Professional Documents

Culture Documents

HAZID Term of Reference

Uploaded by

kokykarkarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HAZID Term of Reference

Uploaded by

kokykarkarCopyright:

Available Formats

HAZID TERM OF REFERENCE

WELLHEAD PRODUCTION & WATER INJECTION WELLHEAD

And

CPF & EXPORT PIPELINES

Document Reference Number

SNBL-STSI/FEED 0001/ 2018- STSI-HSE-HZD-0001

Revision 000 CONFIDENTIAL P a g e | 1 of 16

Doc. No.: SNBL-STSI/FEED 001/2018-STSI-HSE-HZD-0001

All information contained herein is confidential and is released only to the intended recipient as directed by STS.

Revision Control

Issue No. Issued By Issued Date Issued For

0 Jeff Koch 17 Jan 2018 Review and Comment

Revision Approval

Approval Name Title Date Signature

Originator Mohamed Selim HAZOP Chair 17 Jan 2018 Mohamed Selim

Reviewer Jeff Koch, PMP Project Manager 17 Jan 2018

Vice President of

Approval Lance McCarver, PE, PMP 17 Jan 2018

Engineering

Revision 000 CONFIDENTIAL P a g e | 2 of 16

Doc. No.: SNBL-STSI/FEED 001/2018-STSI-HSE-HAZID-0001

All information contained herein is confidential and is released only to the intended recipient as directed by STS.

1.0 INTRODUCTION

A Hazard Identification (HAZID) study will be developed for for the North Bahariya Development - Egypt.

The study will be held at the EGYPT Office (New Maadi ,Cairo), starting on the January 23. 2019 at 9.0 am,

and is scheduled to last presumably for one day.

The scope of this document is to provide the Term of Reference (ToR) for a HAZID session to be carried out

On the design proposed for the for the North Bahariya Development Project located in the West Desert of

Egypt.

In order to ensure that a systematic approach is adopted, the NORPETCO Field Development Project was

divided into a number of stages and ‘zones’ based on layout and the process.

1. Site Clearance

2. Construction

3. Export Pipelines.

4. Production Wells & Injection Wells.

5. CPF facility

Revision 000 CONFIDENTIAL P a g e | 3 of 16

Doc. No.: SNBL-STSI/FEED 001/2018-STSI-HSE-HAZID-0001

All information contained herein is confidential and is released only to the intended recipient as directed by STS.

2.0 HAZID SCOPE SECTIONS THAT CONTAIN GLOBAL HAZARDS AND PROJECT

IMPLEMENTATION ISSUES, WHICH MAY BE COVERED ONCE FOR THE WHOLE

DEVELOPMENT, ARE:

• External Sources and Environmental Hazards,

• Hazards to the Surroundings Community and the Environment,

• Health Hazards,

• Process Hazards,

• Security hazards.

2.1.1 Plant Areas & Nodes

Once all the global issues have been discussed, the team should break down the development into a

number of clearly defined areas. These areas will then be examined in turn to identify issues that have a

specific impact on each location within the development. The definition of an area will usually be either a

geographical location, for a development consisting of many sites, or each major process group/functional

area for a single site containing an integrated plant.

For the HAZID, the team can use smaller areas or ‘nodes’. In this case they may consider each functional

block of the process. The particular hazards for each node can then be addressed

2.1.2 Areas & Node Study Methodology

Once the Team Leader has identified the ‘node’ to be studied, which could range from the whole facility to a

discrete item of plant, the function of that node will be discussed and agreed by the team and then recorded.

The Team Leader will then examine the node against the Checklist and within each Checklist section adopt

the following procedure:

• The Team Leader will nominate a category from the checklist and then ask the team to consider

each guide word.

• In each case the team will analyse each guide word (helped by the examples given in the Checklist)

to identify any hazard and its potential effects which may then be entered on the worksheet.

• The brainstorming process will then be used to identify all the potential threats or causes of the

hazard. During this process the Team Leader may suggest examples from the ‘expanders’ section of

the checklist. It is important however that these expanders are suggested as examples and not

presented as a closed list which will restrict the team’s brainstorming activity.

• The team will analyse the appropriate controls that should be put in place to prevent or control each

threat. Again the Team Leader may suggest mitigation measures.

• Finally, the team will identify the development phase(s) for which the hazard is credible and assess

the HSE risk in accordance with the attached Risk Ranking Criteria (see par. 3.5)

Note, the HAZID Checklist (reported in Annex 1) is comprehensive but not exhaustive and the use of

brainstorming to identify novel or unforeseen sources may be required.

2.1.3 Brainstorming & Analysis

The team knowledge and creativity should be used to identify credible causes and the relevant applicability

of the hazards. It is important that the list of hazards is used in a creative manner and not as a rigid checklist.

It is only in this way that new or unusual hazards will be recognised, or where specific combinations of

factors will be identified as causes of concern.

The process for the brainstorming can best be described as:

• Select plant area / node;

• From the checklist select the category;

• Against each guideword check if the hazard possible / likely;

Revision 000 CONFIDENTIAL P a g e | 4 of 16

Doc. No.: SNBL-STSI/FEED 001/2018-STSI-HSE-HAZID-0001

All information contained herein is confidential and is released only to the intended recipient as directed by STS.

• If “no”, note as such and move onto the next guideword;

• If “yes”, by means of brainstorming identify all the threats and causes;

• Assess what controls or barriers are required to prevent or control the effect and give a

recommendation;

• Rate the hazard using the Risk Ranking Matrix (see paragraph 3.5).

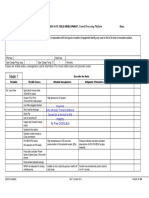

2.2 Risk Ranking Criteria

The level of risk obtained for each activity/operation shall be compared with the tolerability criteria defined

according to NORPETCO Standard Risk Matrix, and A Sample figure here below:

Figure 3.5.1: Risk Screening Matrix

The purpose of the risk screening matrix is to classify hazards as being low, medium or high risk.

The three different colours classify the risk as:

• TOLERABLE RISK: Hazards classified as Tolerable risk are considered to have a negligible impact

and therefore no further impact reduction measures are required. Such hazards should however be

continuously monitored and managed for continuous improvement.

• COMPULSORY REDUCTION: Hazards classified as Compulsory risk are not intolerable when

considered individually, subject to the identification and implementation of appropriate control

measures to reduce their impact. Where several hazards classified as Compulsory risk coexist the

cumulative effect of the hazards may be intolerable. Where this is the case additional impact

reduction measures may be required.

• INTOLERABLE RISK: Hazards classified as Intolerable risk do not satisfy the screening criteria and

shall be considered intolerable without a detailed justification.

2.3 Recording & Reporting

During the study, all hazards which are identified by the team are recorded on a series of worksheets using a

laptop computer and this image will be projected onto a screen for real time viewing and input by the team

members. Participating members shall ensure that this recording is appropriate at the time or that a specific

instruction for further clarification / action is noted.

Following the HAZID Session, the Chairman shall be responsible for preparing and issuing the “HAZID

Report”, to be submitted to the Company for approval. The report lists the critical issues and shall include

Revision 000 CONFIDENTIAL P a g e | 5 of 16

Doc. No.: SNBL-STSI/FEED 001/2018-STSI-HSE-HAZID-0001

All information contained herein is confidential and is released only to the intended recipient as directed by STS.

references of the analysed documentation, the HAZID worksheets and the list of action sheets, i.e. actions

that will be addressed either to engineering disciplines or Company for their close-out

2.4 Close out of HAZID actions

The objective of the HAZID follow up activity is to ensure that all recommendations addressed in the ‘HAZID

Action Response Sheets’ are properly implemented by the Project.

The HSE discipline will send the ‘HAZID Action Response Sheets’ in charge to the relevant responder. The

response shall address the issue, be technically correct and fully auditable. When the response is

completed, the engineer will pass the action to the lead discipline engineer for endorsement, and then the

action is to be returned to the HSE discipline. The verification shall be addressed in a dedicated “HAZID

Close Out Report”, which shall detail the responses to each recommendation and shall contain evidence of

their implementation.

Listed below are the criteria for acceptance of the response:

• Single word answers such as “Done”, “Added”, “OK”, etc. are unacceptable;

• Any answer which makes reference to a data sheet or study must have a copy of the document

annexed;

• If the reference document is lengthy, a copy of the relevant topic plus the document cover sheet will

suffice;

• If the action requires additions to a P&ID’s, layouts etc., a copy of the drawing shall be annexed with

the addition highlighted.

Revision 000 CONFIDENTIAL P a g e | 6 of 16

Doc. No.: SNBL-STSI/FEED 001/2018-STSI-HSE-HAZID-0001

All information contained herein is confidential and is released only to the intended recipient as directed by STS.

3.0 EVENT ADMINISTRATION

3.1 Reference Documentation

HAZID master of relevant documentation shall be provided for the study and displayed in the study room so

that all attendees can consult them.

As a minimum, the following documents will be made available during the review for reference:

Item Doc. N° Title

1 Basis of Design

2 HSE Philosophy

3 Overall Plot Plan

4 CPF Plot Plan

5 Production/Water injection wells Plot Plan

6 PFD (Construction Scheme)

3.2 Workshop Attendance

The HAZID team will be comparatively small, but sufficiently diverse to be able to identify all HSE issues.

The anticipated attendees should comprise the following:

Name Function Company

Eng : Mohamed Sleim HAZID session chairman Third Party

Eng : Hold HAZID Secretary HOLD

Eng : STS Project Manager

Eng : NORPETCO Process Lead Engineer

Eng : NORPETCO Process Engineer

Eng : NORPETCO Instrument & Control Engineer

Eng : NORPETCO Safety Engineer.

In addition to the core HAZID members shown above, the following personnel will be available on call to

provide input to the review:

Name Function Company

3.3 Timing and Location

The event is convened on the 23rd of January 2019 commencing at 09:00 in the morning and it is expected to

take 1 day in NORPETCO Office, Maadi. Cairo. The scheduled completion is at approximately 16.00 (to be

confirmed).

If a preparation will be required for mark-up of relevant documentation or clarification with engineering

disciplines, this will be arranged in a one-day meeting before the HAZID session.

Revision 000 CONFIDENTIAL P a g e | 7 of 16

Doc. No.: SNBL-STSI/FEED 001/2018-STSI-HSE-HAZID-0001

All information contained herein is confidential and is released only to the intended recipient as directed by STS.

4.0 ANNEX A - HAZID GUIDEWORDS

The list of guidewords is indicative of the potential major hazards associated with the facilities. However, this

listing is not intended to be rigidly applied or be exhaustive and should be modified or enhanced by the

HAZID team if appropriate.

EXTERNAL AND ENVIRONMENTAL HAZARDS

GENERIC SPECIFIC EXPANDERS

GUIDEWORDS GUIDEWORDS (Examples of Guide Word Application, not exclusive)

Natural Climate Extremes Temperature, waves, wind, dust, flooding, sandstorms,

ice, blizzards

Lightning Ignition Source

Earthquakes Pipeline Rupture

Erosion Ground slide, coastal, river

Subsidence Ground structure, foundations, reservoir depletion.

Man Made Security Hazards Internal and external security threats

Terrorist Activity Direct attack on installation leading to loss of containment.

Social Instability Riots, civil disturbance, strikes, military action, political

unrest.

Previous Site Base line study, chemical, organic, radioactive.

Contamination

Effect of the Facility on Visual Ruin skyline view

the Surroundings

Socio-Economic Overwhelms existing social infrastructure to the detriment

of local population

Land Take Removes countryside for industrial, residential or

agricultural purposes

Site Of Special Any site that contains environmentally significant flora or

Interest fauna, historic or religious sites

Infrastructure Produce Emergency All associated activities to set up and implement an

Response Plan emergency response plan in the event of an incident

Create / Enhance Road, Rail, Air, Waterways, Utilities, Communications &

Local Infrastructure Waste Management.

Transportation for Food, Cleaning, Toiletries etc.

Consumables

Environmental Continuous Plant Flares, vents, fugitive emissions, energy efficiency

Discharges to Air

Continuous Plant Target/legislative requirements, drainage facilities,

Discharges to Water oil/water separation

Continuous Plant Drainage, chemical storage

Discharges to Land

Maintenance Blow- Flares, vents, drainage, soil or groundwater contamination,

downs / Emergency / additional waste generation, storage and treatment

Upset Discharges

Contaminated

Ground Facility Previous use, pipeline routing, environmental impact

Impact assessment

Waste Disposal Landfill, incineration, recycling

Options

Timing of Seasons, periods of environmental significance

Construction

Revision 000 CONFIDENTIAL P a g e | 8 of 16

Doc. No.: SNBL-STSI/FEED 001/2018-STSI-HSE-HAZID-0001

All information contained herein is confidential and is released only to the intended recipient as directed by STS.

EXTERNAL AND ENVIRONMENTAL HAZARDS

GENERIC SPECIFIC EXPANDERS

GUIDEWORDS GUIDEWORDS (Examples of Guide Word Application, not exclusive)

Other Minimisation of Land Use

Minimisation of Energy use

Impacts on flora and fauna, endangered species, if any

Nuisances – noise, odour, dust

Traffic movement

Sacred, cultural and historic significance

Visual effects

Statutory requirements

Environmental contingency plans

Revision 000 CONFIDENTIAL P a g e | 9 of 16

Doc. No.: SNBL-STSI/FEED 001/2018-STSI-HSE-HAZID-0001

All information contained herein is confidential and is released only to the intended recipient as directed by STS.

FACILITY HAZARDS

GENERIC SPECIFIC EXPANDERS

GUIDEWORDS GUIDEWORDS (Examples of Guide Word Application, not exclusive)

Control Methods/ Manning / Operations Effect on design, effect on locality (Manned,

Philosophy Philosophy unmanned, visited).

Operations Concept One train, x-trains, simplification.

Maintenance Plant/train/equipment item, heavy lifting, access,

Philosophy override, bypass, commonality of equipment, transport.

Control Philosophy Appropriate technology, (DCS/Local panels)

Manning Levels Accommodation, travel, support requirements.

Consistency with operations and maintenance, etc

philosophies.

Emergency Response Isolation, ESD philosophy, blow-down, flaring

requirements.

Concurrent Operations Production, maintenance requirements.

Start-up Shutdown Modular or plant wide.

Fire and Explosion Stored Flammables Improper storage, operator error (release), defect,

Hazards impact, fire (mitigation measures include: substitute

non flammable, minimise and separate inventory).

Sources of Ignition Electricity, flares, sparks, hot surfaces (mitigation

measures include: identify, remove, and separate).

Equipment Layout Confinement, escalation following release of explosive

or flammable fluid (operator error, defect, impact

process control failure, and corrosion), module

layout/proximity, orientation of equipment, predominant

wind direction (mitigation measures include: reduce

degree of confinement, spacing based on

consequence assessment, escalation barriers).

Fire Protection and Active / passive insulation, fire / gas detection, blow-

Response down / relief system philosophy, fire fighting facilities.

Operator Protection Means of escape, PPE, communications, emergency

response, plant evacuation.

Process Hazards Inventory Excess hazardous material (mitigation measures include:

minimise hazardous inventory, alternate processes and

utility systems)

Loss of Containment Excessive process stress, impact (penetration by foreign

object), process control failure, structural failure, erosion

or corrosion (mitigation measures include: recognise and

minimise process hazards during design, inherently safe

plant, containment and recovery measures).

Over Pressure Offsite sources, process blockage, thermal expansion,

connection of process to utility systems, chemical

reaction

Over / Under Atmospheric conditions, blow-down, fire, hot surfaces,

Temperature chemical reaction

Excess / Zero Level Overfill storage tanks, loss of function in separation

vessels, blow-by to downstream vessels

Wrong Composition / Offsite contamination, failure of separation process,

Phase build-up of wrong phase (sand, hydrates, etc), toxic

substances

Control Failure On control failure will the plant shut down / depressurise

safely

Mechanical Failure Vessel / Piping codes, fabrication procedure

Impact From lifting / vehicles

Revision 000 CONFIDENTIAL P a g e | 10 of 16

Doc. No.: SNBL-STSI/FEED 001/2018-STSI-HSE-HZD-0001

All information contained herein is confidential and is released only to the intended recipient as directed by STS.

FACILITY HAZARDS

GENERIC SPECIFIC EXPANDERS

GUIDEWORDS GUIDEWORDS (Examples of Guide Word Application, not exclusive)

Utility Systems System Types Firewater, Fuel Gas, Heating Medium, Diesel Fuel,

Power Supply, Drains, Inert Gas, Potable Water

Waste Storage and Treatment, Chemical/fuel Storage,

Sewerage

Maintenance Hazards Considered Activities Access Requirements, Need to Override, Bypasses

Required, Commonality of Equipment, Heavy Lifting

Requirements, Transportation

Construction / Existing Considered Activities Tie-ins (shutdown requirements)

Facilities Concurrent Operations

Reuse of Materials

Common Equipment Capacity

Interface Shutdown / Blow-down ESD.

Skid Dimensions (weight / handling equipment)

Congestion

Existing Facilities

Mobilisation / Demobilisation

Soil Contamination

Welding Defects

Buckling, Free span

Revision 000 CONFIDENTIAL P a g e | 11 of 16

Doc. No.: SNBL-STSI/FEED 001/2018-STSI-HSE-HAZID-0001

All information contained herein is confidential and is released only to the intended recipient as directed by STS.

HEALTH HAZARDS

GENERIC SPECIFIC EXPANDERS

GUIDEWORDS GUIDEWORDS (Examples of Guide Word Application, not exclusive)

Health Hazards Direct Contact Plants

Insects

Land Animals

Marine Life

Disease Hazards Infectious diseases in the context of occupational health and

safety can include:

• Hepatitis A, B and C, and Human Immunodeficiency

Virus (HIV - which can lead to AIDS.

• Other infections people in close contact institutions -

for example enteric infections, ringworm, scabies,

etc.

• Brucellosis, leptospirosis and Q fever and other

animal infections caught from faecal matter, urine

and materials found in animal pests.

• Legionella infections, in a fine mist spray in the air, in

and around the cooling units of air-conditioning plant,

and in potting mixtures.

• Cytomegalovirus and rubella-causing infections,

• Tuberculosis.

Risk Control (Barrier): If there is a risk of more than one

infectious disease hazard, then control strategies, developed

according to the hierarchy of control, need to be developed

for each one. This is particularly important where food waste;

stagnant water etc may attract disease vectors. (animal,

birds, insects etc.)

Asphyxiation hazards Asphyxiating atmospheres, failure to use appropriate PPE,

vessel entry, working in confined spaces, smoke, exhaust.

Carcinogenic Chemicals in use.

Toxic Hazardous atmosphere, asphyxiating atmosphere, chemicals

in use.

Physical Noise, radiation (ionising, e.g. radioactive scale or non-

ionising, e.g. flares, UV, sunlight), ergonomics.

Mental Shift patterns.

Working Hazards Diving, working in water, working at heights, hazardous

equipment, hazardous surfaces, electricity.

Transport Excessive journeys, extreme weather, and quality of roads

(mitigation measures include: effective journey management.

Revision 000 CONFIDENTIAL P a g e | 12 of 16

Doc. No.: SNBL-STSI/FEED 001/2018-STSI-HSE-HZD-0001

All information contained herein is confidential and is released only to the intended recipient as directed by STS.

PROJECT IMPLEMENTATION

GENERIC SPECIFIC EXPANDERS

GUIDEWORDS GUIDEWORDS (Examples of guideword application, not exclusive)

Contracting Prevailing influence Stability and contractual conditions, contractor selection

Strategy constraints

Non-Compliance with Governmental contracting requirements

Legislation

Ignorance of Standards Additional engineering and construction standards

External Environmental Governmental environmental requirements

Constraints

Logistics Material Supply Chain

Hazards Late Hazard Studies Hazard and Operability studies, Quantitative and Qualitative

Recognition and Risk Assessments, Fire Risk Analysis, Environmental Impact

Management Assessments, etc

Rejection of HSE Case Inadequate Case for Safety

Lack of Hazard

Register

Project Controls Quality assurance (change control, interdepartmental

involvement and interfaces)

Contingency Geographical Plant location, plant layout Medical support, fire fighting

Planning Infrastructure Recovery support, spill leak/clean-up support, security/military support,

Measures evacuation.

Competency Level of Indigenous Quality of local workforce and contractors

Training

Training Requirements

Level of Technology

Revision 000 CONFIDENTIAL P a g e | 13 of 16

Doc. No.: SNBL-STSI/FEED 001/2018-STSI-HSE-HAZID-0001

All information contained herein is confidential and is released only to the intended recipient as directed by STS.

REPUTATION

EXPANDERS

GENERIC SPECIFIC

(Examples of Guide Word Application, not

GUIDEWORDS GUIDEWORDS

exclusive)

Reputation Financial Loss

Shut Down Project

Collapse Share Prices

Adverse Publicity

Revision 000 CONFIDENTIAL P a g e | 14 of 16

Doc. No.: SNBL-STSI/FEED 001/2018-STSI-HSE-HAZID-0001

All information contained herein is confidential and is released only to the intended recipient as directed by STS.

5.0 ANNEX B TABLE 1.2 HAZID WORKSHEETS

Company NORPETCO

Facility/Ref. Docs XX-XX Drawings:

Process Flow Diagram: XXXXX

Plant/Zone/Stage Revision: (0) XX /XX /2019

Activity

Potential

Guide Existing Controls/ Ref Actions/Consideration

Hazard Cause/Threats Consequence L C R

Word Safeguards No. in QRA

& Effects

Revision 000 CONFIDENTIAL P a g e | 15 of 16

Doc. No.: SNBL-STSI/FEED 001/2018-STSI-HSE-HAZID-0001

All information contained herein is confidential and is released only to the intended recipient as directed by STS.

ANNEX C TABLE 2.1 HAZID ACTIONS

Company: NORPETCO System:

Facility CPF Drawings: XXXXX-XXXX

Revision 000 CONFIDENTIAL P a g e | 16 of 16

Doc. No.: SNBL-STSI/FEED 001/2018-STSI-HSE-HAZID-0001

All information contained herein is confidential and is released only to the intended recipient as directed by STS.

You might also like

- HAZID Guideword ChecklistDocument2 pagesHAZID Guideword Checklistqhseconsult100% (2)

- The DIRKS Methodology: A User GuideDocument285 pagesThe DIRKS Methodology: A User GuideJesus Frontera100% (2)

- Case ColorscopeDocument7 pagesCase ColorscopeRatin MathurNo ratings yet

- Template Hazid ReportDocument17 pagesTemplate Hazid ReportJagan Bose75% (4)

- Hazop & Hazid Report - CNG Gas Plant - Tambak Lorok Rev BDocument110 pagesHazop & Hazid Report - CNG Gas Plant - Tambak Lorok Rev BDenstar Ricardo Silalahi94% (16)

- Simultaneous Operation (SIMOPS) : Term of Referance (Tor)Document25 pagesSimultaneous Operation (SIMOPS) : Term of Referance (Tor)kokykarkar80% (5)

- (Quantitative Risk Assessment (QRA) )Document27 pages(Quantitative Risk Assessment (QRA) )MELVIN FONG100% (2)

- HAZOP ExerciseDocument12 pagesHAZOP Exerciseshawalina07No ratings yet

- BP Hazop TrainingDocument37 pagesBP Hazop TrainingObaid Ali100% (3)

- Guidelines for Defining Process Safety Competency RequirementsFrom EverandGuidelines for Defining Process Safety Competency RequirementsRating: 3 out of 5 stars3/5 (1)

- Hazid Hazop Sil TorDocument24 pagesHazid Hazop Sil TorravisankarNo ratings yet

- EGPC PSM GL 003 Inherently Safer Design ISD Guideline PDFDocument52 pagesEGPC PSM GL 003 Inherently Safer Design ISD Guideline PDFkhaled faragNo ratings yet

- OSHA (PSM) Standard, 29 CFR 1910.119 - PSM of Highly Hazardous ChemicalsDocument7 pagesOSHA (PSM) Standard, 29 CFR 1910.119 - PSM of Highly Hazardous ChemicalsKG Shim50% (2)

- HazopDocument4 pagesHazopbaaziz2015No ratings yet

- Process Safety Management PDFDocument31 pagesProcess Safety Management PDFMuhammad Husnul Khuluq100% (4)

- 2970-0-05-0050 - 0 - 1 (1) HAZID ProcedureDocument13 pages2970-0-05-0050 - 0 - 1 (1) HAZID ProcedureArjun Shantaram Zope100% (1)

- Introduction To HAZID and ENVID Reviews 2022Document32 pagesIntroduction To HAZID and ENVID Reviews 2022elmabroukiNo ratings yet

- Hazid Hazop Sil TorDocument24 pagesHazid Hazop Sil Torabboud50% (2)

- HAZOP ReportDocument27 pagesHAZOP ReportMuhammad.Saim100% (3)

- To-HQ-02-075-00 Philosophy Escape Evacuation Rescue OnshoreDocument13 pagesTo-HQ-02-075-00 Philosophy Escape Evacuation Rescue Onshoreagaricus100% (1)

- HazidDocument91 pagesHazidrusticrage2883100% (4)

- SIL MethodologyDocument16 pagesSIL Methodologyhvananth100% (8)

- The Anti-PaladinDocument9 pagesThe Anti-PaladinBobbyNo ratings yet

- EPMS System Guide For Subcontractor - V1 2Document13 pagesEPMS System Guide For Subcontractor - V1 2AdouaneNassim100% (2)

- The Original Lists of Persons of Quality Emigrants Religious Exiles Political Rebels Serving Men Sold For A Term of Years Apprentices Children Stolen Maidens Pressed and OthersDocument609 pagesThe Original Lists of Persons of Quality Emigrants Religious Exiles Political Rebels Serving Men Sold For A Term of Years Apprentices Children Stolen Maidens Pressed and OthersShakir Daddy-Phatstacks Cannon100% (1)

- HAZID Report Rev 0Document39 pagesHAZID Report Rev 0amalhaj20130% (1)

- Essential Practices for Creating, Strengthening, and Sustaining Process Safety CultureFrom EverandEssential Practices for Creating, Strengthening, and Sustaining Process Safety CultureNo ratings yet

- HAZIDDocument54 pagesHAZIDirfankaushar100% (2)

- Hazop PDFDocument33 pagesHazop PDFSDP02No ratings yet

- RLOC Equipment Integrity PolicyDocument10 pagesRLOC Equipment Integrity PolicyMohammed ZubairNo ratings yet

- QRA PresentationDocument34 pagesQRA PresentationAmol LakareNo ratings yet

- Hazop Procedures Kenny SampleDocument178 pagesHazop Procedures Kenny Sampleayuzme123100% (1)

- Hazard Identification (HAZID) StudyDocument27 pagesHazard Identification (HAZID) StudyXiang Jintao100% (2)

- EGPC PSM GL 001 Hazard Identfication HAZID GuidelineDocument56 pagesEGPC PSM GL 001 Hazard Identfication HAZID Guidelinekhaled farag100% (2)

- HAZOPDocument7 pagesHAZOPfairusNo ratings yet

- HAZOP Report Issue 1Document71 pagesHAZOP Report Issue 1achyutNo ratings yet

- Hazard Identification (Hazid) Study Diesel Engine Generator (Deg) 3 River Water IntakeDocument18 pagesHazard Identification (Hazid) Study Diesel Engine Generator (Deg) 3 River Water IntakeXiang JintaoNo ratings yet

- Section 43 - Process Hazard Analysis Protocol PDFDocument5 pagesSection 43 - Process Hazard Analysis Protocol PDFzironelNo ratings yet

- Hazid Vs HazopDocument5 pagesHazid Vs HazopElavarasan RamalingamNo ratings yet

- HAZID TERMS OF REFERENCE - Rev.ADocument27 pagesHAZID TERMS OF REFERENCE - Rev.AXiang Jintao100% (1)

- Blank PSM & RMP Audit FormDocument298 pagesBlank PSM & RMP Audit Formclashu2No ratings yet

- HAZID MethodologyDocument3 pagesHAZID MethodologyNaresh Nutakki50% (2)

- Hazard and Operability Study (Hazop) : Dr. M. Azam SaeedDocument39 pagesHazard and Operability Study (Hazop) : Dr. M. Azam SaeedMuhammad Bilal100% (2)

- Day 5 - Hazop Procedure For CompanyDocument57 pagesDay 5 - Hazop Procedure For CompanyPablo CastroNo ratings yet

- Fertil Hazop StudyDocument9 pagesFertil Hazop Studypkannan0% (1)

- Explosion MitigationDocument261 pagesExplosion Mitigationrommy214uNo ratings yet

- Integrating Hazop and Sil/Lopa Analysis: Best Practice RecommendationsDocument10 pagesIntegrating Hazop and Sil/Lopa Analysis: Best Practice Recommendationsavinash_mokashi7073100% (1)

- Hazop Worksheet Suggested ScenariosDocument16 pagesHazop Worksheet Suggested ScenariosJagan BoseNo ratings yet

- Developing Process Safety Indicators HSE UK GuidlineDocument54 pagesDeveloping Process Safety Indicators HSE UK Guidlinevwagh100% (1)

- Highlight On "Hazop" For Engineering Safety ReviewDocument8 pagesHighlight On "Hazop" For Engineering Safety ReviewliamsiNo ratings yet

- ENI - Technical Proposal - Risk Analysis - Risk Management - Process Safety Process-05.02.19 - DMDocument45 pagesENI - Technical Proposal - Risk Analysis - Risk Management - Process Safety Process-05.02.19 - DMAdele PollardNo ratings yet

- What Is Process Safety EngineeringDocument3 pagesWhat Is Process Safety EngineeringCLPWC100% (11)

- HazopDocument66 pagesHazopBlack WidowNo ratings yet

- 02 - HAZID Techniques - Applications and LimitationsDocument12 pages02 - HAZID Techniques - Applications and Limitationsarman_morala100% (1)

- Process Industry HAZOP Techniques & Applications and HAZOP Leader Training, Indonesia, JohnnyDocument9 pagesProcess Industry HAZOP Techniques & Applications and HAZOP Leader Training, Indonesia, JohnnyEko PoerwantoNo ratings yet

- Guidelines For Quantitative Risk AssessmentDocument237 pagesGuidelines For Quantitative Risk Assessmentsyed_quraishyNo ratings yet

- HAZOP Study Methodology - 2 IEDOSH JB - StudentDocument116 pagesHAZOP Study Methodology - 2 IEDOSH JB - StudentAhmad Fauzie Ibrahim Ismail100% (1)

- SPD0102ERN - 0 - HAZID, ENVID ProcedureDocument11 pagesSPD0102ERN - 0 - HAZID, ENVID ProcedureGabbar SinghNo ratings yet

- Chastainw Advancesinlayerofprotectionanalysis PDFDocument37 pagesChastainw Advancesinlayerofprotectionanalysis PDFanon_770350620100% (1)

- HAZOP TrainingDocument131 pagesHAZOP Trainingtamilnaduchennai100% (14)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Guidelines for Developing Quantitative Safety Risk CriteriaFrom EverandGuidelines for Developing Quantitative Safety Risk CriteriaNo ratings yet

- Guidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisFrom EverandGuidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisNo ratings yet

- Guidelines for Integrating Process Safety into Engineering ProjectsFrom EverandGuidelines for Integrating Process Safety into Engineering ProjectsNo ratings yet

- A New Approach to HAZOP of Complex Chemical ProcessesFrom EverandA New Approach to HAZOP of Complex Chemical ProcessesNo ratings yet

- Quantitative Risk Analysis (QRA) : Germanischer Lloyd - Service/Product DescriptionDocument12 pagesQuantitative Risk Analysis (QRA) : Germanischer Lloyd - Service/Product DescriptionMani KalyanaramanNo ratings yet

- Pipe HangingDocument4 pagesPipe HangingkokykarkarNo ratings yet

- TX242 Ch02 PDFDocument4 pagesTX242 Ch02 PDFkokykarkarNo ratings yet

- Process Safety Randy ChaDocument29 pagesProcess Safety Randy ChakokykarkarNo ratings yet

- Predictive Aspects Chen Fu YiDocument27 pagesPredictive Aspects Chen Fu YikokykarkarNo ratings yet

- Mechanical Aspects Soh Zi QuanDocument28 pagesMechanical Aspects Soh Zi QuankokykarkarNo ratings yet

- Risk Based Approach Risk Reduction Basics 2017Document19 pagesRisk Based Approach Risk Reduction Basics 2017kokykarkarNo ratings yet

- 20 Standing Core Exercises: Lunge and Reach Dumbbell Cross Body Chops TeapotsDocument2 pages20 Standing Core Exercises: Lunge and Reach Dumbbell Cross Body Chops TeapotskokykarkarNo ratings yet

- r2p2 Reducing Risks Protecting People UK HSEDocument88 pagesr2p2 Reducing Risks Protecting People UK HSEpemburu bukuNo ratings yet

- Laminar Flame Speeds Data Collection 2014Document16 pagesLaminar Flame Speeds Data Collection 2014kokykarkarNo ratings yet

- Introduction To Fires and Dynamic Thermal Stress Analysis 2017Document16 pagesIntroduction To Fires and Dynamic Thermal Stress Analysis 2017kokykarkarNo ratings yet

- ALARP Jaime LimeDocument15 pagesALARP Jaime Limekokykarkar0% (1)

- FGS Handbook Rev DDocument19 pagesFGS Handbook Rev DkokykarkarNo ratings yet

- Risk Based Process Safety Design 2002Document13 pagesRisk Based Process Safety Design 2002kokykarkar100% (1)

- Fire and Gas Systems Handbook - KenexisDocument202 pagesFire and Gas Systems Handbook - KenexisardiyantoNo ratings yet

- WP Process Safety Competency UsDocument8 pagesWP Process Safety Competency UskokykarkarNo ratings yet

- Journal of Loss Prevention in The Process Industries: Paul BaybuttDocument8 pagesJournal of Loss Prevention in The Process Industries: Paul BaybuttkokykarkarNo ratings yet

- Legislative Index Land DrillingDocument113 pagesLegislative Index Land DrillingkokykarkarNo ratings yet

- Flare TypeDocument44 pagesFlare TypeBre WirabumiNo ratings yet

- 048Document6 pages048kokykarkarNo ratings yet

- ISC Process Safety Competency Guidance: Edition 2, 2018Document28 pagesISC Process Safety Competency Guidance: Edition 2, 2018kokykarkarNo ratings yet

- SIL For Shiraz Ammonia Project-3thOilHSE-A.banasazDocument9 pagesSIL For Shiraz Ammonia Project-3thOilHSE-A.banasazkokykarkarNo ratings yet

- Agrinome For Breeding - Glossary List For Mutual Understandings v0.3 - 040319Document7 pagesAgrinome For Breeding - Glossary List For Mutual Understandings v0.3 - 040319mustakim mohamadNo ratings yet

- Addendum ESIA Oct 2019Document246 pagesAddendum ESIA Oct 2019melkamuNo ratings yet

- Forensic IR-UV-ALS Directional Reflected Photography Light Source Lab Equipment OR-GZP1000Document3 pagesForensic IR-UV-ALS Directional Reflected Photography Light Source Lab Equipment OR-GZP1000Zhou JoyceNo ratings yet

- OBOE GougerDocument2 pagesOBOE GougerCarlos GaldámezNo ratings yet

- Catalogo PukangDocument41 pagesCatalogo PukangClarita Muller LeigueNo ratings yet

- Prediction of CBR From Index Properties of Cohesive Soils: Magdi ZumrawiDocument1 pagePrediction of CBR From Index Properties of Cohesive Soils: Magdi Zumrawidruwid6No ratings yet

- Aharonov-Bohm Effect WebDocument5 pagesAharonov-Bohm Effect Webatactoulis1308No ratings yet

- Guidelines For Doing Business in Grenada & OECSDocument14 pagesGuidelines For Doing Business in Grenada & OECSCharcoals Caribbean GrillNo ratings yet

- Reference GuideDocument88 pagesReference GuideAnonymous Qm0zbNk100% (1)

- Law of AttractionDocument2 pagesLaw of AttractionKate SummersNo ratings yet

- Final SEC Judgment As To Defendant Michael Brauser 3.6.20Document14 pagesFinal SEC Judgment As To Defendant Michael Brauser 3.6.20Teri BuhlNo ratings yet

- Previews 1633186 PreDocument11 pagesPreviews 1633186 PreDavid MorenoNo ratings yet

- Standard BMW PDFDocument19 pagesStandard BMW PDFIna IoanaNo ratings yet

- Ferobide Applications Brochure English v1 22Document8 pagesFerobide Applications Brochure English v1 22Thiago FurtadoNo ratings yet

- Advanced Oil Gas Accounting International Petroleum Accounting International Petroleum Operations MSC Postgraduate Diploma Intensive Full TimeDocument70 pagesAdvanced Oil Gas Accounting International Petroleum Accounting International Petroleum Operations MSC Postgraduate Diploma Intensive Full TimeMoheieldeen SamehNo ratings yet

- The Phases of The Moon Station Activity Worksheet Pa2Document3 pagesThe Phases of The Moon Station Activity Worksheet Pa2api-284353863100% (1)

- Final - Anarchy One-Sheet Sell SheetDocument2 pagesFinal - Anarchy One-Sheet Sell SheetMaddanie WijayaNo ratings yet

- Learning Competency PDFDocument1 pageLearning Competency PDFLEOMAR PEUGALNo ratings yet

- French Cuisine RecipeDocument6 pagesFrench Cuisine RecipeJimmy AchasNo ratings yet

- Music Production EngineeringDocument1 pageMusic Production EngineeringSteffano RebolledoNo ratings yet

- Ode To The West WindDocument4 pagesOde To The West WindCharis Mae DimaculanganNo ratings yet

- Aircraft Wiring Degradation StudyDocument275 pagesAircraft Wiring Degradation Study320338No ratings yet

- FINAL VERSION On Assessment Tool For CDCs LCs Sept. 23 2015Document45 pagesFINAL VERSION On Assessment Tool For CDCs LCs Sept. 23 2015Edmar Cielo SarmientoNo ratings yet

- Electronics 11 02566Document13 pagesElectronics 11 02566卓七越No ratings yet

- Kortz Center GTA Wiki FandomDocument1 pageKortz Center GTA Wiki FandomsamNo ratings yet