Professional Documents

Culture Documents

Absorption Chiller A4 Sheet Email - En.id

Uploaded by

argaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Absorption Chiller A4 Sheet Email - En.id

Uploaded by

argaCopyright:

Available Formats

Understanding

an Absorption Chiller

The Absorption cooling cycle explained in a step by step process

using a Hot Water Chiller as the example

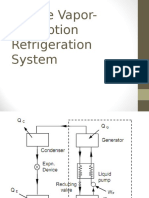

1. Generator 3. Evaporator

Encer dan larutan hangat memasuki ruang tekanan tinggi dan Refrigeran cair memasuki ruang tekanan rendah yang berada di bawah

disemprotkan lebih penukar panas yang mengandung sumber panas vakum tinggi. Karena vakum, air dalam lingkungan ini mendidih pada

(air panas). Panas dipindahkan ke solusi dan solusi encer bisul, 3.5ºC. Refrigeran cair disemprotkan lebih pipa yang berisi bangunan

membebaskan uap refrigeran dan menciptakan solusi terkonsentrasi 12ºC air pendingin. refrigeran mendidih dan mengurangi gedung

panas. pendingin air untuk 6ºC. air pendingin ini kemudian beredar melalui loop

pipa air dingin bangunan sebelum kembali ke chiller di 12ºC lagi. Dalam

2. Kondensor chiller uap refrigeran dibebaskan dari proses penguapan bergerak hak

Uap refrigeran dibuat bergerak ke kanan, di mana ia terkondensasi untuk Absorber tersebut.

kembali menjadi cairan pada penukar panas dingin yang mengandung

air pendingin.

Absorption Chiller - Hot Water Fired

4. Absorber

Cooling

80°c

water 35°c

Panas larutan pekat (orange) yang memiliki

Water Hot Water Chilled transferred its heat to the dilute fluid (pink) enters the absorber and is

vapour

Water Cooling Water

1. Generator 2. Condenser

sprayed into the water vapour saturated atmosphere. The concentrated

90°c Dilute solution

source)

Concentrated solution solution absorbs the refrigerant vapour creating a dilute solution, which

water (heat Liquid Water Water

Low Pressure 1 100

ATM Vapour

liberates heat to the cooling water that is passing through a heat

water

6°c Hot

Pressure 1 10 ATM

exchanger in this area.

Chilled Water

vapour

3. Evaporator 4. Absorber

12°c Cooling 29°c

water

The process then starts over.

Refrigerant Pump Solution Pump Higher

Heat exchanger

Specialists in energy systems for over 80 years

Recent Installations Applications for Absorption Chillers and

Trigeneration

• Commercial and Residential buildings: Comfort cooling or

heating – Shopping centres, offices, hospitals, universities,

airports, auditoriums, factories etc.

• Industries: Process cooling or heating - Cooling or heating of

product like beverages or chemicals. Cooling in manufacturing

applications such as injection moulding machines – Plastics,

petrochemicals, brewery, printing, pulp mills, palm oil, etc.

Castle Hill RSL Club

Castle Hill RSL Club recently installed a Trigeneration system which is the

combination of Cogeneration system (375kWe) and a single stage hot

• Inlet air cooling for engines or gas turbines – Used to cool the

water Absorption Chiller (300kWr). This system provides electricity base

inlet air going to engines or gas turbines to improve the efficiency

load for the building, with free heating, cooling and domestic hot water,

during hot ambient conditions.

delivering energy savings of approximately $250,000 a year.

Maitland City Bowls Swinburne University

Maitland City Bowls recently installed a 152kWe Simons energi hijau memasok

Trigeneration system which is the combination of Cogeneration tanaman 230kWe dan satu

Cogeneration system and a single stage hot water panggung air panas Penyerapan Chiller

Absorption Chiller. This system converts gas into to 250kWr untuk merek gedung kampus

electricity, heating, domestic hot water and chilled baru.

water for air-conditioning thereby significantly

reducing energy costs and the Club’s carbon footprint.

East Village, Sydney 1 King William Street

Simons Energi Hijau adalah segera memasang satu Simons Green Energy is supplying a

tahap 583kWr air panas dengan gas alam 310kWe cogeneration plant and

tambahan dipecat burner. Penyerapan Chiller yang 275kWr single stage hot water

akan menyediakan air dingin untuk pengkondisian Absorption Chiller. To be housed on

udara dengan di dalam gedung. Sistem ini the 17th floor rooftop, to aid in

mengkonversi gas menjadi menjadi listrik, increasing the building’s energy

pemanasan dan pendinginan. Limbah panas dari efficiency during an upcoming

sistem Cogeneration diubah menjadi air dingin refurbishment.

untuk AC sehingga secara signifikan mengurangi

biaya energi dan jejak karbon.

Providing Energy Solutions since 1932

T + 61 2 8338 8660 E info@simonsgreenenergy.com.au

www.simonsgreenenergy.com

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Rac CH 3Document97 pagesRac CH 3GETACHEWNo ratings yet

- Lecture 6 RefrigerationDocument65 pagesLecture 6 RefrigerationRamon Gerald AsiloNo ratings yet

- 13.vapour Absorption Refrigeration (H2O-NH3)Document4 pages13.vapour Absorption Refrigeration (H2O-NH3)Anas AlbasarhNo ratings yet

- Simple Vapor-Absorption Refrigeration SystemDocument49 pagesSimple Vapor-Absorption Refrigeration SystemnaccfrancNo ratings yet

- Refrigeration and Air Conditioning: Instruction To CandidatesDocument2 pagesRefrigeration and Air Conditioning: Instruction To CandidatesSahil KumarNo ratings yet

- Nagpur Institute Mechanical Engineering MCQs Air Conditioning RefrigerationDocument17 pagesNagpur Institute Mechanical Engineering MCQs Air Conditioning RefrigerationRishabh DeshpandeNo ratings yet

- Sciencedirect: I. Andrić, A. Pina, P. Ferrão, J. Fournier ., B. Lacarrière, O. Le CorreDocument8 pagesSciencedirect: I. Andrić, A. Pina, P. Ferrão, J. Fournier ., B. Lacarrière, O. Le Correkrishna maniNo ratings yet

- EME2146 Tutorial 6Document2 pagesEME2146 Tutorial 6iwqb0% (1)

- Absorption Chillers Global MarketDocument246 pagesAbsorption Chillers Global MarketTHERMAX007100% (1)

- Ammonia Absorption Refrigeration PlantsDocument11 pagesAmmonia Absorption Refrigeration PlantsJom BonhayagNo ratings yet

- Solar Absorption ChillerDocument28 pagesSolar Absorption ChillerBrianNo ratings yet

- Solar Energy: DR Vratraj JoshiDocument175 pagesSolar Energy: DR Vratraj Joshistark x4No ratings yet

- The Vapor Absorption Refrigeration System Consists ofDocument2 pagesThe Vapor Absorption Refrigeration System Consists ofJera ObsinaNo ratings yet

- Lecture 3. Refrigeration Cycles 2Document37 pagesLecture 3. Refrigeration Cycles 2addisudagneNo ratings yet

- Computer Controlled Gas Absorption Column, With SCADA and PID Control CagcDocument15 pagesComputer Controlled Gas Absorption Column, With SCADA and PID Control CagcSagar MorjeNo ratings yet

- EDUR Application ExamplesDocument20 pagesEDUR Application ExamplesGabriel BonteaNo ratings yet

- Thermoflex BasicsDocument35 pagesThermoflex BasicsMike100% (2)

- Chillers and Boilers Parts ListDocument29 pagesChillers and Boilers Parts ListAwais JalaliNo ratings yet

- Unit 5 - Refrigeration System StudentsDocument33 pagesUnit 5 - Refrigeration System Studentsshreyansh gaddamwarNo ratings yet

- Gas Absorption: Determining Drag and Flooding FlowsDocument5 pagesGas Absorption: Determining Drag and Flooding FlowsDean Joyce AlborotoNo ratings yet

- PD 038Document31 pagesPD 038AhmedNo ratings yet

- Refrigeration and Air Conditioning SystemsDocument3 pagesRefrigeration and Air Conditioning SystemssivakrishnaNo ratings yet

- Seminar On RACDocument21 pagesSeminar On RACAditya DeshpandeNo ratings yet

- ATD Lab ManualsDocument124 pagesATD Lab ManualsN200266 PONNAGANTI SHEKARNo ratings yet

- Qatar Stadiums Case StudyDocument10 pagesQatar Stadiums Case StudyYenenehNo ratings yet

- Refrigeration and Air Conditioning-IIT Kharagpur NotesDocument803 pagesRefrigeration and Air Conditioning-IIT Kharagpur Notessangeethsreeni87% (30)

- Absorption Cooling: Datasheet 07 FEB 2012Document3 pagesAbsorption Cooling: Datasheet 07 FEB 2012mohamadNo ratings yet

- TESSLibs17 General Descriptions PDFDocument79 pagesTESSLibs17 General Descriptions PDFhoangpalestineNo ratings yet

- Catálogo General Thermax SSDocument30 pagesCatálogo General Thermax SSsleriphocrNo ratings yet

- Absorption Chillers Use Waste Heat for CoolingDocument3 pagesAbsorption Chillers Use Waste Heat for CoolingAbd AbdulNo ratings yet