Professional Documents

Culture Documents

Liebherr LHM 420 Mobile Harbour Crane Datasheet English

Uploaded by

David MOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Liebherr LHM 420 Mobile Harbour Crane Datasheet English

Uploaded by

David MCopyright:

Available Formats

Mobile Harbour Crane

LHM 420

Maximum lifting capacity

124 t

Maximum outreach

48 m

Ship size

Panamax, Post-Panamax

Main Dimensions Lifting Capacities

Bulk Operation Bulk Operation

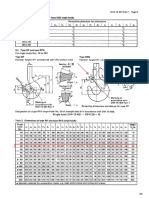

Load Diagram on the ropes motor grab 4-rope grab Maximum crane capacity 124 t Maximum crane capacity 84 t

Hook operation Grab operation Hook operation Grab operation

160

Outreach on the ropes 4-rope grab motor grab Outreach on the ropes 4-rope grab motor grab

140 (m) (t) (t) (t) (m) (t) (t) (t)

10.5 – 12 124.0 75.0 90.0 10.5 – 12 84.0 45.0 52.0

120

13 117.6 75.0 90.0 13 84.0 45.0 52.0

100 14 111.5 75.0 90.0 14 84.0 45.0 52.0

Capacity (t)

80 15 105.6 75.0 90.0 15 84.0 45.0 52.0

16 100.1 75.0 90.0 16 84.0 45.0 52.0

60 18 90.0 75.0 81.0 18 84.0 45.0 52.0

40 19 85.3 75.0 76.8 19 84.0 45.0 52.0

20 81.0 72.9 72.9 20 81.0 45.0 52.0

20

22 73.1 65.8 65.8 22 73.1 45.0 52.0

0 24 66.2 59.6 59.6 24 66.2 45.0 52.0

0 5 10 15 20 25 30 35 40 45 50 55 26 60.2 54.2 54.2 26 60.2 45.0 52.0

Outreach (m) 28 55.1 49.5 49.5 28 55.1 45.0 48.9

30 50.6 45.5 45.5 30 50.6 45.0 45.0

32 48.6 42.1 42.1 32 48.6 41.6 41.6

34 43.4 39.1 39.1 34 43.4 38.6 38.6

36 40.5 36.5 36.5 36 40.5 36.0 36.0

38 38.0 34.2 34.2 38 38.0 33.8 33.8

40 35.7 32.1 32.1 40 35.7 31.7 31.7

42 33.5 30.2 30.2 42 33.5 29.8 29.8

44 31.4 28.3 28.3 44 31.4 27.9 27.9

46 29.3 26.3 26.3 46 29.3 26.0 26.0

48 27.3 24.5 24.5 48 27.3 24.2 24.2

Weight ramshorn hook 3.0 t; Weight rotator 3.5 t Weight ramshorn hook 3.0 t; Weight rotator 2.5 t

Standard Configuration / Turnover up to 1,500 t per Hour

Pactronic® / Turnover up to 2,000 t per Hour

32.8 m

Above quay up to 43 m

Eye level 24 m

(depending on grab)

Boom fulcrum 17.8 m

The powerful hydrostatic transmission and advanced Liebherr electronics ensure short, productive working

cycles during bulk handling.

• During grab operation, hoisting, slewing, and luffing are • To provide safe and stress-free working conditions for the

driven simultaneously at maximized speed to achieve the operator, Liebherr offers the Cycoptronic® including Teach-

highest (possible) turnover. In® feature, a semi-automatic system, which pilots the

crane from the vessel hatch to the quay without any sway.

• During grab filling, features such as automatic lowering and Especially for bulk operation into hoppers, the Teach-In®

hoisting guarantee the optimum filling level of the grab. system increases turnover and ensures consistent turnover

Below quay 10 m

rates during the entire ship unloading.

• The slack rope monitoring system ensures extended life-time

of the ropes and increases operational safety. • Liebherr technology is absolutely resistant to all types of

dust and dirt due to the closed hydraulic system and an

• Reverse power is returned to the drive process through closed electronic system which is military proven and tested.

12.5 m loop hydraulics which results in reduced fuel consumption.

• The airflow needed for cooling hydraulic and engine

Panamax

• The Cycoptronic® anti-sway system automatically compen- systems is routed external from the main machinery

sates for all rotational swing, transverse and longitudinal house. This helps keep the engine room clean and free

sway of the load at maximum speeds. of debris.

2 LHM 420 LHM 420 3

Main Dimensions Lifting Capacities

Container Operation Container Operation

Load Diagram on the ropes twin lift spreader single lift spreader Maximum crane capacity 124 t Maximum crane capacity 84 t

Hook operation Hook operation

160 Spreader operation under Spreader operation under

on the ropes on the ropes

140 Outreach Single lift Twin lift Heavy lift Outreach Single lift Twin lift Heavy lift

(m) (t) (t) (t) (m) (t) (t) (t)

120

11 41.0 50.0 124.0 11 41.0 50.0 84.0

100 12 41.0 50.0 124.0 12 41.0 50.0 84.0

Capacity (t)

13 41.0 50.0 124.0 13 41.0 50.0 84.0

80

14 41.0 50.0 124.0 14 41.0 50.0 84.0

60 16 41.0 50.0 124.0 16 41.0 50.0 84.0

18 41.0 50.0 113.9 18 41.0 50.0 84.0

40

20 41.0 50.0 102.5 20 41.0 50.0 84.0

20 22 41.0 50.0 92.5 23 41.0 50.0 84.0

24 41.0 50.0 83.8 24 41.0 50.0 83.8

0

0 5 10 15 20 25 30 35 40 45 50 55 26 41.0 50.0 76.2 26 41.0 50.0 76.2

28 41.0 50.0 69.7 28 41.0 50.0 69.7

Outreach (m)

30 41.0 49.9 64.1 30 41.0 50.0 64.1

32 41.0 45.0 59.2 32 41.0 46.0 59.2

34 41.0 40.8 55.0 34 41.0 41.8 55.0

35 40.5 38.8 53.0 35 41.0 39.8 53.0

36 38,8 37.1 51.3 36 39.8 38.1 51.3

38 35.6 33.9 48.1 38 36.6 34.9 48.1

40 32.7 31.0 45.2 40 33.7 32.0 45.2

42 30.0 28.3 42.5 42 31.0 29.3 42.5

44 27.3 25.6 39.8 44 28.3 26.6 39.8

46 24.6 22.9 37.1 46 25.6 23.9 37.1

48 22.0 20.3 34.5 48 23.0 21.3 34.5

Weight rotator 3.5 t Weight rotator 2.5 t

Weight fully automatic (telescopic) spreader 9 t Weight fully automatic (telescopic) spreader 9 t

Weight twin lift spreader 10.7 t Weight twin lift spreader 10.7 t

32.8 m

Above quay up to 44 m Standard Configuration / Turnover up to 32 Cycles per Hour

Eye level 24 m

Boom fulcrum 17.8 m

Pactronic® / Turnover up to 38 Cycles per Hour

Precision to perfection: With incredibly short acceleration times for all crane motions, Liebherr is the top

performer in container handling.

• The crane can be fitted with various types of spreaders (fixed • Safety: The luffing cylinder is positioned above the lattice

or telescopic) connected to the rotator. Manual, semi or fully boom. This eliminates the possibility of any damage to the

automatic telescopic spreaders are available for various cylinder through swinging loads or highly stowed rows of

Below quay 10 m

container sizes. containers on board the vessel.

• Liebherr Cycoptronic® is an accurate, sway-free load motion • The Liebherr hydrostatic drive is the most reliable and

control system that uses in-house designed software. highest performing drive system for mobile harbour cranes.

Cycoptronic® allows for direct load positioning and aids Independent closed loop hydraulic systems utilize the

12.5 m the crane driver in mastering his task. With Cycoptronic® minimum number of components to guarantee highly

turnover, safety and the confidence of the operator will be responsive, smooth and precise operation while maximizing

Post-Panamax

improved. operational safety.

4 LHM 420 LHM 420 5

Undercarriage Technical Data

Capacity and Classification Propping Arrangements

Mobility Modular propping system Capacity Classification Standard supporting base 12.5 m x 12.5 m

• Outstanding mobility and manoeuvrability • Minimised stress and strain of undercarriage due to cruciform support base which Four rope grab operation ≤ 52 t A8 Standard pad dimension 5.5 m x 1.8 m

• Curves at any possible radii and even slewing on the spot directs the load path from boom tip to quay Four rope grab operation ≤ 60 t A7 Standard supporting area of pads 9.9 m2

• Modular system allows further reduction of quay loads by installing additional axle sets Motor grab operation ≤ 52 t A8 Optional size of supporting pads and bases on request

• Easy adaptation to various sizes of support pads and bases Container operation ≤ 57 t A7

Schematic diagram Heavy lift operation ≤ 124 t A3

Quay Load Arrangements

Bulk Container

Main Dimensions Uniformly distributed load 1.9 t/m2 1.9 t/m2

Min. to max. outreach 11 — 48 m Max. load per tyre 6.0 t 5.8 t

Height of boom fulcrum 17.8 m

Due to a unique undercarriage design the quay loads specified above can even

Tower cabin height (eye level) 24.0 m be reduced. Pad sizes, supporting base and the number of axle sets can easily be

Overall height (top of tower) 32.8 m adapted to comply with the most stringent quay load restrictions.

Overall length of undercarriage 20.0 m

12.5 m

Overall width of undercarriage 6.0 m

Bulk Container Weight

Number of axle sets (standard) 14 16 Bulk Container

Number of axle sets (optional) 24 24 Total weight of crane LHM 420 approx. 342 t approx. 371 t

5.5 m

Working Speeds Hoisting Heights

1.8 m Hoisting / lowering 0 — 120 m/min Above quay at minimum radius 45.0 m

Slewing 0 — 1.6 rpm Above quay at maximum radius 29.0 m

6 m

Luffing (average horizontal speed) 0 — 55 m/min Below quay level (approx.) 12.0 m

12.5 m

Travelling 0 — 5 km/h

Hydraulic load distribution Optional Equipment

• Hydraulic suspension avoids overloading of individual wheel sets

• Standard trailer tyres making requisition of spares economical and time-saving

• Increased lifetime of tyres due to individually steerable wheel sets Additional products and services

• Pactronic® - power by accumulator and electronics • Cyclone air-intake system for the engine

• SmartGrip − intelligent grabbing • Low temperature package

• Cycoptronic - anti-sway system

®

• Customer-specific painting & logo

• Teach-In - semi-automatic point to point system • Additional (driven) axle sets

• Sycratronic - synchronizing crane control system

®

• Axle sets equipped with foamed tyres

• Vertical Line Finder - diagonal pull preventing system • Different supporting bases and pad sizes

• Collision alert system • And many more as per customers´ requirements

• LiDAT − smartApp

®

• Economy software - for optimised fuel consumption

Optimum pressure distribution • Video monitoring system

and adaption of wheel sets on uneven surfaces

• Radio remote control

• Autopropping undercarriage

6 LHM 420 LHM 420 7

Practical Solutions

LPS 420 LFS 420 LHM 420 LPM 420

Liebherr develops and produces special designs and solutions

to meet customer-specific requirements

• The Liebherr Portal Crane (LPS) is an efficient combination • The Liebherr Portal Mobile Crane (LPM) is the perfect

of a space-saving portal (mounted on rails) and the proven combination of a space-saving portal undercarriage,

mobile harbour crane concept. Particularly on narrow efficient mobile harbour crane technology and unrestricted

quays, individual portal solutions permit (railway) trains and mobility. A gantry on rubber tyres enables the crane to be

(road) trucks to travel below the portal. travelled from one quay to another. Supporting pads allow

the crane to be used on quays with or without rail tracks.

• Liebherr Fixed Slewing Cranes (LFS) are an efficient The LPM offers the same 360-degree mobility as the LHM.

combination of a mobile harbour crane upper carriage and Driving in longitudinal, diagonal or transverse direction.

HM 3513.03.04 MCR-10558651-06.18_en

a fixed pedestal. LFS cranes provide an economical and Performance of conventional steering or slewing on the

space-saving solution for the installation on quaysides and spot is possible and provided as standard.

jetties, especially where room for manoeuvring is limited and

Subject to change without notice.

low ground pressure is essential. Additionally LFS solutions

are also ideally suited for the installation on crane barges.

Liebherr-MCCtec Rostock GmbH

Liebherrstraße 1, 18147 Rostock/GERMANY

Tel.: +49 381 6006 5020

mobile.harbour.crane@liebherr.com

www.liebherr.com

You might also like

- SWF RopeHoists CraneKits 09 2012 enDocument21 pagesSWF RopeHoists CraneKits 09 2012 enGogyNo ratings yet

- DIN 15401 p1Document2 pagesDIN 15401 p1Vinesh Menon100% (1)

- ABUS Overhead Cranes Design GuideDocument12 pagesABUS Overhead Cranes Design GuideGibbs Per100% (1)

- KC SC Spreader en 01Document7 pagesKC SC Spreader en 01Mohammed Muzzammil100% (1)

- Part of My Book of Preventive MaibtenanceDocument5 pagesPart of My Book of Preventive MaibtenanceMohamed Elnagdy0% (1)

- Tailor Made Marine CranesDocument8 pagesTailor Made Marine CranesMauro TognocchiNo ratings yet

- DC Pro Chain Hoist Tech DataDocument24 pagesDC Pro Chain Hoist Tech DataIvan BaracNo ratings yet

- SSX40 TrainingDocument20 pagesSSX40 TrainingDavid Adeola OgunyemiNo ratings yet

- 22.wire RopeSelection enDocument6 pages22.wire RopeSelection enT ThirumuruganNo ratings yet

- ABU CompactDocument32 pagesABU CompactPrimož KozlevčarNo ratings yet

- Mobile Harbour Crane Load Capacity and DimensionsDocument8 pagesMobile Harbour Crane Load Capacity and DimensionsBatu YildirimNo ratings yet

- 4ductor Engl PDFDocument8 pages4ductor Engl PDFNilesh MahajanNo ratings yet

- FEA and Optimization of Telescopic Boom of Mobiles Hydraulic CraneDocument6 pagesFEA and Optimization of Telescopic Boom of Mobiles Hydraulic Cranenpd1986100% (2)

- Technical details of a large craneDocument10 pagesTechnical details of a large cranejmmNo ratings yet

- Rope AppreciationDocument28 pagesRope Appreciationfajrin_nurdiansyah88No ratings yet

- Explosion CraneDocument44 pagesExplosion CraneGolfkung PairojNo ratings yet

- KoneDocument2 pagesKoneImran OdeNo ratings yet

- Ipmaidadb2llowmokobelco sl4500 440-Ton Standard Configuration Crawler Crane NetworkDocument64 pagesIpmaidadb2llowmokobelco sl4500 440-Ton Standard Configuration Crawler Crane Network이현기No ratings yet

- Load Chart Gottwald HMK 7408Document2 pagesLoad Chart Gottwald HMK 7408Douglas MatsudaNo ratings yet

- D 0498Document28 pagesD 0498Bang OchimNo ratings yet

- Hydraulic valve block and solenoid functionsDocument8 pagesHydraulic valve block and solenoid functionsThanh CongNo ratings yet

- Special wire ropes for demanding applicationsDocument60 pagesSpecial wire ropes for demanding applicationsEvandro BeserraNo ratings yet

- Crane Wheel Bearing Dimensions and SpecificationsDocument1 pageCrane Wheel Bearing Dimensions and SpecificationsayavuzbvsNo ratings yet

- Cargotec Lashing Systems Items FALDocument41 pagesCargotec Lashing Systems Items FALstopless_dalian685No ratings yet

- Extracted Pages From 3601709 - Fabrication Drawings1Document1 pageExtracted Pages From 3601709 - Fabrication Drawings1ahmed aboyosefNo ratings yet

- OECP Crane Operator Candidate ManualDocument66 pagesOECP Crane Operator Candidate ManualkhalidNo ratings yet

- Thong So Ky ThuatDocument30 pagesThong So Ky ThuatQuang HưngNo ratings yet

- Abm Motor KatalogDocument16 pagesAbm Motor Katalogakın ersözNo ratings yet

- MobileHarbourCrane SpreaderDocument9 pagesMobileHarbourCrane SpreaderMauricio Bulla ValenciaNo ratings yet

- Port Douglas 3 304Document1 pagePort Douglas 3 304Ngaire TaylorNo ratings yet

- Linden ComansaDocument14 pagesLinden ComansaJamal CareyNo ratings yet

- S Announcement 25288 PDFDocument5 pagesS Announcement 25288 PDFOnyx XynoNo ratings yet

- Verlinde Electric Wire Rope HoistDocument12 pagesVerlinde Electric Wire Rope HoistMahmoud AllamNo ratings yet

- Crane Components Technical CatalogueDocument32 pagesCrane Components Technical CatalogueGogyNo ratings yet

- Demag DR Rope Hoist: Without Electrical ControlDocument32 pagesDemag DR Rope Hoist: Without Electrical ControlDante WilliamsNo ratings yet

- Tadano CranesDocument6 pagesTadano CranesvikrantparikhNo ratings yet

- EOT Crane Maintenance ManualDocument99 pagesEOT Crane Maintenance ManualAvishek DasNo ratings yet

- Paadeye S TypeDocument148 pagesPaadeye S TypeansarALLAAHNo ratings yet

- GunneboDocument36 pagesGunnebomordidomiNo ratings yet

- Technical Information: 1. Hoist RopesDocument17 pagesTechnical Information: 1. Hoist RopesvikasgahlyanNo ratings yet

- 31 SeriesDocument4 pages31 SeriesJESUSCALVILLONo ratings yet

- 203 656 44 Accesorios ElectricosDocument32 pages203 656 44 Accesorios ElectricosJESUSCALVILLONo ratings yet

- Gunnebo 2000Document36 pagesGunnebo 2000Ed CalheNo ratings yet

- k2 ProfileDocument21 pagesk2 ProfilepreanandNo ratings yet

- GM - 6000 20000 - L-242 41 15000 3 D - 200 24 2500 GBDocument1 pageGM - 6000 20000 - L-242 41 15000 3 D - 200 24 2500 GBEduardo Garcia SaraviaNo ratings yet

- Guide Lifting Materials HandlingDocument6 pagesGuide Lifting Materials Handlingasdasd asdasdNo ratings yet

- Fixed Boom Marine Crane - EBIDocument3 pagesFixed Boom Marine Crane - EBIalikajbafNo ratings yet

- Customer Plant Designation Drawing Number Port of Hai Pong A1 BR1701342::: Revision: CDocument27 pagesCustomer Plant Designation Drawing Number Port of Hai Pong A1 BR1701342::: Revision: CDuong Hoang Tin tin-dhNo ratings yet

- Telescopic Boom Cranes - Lifetime ExcellenceDocument3 pagesTelescopic Boom Cranes - Lifetime ExcellenceAzwar SalehNo ratings yet

- Service-Products TPS PDFDocument39 pagesService-Products TPS PDFJack CorreiaNo ratings yet

- Abus Electric Chain HoistDocument32 pagesAbus Electric Chain HoistراموندولدولاوNo ratings yet

- SpanSet Against Sharp Edges No CutDocument16 pagesSpanSet Against Sharp Edges No CutErwin Baharuddin100% (2)

- Terex Gottwald Model 3 Harbour Crane: The Entry Model For The 100-Tonne SegmentDocument36 pagesTerex Gottwald Model 3 Harbour Crane: The Entry Model For The 100-Tonne SegmentAri Yandoko100% (1)

- Liebherr Oc Ram Luffing Knuckle Boom Crane Series Brochure 170e174 EngDocument2 pagesLiebherr Oc Ram Luffing Knuckle Boom Crane Series Brochure 170e174 EngCarlos Gonzalez TorresNo ratings yet

- 3.2t X 6m Span Elv PDFDocument2 pages3.2t X 6m Span Elv PDFpawan0% (1)

- Lifting+Matters+Q3+2021 210930 WEB LRDocument36 pagesLifting+Matters+Q3+2021 210930 WEB LRAlex Sandro Borges PereiraNo ratings yet

- Hydraulic Crawler Crane: S P E C I F I C A T I O N SDocument8 pagesHydraulic Crawler Crane: S P E C I F I C A T I O N SSANDEEP PRASAD100% (1)

- Look Ahead!: Wire Rope HoistDocument4 pagesLook Ahead!: Wire Rope HoistAri Binar SembiringNo ratings yet

- Liebherr LHM 420 Mobile Harbour Crane Datasheet EnglishDocument5 pagesLiebherr LHM 420 Mobile Harbour Crane Datasheet EnglishFarid BakiriNo ratings yet

- Government Publications: Key PapersFrom EverandGovernment Publications: Key PapersBernard M. FryNo ratings yet

- Cordlash Quick Lashing Guide IMPERIAL Issue 2 May 2012Document32 pagesCordlash Quick Lashing Guide IMPERIAL Issue 2 May 2012David MNo ratings yet

- LHM 500Document8 pagesLHM 500David M100% (1)

- Motor Om 444 La Liebherr LHM 400Document2 pagesMotor Om 444 La Liebherr LHM 400Liebherr100% (1)

- Ihr Authorized Ports ListDocument85 pagesIhr Authorized Ports Listjohnny al-caponeNo ratings yet

- Shipping GlossaryDocument12 pagesShipping GlossaryAnand Khisti.100% (5)

- Motor Om 444 La Liebherr LHM 400Document2 pagesMotor Om 444 La Liebherr LHM 400Liebherr100% (1)

- ISO - 1161 - 1984 Corrigendum 1 - 1990Document2 pagesISO - 1161 - 1984 Corrigendum 1 - 1990David MNo ratings yet

- Protubsa Barra Perforada 2016Document8 pagesProtubsa Barra Perforada 2016David MNo ratings yet

- Grand Vitara Despiece ComplementoDocument453 pagesGrand Vitara Despiece ComplementoChristian GutierrezNo ratings yet

- Revised IRCA Part-III FinalDocument296 pagesRevised IRCA Part-III Finalarun13100% (7)

- RT 40 BrochureDocument4 pagesRT 40 BrochurewagzworxhireNo ratings yet

- Productos MDocument6 pagesProductos MMAJIUMI KETTY ROQUE INGANo ratings yet

- Car EssayDocument13 pagesCar Essayapi-582801838No ratings yet

- Ride Details Bill Details: Nagarajan A NADocument3 pagesRide Details Bill Details: Nagarajan A NAnagendranNo ratings yet

- New Self Loading Mixer Range from Schwing Stetter IndiaDocument2 pagesNew Self Loading Mixer Range from Schwing Stetter Indiavenki babuNo ratings yet

- Sol 2-E. Extra Exercise PA - 8GDocument2 pagesSol 2-E. Extra Exercise PA - 8GAnika ŠarkaNo ratings yet

- Chapter 2: Driver Attitude and AptitudeDocument32 pagesChapter 2: Driver Attitude and Aptitudeshadowdream101No ratings yet

- Ford Ranger Cruise Control Self-DiagnosticDocument1 pageFord Ranger Cruise Control Self-DiagnosticTsoojiNo ratings yet

- 1 History of The StackersDocument8 pages1 History of The Stackerspruebas100% (1)

- Amsa 1566Document6 pagesAmsa 1566TrucMaiNo ratings yet

- Ecosky CommercialDocument21 pagesEcosky CommercialJia Xun NgNo ratings yet

- Highway: Service Road Plan & ProfileDocument10 pagesHighway: Service Road Plan & ProfileAmritsar JamnagarNo ratings yet

- SB-16-86-12 5EAT TCM ReprogrammingDocument3 pagesSB-16-86-12 5EAT TCM ReprogrammingossoskiNo ratings yet

- EV6 BrochureDocument21 pagesEV6 BrochureDeep BhanushaliNo ratings yet

- Print Pilatus PC12-NG - 2 - PC-12 NG Normal Proc Short Checklist Rev 0 PDFDocument2 pagesPrint Pilatus PC12-NG - 2 - PC-12 NG Normal Proc Short Checklist Rev 0 PDFKevin ChenNo ratings yet

- Manual of Transportation Engineering StudiesDocument640 pagesManual of Transportation Engineering StudiesStivenStifler91% (23)

- AP03120210037482DLDocument1 pageAP03120210037482DLKRISH7698No ratings yet

- 6003 Series 6403 6603 Tractors Mexican South Africa and Asian EditionDocument3 pages6003 Series 6403 6603 Tractors Mexican South Africa and Asian EditionGerardo Roa MedinaNo ratings yet

- 1 Introduction To Transportation Engineering 1Document5 pages1 Introduction To Transportation Engineering 1chileNo ratings yet

- Pakyong Airport Aerodrome InformationDocument13 pagesPakyong Airport Aerodrome InformationArgha BanerjeeNo ratings yet

- Demage ReprotDocument4 pagesDemage ReprotIsraelNo ratings yet

- Fresh Air: A220-100 & - 300 FUEL BURN & Operating PerformanceDocument52 pagesFresh Air: A220-100 & - 300 FUEL BURN & Operating Performancerobertas negudinasNo ratings yet

- Daily Running Chart - 2010.11.16Document1 pageDaily Running Chart - 2010.11.16Dinesh WeerasingheNo ratings yet

- Ulwe - Navi Mumbai Report 21257 22206 8979Document17 pagesUlwe - Navi Mumbai Report 21257 22206 8979Govind MauryaNo ratings yet

- 01 PDFDocument334 pages01 PDFjohnson swaiNo ratings yet

- Chevrolet Optra Brochure en CADocument20 pagesChevrolet Optra Brochure en CAArun KumarNo ratings yet

- 2021 POLIS Conference Draft Programme Final v6Document22 pages2021 POLIS Conference Draft Programme Final v6Riccardo TosoNo ratings yet