Professional Documents

Culture Documents

Metal Building Roof Systems: X Simposio-Internacional de Estructurasde Acer

Uploaded by

Sergio Manuel Céh ChaleOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metal Building Roof Systems: X Simposio-Internacional de Estructurasde Acer

Uploaded by

Sergio Manuel Céh ChaleCopyright:

Available Formats

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

METAL BUILDING FRAMING

METAL BUILDING

ROOF SYSTEMS

Presented by

Thomas M. Murray, Ph.D., P.E.

Department of Civil and Environmental Engineering

Virginia Tech, Blacksburg, Virginia

thmurray@vt.edu

X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

06 March 2008

1 2

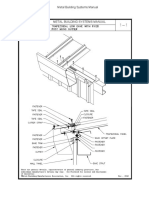

METAL BUILDING FRAMING ROOF PANELS

Sheet to sheet fastener

Purlin Sheet to structural fastener

Eave

strut

Z - purlin

Roof

panel

Girt

(a) Through-fastened panel

Wall Ridge

panel Anti-roll Clip fastener Standing seam clip

clip

Rigid Z - purlin

frame

3 4

(b) Standing seam panel

Presented by Thomas M. Murray, PhD1, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 1

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

ROOF PANELS STANDING SEAM CLIPS

Pan Type Panel Profile

Rib Type Panel Profile

(a) Fixed Clip (b) Sliding or Two-Piece Clip

5 6

ANTI-ROLL CLIPS LECTURE OUTLINE

• Structural Behavior of C - and Z - Purlins

• Specific AISI Design Methods for Purlins

• Continuous Purlin Design

• System Anchorage Requirements

7 8

Presented by Thomas M. Murray, PhD2, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 2

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

C – Purlins

STRUCTURAL BEHAVIOR

OF

C – and Z – PURLINS Building

rafter

An Overview

9 10

C – Purlins C – Purlins

Resultant Applied Force

Resultant Applied Force

Anchorage Force

+ Shear Center + Shear Center

e

Resulting Torque = Force x e

C-purlins tend to twist because applied force An anchorage system must be provided to

does not act through the shear center. resist this torque.

11 12

Presented by Thomas M. Murray, PhD3, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 3

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

Z - Purlins Z - Purlins

y

Resultant Applied Force

b

x2

Building

rafter Principal

θp

θp

x d

Axes

S.C. y2

13 14

Z - Purlins Z - Purlins

y

e

Torque is induced Unless restrained,

b

x2 because load does b

x2 the Z – Purlin

not pass through the deflects in the

search center. principal axes

θp

θp

θp

x x directions, e.g.

d

Location of resultant d

S.C.

y2 y2 x2 and y2 -directions.

force, e, is not easily

t

determined. t

15 16

Presented by Thomas M. Murray, PhD4, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 4

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

Z - Purlins Z - Purlins

The combined effects of W For constrained bending and

W

applied force eccentricity the load acting through the

and non-principal axes shear center, there is a force

bending cause W(Ixy/Ix) which must be

y y

resisted.

W(Ixy/Ix) (1) twisting of the Z-purlin W(Ixy/Ix)

x x

(2) need for an anchorage

system Attachment to roof panels

causes partially constrained

bending and a system effect.

17 18

Z - Purlins C- and Z – Purlins

W Ixy = product of inertia Industry Practice

= Σ Ixy + Σ Adxdy •Constrained Bending is Assumed for

Calculation of Stresses.

y Ix = moment of inertia

about x-axis • Stresses are Calculated for Bending

x About the X-axis using fb = Mx y / Ix

W(Ixy/Ix)

• AISI Specification Provisions are used to

Determine LRFD Strength or ASD

Capacity

19 20

Presented by Thomas M. Murray, PhD5, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 5

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

Definitions Definitions

Negative Moment

w

Moment which causes compression in M

the bottom flange of a purlin.

Positive Moment M

Moment which causes tension in the

bottom flange of a purlin. M(+) M(-)

Note: Moment diagram is drawn on the tension side.

21 22

AISI Specification and Commentary

SPECIFIC AISI DESIGN

METHODS FOR

C – and Z – PURLINS

A Brief Overview

23 24

Presented by Thomas M. Murray, PhD6, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 6

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

Combined LRFD and ASD Sheathing and Purlin Provisions

LRFD Design Flexural Strength:

• Through Fastened Panels

φbRn = 0.9 Rn

ASD Allowable Flexural Strength • Standing Seam Panels

Ra = Rn/Ω

Ω = Rn/1.67 • Gravity Loading

where Rn = Nominal Strength • Uplift Loading

25 26

Through Fastened Panels Through Fastened Panels

Gravity Loading

Sheet to sheet fastener

• Constrained Bending

Sheet to structural fastener

• AISI Provisions for

Yielding,

Z - purlin

Local Buckling, and

Lateral-Torsional Buckling.

27 28

Presented by Thomas M. Murray, PhD7, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 7

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

Through Fastened Panels Through Fastened Panels

Uplift Loading R-Factor Method

Uplift Loading

Nominal Strength:

• Constrained Bending

Mn = R Se Fy

• AISI Provisions for Yielding and

Local Buckling where Se = effective section modulus

• AISI R-Factor Method for flexural- Fy = material yield stress

torsional and nonlinear distortional

behavior. R = reduction factor

29 30

Through Fastened Panels Through Fastened Panels

Uplift Loading R-Factor Method Uplift Loading R-Factor Method

R = reduction factor TABLE C3.1.3-1

Simple Span C- or Z-Section R Values

= 0.6 for continuous C-purlins

Depth Range, in. (mm) Profile R

= 0.7 for continuous Z-purlins d < 6.5 (165) C or Z 0.70

6.5 (165) < d < 8.5 (216) C or Z 0.65

Values determined experimentally.

8.5 (216) < d < 11.5 (292) Z 0.50

8.5 (216) < d < 11.5 (292) C 0.40

31 32

Presented by Thomas M. Murray, PhD8, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 8

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

Through Fastened Panels Through Fastened Panels

Uplift Loading R-Factor Method Uplift Loading R-Factor Method

• R-values were determined from LRFD Design Strength:

tests of purlin systems without

intermediate lateral restraints. φbMn = 0.9 Mn = 0.9 RSeFy

• Reduction factors apply only to ASD Allowable Strength

systems within limits of testing Ma = Mn/Ω

Ω = RSeFy/1.67

matrix, which is included in the

Specification. where Se = effective section modulus

33 34

Through Fastened Panels Standing Seam Panels

Uplift Loading R-Factor Method Clip fastener Standing seam clip

Limitations: Does NOT apply to Z - purlin

(1) to a negative moment region between

an inflection point and a support

Applies Does not apply

(2) to cantilevers.

(a) Fixed clamp (b) Sliding or two piece clip

35 36

Presented by Thomas M. Murray, PhD9, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 9

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

Standing Seam Panels Standing Seam Panels

• Panel drape and clip friction provide

some lateral restraint.

• Degree of restraint depends on details of

standing seam system.

• Restraint varies from ~40% to near Sheathing

100% of through-fastened systems.

• Mathematical procedures are not available

for determining degree of restraint.

37 38

Standing Seam Panels Standing Seam Panels

AISI Permitted Design Procedures: AISI Permitted Design Procedures:

A. Design purlins as unbraced between B. AISI TS-8-02

lateral restraints using lateral-torsional Base Test Method for Purlins Supporting

and distortional buckling provisions. a Standing Seam Roof System

Method ignores clip friction and hugging The Base Test Method uses the

or drape effects of the standing seam panel. results from two purlin line, simple span

tests to determine the gravity loading

This approach is very conservative for positive moment strength or the uplift

systems without intermediate lateral loading negative moment strength of

restraints. 39 continuous systems. 40

Presented by Thomas M. Murray, PhD10, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 10

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

The Base Test Method The Base Test Method

AISI Base Test Procedure AISI Base Test Procedure

a) Conduct six single span, two purlin line A set of six tests is required for each

tests. combination of panel profile, purlin depth,

and clip type.

b) Three tests are to use the thinnest purlin

and three tests to use the thickest purlin in A procedure is available to significantly

the inventory. reduce the number of tests when several

clip heights or types are used by the

c) Develop the R-factor relationship from the

manufacturer.

test results.

The tests are conducted in a vacuum chamber.

41 42

The Base Test Method The Base Test Method

Standing seam

panels

Support

beam

Eave angle

Ridge angle

Purlins

Vacuum

Chamber

43 44

Presented by Thomas M. Murray, PhD11, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 11

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

The Base Test Method The Base Test Method

AISI Test Procedure Procedure AISI Procedure Procedure

100

The Reduction Factor for each test is 90

Moment reduction factor R (%)

80 Thinnest Thickest

M ts 70

Rt = ≤ 1.0

Mnt 60

50 R-Factor Relationship

where Mts = maximum moment from test 40

30

Mnt = fully constrained flexural 20

strength using measured 10

dimensions and yield stress 0

50 70 90 110 130 150 170 190 210 230 250

45 46

Nominal moment strength (K - in)

The Base Test Method The Base Test Method

AISI Procedure Procedure AISI Base Test Procedure

100

90 The R-Factor relationship is a straight line,

Moment reduction factor R (%)

80 one standard deviation below the mean of

70

the test results.

60

50

Possible Slope R t ,max − R t ,min

40 R=( )( M n − M nt ,min ) + R t ,min

30 M nt ,max - M nt ,min

20

10

0

50 70 90 110 130 150 170 190 210 230 250

47 48

Nominal moment strength (K - in)

Presented by Thomas M. Murray, PhD12, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 12

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

The Base Test Method The Base Test Method

AISI Base Test Procedure AISI Base Test Procedure

R t ,max − R t ,min The gravity loading positive moment region

R=( )(M n − M nt ,min ) + R t ,min or uplift loading negative moment region

M nt ,max - M nt ,min nominal strength is then

Rt,max and Rt,min = mean minus one standard deviation of

the three test results Mn =RSeFy

Mn = SeFy= for the section for which R is being For LRFD φ = 0.90

determined

For ASD Ω = 1.67

Mnt,min and Mnt,max = average tested flexural strengths

49 50

The Base Test Method The Base Test Method

Note: R can be greater for uplift loading. Example Results

100

90

Moment reduction factor R (%)

80

Sheathing Sheathing 70

60

50

(a) Gravity loading (b) U plift loading 40

30

Gravity loading tends to increase rotation. Uplift Nominal Strength Range

20

loading tends to decrease rotation. Also, for 10

uplift, torsional restraint is provided by the clip. 0

50 70 90 110 130 150 170 190 210 230 250

51 Nominal moment strength (K - in) 52

Presented by Thomas M. Murray, PhD13, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 13

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

Continuous Purlin Line Design

CONTINUOUS PURLIN ww

LINE DESIGN

M(+) M(-)

Lapped Purlins

B u ild in g

ra fte r

53 54

Continuous Purlin Line Design Continuous Purlin Line Design

Typical Design and Analysis Assumptions Typical Design and Analysis Assumptions

• Constrained Bending • An Inflection Point is a Brace Location

• Full Lateral Support Provided by • Use of Vertical Slotted Holes in Laps does

Through Fastened Panels not Effect Strength

• Partial Lateral Restraint Provided by • Critical Location for Checking Combined

Standing Seam Roof Panels Bending and Shear is Immediately

Outside the Lap

• Continuous Purlin Line is Considered

Prismatic or Non-Prismatic Are these assumptions valid?

55 56

Presented by Thomas M. Murray, PhD14, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 14

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

Continuous Purlin Line Design Continuous Purlin Line Design

• Constrained Bending • Full Lateral Support Provided by Through

Fastened Panels

Constrained bending implies that the

purlin will deflect only in the plane parallel to This assumption implies that there will be

the web. no lateral movement of the purlin.

Obviously, not true, but universally used. Again, obviously not true, but universally

accepted.

Even implied in the AISI Specification

Section C3.1.2 “Z-section bent about the

centroidal axis perpendicular to the web …” Sheathing

57 58

Continuous Purlin Line Design Continuous Purlin Line Design

• Partial Lateral Support Provided by Standing • Partial Lateral Support Provided by

Seam Panels Standing Seam Panels Cont.

This assumption implies that there will be Use of lateral-torsional/distortional

some lateral movement of the purlin. buckling equations is very conservative for roof

systems without intermediate braces.

Lateral restraint comes from clip friction

or panel drape/hugging. R-values are 0.12 - 0.20 from L-T-B

analyses, whereas the Base Test Method gives

AISI Specification allows use of lateral-

R-values of 0.40 - 0.95.

torsional/distorsional buckling equations or the

Base Test Method

59 60

Presented by Thomas M. Murray, PhD15, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 15

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

Continuous Purlin Line Design Continuous Purlin Line Design

• Continuous Purlin Line is Considered • Continuous Purlin Line is Considered

Prismatic or Non-Prismatic Prismatic or Non-Prismatic Cont.

One of two assumptions are commonly For Gravity Loading:

used for design:

The Prismatic assumption results in

1) The purlin line is prismatic, that is, a larger positive moments and smaller negative

constant moment of inertia is assumed. moments.

w

2) The purlin line is non-prismatic, that

is, the moment of inertia within the lap is taken

as the sum of the moments of inertia of the two

61 62

purlins. M(+) M(-)

Continuous Purlin Line Design Continuous Purlin Line Design

• Continuous Purlin Line is Considered • Continuous Purlin Line is Considered

Prismatic or Non-Prismatic Cont. Prismatic or Non-Prismatic Cont.

For Gravity Loading: For Gravity Loading:

The Non- Prismatic assumption results in The Prismatic assumption is more

larger negative moments and smaller positive conservative if the positive moment region

moments. controls

w

The Non-Prismatic assumption is more

conservative if the negative moment region

controls

63 64

M(+) M(-)

Presented by Thomas M. Murray, PhD16, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 16

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

Continuous Purlin Line Design Continuous Purlin Line Design

• Continuous Purlin Line is Considered • Continuous Purlin Line is Considered

Prismatic or Non-Prismatic Cont. Prismatic or Non-Prismatic Cont.

For Uplift Loading: Two studies have shown that the Non-Prismatic

assumption is more correct.

The reverse of gravity loading occurs.

Study 1:

Fact: Purlins are not continuously connected in

the lap and full continuity is not achieved. 24 Through-Fastened Tests

Therefore, which assumption is correct??????? (3 two-span and 21 three-span; 10 organizations)

Analyzed using the non-prismatic assumption.

65 66

Continuous Purlin Line Design Continuous Purlin Line Design

• Continuous Purlin Line is Considered • Continuous Purlin Line is Considered

Prismatic or Non-Prismatic Cont. Prismatic or Non-Prismatic Cont.

R = experimental / predicted Conclusion from Study 1:

Combined Bending and Shear Failures Prismatic assumption decreases calculated

Avg. R = 0.93 Range 0.81 – 1.06 moment for combined bending & shear, thus

results become more unconservative.

Positive Moment Failures

R = 0.93 and 0.94 ⇓ R = experimental/predicted ⇑)

(⇓

Note: R < 1.0 is unconservative For positive moment failures, the R-values

67 become closer to 1.0. 68

Presented by Thomas M. Murray, PhD17, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 17

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

Continuous Purlin Line Design Continuous Purlin Line Design

• Continuous Purlin Line is Considered • Continuous Purlin Line is Considered

Prismatic or Non-Prismatic Cont. Prismatic or Non-Prismatic Cont.

I. P.

Study 2: 6" 6"

Inflection Point

6" 6"

7 Two- and Three-Span Tests FAR PURLIN

3 Through-Fastened 4 Standing Seam 6 7 8 9 10

STRAIN GAGE

POSITIONS

STRAIN GAGE

1 2 3 4 5

Analyzed using the non-prismatic assumption. NEAR PURLIN

POSITIONS

Strain gages installed on the tension flange at and 6" 6"

INTERIOR SUPPORT

6" 6" EXTERIOR SUPPORT

near the theoretical inflection point of an exterior

TEST BAY

span. 69 70

Continuous Purlin Line Design Continuous Purlin Line Design

Theoretical inflection point

300

6 7 8 9 10 • Continuous Purlin Line is Considered

250

Position Prismatic or Non-Prismatic Cont.

200

Load (lb/ft)

150 CONCLUSION

100

Continuous purlin lines should be analyzed

50 using the non-prismatic assumption.

0

-300 -200 -100 0 100 200 300 400 500

Strain (µε)

71 72

Presented by Thomas M. Murray, PhD18, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 18

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

Continuous Purlin Line Design Continuous Purlin Line Design

• An Inflection Point is a Brace Point Location • An Inflection Point is a Brace Location

Traditionally considered a brace point.

AISC says not so for H-Shapes (both lateral

and torsional braces may be required at an I.P.)

2007 AISI Specification is silent but uses Cb

from AISC Specification which follows AISC.

I.P. Lb End of Lap Center for Cold-Formed Steel Structures,

Bulletin, Vol. 1, No. 2, August 1992, says I.P. is a

73 brace point and Cb =1.75. 74

Continuous Purlin Line Design Continuous Purlin Line Design

• An Inflection Point is a Brace Location • An Inflection Point is a Brace Location

AISI Design Guide says I.P. is not a brace Purlin movement at an I.P. was measured at

point. Design examples assume a cantilever from Virginia Tech:

the end of the lap to the I.P. with Cb= 1.0.

Three span setup with

instrumentation in I.P.

exterior bay.

Which is correct???????

75 76

Presented by Thomas M. Murray, PhD19, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 19

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

Continuous Purlin Line Design Continuous Purlin Line Design

•An Inflection Point is a Brace Location •An Inflection Point is a Brace Location

350

Through Fastened Panel 300

250

Potentiometers

Load (plf)

200

150

100

50

Positive Spread Outward

0

-0.100 -0.050 0.000 0.050

Spread (in.)

77 78

Continuous Purlin Line Design Continuous Purlin Line Design

• An Inflection Point is a Brace Location • An Inflection Point is a Brace Location

Results from Testing at VT: Strength Comparisons of 7 test results

a) Lateral movement occurs at an I.P. assuming:

b) I.P. movement is much less than other a) I.P. is not a brace point.

locations. b) I.P. is a brace point.

c) Movement on both sides in same direction. c) Fully braced between end of lap

d) Double curvature did not occur. and I.P.

e) C-purlins move more than Z-purlins. 79 80

Presented by Thomas M. Murray, PhD20, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 20

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

Continuous Purlin Line Design Continuous Purlin Line Design

• An Inflection Point is a Brace Location • An Inflection Point is a Brace Location

a) I.P. is not a brace point. Can fully braced between end of lap and I.P. be

justified within the AISI Specification?

Avg. Exp./Predicted = 1.056 Conservative

Probably “yes”, since Specification is silent on

(b) I.P. is a brace point.

the issue.

Avg. Exp./Predicted = 1.037 Conservative

Note: Section 3.1.3 Beams Having One Flange

(c)Fully braced between end of lap and I.P. Through-Fastened to Deck or Sheathing does

not apply to “a continuous beam for the

Avg. Exp./Predicted = 1.033 Conservative

region between inflection points adjacent to a

81 82

support”.

Continuous Purlin Line Design Continuous Purlin Line Design

• Use of Vertical Slotted Holes in Laps does • Use of Vertical Slotted Holes in Laps does

not Effect Strength not Effect Strength

Vertical slotted holes in purlin webs at the ends The data from over 50 multiple span

of lap splices are used to facilitate erection. continuous purlin line test results does not

show any effect.

Vertical slotted holes are permitted in

Specification with some limitations.

83 84

Presented by Thomas M. Murray, PhD21, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 21

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

Continuous Purlin Line Design Continuous Purlin Line Design

• Critical Location for Checking Combined • Critical Location for Checking Combined

Bending and Shear is Immediately Bending and Shear is Immediately

Outside the Lap Outside the Lap

Where should combined bending and shear be

checked in a lapped purlin line?

Within the lap?

At the bolt line?

Outside the lap?

85 86

System Anchorage

SYSTEM ANCHORAGE • Z - Purlins

PL

REQUIREMENTS

• Roof deck

PL

provides full or

partial lateral

restraint.

• An anchorage device removes

force, PL, from the diaphragm.

87 88

Presented by Thomas M. Murray, PhD22, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 22

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

System Anchorage System Anchorage

Gravity Loading on Z-Purlins Z-Purlins

y yp W W

y

w

θp Initial

x position

x

xp

θ (a) Axes (b) Unrestrained movement

89 90

System Anchorage Providing Anchorage

Z-Purlins • Lateral Restraint at Discrete Points

Wcosθ

Wsinθ

PL

θ

Lateral Discrete Braces Sheathing Supports Purlin

Remove Force from System

(c) Movement because of large (d) Panel and anchorage

downslope component restraints

91 92

Presented by Thomas M. Murray, PhD23, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 23

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

Providing Anchorage Providing Anchorage

• External Restraints • Bracing Details that are not Recommended

– Must Anchor Interior Restraints Externally

Str

ace

a

Br

pB

ap

rac

Str

e

C10x15.3

Horizontal

93 94

System Effect 2007 AISI Provisions

• A System of Purlins has Inherent Stiffness 2007 AISI Specification

• Which is Called the “System Effect”

”

• The System Effect Complicates Analysis of Roof D6 Metal Roof and Wall Systems

Systems D6.3 Roof System Bracing and Anchorage

• D6.3.1 Anchorage of Bracing

• D6.3.2 Alternate Lateral and Stability Bracing

– Torsional Braces

95 96

Presented by Thomas M. Murray, PhD24, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 24

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

Experimental Verification AISI Analysis Methods

Testing Conducted at Virginia Tech

• Stiffness Models

– Shell Finite Element Model

– Frame Element Stiffness Model

• Computational Solutions

– Component Stiffness Method

– Matrix Solution Method

– Manual Specification Method

– Simplified Solution Method

97 98

AISI Analysis Methods AISI Manual Calculation Method

Stiffness Models Four Computational Steps Required:

– Determine Stiffness of the System

Shell Finite Element Model – Determine Force Introduced into System by

Each Purlin, Pi

– Distribute Forces According to Stiffness

– Evaluate Anchor Effectiveness

Frame Element

Model

99 100

Presented by Thomas M. Murray, PhD25, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 25

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

AISI Manual Calculation Method AISI Manual Calculation Method

• Stiffness Model used to determine anchorage Step 1 – Stiffness of the System

forces

– Anchor Stiffness, Ka

– Inherent Stiffness of System

• Connection of Purlin to Frame Line

• Connection of Purlin to Sheathing

∆

∆

C5 ELt 2

K sys = ⋅ Np

Pi Pi 1000 d2

Na

K total (i ) = ∑ (K

j =1

eff i , j )+ K sys

101 102

AISI Manual Calculation Method AISI Manual Calculation Method

Step 2 - Force Introduced to System, Pi Step 3 – Distribute Forces According to

– Combined Effects Stiffness

• Down Slope Force – Portion of Force Absorbed by System

• Eccentrically Applied Load – Forces Distributed to Anchors

(normal component)

Purlin “i”

• Load Oblique to Principal Axes Inverse

Anchor “j”

C 2 I xy L (m + 0.25 b )t −1 Yields

wLcosθ Pi = C1 ⋅ W pi ⋅ ⋅ + C3 ⋅ α ⋅ cos θ − C 4 ⋅ sin θ

d pi, j

e

1 Stiffness

K eff (i , j ) =

1000 I x d d2

+

wLsinθ Pi K a C 6 ⋅ LAp E

x2

d

y

2

Anchor Panel

103 Flexibility Flexibility 104

Presented by Thomas M. Murray, PhD26, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 26

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

AISI Manual Calculation Method AISI Simplified Method

Step 4 – Evaluate Anchor Effectiveness • Simplified Solution Procedure

– Stiffness of System for Stability – Simplified Form of Main Specification

• Stiffness (displacement) at Line of Anchorage Procedure

• Diaphragm Displacement Between Lines of – Conservatively Neglects System Effect

Anchorage

– Conservative Stiffness Check

Np

– Assumes Forces Evenly Distributed

20 ⋅ ∑P i

1 i=1

K req = ≤ K total

φ d

105 106

AISI Simplified Method AISI Simplified Method

• Simplified Solution Procedure • Simplified Solution Procedure

– Find Anchorage Force – Check Minimum Stiffness

– Compare to Ka

C 2 I xy L (m + 0.25b)t W

PL − s = C1 ⋅ ⋅ + C3 ⋅ cosθ − C 4 ⋅ sinθ s

1000 I x d d2 N a 20 ⋅ C6 ⋅ LA pEPL − s

K a _ req=

φC6 ⋅ LA pEd − 20PL − s S(Np − Na )

107 108

Presented by Thomas M. Murray, PhD27, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 27

METAL BUILDING ROOF SYSTEMS X SIMPOSIO-INTERNACIONAL DE

ESTRUCTURASDE ACER

New AISI Design Guide

Table of Contents

• Introduction

• Design Methods for Purlins

• Continuous Purlin Line Design

• System Anchorage Requirements Thank You!!

• References

To be Published by AISI

Late 2009.

109 110

Presented by Thomas M. Murray, PhD28, P.E.

Virginia Tech, Blacksburg, VA 06 March 2009 28

You might also like

- Model Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandModel Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- 8 Braces and Ties (Compatibility Mode)Document16 pages8 Braces and Ties (Compatibility Mode)susan870% (1)

- MBMA What's New in The AISI Spec 2009Document153 pagesMBMA What's New in The AISI Spec 2009LeoNo ratings yet

- Purlin Design To AISI LRFD Using Rational Buckling Analysis 09007dcc809cfddfDocument14 pagesPurlin Design To AISI LRFD Using Rational Buckling Analysis 09007dcc809cfddfEmrE GöktuĞ100% (1)

- Hollow Sections ConnectionsDocument4 pagesHollow Sections Connectionsאחמד סלאח כאמלNo ratings yet

- 1983 (Q2) - Design of Headed Anchor BoltsDocument13 pages1983 (Q2) - Design of Headed Anchor BoltsCesar RjszvlNo ratings yet

- Sherman - Extended Shear TabsDocument148 pagesSherman - Extended Shear TabsRohan KarandeNo ratings yet

- Design of Steel Beams To Aisc LRFD - 02Document52 pagesDesign of Steel Beams To Aisc LRFD - 02ArchIEF Form (JASA ARSITEK)No ratings yet

- Risa Base Plate ExampleDocument2 pagesRisa Base Plate ExampleFandy SipataNo ratings yet

- Steel Detailing Standard - Fabrication Drawing BasicsDocument13 pagesSteel Detailing Standard - Fabrication Drawing BasicsShrini TSNo ratings yet

- Aisc - StudentDocument148 pagesAisc - StudentRamiro Flores MoraNo ratings yet

- AISC DESIGN GUIDE eXCERPTDocument3 pagesAISC DESIGN GUIDE eXCERPTMike2322No ratings yet

- S16 16 Updates AMDocument141 pagesS16 16 Updates AMMG Xie0% (1)

- Lateral Bracing of Beams Provided by Standing Seam Roof System Concepts and Case StudyDocument11 pagesLateral Bracing of Beams Provided by Standing Seam Roof System Concepts and Case Studyjackcan501No ratings yet

- AISI S100-07 Appendix 1 With CommentaryDocument32 pagesAISI S100-07 Appendix 1 With CommentaryPrima AdhiyasaNo ratings yet

- Behavior and Design of Single AngleDocument18 pagesBehavior and Design of Single AngleandyhrNo ratings yet

- Roof Details Section 1Document27 pagesRoof Details Section 1parthi banNo ratings yet

- Petra PDFDocument32 pagesPetra PDFtopnoch5454No ratings yet

- Stability of SpeedCore Walls Under Fire Loading Summary of Numerical AnalysesDocument13 pagesStability of SpeedCore Walls Under Fire Loading Summary of Numerical Analysesjackcan501No ratings yet

- Night School 23 Session 3Document50 pagesNight School 23 Session 3Luis CortesNo ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 7Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 7Anonymous 0x2pwMCWgjNo ratings yet

- Licence: Licensee: DateDocument5 pagesLicence: Licensee: DateAntonio Moralejo GilNo ratings yet

- Metal Building Systems: Pdhonline Course S120 (1 PDH)Document11 pagesMetal Building Systems: Pdhonline Course S120 (1 PDH)SunilBhargavSanathiNo ratings yet

- New Design Rules For Plated Structures in Eurocode 3Document33 pagesNew Design Rules For Plated Structures in Eurocode 3Tran Khanh LeNo ratings yet

- NBC 2010 - Commentaries - Section IDocument24 pagesNBC 2010 - Commentaries - Section IRick HenbidNo ratings yet

- HDG Datasheet 4b A Guide To Hot Dip Galvanizing To Standard BS en ISO 1461 Low Res LDocument2 pagesHDG Datasheet 4b A Guide To Hot Dip Galvanizing To Standard BS en ISO 1461 Low Res LMehman NasibovNo ratings yet

- CFSEI Shear Wall Design GuideDocument45 pagesCFSEI Shear Wall Design GuideDaniel AielloNo ratings yet

- Metsec Design GuideDocument86 pagesMetsec Design GuideRm1262No ratings yet

- Finite-Element Investigation of Cold-Formed Steel Portal Frames in FireDocument17 pagesFinite-Element Investigation of Cold-Formed Steel Portal Frames in FireMohamedNo ratings yet

- Cold Formed Steel Design Design Standards Part 1 PDFDocument85 pagesCold Formed Steel Design Design Standards Part 1 PDFLukusa BadimuenaNo ratings yet

- AD 330 - Vibration of Steel StaircasesDocument2 pagesAD 330 - Vibration of Steel Staircasessymon ellimacNo ratings yet

- Industrial Structures - Scia7014Document100 pagesIndustrial Structures - Scia7014charvi shinyNo ratings yet

- CFSEI Shear Wall Design GuideDocument23 pagesCFSEI Shear Wall Design GuideJaypee Chang100% (1)

- AISI Design Guide D111-09 Design Guide For Cold-Formed Steel Purlin Roof Framing Systems (Canvas)Document203 pagesAISI Design Guide D111-09 Design Guide For Cold-Formed Steel Purlin Roof Framing Systems (Canvas)Nguyen Co ThachNo ratings yet

- Steelwise PDFDocument3 pagesSteelwise PDFYan Naung KoNo ratings yet

- AISC Design ChecksDocument22 pagesAISC Design ChecksYogeshUndeNo ratings yet

- ASCE 7-16 Practical Seismic DesignDocument21 pagesASCE 7-16 Practical Seismic Designcloudbooks007No ratings yet

- Struc Steel Erection AidsDocument3 pagesStruc Steel Erection AidsSridhar MaharajaNo ratings yet

- Application of AISC Design Provisions For Tapered Members PDFDocument13 pagesApplication of AISC Design Provisions For Tapered Members PDFclam2014No ratings yet

- Bolt To Hss (Long)Document1 pageBolt To Hss (Long)ronyNo ratings yet

- Bracing Connections To Rectangular Hss Columns: N. Kosteski and J.A. PackerDocument10 pagesBracing Connections To Rectangular Hss Columns: N. Kosteski and J.A. PackerJordy VertizNo ratings yet

- Review of AISI Design Guide For Cold-Formed Steel Purlin Roof Framing SystemsDocument17 pagesReview of AISI Design Guide For Cold-Formed Steel Purlin Roof Framing SystemsapirakqNo ratings yet

- Haunch EquationsDocument8 pagesHaunch EquationsJacques Ontal0% (1)

- 27 Stainless SteelDocument159 pages27 Stainless SteelnvnagarajuNo ratings yet

- DCB 68 Sliding Hinge JointDocument34 pagesDCB 68 Sliding Hinge JointczapatachueNo ratings yet

- Diaphragm Design Manual: FOURTH EDITION - First PrintingDocument1 pageDiaphragm Design Manual: FOURTH EDITION - First Printingaandueza_1No ratings yet

- STEEL HSS Beam Load Table Bro PDFDocument116 pagesSTEEL HSS Beam Load Table Bro PDFtyger089No ratings yet

- Base Plate DesignDocument15 pagesBase Plate DesignGurkan100% (1)

- Seismic Behavior & Design of Gusset PlatesDocument41 pagesSeismic Behavior & Design of Gusset PlateswilfredNo ratings yet

- Shear Peeling of Steel Plates Adhesively Bonded To The Sides of Reinforced Concrete BeamsDocument11 pagesShear Peeling of Steel Plates Adhesively Bonded To The Sides of Reinforced Concrete BeamsAbualtayef KhalilNo ratings yet

- TerritoryDocument4 pagesTerritoryShell DNo ratings yet

- Minimum Cost and Weight Design of Fuselage Frames Part A: Design Constraints and Manufacturing Process CharacteristicsDocument8 pagesMinimum Cost and Weight Design of Fuselage Frames Part A: Design Constraints and Manufacturing Process CharacteristicsArmando VasquezNo ratings yet

- Design of Beams - PPT SONAMDocument111 pagesDesign of Beams - PPT SONAMLovely Mae Cruza GawinganNo ratings yet

- TAS-COR-105 Corium Details Light Gauge Steel FramingDocument15 pagesTAS-COR-105 Corium Details Light Gauge Steel FramingVlad CondreaNo ratings yet

- 2 PPT 1 Design ConceptsDocument33 pages2 PPT 1 Design ConceptsLuis Hernán Guillén CardonaNo ratings yet

- TS of HardwareDocument9 pagesTS of HardwareabhishekNo ratings yet

- Influence of Optimum Number of Sag-Rods and Sag-Rod Spacing On Deformations of Zee ProfileDocument7 pagesInfluence of Optimum Number of Sag-Rods and Sag-Rod Spacing On Deformations of Zee ProfileIJRASETPublicationsNo ratings yet

- Quality Systems Quality Systems: One SourceDocument4 pagesQuality Systems Quality Systems: One SourceHamzah Al-HashemiNo ratings yet

- K StageDocument8 pagesK Stagedeco lombNo ratings yet

- AISC Design Guides: A Resource For Practicing EngineersDocument40 pagesAISC Design Guides: A Resource For Practicing EngineersSergio Manuel Céh ChaleNo ratings yet

- Evolution of Design Codes For Steel Structures StructuresDocument67 pagesEvolution of Design Codes For Steel Structures StructuresSergio Manuel Céh ChaleNo ratings yet

- Gaining A 70% Market Share: The UK Experience in Structural SteelworkDocument55 pagesGaining A 70% Market Share: The UK Experience in Structural SteelworkSergio Manuel Céh ChaleNo ratings yet

- Teklastructures PDFDocument42 pagesTeklastructures PDFSergio Manuel Céh Chale100% (2)

- SAP Etabs Course 360Document0 pagesSAP Etabs Course 360Seifeldin Ali Marzouk83% (6)

- There Are Two Ways of Describing An EarthquakeDocument2 pagesThere Are Two Ways of Describing An EarthquakeJorren Faith C. BalbaNo ratings yet

- Me139 E1 ArroyoDocument13 pagesMe139 E1 ArroyojamesNo ratings yet

- API Calcs Rev1 Version 2Document107 pagesAPI Calcs Rev1 Version 2JithuJohnNo ratings yet

- Pump NotesDocument10 pagesPump NotesSasmita SahooNo ratings yet

- Aerodynamics FormulasDocument9 pagesAerodynamics Formulasmargarette reyesNo ratings yet

- Formal Lab Report 2Document4 pagesFormal Lab Report 2Bren SisonNo ratings yet

- Electromagnetic Fields (ELTE 207) : Faculty of EngineeringDocument12 pagesElectromagnetic Fields (ELTE 207) : Faculty of EngineeringRyiadh Al-AreibiNo ratings yet

- Design Project AuditoriumDocument66 pagesDesign Project AuditoriumganapathyNo ratings yet

- Physics AS P1Document16 pagesPhysics AS P1Umaima ZainabNo ratings yet

- Air Cooler - DesignDocument7 pagesAir Cooler - Designkarthipetro100% (1)

- Lecture - 3-The Second Law of Thermodynamics and EntropyDocument16 pagesLecture - 3-The Second Law of Thermodynamics and EntropyahmedNo ratings yet

- Chai, Lu PDFDocument80 pagesChai, Lu PDFparvejNo ratings yet

- P5643 Projectile Launcher: Mechatronics Term ProjectDocument19 pagesP5643 Projectile Launcher: Mechatronics Term ProjectRenz MaguilaNo ratings yet

- Lab Manual ENTC376 Fall08Document69 pagesLab Manual ENTC376 Fall08Aamir ShafiqueNo ratings yet

- Method of Calculating Plate and Shell ReinforcementDocument5 pagesMethod of Calculating Plate and Shell ReinforcementeloyrodoNo ratings yet

- Etd 137Document254 pagesEtd 137Aneez KoyattyNo ratings yet

- Numerical and Experimental Approach For Roll Grinding ProcessDocument7 pagesNumerical and Experimental Approach For Roll Grinding ProcessGinanjar Surya RamadhanNo ratings yet

- Orbit v27n207 SlowrollDocument13 pagesOrbit v27n207 SlowrollAyman ElsebaiiNo ratings yet

- Edward Witten Ponders The Nature of RealityDocument17 pagesEdward Witten Ponders The Nature of Realityeldelmoño luciNo ratings yet

- Spreader Beam Report-R0Document9 pagesSpreader Beam Report-R0Tech DesignNo ratings yet

- JEE - Physics - Waves and SoundDocument16 pagesJEE - Physics - Waves and SoundSanjana KumariNo ratings yet

- 3 (Advances in Quantum Chemistry 3) Per-Olov Löwdin (Eds.) - Academic Press, Elsevier (1967)Document396 pages3 (Advances in Quantum Chemistry 3) Per-Olov Löwdin (Eds.) - Academic Press, Elsevier (1967)Benancio Dorantess100% (1)

- Purlin Design For Roof TrussDocument48 pagesPurlin Design For Roof TrusseseemNo ratings yet

- Compilation Physics TestbanksDocument21 pagesCompilation Physics Testbankschristine geronimoNo ratings yet

- Cohesion - Geotechdata - InfoDocument2 pagesCohesion - Geotechdata - InfoSarath Chandran S100% (1)

- Chemistry Modules 4 9Document10 pagesChemistry Modules 4 9JasminNo ratings yet

- Physical Science SyllabusDocument4 pagesPhysical Science SyllabusJamal MorelliNo ratings yet

- Shape Functions Solid 186Document12 pagesShape Functions Solid 186Apurva MantriNo ratings yet

- Cambridge International AS & A Level: PHYSICS 9702/21Document16 pagesCambridge International AS & A Level: PHYSICS 9702/21aliexpress0230170No ratings yet