,

kc·E

λr = 0.95 λr = 27.742

FL

Width-to-thickness Ratio,

bst

≤ λr

2tst

bst

= 3.5 λr = 27.742

2tst

Stiffener Plate is not slender

Net Section Modulus,

I

Snet = Snet = 6.121 in³

max(xb,xt)

Eccentricity,

e = c + gap e = 4.5 in

Flexural Local Buckling Capacity or Yielding Capacity

Fcr·Snet

Rbc = ᴧb· Rbc = 40.725 kips

e

Flexural Rupture Capacity,

Fu·Snet

Rfr = ᴧfr· Rfr = 44.207 kips

e

Shear Capacity of Reduced Section,

Vwg = ᴧvy·0.6·Fy·ho·tw Vwg = 49.75 kips

Coped Beam Capacity,

Rcb = min(Rbc,Rfr,Vwg)

Rcb = 40.725 kips V = 29.5 kips

Flexural Cope Buckling Capacity > Applied Force, UCV = 0.724, OK

4. Weld Capacity of Horizontal Stiffener Plate to Beam Web

(AISC 14th Ed. Specifications, Chapter J, pages 16.1-110 to 16.1-117)

(AISC 14th Ed. Manual, Part 8, pages 8-9 to 8-15)

Number of Weld Sides,

nws = 4

Description:Detailed Report Created by: Giza 17

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 10 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

Minimum Weld Size,

wmin = 0.125 in w = 0.25 in

Preferred Weld Size > Minimum Weld Size, OK

Length of Horizontal Stiffener Plate,

L = 7 in

Force Acting on the Connection,

Ruw = 23.865 kips

Shear Strength,

For Beam Web,

Rv1 = Λvr·0.6·Fu·tw Rv1 = 9.75 kips/in

For Horizontal Stiffener Plate,

Rv2 = Λvr·0.6·Fu·t Rv2 = 14.625 kips/in

For Weld,

Rv3 = Λvw·0.6·Fu·sin(45deg)·nws Rv3 = 59.397 ksi

Maximum Effective Weld Size,

min(Rv1, Rv2)

weff = weff = 0.164 in

Rv3

Length of Weld,

Lw = L Lw = 7 in

Weld Capacity,

Rw = Λvw·0.6·Fu·sin(45deg)·nws·Lw·min(w,weff)

Rw = 68.25 kips Ruw = 23.865 kips

Weld Capacity > Applied Force, UCV = 0.35, OK

5. Shear Capacity

(AISC 14th Ed. Specifications, Chapter G, Section G2.1, pages 16.1-67 to

16.1-69)

Clear Distance Between Flanges of Beam Less the Fillet or Corner Radii,

h = d - 2·kdes h = 14.206 in

Limiting Depth-thickness Ratio,

h

htw = htw = 56.824

tw

Clear Distance Between Transverse Stiffeners,

htw < 260

a = 0 in a = 0 in

Web Plate Buckling Coefficient, (G2-6)

htw < 260

Description:Detailed Report Created by: Giza 17

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 11 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

kv = 5 kv = 5

Web Shear Coefficient, (G2-3, G2-4, G2-5)

0.5

kv·E

htw ≤ 1.1·

Fy

Cv = 1 Cv = 1

Shear Capacity, (G2-1)

Rv = Λvbm·0.6·Fy·d·tw·Cv

Rv = 70.509 kips V = 29.5 kips

Shear Capacity of Section > Applied Force, UCV = 0.418, OK

B. BEAM WEB TO CONNECTION ANGLE CHECK

1. Bolt Shear Capacity

(AISC 14th Ed. Specifications, Chapter J, Section J3.6, pages 16.1-125)

Shear Capacity Per Bolt,

Λrv = 11.928 kips

Bolt Shear Capacity,

Rb = n·nb·Λrv

Rb = 71.569 kips V = 29.5 kips

Bolt Shear Capacity > Applied Force, UCV = 0.412, OK

2.Check for Spacing

(AISC 14th Ed. Specifications Chapter J, Section J3.3 and J3.5, pages 16.1-122 to

16.1-124)

Connection Angle Thickness,

t1 = 0.313 in

Beam Web Thickness,

t2 = 0.25 in

Vertical Spacing of Bolts,

s = 3 in

2

smin = 2 ·db smin = 2 in

3

smax = min(12in, 24·min (t1, t2)) smax = 6 in

Spacing > Min. Spacing & Spacing < Max. Spacing, OK

3. Check for Edge Distance

(AISC 14th Ed. Specifications, Chapter J, Section J3.4 and J3.5, pages 16.1-122

to 16.1-124)

Connection Angle Thickness,

Description:Detailed Report Created by: Giza 17

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 12 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

t1 = 0.313 in

Connection Angle Edge Distances,

Lev1 = 1.25 in

Leh1 = 1.25 in

Beam Web Thickness,

t2 = 0.25 in

Beam Web Edge Distances,

Lev2 = 2.438 in

Leh2 = NA

Vertical Edge Distance,

1.25 in

Levcon = Lev1 Levcon =

2.438 in

Lev2

Levmin1 1 in

Levmin = Levmin =

Levmin2 1 in

min(Levcon) = Lev1

Levmax = min(6in,12·t1)

Levmax = 3.756 in

Edge Distance ≥ Min. Edge Distance & Edge Distance ≤ Max. Edge Distance, OK

Horizontal Edge Distance,

Leh1 1.25 in

Lehcon = Lehcon =

Leh2 NA

Lehmin1 1 in

Lehmin = Lehmin =

Lehmin2 NA

min(Lehcon) = Leh1

Lehmax = min(6in,12·t1)

Lehmax = 3.756 in

Edge Distance ≥ Min. Edge Distance & Edge Distance ≤ Max. Edge Distance, OK

C. CONNECTION ANGLE CHECK

1. Bolt Capacity

(AISC 14th Ed. Specifications, Chapter J, Section J3.10, pages 16.1-127 to

16.1-128)

a. Bolt Capacity due to Shear Load (Secondary Side)

Bearing Area,

Abrg = db·t Abrg = 0.235 in²

Bolt Centerline Distance from Face of Support,

ab = g2 + 0.5·(nv - 1)·sv ab = 2.25 in

Description:Detailed Report Created by: Giza 17

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 13 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

Eccentricity Distance of End Reaction from Bolt Line,

ab ≤ 3.0in ˄ nv = 1

ebv = 0 in ebv = 0 in

Load Inclination from Vertical,

θ = 0 deg

Eccentric Load Coefficient,

(AISC 14th Ed. Manual Part 7, Instantaneous Center of Rotation Method, pages

7-6 to 7-8)

C = 3

Allowable Bearing Strength Using Edge Distance, (J3-6a, J3-6c)

hdh < hdls

Fbe = Λbrg·Fu· 1.2·(Lev-0.5·hdv)·t

1.2·(Leh-0.5·hdh)·t

2.4·Abrg

ebv ≤ 0in

Fbe = min(Fbe₀, Fbe₂) Fbe = 8.85 kips

Allowable Bearing Strength Using Bolt Spacing, (J3-6a, J3-6c)

hdh < hdls

Fbs = Λbrg·Fu·min[1.2·(s - hdv)·t,2.4·Abrg]

Fbs = 16.339 kips

Number of Areas in Consideration,

n1 = n

Connection Angle,

n2 = n

Bolt Capacity,

ebv ≤ 0in

Rbrg1 = nv·[min(n1·Fbe,n2·Λrv) + min(n1·Fbs,n2⋅Λrv)·(nr - 1)]

Rbrg1 = 65.413 kips V = 29.5 kips

Bolt Capacity > Applied Force, UCV = 0.451, OK

b. Bolt Capacity due to Shear Load (Primary Side)

Bearing Area,

Abrg = db·t Abrg = 0.235 in²

Allowable Bearing Strength Using Edge Distance,(J3-6a,J3-6c)

hdh < hdls

Fbe = Λbrg·Fu·min[1.2·(Lev - 0.5·hdv)·t,2.4·Abrg]

Fbe = 8.85 kips

Allowable Bearing Strength Using Bolt Spacing,(J3-6a,J3-6c)

Description:Detailed Report Created by: Giza 17

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 14 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

hdh < hdls

Fbs = Λbrg·Fu·min[1.2·(s - hdv)·t,2.4·Abrg]

Fbs = 16.339 kips

Number of Areas in Consideration,

n1 = n

Connection Angle,

n2 = n

Bolt Capacity,

Rbrg2 = nv·[min(n1·Fbe,n2·Λrv) + min(n1·Fbs ,n2·Λrv)·(nr - 1)]

Rbrg2 = 65.413 kips V = 29.5 kips

Bolt Capacity > Applied Force, UCV = 0.451, OK

Governing Bolt Capacity,

Rbrg = min(Rbrg1, Rbrg2)

Rbrg = 65.413 kips V = 29.5 kips

Bolt Capacity > Applied Force, UCV = 0.451, OK

2. Yielding Capacity

(AISC 14th Ed. Specifications, Chapter J, Section J4.2, page 16.1-129)

a. Shear Yielding Capacity due to Shear Load

Length,

L = (nr - 1)·s + 2·Lev L = 8.5 in

Erection Stability,

(AISC 14th Ed. Manual, Part 10, page 10-9)

Length of Connector > One-half of T-Dimension, OK

Number of Areas in Consideration,

n1 = n

Shear Yielding Capacity, (J4-3)

Rvy = Λvy·n1·0.6·Fy·L·t

Rvy = 76.622 kips V = 29.5 kips

Shear Yielding Capacity > Applied Force, UCV = 0.385, OK

3. Rupture Capacity

(AISC 14th Ed. Specifications Chapter J, Section J4.2, page 16.1-129)

a. Shear Rupture Capacity due to Shear Load(Secondary Side)

Description:Detailed Report Created by: Giza 17

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 15 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

Net Shear Area,

Anv = (L - nr·hdv)·t Anv = 1.839 in²

Number of Areas in Consideration,

n1 = n

Shear Rupture Capacity, (J4-4)

Rvr1 = Λvr·n1·0.6·Fu·Anv

Rvr1 = 63.993 kips V = 29.5 kips

Shear Rupture Capacity > Applied Force, UCV = 0.461, OK

b. Shear Rupture Capacity due to Shear Load (Primary Side)

Net Shear Area,

Anv = (L - nr·hdv)·t Anv = 1.839 in²

Number of Areas in Consideration,

n1 = n

Shear Rupture Capacity, (J4-4)

Rvr2 = Λvr·n1·0.6·Fu·Anv

Rvr2 = 63.993 kips V = 29.5 kips

Shear Rupture Capacity > Applied Force, UCV = 0.461, OK

Governing Shear Rupture Capacity,

Rvr = min(Rvr1, Rvr2)

Rvr = 63.993 kips V = 29.5 kips

Shear Rupture Capacity > Applied Force, UCV = 0.461, OK

4. Block Shear Capacity

(AISC 14th Ed. Specifications, Chapter J, Section J4.3, page 16.1-129)

a. Block Shear Capacity due to Shear Load (Secondary Side)

Reduction Factor,

nv = 1

Ubs = 1.0 (tension stress is uniform)

Gross Shear Area,

Agv = [(nr - 1·s+Lev]·t Agv = 2.269 in²

Net Tension Area,

Ant = [Leh + (nv - 1)·sv - (nv - 0.5)·hdh]·t

Ant = 0.254 in²

Net Shear Area,

Anv = Agv - [(nr - 0.5)·hdv]·t Anv = 1.585 in²

Number of Areas in Consideration,

Description:Detailed Report Created by: Giza 17

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 16 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

n1 = n

Block Shear Capacity,(J4-5)

Rbs1 = Λbs·n1·min(0.6·Fu·Anv + Ubs·Fu·Ant,0.6·Fy·Agv + Ubs·Fu·Ant)

Rbs1 = 63.766 kips V = 29.5 kips

Block Shear Capacity > Applied Force, UCV = 0.463, OK

b. Block Shear Capacity due to Shear Load (Primary Side)

Reduction Factor,

Ubs = 1.0 (tension stress is uniform)

Gross Shear Area,

Agv = [(nr - 1)·s + Lev]·t Agv = 2.269 in²

Net Tension Area,

Ant = [Leh + (nv - 1)·sv - (nv - 0.5)·hdh]·t

Ant = 0.303 in²

Net Shear Area,

Anv = Agv -[(nr - 0.5)·hdv]·t Anv = 1.585 in²

Number of Areas in Consideration,

n1 = n

Block Shear Capacity, (J4-5)

Rbs2 = Λbs·n1·min(0.6·Fu·Anv + Ubs·Fu·Ant, 0.6·Fy·Agv + Ubs·Fu·Ant)

Rbs2 = 66.602 kips V = 29.5 kips

Block Shear Capacity > Applied Force, UCV = 0.443, OK

Governing Block Shear Capacity,

Rbs = min(Rbs1, Rbs2)

Rbs = 63.766 kips V = 29.5 kips

Block Shear Capacity > Applied Force, UCV = 0.463, OK

D. CONNECTION ANGLE TO GIRDER WEB CHECK

1. Bolt Shear Capacity

(AISC 14th Ed. Specifications, Chapter J, Section J3.6, pages 16.1-125)

Shear Capacity Per Bolt,

Λrv = 11.928 kips

Bolt Shear Capacity,

Rb = n·nb·Λrv

Rb = 71.569 kips V = 29.5 kips

Bolt Shear Capacity > Applied Force, UCV = 0.412, OK

2. Check for Spacing

Description:Detailed Report Created by: Giza 17

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 17 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

(AISC 14th Ed. Specifications Chapter J, Section J3.3 and J3.5, pages 16.1-122 to

16.1-124)

Connection Angle Thickness,

t1 = 0.313 in

Girder Web Thickness,

t2 = 0.295 in

Vertical Spacing of Bolts,

s = 3 in

2

smin = 2 ·db smin = 2 in

3

smax = min(12in, 24·min (t1, t2)) smax = 7.08 in

Spacing > Min. Spacing & Spacing < Max. Spacing, OK

3. Check for Edge Distance

(AISC 14th Ed. Specifications, Chapter J, Section J3.4 and J3.5, pages 16.1-122

to 16.1-124)

Connection Angle Thickness,

t1 = 0.313 in

Connection Angle Edge Distances,

Lev1 = 1.25 in

Leh1 = 1.5 in

Vertical Edge Distance,

1.25 in

Levcon = Lev1 Levcon =

NA

Lev2

Levmin1 1 in

Levmin = Levmin =

Levmin2 NA

min(Levcon) = Lev1

Levmax = min(6in,12·t1)

Levmax = 3.756 in

Edge Distance ≥ Min. Edge Distance & Edge Distance ≤ Max. Edge Distance, OK

Horizontal Edge Distance,

Leh1 1.5 in

Lehcon = Lehcon =

Leh2 NA

Lehmin1 1.125 in

Lehmin = Lehmin =

Lehmin2 NA

min(Lehcon) = Leh1

Lehmax = min(6in,12·t1)

Lehmax = 3.756 in

Description:Detailed Report Created by: Giza 17

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 18 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

Edge Distance ≥ Min. Edge Distance & Edge Distance ≤ Max. Edge Distance, OK

E. GIRDER WEB CHECK

1. Bolt Capacity

(AISC 14th Ed. Specifications, Chapter J, Section J3.10, pages 16.1-127 to 16.1-128)

Total Force Acting Per Bolt,

V

V1 = V1 = 4.917 kips

nr· n

nr2 = 0

V2 = 0 kips V2 = 0 kips

V12 = V1 + V2 V12 = 4.917 kips

Effective Thickness of Web,

V1

tweff = tw· tweff = 0.295 in

V12

Bearing Area,

Abrg = db·tweff Abrg = 0.221 in²

Allowable Bearing Strength Using Edge Distance, (J3-6a, J3-6c)

hdh < hdls

Fbe = Λbrg·Fu·2.4·Abrg

Fbe = 17.258 kips

Allowable Bearing Strength Using Bolt Spacing, (J3-6a, J3-6c)

hdh < hdls

Fbs = Λbrg· Fu·min[1.2·(s - hdv)·tweff , 2.4·Abrg]

Fbs = 17.258 kips

Number of Areas in Consideration,

n1 = n

Connection Angle,

n2 = n

Bolt Capacity,

Rbrg = nv·[min(n1· Fbe, n2· Λrv) + min(n1·Fbs, n2· Λrv)·(nr - 1)]

Rbrg = 71.569 kips V = 29.5 kips

Bolt Capacity > Applied Force, UCV = 0.412, OK

Description:Detailed Report Created by: Giza 17

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 19 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

III. DETAILS

A. SKETCH

SHEAR CONNECTION:W BEAM WITH DOUBLE ANGLE (BOLTED/BOLTED)

ONE-WAY SHEAR CONNECTION TO W GIRDER WEB

Description:Detailed Report Created by: Giza 17

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 20 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

B. CONNECTION DETAILS

Girder

Mark Size Grade g

B10159 W12X40 A992 5 1/4"

Bolts at Girder Web

db Bolt Type Remarks nr s nv sv

Short Slot on

3/4" A325-N Outstanding Leg of 3 3" 1 0"

Angle Only

Beam Web

Mark Size Grade gap θsl θsk D Leh

B10146 W16X26 A992 1/2" 0° 0° 5 7/16" 1 3/4"

Cope Dimensions

dcT cT dcB cB Cut Flush Case

3" 4" 2 3/4" 4" NR

Description:Detailed Report Created by: Giza 17

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 21 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

Bolts at Beam Web

db Bolt Type Remarks nr s nv sv

Short Slot on

3/4" A325-N Outstanding Leg of 3 3" 1 0"

Angle Only

Connection Angle

Size Grade Lev g2 g1 leg2 leg1

2L4X3-1/2

X5/16 A36 1 1/4" 2 1/4" 2 1/2" 3 1/2" 4"

SLBB

Weld

Horizontal Stiffener Plate (As Req'd) Connection

(As Req'd)

t n Grade b L w13 Remarks

Horizontal

Stiffener

3/8" 2 A572-50 2 5/8" 10 1/2" 1/4" Plate is

Required

Governing Limit State of SC Connection

Connection

V UCV Governing Check

Capacity

Flexural Cope

29.5 kips 40.725 kips 0.724 Buckling Capacity of

Beam

Description:Detailed Report Created by: Giza 17

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 22 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

Remarks on Connection / Connecting Elements

For Connector For Connector For Bolt For Edge

For Bolts

Thickness Length Spacing Distance

OK OK OK OK OK

Remarks on Beam Web / Girder Web

For Beam Web For Girder Web

OK OK

Description:Detailed Report Created by: Giza 17

Job Code: Giza

Job Name: NASCC 2017

Sheet No: 23 of 23

Created by: Giza

Revision No: 00 Date: 3/17/2017

Subject: S2E-A1

IV. REFERENCES

Steel Construction Manual ,(14th Ed.), ASD, American Institute of Steel Construction,

Inc. ,2011

Description:Detailed Report Created by: Giza 17

You might also like

- Shear Connection: W Beam With Shear Plate (Partial Depth) One-Way Shear Connection To W Girder WebDocument17 pagesShear Connection: W Beam With Shear Plate (Partial Depth) One-Way Shear Connection To W Girder WebDass DassNo ratings yet

- S-1 Stilt Floor: Edge ConditionDocument7 pagesS-1 Stilt Floor: Edge ConditionMohdDanishNo ratings yet

- Steel Member DesignDocument41 pagesSteel Member DesignYanfei Jin100% (1)

- Waste Water Equalising Tank Anchor Chair DetailsDocument4 pagesWaste Water Equalising Tank Anchor Chair DetailsShaheed HossainNo ratings yet

- Sepakat Setia Perunding SDN BHD: Design of Up-Stand Wall or Headwall To Bs 5400Document4 pagesSepakat Setia Perunding SDN BHD: Design of Up-Stand Wall or Headwall To Bs 5400Afiq SyahmiNo ratings yet

- BEAMS DesignDocument22 pagesBEAMS DesignRathinavel VenkateshwaranNo ratings yet

- Crack Width Calculation: MaterialsDocument2 pagesCrack Width Calculation: MaterialsIrfan AliNo ratings yet

- Pile Cap DesignDocument35 pagesPile Cap Designعصام السامرائي100% (2)

- Plinth Beams DesignDocument24 pagesPlinth Beams DesignRathinavel VenkateshwaranNo ratings yet

- Formula-1 truss design analysisDocument3 pagesFormula-1 truss design analysisSM WorldNo ratings yet

- Design of Base PlateDocument26 pagesDesign of Base Plateraghav abudhabiNo ratings yet

- Screwed connection design calculationsDocument3 pagesScrewed connection design calculationsvtalexNo ratings yet

- Cantilever Slab Design: (Based On BS8110:2000-Part1)Document2 pagesCantilever Slab Design: (Based On BS8110:2000-Part1)mayphyoNo ratings yet

- Purlin Data:-: 26-Apr-2022 1 OF 2 Port RK SSK Design of End Purlin 0 SSK Vizag IS: 801Document2 pagesPurlin Data:-: 26-Apr-2022 1 OF 2 Port RK SSK Design of End Purlin 0 SSK Vizag IS: 801keerthivasan_mrvNo ratings yet

- 1th SectionDocument10 pages1th SectionfaridullahNo ratings yet

- R.C. Design of Rigid Pavement and RoadDocument2 pagesR.C. Design of Rigid Pavement and RoadMitali MajumderNo ratings yet

- Design of Wall Girt: Input DataDocument3 pagesDesign of Wall Girt: Input DataAnonymous V6up3d0QGNo ratings yet

- Aluminium TransomDocument2 pagesAluminium TransomRaju SainiNo ratings yet

- Project: Beam Number: Engineer: Date:: Design Doubly Reinforcement Rectangular BeamDocument4 pagesProject: Beam Number: Engineer: Date:: Design Doubly Reinforcement Rectangular BeamAnonymous e2wolbeFsNo ratings yet

- Connection Check: Cast in RebarsDocument2 pagesConnection Check: Cast in RebarsSiva JaseNo ratings yet

- Slab Design 2 Way IsDocument3 pagesSlab Design 2 Way IsRam LangheNo ratings yet

- Slab Design CalculationDocument3 pagesSlab Design CalculationParwan ExceltechNo ratings yet

- Calc Steel Metal PerporatedDocument13 pagesCalc Steel Metal PerporatedOecoep Iteem100% (1)

- Bearing Design Design NoteDocument4 pagesBearing Design Design Notearepelli madhuNo ratings yet

- Qdoc - Tips Helicoidal Stair Design Spreadsheet by OlusegunverDocument2 pagesQdoc - Tips Helicoidal Stair Design Spreadsheet by OlusegunverZaw Hlaing AungNo ratings yet

- Geometry Materials: AASHTO Standard Specification, Division 1ADocument5 pagesGeometry Materials: AASHTO Standard Specification, Division 1AMahesh SuranaNo ratings yet

- Slab Design 2 Way IsDocument5 pagesSlab Design 2 Way IsPirpasha UjedeNo ratings yet

- Two-way slab design analysis and reinforcement detailsDocument5 pagesTwo-way slab design analysis and reinforcement detailsKamran AliNo ratings yet

- Shear Connection Beam To Beam by Double Angle Cleat by IS CodeDocument38 pagesShear Connection Beam To Beam by Double Angle Cleat by IS CodeStructural SpreadsheetsNo ratings yet

- MCD 00001Document10 pagesMCD 00001ariyaNo ratings yet

- Slab DesignDocument38 pagesSlab Designmathewsujith31No ratings yet

- Design of Composite BeamDocument7 pagesDesign of Composite BeamAamir SuhailNo ratings yet

- Project calculations for staircase designDocument3 pagesProject calculations for staircase designManinder ChaudharyNo ratings yet

- Beam design and reinforcement detailsDocument1 pageBeam design and reinforcement detailsEmdadul HuqNo ratings yet

- Geometry Materials: AASHTO Standard Specification, Division 1ADocument5 pagesGeometry Materials: AASHTO Standard Specification, Division 1AHayman AhmedNo ratings yet

- Steel Column Base PlateDocument17 pagesSteel Column Base PlateVAN HUNG TRANNo ratings yet

- Group 12 p2Document2 pagesGroup 12 p2SM WorldNo ratings yet

- Purlin and RunnerDocument8 pagesPurlin and RunnerBabu Sundararaman0% (1)

- Bolt TorqueDocument3 pagesBolt TorqueHeri KurniawanNo ratings yet

- Ibadan Str. Calculation SheetsDocument74 pagesIbadan Str. Calculation Sheetsbakare gafar omotayoNo ratings yet

- Slab DesignDocument1 pageSlab DesignSita G ShresthaNo ratings yet

- Stair Case One Way SlabDocument3 pagesStair Case One Way SlabPiyush Machhi0% (1)

- Attachment 1 - Bi-Axial Bending CheckDocument2 pagesAttachment 1 - Bi-Axial Bending CheckYang W OngNo ratings yet

- Shear Connection Beam To Beam by Fin Plate by Is CodeDocument37 pagesShear Connection Beam To Beam by Fin Plate by Is CodeStructural SpreadsheetsNo ratings yet

- 2015-0075 1 5 KH Tann 3/20/2018 Dawson Deep Beam Formworks: 149b Selegie Road Singapore 188314Document6 pages2015-0075 1 5 KH Tann 3/20/2018 Dawson Deep Beam Formworks: 149b Selegie Road Singapore 188314jasekan.dcNo ratings yet

- Design of Bearing Replacement SchemeDocument10 pagesDesign of Bearing Replacement SchemeShivendra KumarNo ratings yet

- Staircase Design IS456-2000Document2 pagesStaircase Design IS456-2000Nitesh SinghNo ratings yet

- Stainless Steel Vessel Weight and Pressure CalculationsDocument11 pagesStainless Steel Vessel Weight and Pressure CalculationsVarun MalhotraNo ratings yet

- Grade Beam - Grade Foundation Analysis & DesignDocument2 pagesGrade Beam - Grade Foundation Analysis & DesignAdam Michael Green100% (1)

- Design of Kitchen Slab: Load CalculationDocument1 pageDesign of Kitchen Slab: Load Calculationmanoj_structureNo ratings yet

- Skid lug and lifting lug stress analysisDocument8 pagesSkid lug and lifting lug stress analysismiteshpatel191No ratings yet

- Design of Purlins - NSCP 2015Document1 pageDesign of Purlins - NSCP 2015Ferdinand AlbarNo ratings yet

- UB 610 X 179 - BP - PinnedDocument3 pagesUB 610 X 179 - BP - PinnedArivoli JayaramanNo ratings yet

- Head Nozzle and Flange Calculation, DN100 (CF) Size NozzleDocument7 pagesHead Nozzle and Flange Calculation, DN100 (CF) Size Nozzleakın ersözNo ratings yet

- EPS SlabPanelDocument2 pagesEPS SlabPanelJay EvansNo ratings yet

- Design of Eccentric FootingDocument6 pagesDesign of Eccentric FootingGuru AgastheeshNo ratings yet

- 2way Wall Table53 ReynoldsDocument2 pages2way Wall Table53 Reynoldsdsananda100% (1)

- Structural DesignDocument127 pagesStructural Designbakare gafar omotayoNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Fisher 60 FT Beam CivilBay InputDocument2 pagesFisher 60 FT Beam CivilBay InputMichenerparkNo ratings yet

- MC 310ub46Document3 pagesMC 310ub46MichenerparkNo ratings yet

- MC RF 1Document3 pagesMC RF 1MichenerparkNo ratings yet

- S-P5-1 610ub125Document3 pagesS-P5-1 610ub125MichenerparkNo ratings yet

- MC RF 1Document3 pagesMC RF 1MichenerparkNo ratings yet

- Fisher 60 FT Beam CivilBay InputDocument2 pagesFisher 60 FT Beam CivilBay InputMichenerparkNo ratings yet

- Anchor 1Document3 pagesAnchor 1MichenerparkNo ratings yet

- Weld Size AISC 9Document1 pageWeld Size AISC 9MichenerparkNo ratings yet

- Weld Size AISC 1Document1 pageWeld Size AISC 1MichenerparkNo ratings yet

- Anchor FIX C1 BP1 P1 BRACE GL B1 Max PT SEISMIC U 067Document3 pagesAnchor FIX C1 BP1 P1 BRACE GL B1 Max PT SEISMIC U 067MichenerparkNo ratings yet

- Fisher 60 FT Beam CivilBay InputDocument2 pagesFisher 60 FT Beam CivilBay InputMichenerparkNo ratings yet

- Effective Length of Cantilevers Nethercot Effective Length FactorsDocument1 pageEffective Length of Cantilevers Nethercot Effective Length FactorsMichenerparkNo ratings yet

- Need 4Document8 pagesNeed 4MichenerparkNo ratings yet

- CivilBay-Connection designDocument6 pagesCivilBay-Connection designMichenerparkNo ratings yet

- CivilBay-Connection designDocument6 pagesCivilBay-Connection designMichenerparkNo ratings yet

- BR 16 Alternative 1Document4 pagesBR 16 Alternative 1MichenerparkNo ratings yet

- Anchor FIX C3 BP4 P8 BRACE GL G13 SEISMIC U 050Document3 pagesAnchor FIX C3 BP4 P8 BRACE GL G13 SEISMIC U 050MichenerparkNo ratings yet

- Anchor FIX C4 BP6 P14 NON BRACE GL P7 Max M SEISMIC U 094Document3 pagesAnchor FIX C4 BP6 P14 NON BRACE GL P7 Max M SEISMIC U 094MichenerparkNo ratings yet

- Anchor FIX C1 BP1 P1 BRACE GL B1 Max PT SEISMIC U 067Document3 pagesAnchor FIX C1 BP1 P1 BRACE GL B1 Max PT SEISMIC U 067MichenerparkNo ratings yet

- Anchor FIX C1 BP1 P1 BRACE GL B1 Max PT SEISMIC U 067Document3 pagesAnchor FIX C1 BP1 P1 BRACE GL B1 Max PT SEISMIC U 067MichenerparkNo ratings yet

- Anchor FIX C1 BP1 P1 BRACE GL B1 Max PT SEISMIC U 067Document3 pagesAnchor FIX C1 BP1 P1 BRACE GL B1 Max PT SEISMIC U 067MichenerparkNo ratings yet

- Anchor FIX C1 BP1 P1 BRACE GL B1 Max PT SEISMIC U 067Document3 pagesAnchor FIX C1 BP1 P1 BRACE GL B1 Max PT SEISMIC U 067MichenerparkNo ratings yet

- Anchor FIX C1 BP1 P1 BRACE GL B1 Max PT SEISMIC U 067Document3 pagesAnchor FIX C1 BP1 P1 BRACE GL B1 Max PT SEISMIC U 067MichenerparkNo ratings yet

- Anchor FIX C1 BP1 P1 BRACE GL B1 Max PT SEISMIC U 067Document3 pagesAnchor FIX C1 BP1 P1 BRACE GL B1 Max PT SEISMIC U 067MichenerparkNo ratings yet

- Anchor FIX C4 BP6 P14 NON BRACE GL P7 Max M SEISMIC U 094Document3 pagesAnchor FIX C4 BP6 P14 NON BRACE GL P7 Max M SEISMIC U 094MichenerparkNo ratings yet

- Brace 1Document5 pagesBrace 1MichenerparkNo ratings yet

- Anchor FIX C1 BP1 P1 BRACE GL B1 Max PT SEISMIC U 067Document3 pagesAnchor FIX C1 BP1 P1 BRACE GL B1 Max PT SEISMIC U 067MichenerparkNo ratings yet

- Anchor FIX C1 BP1 P1 BRACE GL B1 Max PT SEISMIC U 067Document3 pagesAnchor FIX C1 BP1 P1 BRACE GL B1 Max PT SEISMIC U 067MichenerparkNo ratings yet

- Anchor FIX C1 BP1 P1 BRACE GL B1 Max PT SEISMIC U 067Document3 pagesAnchor FIX C1 BP1 P1 BRACE GL B1 Max PT SEISMIC U 067MichenerparkNo ratings yet

- Anchor FIX C1 BP1 P1 BRACE GL B1 Max PT SEISMIC U 067Document3 pagesAnchor FIX C1 BP1 P1 BRACE GL B1 Max PT SEISMIC U 067MichenerparkNo ratings yet

- MARCH 2020 AMENDMENTS TO MCHW VOLUME 1 SPECIFICATIONDocument7 pagesMARCH 2020 AMENDMENTS TO MCHW VOLUME 1 SPECIFICATIONalejandraoy9No ratings yet

- Basic Concepts Rectangular and T Beams PDFDocument49 pagesBasic Concepts Rectangular and T Beams PDFBookienowNo ratings yet

- The Concrete Norway: Cablewstayed Helgeland Bridge inDocument1 pageThe Concrete Norway: Cablewstayed Helgeland Bridge inArmus MarsNo ratings yet

- SCI ED017 Design and Installation of Light Steel External Wall SystemsDocument36 pagesSCI ED017 Design and Installation of Light Steel External Wall SystemsTiago CastelaniNo ratings yet

- Quick Installation Benefits of Inverted T BeamsDocument2 pagesQuick Installation Benefits of Inverted T BeamsUhGuanHongNo ratings yet

- Detailed Estimation For Construction of Proposed Building: 27, Navarathinanagar, BPL Complex Karaikudi - 630 001Document2 pagesDetailed Estimation For Construction of Proposed Building: 27, Navarathinanagar, BPL Complex Karaikudi - 630 001ganesh15No ratings yet

- General Notes: Roof Slab PlanDocument1 pageGeneral Notes: Roof Slab PlansolebNo ratings yet

- Applicability of API p-y Curves for Offshore Foundation AnalysisDocument28 pagesApplicability of API p-y Curves for Offshore Foundation AnalysisnsaifulNo ratings yet

- Short RCC Notes by Devesh Sir.Document93 pagesShort RCC Notes by Devesh Sir.sandeepknit3428No ratings yet

- Al-Moiz Sugar Mills Limited at Pharrpur Di Khan Hospital Building Revised Summary of Cost (Phase # 1) Dated 24-02-2021 S. No. Particulars Cost RsDocument26 pagesAl-Moiz Sugar Mills Limited at Pharrpur Di Khan Hospital Building Revised Summary of Cost (Phase # 1) Dated 24-02-2021 S. No. Particulars Cost RsZaid AliNo ratings yet

- Steel Cap Plate Connections DesignDocument18 pagesSteel Cap Plate Connections DesignVinoth KumarNo ratings yet

- Newman Raju Improved Semi Elliptical Crack SurfaceDocument30 pagesNewman Raju Improved Semi Elliptical Crack SurfaceShaun Raphael LeeNo ratings yet

- Design of Laterally Restrained BeamsDocument15 pagesDesign of Laterally Restrained Beamsdixn__No ratings yet

- An Empirical Stress-Intensity Factor Equation For The Surface CrackDocument8 pagesAn Empirical Stress-Intensity Factor Equation For The Surface CrackShaun Raphael LeeNo ratings yet

- Bar Bending Schedule of Box CulvertDocument1 pageBar Bending Schedule of Box CulvertganmalNo ratings yet

- S. Suresh: Fatigue of Materials (Cambridge Solid State Science Series)Document20 pagesS. Suresh: Fatigue of Materials (Cambridge Solid State Science Series)Akshay YarlapatiNo ratings yet

- MFE Accessories Brochure (Old)Document8 pagesMFE Accessories Brochure (Old)David LawNo ratings yet

- Design Moments for Hume Pipe CulvertDocument4 pagesDesign Moments for Hume Pipe CulvertYatendra TyagiNo ratings yet

- HB Ground Improvement Solutions MatrixDocument3 pagesHB Ground Improvement Solutions MatrixSheik Mohamed LiakathNo ratings yet

- Concrete Construction Article PDF - Isolation and Expansion Joints in Concrete PavementsDocument2 pagesConcrete Construction Article PDF - Isolation and Expansion Joints in Concrete PavementsMaria RosaNo ratings yet

- Pavement Layer DesignDocument3 pagesPavement Layer DesignmarieojikenNo ratings yet

- Post-Tension Flat Slab Design ExampleDocument17 pagesPost-Tension Flat Slab Design ExampleAwni Alkhteeb92% (12)

- Purlin section design beam displacement analysisDocument7 pagesPurlin section design beam displacement analysisIjaz AhmedNo ratings yet

- RAM Connection Verification ManualDocument47 pagesRAM Connection Verification ManualBenedict OgbaghaNo ratings yet

- Effect of Aggregate Quality on Concrete PropertiesDocument8 pagesEffect of Aggregate Quality on Concrete PropertiesElakkiya KarthicNo ratings yet

- Tec 302 HF (UAE) : Highly Fluid Expansive Bedding GroutDocument3 pagesTec 302 HF (UAE) : Highly Fluid Expansive Bedding Groutmanikandan4strlNo ratings yet

- NASSPA Retaining Wall Comparison Technical Report 2009Document90 pagesNASSPA Retaining Wall Comparison Technical Report 2009Russ PopeNo ratings yet

- BRIDGE Cat + Exams-01Document14 pagesBRIDGE Cat + Exams-01SHOTURU PNo ratings yet

- Shear and Diagonal Tension in BeamsDocument13 pagesShear and Diagonal Tension in Beamsdilnessa azanawNo ratings yet

- BoQ - Final Railway Over BridgesDocument22 pagesBoQ - Final Railway Over Bridgesrajiv kumarNo ratings yet