Professional Documents

Culture Documents

Data Sheet Pompa Mojokerto MFO

Uploaded by

Anonymous 6S9tcbh0 ratings0% found this document useful (0 votes)

40 views2 pagesdata sheet pump MFO

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdata sheet pump MFO

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

40 views2 pagesData Sheet Pompa Mojokerto MFO

Uploaded by

Anonymous 6S9tcbhdata sheet pump MFO

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Document No.

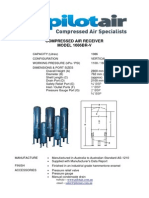

MFO Pumps Data Sheet MJK-DS-20-002-A4

Rev 1

Page

LOCATION : MOJOKERTO MANUFACTURER :

EQUIPMENT NAME : MODEL NO. :

ITEM NO. : NO. OF UNITS :

1 APPLICABLE TO: PROPOSAL PURCHASE AS BUILT

2 FOR: PT.PAHALA GLOBALINDO ENERGI UNIT

3 SITE: MOJOKERTO - JAWA TIMUR SERVICE MARINE FUEL OIL

4 NO. REQ: 1 PUMP SIZE TYPE CENTRIFUGAL NO. STAGES 1 (one)

5 MANUFACTURER MODEL SERIAL NO.

6 NOTES: INFORMATION BELOW TO BE COMPLETED BY PURCHASER BY MANUFACTURER BY MANUFACTURER OR PURCHASER

7 GENERAL (3.1.1)

8 PUMPS TO OPERATE IN (PARAREL) NO. MOTOR DRIVEN 1 NO. TURBIN DRIVEN N/A

9 (SERIES) WITH PUMP ITEM NO. PUMP ITEM NO. N/A

10 GEAR ITEM NO N/A MOTOR ITEM NO. TURBINE ITEM NO. N/A

11 GEAR PROVIDED BY N/A MOTOR PROVIDED BY PUMP SUPPLIER TURBINE PROVIDED BY N/A

12 GEAR MOUNTED BY N/A MOTOR MOUNTED BY PUMP SUPPLIER TURBINE MOUNTED BY N/A

13 GEAR DATA SHT. NO N/A MOTOR DATA SHT. NO. TURBINE DATA SHT. NO N/A

14 OPERATING CONDITION (REMARK 1,2&10) SITE AND UTILITY DATA (CONT'D)

3 3

15 CAPACITY, NORMAL 40 (m /h) RATED 40 (m /h) WATER SOURCE

16 OTHER CHLORIDE CONCENTRATION (PPM) (3.5.26)

17 SUCTION PRESSURE, Min. /Rated / 0.95 / 1.01/ 1.42 (bar a) INSTRUMENT AIR: MAXIMUM PRESS (kg/cm2G)

18 DISCHARGE PRESS. 7.29 (barG) LIQUID

19 DIFFERENTIAL PRESS. 6.34 (bar) TYPE OR NAME OF LIQUID HSD

20 DIFF. HEAD 64.4 (m) NPSHA 8.55 (m) PUMPING TEMPERATURE

21 PROCESS VARIATIONS (3.1.2) NORMAL 30 (O C) MAX. 32 (0C) MIN. 30 (O C)

22 STARTING CONDITIONS (3.1.2) VAPOR PRESSURE 0.11 (BarA) @ 30.00 (O C)

23 SERVICE : CONTINUOUS INTERMITTENT (STARTS/DAY) RELATIVE DENSITY (SPESIFIC GRAVITY):

24 PARAREL OPERATION REC'D NORMAL 870 MAX MIN

25 SITE AND UTILITY DATA SPECIFIC HEAT, Cp (kJ/kg OC)

26 LOCATION : (2.1.2 VISCOSITY 180.00 (Cp) @ 30.00 (O C)

27 INDOOR HEATED UNDER ROOF MAX. VISCOSITY @ MIN. TEMP : (Cp)

28 OUTDOOR UNHEATED PARTIAL SIDES CORROSIVE/EROSIVE AGENT (2.11.1.8)

29 GRADE MEZZANINE ONSHORE CHLORIDE CONCENTRATION (PPM) (3.5.2.6)

30 ELECTRIC AREA CLASSIFICATION (2.1.22/ 3.1.5) H2S CONCENTRATION (PPM) (2.11.1.11)

31 ZONE 1 GROUP 2 TEMP 30 LIQUID (2.1.3) HAZARDOUS FLAMMABLE TOXIC

32 WINTERZATION REQ'D TROPICALIZATION REQ'D OTHER

33 SITE DATA (2.1.29) : (REFER TO TBBM-09-PRO-BOD-001-A4) PERFORMANCE

34 ALTITUDE 0 (m) BAROMETER 1.0 (barA) PROPOSAL CURVE NO. RPM

35 RANGE OF AMBIENT TEMPS. MIN/MAX / (O C) IMPELLER DIA. RATED MAX MIN (mm)

36 RELATIIVE HUMIDITY : MIN/MAX / (%) RATED POWER 5.79 (kW) EFFICIENCY (%)

37 UNUSUAL CONDITIONS : (2.1.23) DUST FUMES MNIMUM CONTINUOUS FLOW :

38 OTHER ON SHORE COASTAL ENVIRONMENT THERMAL (m3/h) STABLE > (m3/h)

39 UTILITY CONDITIONS PREFERRED OPERATING REGION TO (m3/h)

40 STEAM : N/A DRIVERS HEATING ALLOWABL OPERATING REGION TO (m3/h)

O

41 MIN (kg/cm2G) ( C) (kg/cm2G) (O C) MAX HEAD @ RATED IMPELLER (m)

42 MAX (kg/cm2G) (O C) (kg/cm2G) (O C) MAX. POWER @ RATED IMPELLER (kW)

43 ELECTRICITY DRIVERS HEATING CONTROL SHUTDOWN NPSHR AT RATED CAPACITY (m)(2.1.8)

44 VOLTAGE 380 230 SUCTION SPECIFIC SPEED

45 HERTZ 50 50 MAX. SOUND PRESS LEVEL REQ'D 85 @ 1 M (dBA)

46 PHASE 3 1 EST MAX SOUND PRESS. LEVEL (dBA)

47 COOLING WATER : (2.1.1 N/A REMARKS :

48 TEMP INLET (O C) MAX RETURN (O C) 1.

49 PRESS. NORM (BarG) DESIGN (BarG)

50 MIN RETURN (BarG) MAX ALLOW DP (BarG)

51

Document No.

MFO Pumps Data Sheet MJK-DS-20-002-A4

Rev :1

Page

1 CONSTRUCTION CONSTRUCTION (CONT)

2 APPLICABLE STANDARD : SHAFT DIAMETER BETWEEN BEARINGS (mm)

3 API 610 10 TH EDITION SPAN BETWEEN BEARING CENTERS (mm)

4 OTHER (SEE REAMARKS) SPAN BETWEEN BEARING & IMPELLER (mm)

5 PUMP TYPE: (1.1.2) REMARKS :

6 OH2 BB1 VS1 VS6

7 OH3 BB2 VS2 VS7

8 OH6 BB3 VS3 OTHER COUPLINGS: (3.2.2) DRIVER - PUMP

9 BB4 VS4 MAKE METASTREAM

10 BB5 VS5 MODEL

11 NOZZLE CONDITIONS: (2.3.2) (REM. 2, 6) RATING (HP/100 RPM)

12 SIZE RATING FAC'G POSITION LUBRICATION NON LUBRICATED

13 SUCTION 6" 150# RF End LIMITED END FLOAT REQUIRED

14 DISCHARGE 4" 150# RF Top SPACER LENGTH (mm)

15 BALANCE DRUM SERVICE FACTOR 1.15

16 PRESSURE CASING CONNECTIONS: (2.3.1) MFR STANDARD DRIVER HALF COUPLING MOUNTED BY: (3.2.11)

17 NO SIZE (NPS) TYPE PUMP MFR DRIVER MFR. PURCHASER

18 DRAIN 1 3/4" FLANGED COUPLING PER API 671 (5.2.7)

19 VENT 2 3/4" FLANGED BASEPLATES:

20 PRESSURE GAUGE API BASEPLATE NUMBER (APPENDIX M)

21 TEMP GAUGE NON -GROUT CONSTRUCTION: (3.3.13/5.3.7.3.5)

22 WARM-UP REMARKS :

23 BALANCE / LEAK OFF

24 CYLINDRICAL THREADS REQUIRED (2.3.3)

25 CASING MOUNTING: MATERIAL

26 CENTERLINE NEAR CENTERLINE APPENDIX H CLASS S-6

27 FOOT SEPARATE MOUNTING PLATE MIN DESIGN METAL TEMP (2.11.4.5) 0/20 as per API 610

28 IN-LINE BOWL/DIFFUSER 12% Cr IMPELLER 12% CHR A743 Gr.CA6NM

29 CASING SPLIT: CASE/IMPELLER WEAR RINGS 12 % CHR Hardened

30 AXIAL RADIAL SHAFT AISI 4140

31 CASING TYPE: BARREL/CAN Carbon Steel

32 SINGLE VOLUTE MULTIPLE VOLUTE DIFFUSER COUPLING SPACER/HUBS Flexible Disk

33 OVERHUNG BETWEEN BEARINGS BARREL COUPLING DIAPHRAGMS (DISKS)

34 CASE PRESSURE RATING:

35 MAX ALLOWABLE WORKING PRESSURE (REM. 4) (BarG) REMARKS :

O

36 @ ( C)

37 HYDROTEST PRESSURE (BarG) BEARINGS AND LUBRICATION

38 SUCT'N PRESS, REGIONS MUST BE DESIGNED FOR MAWP (2.2.4) BEARING (TYPE/NUMBER) :

39 ROTATION : (VIEWED FROM COUPLING END) RADIAL BUSHING /

40 CW CCW THRUST BALL /

41 IMPELLERS INDIVIDUALLY SECURED (5.2.2.2) REVIEWED AND APPROVE THRUST BEARINGS SIZE (5.2.5.2.4)

42 REMARKS : LUBRICATION: (2.10)

43 GREASE FLOOD RING OIL

44 FLINGER PURGE OIL MIST PURE OIL MIST

45 BOLT OHS PUMP TO PAD/FOUNDATION (5.1.2.4) CONSTANT LEVEL OILER PREFERENCE (SEE REMARKS) (2.9.2.2)

46 SHAFT : PRESSURE LUBE SYS (5.2.6) API-610 API-614

47 SHAFT DIAMETER AT COUPLING (mm) OIL VISC. ISO GRADE (5.2.6.5)

48 REMARKS :

49 1

50 2.

51

52 3.

53 4.

54

55

56

57

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- RAB Kurau-Pekanbaru (Edit)Document1 pageRAB Kurau-Pekanbaru (Edit)Anonymous 6S9tcbhNo ratings yet

- Calculation Tank - 1500 KL SolarDocument2 pagesCalculation Tank - 1500 KL SolarAnonymous 6S9tcbhNo ratings yet

- Calculation Fire Water Demand.Document3 pagesCalculation Fire Water Demand.Anonymous 6S9tcbhNo ratings yet

- Weight of Tank 1.500 KL: NO Item WEIGHT (KG) 1Document1 pageWeight of Tank 1.500 KL: NO Item WEIGHT (KG) 1Anonymous 6S9tcbhNo ratings yet

- Data Sheet Pompa HydrantDocument3 pagesData Sheet Pompa HydrantAnonymous 6S9tcbhNo ratings yet

- Hydro Test FormDocument2 pagesHydro Test FormAnonymous 6S9tcbhNo ratings yet

- Pump Sizing Fire Hydrant MojoDocument2 pagesPump Sizing Fire Hydrant MojoAnonymous 6S9tcbhNo ratings yet

- BOQ Alva Valves IndonesiaDocument1 pageBOQ Alva Valves IndonesiaAnonymous 6S9tcbhNo ratings yet

- Branch CalcDocument111 pagesBranch CalcAnonymous 6S9tcbh100% (2)

- Perhitungan Elbow Mitter PDFDocument4 pagesPerhitungan Elbow Mitter PDFAnonymous 6S9tcbhNo ratings yet

- 650-680 Rev 4 - Hydrostatic Test ExemptionsDocument3 pages650-680 Rev 4 - Hydrostatic Test ExemptionsAnonymous 6S9tcbhNo ratings yet

- 5.Pc Sheet PilesDocument2 pages5.Pc Sheet PilesAnonymous 6S9tcbhNo ratings yet

- ASME B16.21 & B16.47 Gasket Dimensions For ASME B16.5 150# FlangesDocument12 pagesASME B16.21 & B16.47 Gasket Dimensions For ASME B16.5 150# FlangesAnonymous 6S9tcbhNo ratings yet

- P-501-502 GA DWG Certified Dynapro Pumps SJA-S 4x6x10 55kW-2P 12oct15Document1 pageP-501-502 GA DWG Certified Dynapro Pumps SJA-S 4x6x10 55kW-2P 12oct15Anonymous 6S9tcbhNo ratings yet

- Nonconvergence in Caesar in Caesar IIDocument11 pagesNonconvergence in Caesar in Caesar IIviv0102No ratings yet

- Mto Valve: CHKD Appd Appd Date DEC DSP/PPN REV Date Description BYDocument4 pagesMto Valve: CHKD Appd Appd Date DEC DSP/PPN REV Date Description BYAnonymous 6S9tcbhNo ratings yet

- 1086BR V Data SheetDocument1 page1086BR V Data SheetAnonymous 6S9tcbhNo ratings yet

- Pressure Drop CalculatorDocument26 pagesPressure Drop CalculatorAnonymous 6S9tcbhNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Guide To Downloading and Installing The WebMethods Free Trial Version - Wiki - CommunitiesDocument19 pagesGuide To Downloading and Installing The WebMethods Free Trial Version - Wiki - CommunitiesHieu NguyenNo ratings yet

- Editing For BeginnersDocument43 pagesEditing For BeginnersFriktNo ratings yet

- Parts Price ListDocument5,325 pagesParts Price ListAlva100% (1)

- AMC Mining Brochure (A4 LR)Document2 pagesAMC Mining Brochure (A4 LR)Bandung WestNo ratings yet

- Module 8 - Simple Interest and Compound InterestDocument11 pagesModule 8 - Simple Interest and Compound InterestDawn Juliana AranNo ratings yet

- Analisa SWOT Manajemen Pendidikan Di SMK Maarif 1 KebumenDocument29 pagesAnalisa SWOT Manajemen Pendidikan Di SMK Maarif 1 Kebumenahmad prayogaNo ratings yet

- ISA 265 Standalone 2009 HandbookDocument16 pagesISA 265 Standalone 2009 HandbookAbraham ChinNo ratings yet

- Maturity AssessmentDocument228 pagesMaturity AssessmentAli ZafarNo ratings yet

- 9MFY18 MylanDocument94 pages9MFY18 MylanRahul GautamNo ratings yet

- Estimating Capital Costs From An Equipment List: A Case StudyDocument8 pagesEstimating Capital Costs From An Equipment List: A Case StudyWatsonnNo ratings yet

- Enhancing LAN Using CryptographyDocument2 pagesEnhancing LAN Using CryptographyMonim Moni100% (1)

- CVDocument1 pageCVotieNo ratings yet

- Republic vs. CA (G.R. No. 139592, October 5, 2000)Document11 pagesRepublic vs. CA (G.R. No. 139592, October 5, 2000)Alexandra Mae GenorgaNo ratings yet

- 1849 1862 Statutes at Large 601-779Document200 pages1849 1862 Statutes at Large 601-779ncwazzyNo ratings yet

- CSFP's Annual Executive Budget 2014Document169 pagesCSFP's Annual Executive Budget 2014rizzelmangilitNo ratings yet

- Ca50c584 MAYTAGE00011 1 2Document2 pagesCa50c584 MAYTAGE00011 1 2Michael MartinNo ratings yet

- Bill (Law) : Jump To Navigation Jump To SearchDocument9 pagesBill (Law) : Jump To Navigation Jump To SearchPunitNo ratings yet

- AP Physics Name: AP Thermal PracticeDocument2 pagesAP Physics Name: AP Thermal PracticeMuddamsetty ArunkalyanNo ratings yet

- Termsconditions of JionetDocument3 pagesTermsconditions of JionetskNo ratings yet

- Report - Summary - Group 3 - MKT201Document4 pagesReport - Summary - Group 3 - MKT201Long Nguyễn HảiNo ratings yet

- KR 10 Scara: The Compact Robot For Low PayloadsDocument4 pagesKR 10 Scara: The Compact Robot For Low PayloadsBogdan123No ratings yet

- New Car Info PDFDocument1 pageNew Car Info PDFSelwyn GullinNo ratings yet

- The 8051 Microcontroller & Embedded Systems: Muhammad Ali Mazidi, Janice Mazidi & Rolin MckinlayDocument15 pagesThe 8051 Microcontroller & Embedded Systems: Muhammad Ali Mazidi, Janice Mazidi & Rolin MckinlayAkshwin KisoreNo ratings yet

- Rule 63Document43 pagesRule 63Lady Paul SyNo ratings yet

- MBA-CM - ME - Lecture 16 Market Structure AnalysisDocument11 pagesMBA-CM - ME - Lecture 16 Market Structure Analysisrohan_solomonNo ratings yet

- Gitanjali Gems Annual Report FY2012-13Document120 pagesGitanjali Gems Annual Report FY2012-13Himanshu JainNo ratings yet

- Types of Foundation and Their Uses in Building ConstructionDocument4 pagesTypes of Foundation and Their Uses in Building ConstructionCraig MNo ratings yet

- BR186 - Design Pr¡nciples For Smoke Ventilation in Enclosed Shopping CentresDocument40 pagesBR186 - Design Pr¡nciples For Smoke Ventilation in Enclosed Shopping CentresTrung VanNo ratings yet

- Ex-Capt. Harish Uppal Vs Union of India & Anr On 17 December, 2002Document20 pagesEx-Capt. Harish Uppal Vs Union of India & Anr On 17 December, 2002vivek6593No ratings yet

- APCJ Directory 2019Document34 pagesAPCJ Directory 2019Anonymous Pu3OF7100% (3)