Professional Documents

Culture Documents

EXX-EME-STD-0008 - Wear Liners For Plate Work and Chutes

Uploaded by

jonodo89Original Title

Copyright

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

EXX-EME-STD-0008 - Wear Liners For Plate Work and Chutes

Uploaded by

jonodo89Copyright:

••

exxaro

POWERING POSSIBILITY

MECHANICAL ENGINEERING STANDARD

EXX-EME-STD-0008

MECHANICAL ENGINEERING STANDARD

FOR

WEAR LINERS FOR PLATE WORK AND CHUTES

EXXARO

EXX-EME-STD-0008

COMPILED BY:

TITLE SIGNATURE DATE

MARIUS SMIT 18/11/2015

ACCEPTED AND APPROVED BY:

TITLE DATE

MANAGER MECHANICAL ENGINEERING

GROUP MANAGER ENGINEERING

Doc ID: EWPM-8453-222 Version: 1.1 Date: 2015-11-18 Page: 1 of22

••

exxaro

POWERING POSSIBILITY

MECHANICAL ENGINEERING STANDARD

EXX-EME-STD-0008 ~~II II

E p T D

DOCUMENT APPROVALS

ROLE NAME SIGNA#~ DATE

#

PRINCIPAL MECHANICAL

ENGINEER

HENNIE FOURIE

4/t;J/6

I~

DOCUMENT CONTROL

DOCUMENT INFORMATION

INFORMATION

Document Owner MARIUS SMIT

Publish Date 2015/11/18

DOCUMENT HISTORY

VERSION DATE CHANGES

Transfer from GMEP template to Exxaro template, modify table 1

1 2015/11/18

(previously table 8.2.1) and add paragraph 8.5 Lip liners.

Doc ID: EWPM-8453-222 Version: 1.1 Date: 2015-11-18 Page: 2 of22

MECHANICAL ENGINEERING STANDARD

EXX-EME-STD-0008 EPM/ENGINEERING-ENG-STD

VERSION DATE CHANGES

ABBREVIATIONS AND ACRONYMS

The following acronyms are applicable to this document: For more details, please consult the

Glossary.

ACRONYM DESCRIPTION

CSK Countersunk – In industry, countersunk nib bolts are sometimes

referred to as CSK nib bolts.

DEFINITIONS

The definitions listed below apply to this document. For more details, please consult the

Glossary.

TERM DEFINITION

Doc ID: EWPM-8453-222 Version: 1.1 Date: 2015-11-18 Page: 3 of 22

MECHANICAL ENGINEERING STANDARD

EXX-EME-STD-0008 EPM/ENGINEERING-ENG-STD

REFERENCES

The following documents are either Applicable Documents - applicable to the extent

specified herein and thus forming part of this document. The applicability will generally relate

to the Project in terms of policy, procedures, standards, qualification, etc.; or Reference

Documents - where the information concerned has been fully extracted from the reference

document and added to this document, or where the reference document contains

information relevant to this document, or for information only.

DOCUMENT NAME RELEVANCE

ISO 8501-1: Preparation of steel substrates before application of paints and related Applicable

products - Visual assessment of surface cleanliness

SANS1143: Countersunk and Mushroom Head Bolts Applicable

ESP-XX-0016: Engineering specification for corrosion control Applicable

Mine Health and Safety Act no. 29 of 1996 Applicable

Occupational Health and Safety Act no. 83 of 1993 Applicable

DOCUMENT DISTRIBUTION

This document is available for internal and external use at Exxaro Resources Technology

and related projects.

Doc ID: EWPM-8453-222 Version: 1.1 Date: 2015-11-18 Page: 4 of 22

MECHANICAL ENGINEERING STANDARD

EXX-EME-STD-0008 EPM/ENGINEERING-ENG-STD

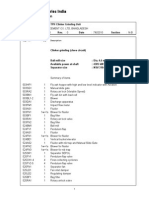

TABLE OF CONTENTS

1. PURPOSE ......................................................................................................................................7

2. SCOPE DEFINITION .....................................................................................................................7

3. BATTERY LIMITS..........................................................................................................................7

4. EXCLUSIONS ................................................................................................................................7

5. DEFINITIONS AND ABREVIATIONS ...........................................................................................7

6. RESPONSIBILITIES ......................................................................................................................7

7. REQUIREMENTS FOR WEAR LINING ........................................................................................8

7.1 GENERAL ............................................................................................................................8

7.2 WEAR LINING REQUIREMENTS FOR SPECIFIC APPLICATIONS .................................9

7.3 CERAMIC WEAR LINERS .................................................................................................10

7.3.1 General .................................................................................................................10

7.3.2 Standard ceramic tiles...........................................................................................11

7.3.3 Engineered tiles ....................................................................................................11

7.3.4 Liner thickness ......................................................................................................12

7.3.5 Surface preparation for ceramic tiling ...................................................................12

7.3.6 Ceramic tile layout .................................................................................................12

7.3.6.1 General .................................................................................................12

7.3.6.2 Protection of epoxy adhesives .............................................................12

7.3.7 Permanent marking of ceramic lined plate work ...................................................14

7.4 REQUIREMENTS FOR STEEL LINERS ...........................................................................15

7.4.1 General .................................................................................................................15

7.4.2 Steel lining layout ..................................................................................................16

7.4.3 Steel lining fixing requirements .............................................................................18

7.4.4 Surface preparation for steel liners .......................................................................20

7.4.5 Steel liners in dead box areas ...............................................................................20

7.5 Lip liners .............................................................................................................................20

8. MANUFACTURING REQUIREMENTS .......................................................................................20

9. PACKING, DELIVERY, OFF LOADING AND STORAGE ON SITE ..........................................20

10. ASSEMBLY, INSTALLATION, ERECTION AND CONSTRUCTION REQUIREMENTS ...........21

10.1 CERAMIC TILES................................................................................................................21

10.1.1 Attachment of tiles.................................................................................................21

10.1.2 Erection and installation of ceramic lined components .........................................21

10.2 INSTALLATION OF STEEL LINERS .................................................................................21

11. COMMISSIONING REQUIREMENTS .........................................................................................21

12. PROJECT DOCUMENTATION ...................................................................................................22

12.1 DRAWINGS .......................................................................................................................22

Doc ID: EWPM-8453-222 Version: 1.1 Date: 2015-11-18 Page: 5 of 22

MECHANICAL ENGINEERING STANDARD

EXX-EME-STD-0008 EPM/ENGINEERING-ENG-STD

12.2 DATA SCHEDULES ..........................................................................................................22

FIGURES

Figure 1: Chamfering of tiles for welding. ................................................................................................ 9

Figure 2: Tile staggering ........................................................................................................................ 13

Figure 3: Corner tiles ............................................................................................................................. 13

Figure 4: Bending stresses .................................................................................................................... 14

Figure 5: Chute stiffeners ...................................................................................................................... 14

Figure 6. Staggered Liner Arrangement ............................................................................................... 16

Figure 7. Correct and Incorrect Placement of Liners in Corners .......................................................... 17

Figure 8. Steel Liner Countersunk Hole Detail ..................................................................................... 19

TABLES

Table 1: Mass of Ceramic tiles ................................................................................................................ 8

Table 2. Lining requirement for plate work components in different applications ................................ 10

Doc ID: EWPM-8453-222 Version: 1.1 Date: 2015-11-18 Page: 6 of 22

MECHANICAL ENGINEERING STANDARD

EXX-EME-STD-0008 EPM/ENGINEERING-ENG-STD

1. PURPOSE

This Exxaro Wear Protection for Plate Work and Chutes (number EXX-EME-STD-

0008) states the standard requirements for metallic and ceramic wear lining for

plate work and chutes in abrasive environments. The life cycle phases covered

are from design up to commissioning.

2. SCOPE DEFINITION

This specification details the requirements for metallic and ceramic wear lining for

plate work and chutes in abrasive environments. The specification covers chutes,

bins and underpans as well as plate work surfaces of vibrating feeders and screen

underpans requiring wear lining. It includes the specification, design and

installation of wear lining. It also informs designers of plate work and chutes of the

lining requirements to be provided for in the design phase.

3. BATTERY LIMITS

This specification is applicable to all wear areas that will be lined with steel or

ceramic liners, excluding pipe work.

4. EXCLUSIONS

The specification is limited to wear lining and excludes the specification, structural

and functional design requirements of the components to be lined.

5. DEFINITIONS AND ABREVIATIONS

Ceramic tiles refer to high alumina ceramic tiles containing not less than 92%

Al2O3 with a minimum density of 3.52g/cm3 (3520 kg/m3).

6. RESPONSIBILITIES

The Exxaro Principal Mechanical Engineer is responsible for this standard.

Doc ID: EWPM-8453-222 Version: 1.1 Date: 2015-11-18 Page: 7 of 22

MECHANICAL ENGINEERING STANDARD

EXX-EME-STD-0008 EPM/ENGINEERING-ENG-STD

7. REQUIREMENTS FOR WEAR LINING

7.1 GENERAL

The type of lining specified dictates the design of the equipment being lined. The

designer must make provision for the thickness of the lining when specifying inside

dimensions of components to be lined.

The mass of the lining material and the stiffness requirement for lining shall be

taken into account by the designer when designing components requiring lining.

The designer shall ensure that the lined components are of suitable section sizes

to be installed and handled safely during construction and maintenance.

Liners shall be designed taking into consideration instrumentation positions and

requirements.

Lined items shall be designed to ensure safe maintenance access for replacement

of liners or panels.

The typical mass of ceramic tiles is shown inTable 1.

Table 1: Mass of Ceramic tiles

Length Width Thickness Mass/area

covered

[mm] [mm] [mm]

[kg/m2]

150 100 6 24

150 100 12 48

150 100 20 75

150 100 25 96

150 100 50 192

The thickness, type of lining material and area to be lined shall be indicated on

detail drawings.

Welding shall be done on the outside of the component and not on the side that

must be lined. Where internal welding is required, it shall be grinded flush to

prevent interference with the installation of tiles.

Doc ID: EWPM-8453-222 Version: 1.1 Date: 2015-11-18 Page: 8 of 22

MECHANICAL ENGINEERING STANDARD

EXX-EME-STD-0008 EPM/ENGINEERING-ENG-STD

Where internal welds cannot be removed to ensure the structural integrity of the

component, liners shall be chamfered to accommodate the weld. This is

applicable for all corners, angles and joint sections as shown in Figure 1.

Figure 1: Chamfering of tiles for welding.

All work executed shall satisfy the requirements contained in the approved Quality

Control Plan, by the engineer.

Liners must be guaranteed for at least 12 months against latent defects.

Alternative lining materials than that specified may be offered for consideration by

Exxaro. Such requests shall be accompanied by full technical details of the

material and evidence that the proposed alternative shall be more cost effective

than the material specified by Exxaro. Alternative proposals shall only be

implemented after obtaining approval from the Exxaro engineer.

7.2 WEAR LINING REQUIREMENTS FOR SPECIFIC APPLICATIONS

Table 2 indicates the lining requirement for plate work components in different coal

applications. Wear liners shall be designed considering high and low wear areas.

The designer shall specify liners considering cost and wear patterns.

It is the designer’s responsibility to review the general availability of the liner

thickness specified prior to detailing wear liners, as availability may vary from time

to time.

Doc ID: EWPM-8453-222 Version: 1.1 Date: 2015-11-18 Page: 9 of 22

MECHANICAL ENGINEERING STANDARD

EXX-EME-STD-0008 EPM/ENGINEERING-ENG-STD

Table 2. Lining requirement for plate work components in different applications

Max UHMW-PE Steel Ceramic protection

particle (Ultra High liner thickness

size Molecular thickness

Description Impact Non-

[mm] Weight Poly- [mm]

area impact

Ethylene)

[mm] area

[mm]

[mm]

ROM 1200 25

ROM 50 25 25

Product & Waste 50 25 12

Product 1 6

Dribblings 1 6 20

Screen underpans 10 25

Screen underpans 1.6 6

Mixing box 25

Degrit/classifying cyclone boxes 1.6 12

Cones:

50 12

Vertical section

25

Conical section

Cones:

6

Vertical sections 4

12

Conical sections

7.3 CERAMIC WEAR LINERS

7.3.1 GENERAL

Standard tiles rather than engineered tiles shall be used wherever possible.

Cutting of tiles shall be by means of diamond saw cutting or green cutting.

Chipping of tiles shall not be allowed under any circumstance.

The epoxy adhesive shall have minimum 38MPa tensile strength and 80MPa

compressive strength. The supplier shall specify the adhesive best suited for

application on passivated 3CR12 plate work.

Doc ID: EWPM-8453-222 Version: 1.1 Date: 2015-11-18 Page: 10 of 22

MECHANICAL ENGINEERING STANDARD

EXX-EME-STD-0008 EPM/ENGINEERING-ENG-STD

The ceramic tile supplier will be required to provide product and workmanship

guarantees for each application.

A minimum steel plate thickness of 6 mm is required for plate work to be tiled.

Stiffeners must be typically placed at 500 x 500 mm increments. Appropriate

stiffeners shall be installed if the existing stiffeners are deemed to be inadequate.

Additional bracing must be provided if the lining is at risk during lifting or handling

of the lined component.

Backing plates and stiffeners shall be the same material as the plate work.

Ceramic lining shall be done in the workshop or on site and shall be carried out in

a controlled environment under cover. Very large components can be lined in situ

with the approval of Exxaro. Lined items shall be devided into sections to ensure

transport of lined panels from fabricators to site as far as practically possible.

Tile layout drawings with unique numbers per item shall be provided for all tiled

surfaces on the Exxaro drawing template.

The layout of the tiles shall be detailed and submitted to Exxaro for approval. Liner

designs shall be done to minimize the use of special tiles as far as practically

possible to the discretion of the engineer.

The weight of the complete assembly, including backingplate and liner materials

shall be clearly shown on the drawing.

7.3.2 STANDARD CERAMIC TILES

Standard ceramic tiles 6, 12, 20, 25 or 50 mm thick shall be used. Standard tiles

shall be rectangular, starting from 100 x 25 mm to 150 x 100 mm in the thickness

specified. The maximum tile size shall be 100 x 150 mm. The maximum tile size

shall be used wherever possible on large flat surfaces.

7.3.3 ENGINEERED TILES

Engineered tiles shall be used for specific applications like square to round

sections where the use of standard tiles is not feasible.

Doc ID: EWPM-8453-222 Version: 1.1 Date: 2015-11-18 Page: 11 of 22

MECHANICAL ENGINEERING STANDARD

EXX-EME-STD-0008 EPM/ENGINEERING-ENG-STD

7.3.4 LINER THICKNESS

A distinction shall be made in the tile thickness between the impact areas and the

non-impact zones of plate work as indicated in Table 2.

7.3.5 SURFACE PREPARATION FOR CERAMIC TILING

All surfaces shall be properly prepared before tiling in accordance with ESP-XX-

0016-01. Steel surfaces to be lined shall be ground flush. No weld beads shall

protrude on the inside of the steelwork.

Bins and chutes fabricated from 3CR12 will require sandblasting to Standard Sa

2½ as per ISO 8501-1 before application of tiles. Tiling shall cease when

discolouration of the steel is noticed. When discolouration is noticed, the remaining

area to be tiled will be sandblasted again before tilling continues.

7.3.6 CERAMIC TILE LAYOUT

7.3.6.1 General

Each tile shall be in intimate contact with the adjacent tile. In exceptional cases a

maximum joint width of 3 mm shall be allowed, provided that such tiles are in direct

contact for at least 90% of the length of the contact area.

The maximum allowable height variation (step) between adjacent tiles shall be 2

mm.

The bottom edge of a chute shall have a steel lip protruding to provide additional

tile support and prevent chipping of tiles.

Supporting bars shall be fitted inside large plate lining areas where support is

required.

Tiling on inspection and maintenance doors shall be flush with the lining of the

main platework.

7.3.6.2 Protection of epoxy adhesives

Epoxy shall be protected against abrasion material and tiles against damage in the

following ways:

Doc ID: EWPM-8453-222 Version: 1.1 Date: 2015-11-18 Page: 12 of 22

MECHANICAL ENGINEERING STANDARD

EXX-EME-STD-0008 EPM/ENGINEERING-ENG-STD

a. Tiles shall be staggered to ensure that the epoxy route ends at a T-piece. The

shortest side of the tile shall always be in the direction of the flow as indicated

in Figure 2.

Material

flow

direction

Figure 2: Tile staggering

b. Corner tiles shall be used to line corners. Where the use of corner tiles is not

possible the following shall apply for bottom corners(Figure 3):

Preferred Acceptable Unacceptable

Figure 3: Corner tiles

c. The dimensions of engineered corners tiles shall be such that it can be

replaced with standard tiles, i.e. the layout shall allow for engineered and

standard tiles to be interchangeable as shown above.

d. Material flow shall be distributed over the largest area to minimise localised

wear when viewing a section of a chute.

Correct Unacceptable Unacceptable

Doc ID: EWPM-8453-222 Version: 1.1 Date: 2015-11-18 Page: 13 of 22

MECHANICAL ENGINEERING STANDARD

EXX-EME-STD-0008 EPM/ENGINEERING-ENG-STD

e. Prevent bending stresses on ceramic lining at all flanged connections (Figure

4).

Unacceptable

Acceptable

Figure 4: Bending stresses

f. If a chute is flexible, stiffeners shall be used shown in Figure 5.

Stiffeners

Figure 5: Chute stiffeners

7.3.7 PERMANENT MARKING OF CERAMIC LINED PLATE WORK

All components lined with ceramic tiles shall have a permanent and clearly visible

warning stating

Doc ID: EWPM-8453-222 Version: 1.1 Date: 2015-11-18 Page: 14 of 22

MECHANICAL ENGINEERING STANDARD

EXX-EME-STD-0008 EPM/ENGINEERING-ENG-STD

Ceramic lined: No cutting,

welding or hammering.

and stenciled onto the exterior of the component, on all sides visible from

walkways.

7.4 REQUIREMENTS FOR STEEL LINERS

7.4.1 GENERAL

Where the use of steel liners is indicated, VRN 500 or approved alternative of the

specified thickness shall be used.

Liner plates shall preferably be square, rectangular or triangular. Preference shall

be given to square plates to allow turning through 90 or 180 degrees where the

total plate is not immersed in the flow stream.

Liners shall be a maximum size of 300 mm x 300 mm. The maximum diagonal

dimension of any liner plate shall be less than the minimum chute outlet dimension

to ensure that dislodged liners can be discharged through the chute. The

maximum weight of a liner shall be limited to 25kg for liners with limited

maintenance access for rigging equipment.

Liner shall be arrange (pattern) to allow for standardization of plates as far as

possible to the discretion of the Exxaro engineer. Similar chutes will have identical

liner layouts. The starting point of the liner pattern for set out shall be similar for all

chutes.

A detailed drawing of the chute face shall be made, indicating the following:

arrangement of the liner plates on the face, corners and angles

mark number of each plate

the dimensions of each plate

thickness of each plate

back marking of each plate

gaps and overlapping distances between plates

stiffeners in relation to the holes

Doc ID: EWPM-8453-222 Version: 1.1 Date: 2015-11-18 Page: 15 of 22

MECHANICAL ENGINEERING STANDARD

EXX-EME-STD-0008 EPM/ENGINEERING-ENG-STD

The liner layout must be submitted to Exxaro for approval.

7.4.2 STEEL LINING LAYOUT

Liner plates shall be arranged on any chute face in staggered rows across the flow

of material. No long joints will be permitted in the direction of the flow of material.

This must be achieved through a combination of square and rectangular (triangular

where applicable) plates fitted in a staggered pattern from row to row. Figure 6

shows a typical staggered arrangement.

Figure 6. Staggered Liner Arrangement

Steel liners shall be mounted in intimate contact with the chute, bin or hopper

steelwork.

Individual liner plates must be removable without restriction from surrounding

plates. Liner plates with a thickness of 20mm and below shall have a gap of 5mm

between them. Liner plates with a thickness of more than 20mm shall have a gap

of 10mm between them.

Liners shall overlap each other in corners. Liners shall be chamfered to clear welds

in internal corners. The correct and incorrect placement of liners in corners is

indicated in Figure 7 below.

Doc ID: EWPM-8453-222 Version: 1.1 Date: 2015-11-18 Page: 16 of 22

MECHANICAL ENGINEERING STANDARD

EXX-EME-STD-0008 EPM/ENGINEERING-ENG-STD

Figure 7. Correct and Incorrect Placement of Liners in Corners

Doc ID: EWPM-8453-222 Version: 1.1 Date: 2015-11-18 Page: 17 of 22

MECHANICAL ENGINEERING STANDARD

EXX-EME-STD-0008 EPM/ENGINEERING-ENG-STD

7.4.3 STEEL LINING FIXING REQUIREMENTS

The liner plates will be attached to the chute or bin plate work by means of

countersunk-head nib bolts as specified in SANS1143: “Countersunk and

Mushroom Head Bolts”, Table 2.

All nuts shall be easily accessible for liner replacement. Outside stiffener positions

must be taken into account for liner spacing and layout. Cutting away or removal of

stiffeners to accommodate fixing holes and/or nuts shall not be allowed.

Each steel liner shall be fitted with a minimum of 4 bolts

Bolt holes shall be such that no two holes on the same or adjacent plates are

closer than 80 mm.

Countersunk bolt holes for the fixing of liner plates of various thicknesses shall be

as indicated in Figure 8.

Doc ID: EWPM-8453-222 Version: 1.1 Date: 2015-11-18 Page: 18 of 22

MECHANICAL ENGINEERING STANDARD

EXX-EME-STD-0008 EPM/ENGINEERING-ENG-STD

Figure 8. Steel Liner Countersunk Hole Detail

Doc ID: EWPM-8453-222 Version: 1.1 Date: 2015-11-18 Page: 19 of 22

MECHANICAL ENGINEERING STANDARD

EXX-EME-STD-0008 EPM/ENGINEERING-ENG-STD

7.4.4 SURFACE PREPARATION FOR STEEL LINERS

Painting, for insulation purposes, of internal surfaces of hoppers, bins or chutes,

fabricated from 3CR12 where steel liners of different material to the bin will be

fitted, the surfaces to be lined, shall be painted as per specification.

7.4.5 STEEL LINERS IN DEAD BOX AREAS

There shall be no distinction between liners in dead box areas and normal flow

areas.

7.5 LIP LINERS

Lip liners shall generally be of the same material as the adjacent liners, i.e.

ceramic lip liners shall be used where the adjacent plate work is lined with ceramic

tiles and steel liners used where the adjacent plate work is lined with steel liners.

The chute designer shall confirm the suitability of the material for the specific

application, dependent of material abrasiveness, size and impact energy.

Lip liners mass must not exceed 25kg per individual section to ensure ease of

replacement. In large chutes this will require that a lip liner consist of multiple

sections.

Lip liners must be easily adjustable to allow adjustment during commissioning.

8. MANUFACTURING REQUIREMENTS

Specific manufacturing requirements will be determined during detail design, if

required.

9. PACKING, DELIVERY, OFF LOADING AND STORAGE ON

SITE

Size and stiffness of platework sections shall be considered in the design to ensure

shipping of components without damage to liners.

Further details shall be furnished in the tender document.

Doc ID: EWPM-8453-222 Version: 1.1 Date: 2015-11-18 Page: 20 of 22

MECHANICAL ENGINEERING STANDARD

EXX-EME-STD-0008 EPM/ENGINEERING-ENG-STD

10. ASSEMBLY, INSTALLATION, ERECTION AND

CONSTRUCTION REQUIREMENTS

10.1 CERAMIC TILES

10.1.1 ATTACHMENT OF TILES

Tiles shall be fitted according to the approved detail drawings.

Tiles shall be attached by means of epoxy adhesive. This may be a one-part or

two-part resin/hardener compound, but shall not contain any filler material which

may adversely affect the strength of the epoxy bond. Epoxies shall be specified by

the Contractor to suit the application. Data sheets of proposed epoxy shall be

provided for review.

The ceramic tiles shall provide a complete lining system, thus preventing any

ingress of moisture through gaps between tiles. The epoxy adhesive shall be used

solely for adhesion of tile to substrate and tile to tile, and not for filling gaps

between tiles. A proper wear resistant epoxy shall be used to fill all gaps between

liners.

10.1.2 ERECTION AND INSTALLATION OF CERAMIC LINED COMPONENTS

Due care shall be taken to prevent damage to ceramic lining during installation of

lined components. Additional stiffeners shall be used to prevent flexing of the

components if necessary.

10.2 INSTALLATION OF STEEL LINERS

Installation of steel liners shall be done in accordance with the approved Quality

Control Plan and detail drawings, after approval by the Exxaro Engineer.

11. COMMISSIONING REQUIREMENTS

High impact areas and wear patterns must be verified after commissioning and

compared to the liner design. Where differences exist that compromises the wear

life of components, it shall be rectified.

Doc ID: EWPM-8453-222 Version: 1.1 Date: 2015-11-18 Page: 21 of 22

MECHANICAL ENGINEERING STANDARD

EXX-EME-STD-0008 EPM/ENGINEERING-ENG-STD

12. PROJECT DOCUMENTATION

12.1 DRAWINGS

All drawings shall be according to Exxaro drawing numbering and standards.

12.2 DATA SCHEDULES

Material data sheets and batch test certificates shall be submitted for all liners on

delivery, including backing material and epoxy and adhesive information.

Doc ID: EWPM-8453-222 Version: 1.1 Date: 2015-11-18 Page: 22 of 22

You might also like

- Pulleys - Pulley LaggingDocument4 pagesPulleys - Pulley LaggingWaris La Joi WakatobiNo ratings yet

- Takraf Apron Feeder: Optimal Solutions For Mining, Material Handling and ProcessingDocument6 pagesTakraf Apron Feeder: Optimal Solutions For Mining, Material Handling and ProcessingJakesNo ratings yet

- Precedure Rubber LiningDocument4 pagesPrecedure Rubber LiningKarthikeyan ShanmugavelNo ratings yet

- Method Statement For Rubber LiningDocument7 pagesMethod Statement For Rubber LiningJoseph PerezNo ratings yet

- AA SPEC 371001 - Conveyor Pulleys and ShaftsDocument14 pagesAA SPEC 371001 - Conveyor Pulleys and Shaftsjonodo89No ratings yet

- Quality Requirements For CrMo Alloys SAG Mill Liner and GratesDocument16 pagesQuality Requirements For CrMo Alloys SAG Mill Liner and GratesFrancis ChavezNo ratings yet

- F175 (M) 018-Apron Feeder BZ2300×12000 With Scraper Conveyer B2500×10800-User ManualsDocument60 pagesF175 (M) 018-Apron Feeder BZ2300×12000 With Scraper Conveyer B2500×10800-User ManualssuhardiantoNo ratings yet

- Apron FeederDocument10 pagesApron FeederKenny Ruiz100% (1)

- Conveyor Idler StandardsDocument10 pagesConveyor Idler StandardsObiwan1483100% (1)

- Rubber Conveyor Belt Splice Cure CalculationDocument7 pagesRubber Conveyor Belt Splice Cure CalculationnicolasNo ratings yet

- 7155 - 5 Apron Conveyors Apron FeedersDocument5 pages7155 - 5 Apron Conveyors Apron FeedersMann GurpreetNo ratings yet

- Manual Book Vibrating ScreenDocument3 pagesManual Book Vibrating Screenrizki arfi100% (2)

- Bucket ElevatorsDocument11 pagesBucket ElevatorsMehmet CNo ratings yet

- Manual Delkor 04097 - SQM Coya Sur (HBF 9m )Document60 pagesManual Delkor 04097 - SQM Coya Sur (HBF 9m )Ruben Antonio Baeza Diaz100% (3)

- Training Manual Green Anode Plant Vedanta - Jharsuguda: File: 138-02-043 - 08 - 0.doc, Codeword: VedantaDocument47 pagesTraining Manual Green Anode Plant Vedanta - Jharsuguda: File: 138-02-043 - 08 - 0.doc, Codeword: VedantaSubhransu MohapatraNo ratings yet

- Thyssenkrupp Industries India: Polysius Cement DivisionDocument23 pagesThyssenkrupp Industries India: Polysius Cement DivisionunimarinesNo ratings yet

- Rotary Valve Functions BookletDocument17 pagesRotary Valve Functions Bookletamahmoud3No ratings yet

- Pump SealingDocument4 pagesPump Sealingsushant_jhawerNo ratings yet

- AA - SPEC - 114005 - Flooring, Stairs, Ladders & HandrailsDocument45 pagesAA - SPEC - 114005 - Flooring, Stairs, Ladders & HandrailsJakesNo ratings yet

- Lessons Learned When Handling Synthetic Gypsum Rev 5Document6 pagesLessons Learned When Handling Synthetic Gypsum Rev 5cemsavantNo ratings yet

- EHP Series Piston Accumulators: 0.1 To 1000 Litres, Up To 350 BarDocument32 pagesEHP Series Piston Accumulators: 0.1 To 1000 Litres, Up To 350 BarMichael Akhramovich100% (1)

- Apron FeederDocument12 pagesApron FeederMidDeL'OrmeNo ratings yet

- Ball Mill Erection ScheduleDocument2 pagesBall Mill Erection SchedulesatishflsNo ratings yet

- Apron Feeder Application Datasheet enDocument1 pageApron Feeder Application Datasheet enVaijayanti JoshiNo ratings yet

- COnveyor SkirtsDocument4 pagesCOnveyor SkirtsdivashmNo ratings yet

- RATIONAL DESIGN OF CONVEYOR CHUTES - J Rozentals PDFDocument9 pagesRATIONAL DESIGN OF CONVEYOR CHUTES - J Rozentals PDFJakesNo ratings yet

- Pulley Lagging Rubber Sheet PDFDocument1 pagePulley Lagging Rubber Sheet PDFSanatha AgungNo ratings yet

- R0404-MT - Rev - 0 DF Da Bateria de CicloneDocument2 pagesR0404-MT - Rev - 0 DF Da Bateria de CiclonecaapasaNo ratings yet

- 16' X 22' Ball Mill Installation ManualDocument54 pages16' X 22' Ball Mill Installation Manualpataza011100% (3)

- Barrel Reclaimers TRFDocument4 pagesBarrel Reclaimers TRFkaustavNo ratings yet

- 6000 - Rex-Idlers Belt-Conveyor-Component PDFDocument27 pages6000 - Rex-Idlers Belt-Conveyor-Component PDFoscarlopez12345No ratings yet

- 02b. BANDO Conveyor Belt Rubber Sheet Rubber Lagging Presentation PDFDocument41 pages02b. BANDO Conveyor Belt Rubber Sheet Rubber Lagging Presentation PDFYuliantoNo ratings yet

- Vibrating Feeder: Henan Liming Road & Bridge Heavy Industry Co., LTDDocument8 pagesVibrating Feeder: Henan Liming Road & Bridge Heavy Industry Co., LTDMiguel Pereyra OyarceNo ratings yet

- BELTSTAT v7.0 User ManualDocument147 pagesBELTSTAT v7.0 User Manualleomar61No ratings yet

- Pfi Es24Document9 pagesPfi Es24punitdubey100% (2)

- Refractory Installation in The Cement Rotary Kiln 3.1 Installation of Refractory Bricks in The Cement Rotary KilnDocument51 pagesRefractory Installation in The Cement Rotary Kiln 3.1 Installation of Refractory Bricks in The Cement Rotary KilnkINGNo ratings yet

- Minerals: Mill Circuit Duty PumpsDocument8 pagesMinerals: Mill Circuit Duty PumpsVic Andres E. AracenaNo ratings yet

- Dust Collector Installation ProcedureDocument9 pagesDust Collector Installation Procedureadil shidiq100% (1)

- Apron Feeder ManualDocument10 pagesApron Feeder Manual7atemmohNo ratings yet

- A Total Solution For Your Concentrator: Thickener Commissioning ReportDocument13 pagesA Total Solution For Your Concentrator: Thickener Commissioning ReportJesus Sing RoblesNo ratings yet

- Slurry PumpsDocument69 pagesSlurry PumpsJhonny AlvarezNo ratings yet

- 5 Poppet ValvesDocument14 pages5 Poppet ValvesVIJAYIOCLNo ratings yet

- Rubber Linings OverviewDocument10 pagesRubber Linings OverviewhabibNo ratings yet

- Pans PDFDocument8 pagesPans PDFJorge Prado DiazNo ratings yet

- Renold Wheels SprocketsDocument36 pagesRenold Wheels Sprocketssumanthkulkarni07No ratings yet

- SM 226 Rev 0 Apex Steel Cord Vulcanised Splicing ManualDocument20 pagesSM 226 Rev 0 Apex Steel Cord Vulcanised Splicing ManualIshi BashiNo ratings yet

- Method Statement of Textile Belt Splicing and LayingDocument16 pagesMethod Statement of Textile Belt Splicing and LayingShantanu DuttaNo ratings yet

- Conveyor Idlers PDFDocument10 pagesConveyor Idlers PDFDhirendraRaviNo ratings yet

- Single Toggle Jaw Crusher Manufacturers, Single Toggle Jaw Crusher For SaleDocument3 pagesSingle Toggle Jaw Crusher Manufacturers, Single Toggle Jaw Crusher For SaleHashani Anuttara AbeygunasekaraNo ratings yet

- Write Up Apron FeederDocument11 pagesWrite Up Apron FeederParmeshwar Nath Tripathi0% (1)

- ConyevorsDocument9 pagesConyevorsRohan MalkarNo ratings yet

- Housing Designs & Seal Options PDFDocument27 pagesHousing Designs & Seal Options PDFmimi_chan_17100% (1)

- Sample: Not For Commercial UseDocument11 pagesSample: Not For Commercial UseHarjasa Adhi100% (1)

- RESE001Document37 pagesRESE001mallesh100% (2)

- Sample STF05501Document11 pagesSample STF05501Mukuka KangwaNo ratings yet

- Process Industry Practices Structural: PIP STF05501 Fixed Ladders and CagesDocument11 pagesProcess Industry Practices Structural: PIP STF05501 Fixed Ladders and CagesAbdul Qayyum MianNo ratings yet

- Piping and Equipment InsulationDocument22 pagesPiping and Equipment InsulationRampal Rahul Rampal RahulNo ratings yet

- Rexroth Weld Module PSI 6100Document122 pagesRexroth Weld Module PSI 6100Thales ValimNo ratings yet

- Insulation Design GuideDocument38 pagesInsulation Design GuideGunawan Suryana100% (1)

- Specification 01286 SPE EPC 302 210 0001 IFB0-01Document27 pagesSpecification 01286 SPE EPC 302 210 0001 IFB0-01minakirolosNo ratings yet

- ENG ECI ELC SPC 004 Electrical InstallationDocument68 pagesENG ECI ELC SPC 004 Electrical Installationjonodo89No ratings yet

- Fire Protection Standard For Use of Plastic PipesDocument6 pagesFire Protection Standard For Use of Plastic Pipesjonodo89No ratings yet

- Static Shaft Pulleys With Internal BearingsDocument14 pagesStatic Shaft Pulleys With Internal Bearingsjonodo89100% (1)

- Fire Protection Standard For Electrical Equipment and InstallationsDocument27 pagesFire Protection Standard For Electrical Equipment and Installationsjonodo89100% (1)

- Fire Protection Standard For Vehicles and Moving MachineryDocument39 pagesFire Protection Standard For Vehicles and Moving Machineryjonodo89100% (1)

- L100 (0a)Document1 pageL100 (0a)jonodo89No ratings yet

- Cable Racking Oline Catalogue - 2011 Pages 84 86Document3 pagesCable Racking Oline Catalogue - 2011 Pages 84 86jonodo89No ratings yet

- Sole PlatesDocument12 pagesSole Platesjonodo89No ratings yet

- K0001 A430 M SPC 0011 Rev02 Metallic Wear LiningDocument15 pagesK0001 A430 M SPC 0011 Rev02 Metallic Wear Liningjonodo89No ratings yet

- Belt Conveyor Idlers and RollsDocument14 pagesBelt Conveyor Idlers and Rollsjonodo89No ratings yet

- Generic Geared ReducersDocument12 pagesGeneric Geared Reducersjonodo89No ratings yet

- K0001 A430 M SPC 0011 Rev02 Metallic Wear LiningDocument15 pagesK0001 A430 M SPC 0011 Rev02 Metallic Wear Liningjonodo89No ratings yet

- Surface Preparation and Paint SpecificationDocument63 pagesSurface Preparation and Paint Specificationjonodo89No ratings yet

- Mechanical StandardsDocument10 pagesMechanical Standardsjonodo890% (1)

- AATC000859 - AATC Design Criteria and Guidelines For Surface Infrastructure - Mechanical & StructuralDocument68 pagesAATC000859 - AATC Design Criteria and Guidelines For Surface Infrastructure - Mechanical & Structuraljonodo89No ratings yet

- The Design of Troughed Belt ConveyorsDocument44 pagesThe Design of Troughed Belt Conveyorsjonodo89No ratings yet

- Conveyor Equipment SpecificationDocument20 pagesConveyor Equipment Specificationjonodo89No ratings yet

- Conveyor Belt Protection SystemsDocument12 pagesConveyor Belt Protection Systemsjonodo89No ratings yet

- 2RVRETURNS25Document1 page2RVRETURNS25jonodo89No ratings yet

- Equipment SafeguardingDocument40 pagesEquipment Safeguardingjonodo89No ratings yet

- Screw Take UpsDocument7 pagesScrew Take Upsjonodo89No ratings yet

- M&T Risk & AssuranceDocument39 pagesM&T Risk & Assurancejonodo89No ratings yet

- Single ClampDocument1 pageSingle Clampjonodo89No ratings yet

- 2RVRETURNS25Document1 page2RVRETURNS25jonodo89No ratings yet

- BB Design ReportDocument79 pagesBB Design Reportjonodo89No ratings yet

- Aa Spec 114005Document45 pagesAa Spec 114005jonodo8950% (2)

- New Doc 2018-04-24Document6 pagesNew Doc 2018-04-24jonodo89No ratings yet

- SolidwovendatasheetDocument1 pageSolidwovendatasheetjonodo89No ratings yet

- New Doc 2018-04-24Document6 pagesNew Doc 2018-04-24jonodo89No ratings yet

- The 5 Competitive Forces That Shape StrategyDocument36 pagesThe 5 Competitive Forces That Shape StrategydanilynfNo ratings yet

- Ds Transmitter U952TDocument2 pagesDs Transmitter U952TZafar YabNo ratings yet

- Risk Assessment FormDocument2 pagesRisk Assessment FormYu JunanNo ratings yet

- System Analysis and DesignDocument3 pagesSystem Analysis and DesignhemantsajwanNo ratings yet

- Android App Development NotesDocument6 pagesAndroid App Development NotesTony Jiang0% (1)

- 020-Aircraft General Knowledge 1 PDFDocument190 pages020-Aircraft General Knowledge 1 PDFPedro SantosNo ratings yet

- Domain Name SystemDocument8 pagesDomain Name SystemSrishti AroraNo ratings yet

- The Five Cs of Neighborhood PlanningDocument6 pagesThe Five Cs of Neighborhood PlanningFadly Bron IbrahimNo ratings yet

- Network Code For Requirements For Grid Connection Applicable To All GeneratorsDocument85 pagesNetwork Code For Requirements For Grid Connection Applicable To All GeneratorsEliza Maria CloteaNo ratings yet

- Intelliheat Manual enDocument21 pagesIntelliheat Manual enĐiềnNo ratings yet

- Jetstream Europe Brochure EnglishDocument6 pagesJetstream Europe Brochure EnglishFernando ZamoraNo ratings yet

- RT 1120 Op ManualDocument130 pagesRT 1120 Op ManualfrankNo ratings yet

- KANTRODocument8 pagesKANTROFabio Teodoro100% (1)

- Tacoma: Here's The Tacoma TRD Pro 4x4 Double Cab V6 6-Speed Automatic Short BedDocument7 pagesTacoma: Here's The Tacoma TRD Pro 4x4 Double Cab V6 6-Speed Automatic Short Bedk2057282No ratings yet

- RexrothDocument132 pagesRexrothmotasem alqaisiNo ratings yet

- Hitachi ZX65USB 6 Mini Excavator KS EN438EUDocument20 pagesHitachi ZX65USB 6 Mini Excavator KS EN438EUAkhmad SebehNo ratings yet

- SAE J551-13 Suface Vehicle StandardDocument10 pagesSAE J551-13 Suface Vehicle StandardLê Đình ĐiềuNo ratings yet

- Standards and Regulations For Engine Watch KeepingDocument14 pagesStandards and Regulations For Engine Watch KeepingJustin CaliguiaNo ratings yet

- LF90LS Operations and Service Manual PDFDocument154 pagesLF90LS Operations and Service Manual PDFJose Vidal100% (9)

- Twister Electronic Throttle, Can - 120477 Oem External Datasheet - 1-5-2010Document24 pagesTwister Electronic Throttle, Can - 120477 Oem External Datasheet - 1-5-2010Halit Yalçınkaya0% (1)

- 664 Publist 2014 DecemberDocument15 pages664 Publist 2014 DecemberJ Salvador Calderón BarrancosNo ratings yet

- PQP Vs ISO 9001 Clauses List PDFDocument1 pagePQP Vs ISO 9001 Clauses List PDFVpln Sarma100% (1)

- EE 2355-DEM 1-LibreDocument26 pagesEE 2355-DEM 1-LibreAmit GurungNo ratings yet

- Eu63 PDFDocument59 pagesEu63 PDFriade88No ratings yet

- F303EDocument2 pagesF303EswnjiopmyNo ratings yet

- Sist en 55014 1 2017Document15 pagesSist en 55014 1 2017Manish PatilNo ratings yet

- C Question BankDocument6 pagesC Question BankRenuka ChoudharyNo ratings yet

- Handler Compliance Plan - NGPDocument12 pagesHandler Compliance Plan - NGPAntonio JoseNo ratings yet

- Data Teknis Dan Penomoran IP Address Jaringan HotspotDocument6 pagesData Teknis Dan Penomoran IP Address Jaringan HotspotEgit WidiyantoNo ratings yet