Professional Documents

Culture Documents

Cut-Back Asphalt (Rapid-Curing Type) : Standard Specification For

Uploaded by

Katerin HernandezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cut-Back Asphalt (Rapid-Curing Type) : Standard Specification For

Uploaded by

Katerin HernandezCopyright:

Available Formats

M 81 SPECIFICATIONS FOR MATERIALS

Standard Specification for

Cut-Back Asphalt (Rapid-Curing Type)

AASHTO DESIGNATION M 81-92

1. SCOPE shall not foam when heated to the with the following standard methods of

application temperature. the American Association of State

Highway and Transportation Officials:

1.1 This specification covers liquid

petroleum products, produced by fluxing 3. PROPERTIES Sampling..........................................T 40

an asphaltic base with suitable petroleum Solubility .........................................T 44

distillates, to be used in treatment of road Penetration........................................T 49

surfaces. 3.1 Cut-back asphalt of the grade Ductility............................................T 51

designated shall conform to the Water................................................T 55

1.2 The values stated in SI units are to be requirements shown in Table 1 on page Saybolt Furol viscosity ....................T 72

regarded as the standard. 66. Distillation .......................................T 78

Flash point........................................T 79

2. GENERAL REQUIREMENTS Spot test..........................................T 102

4. METHODS OF SAMPLING AND

Kinematic viscosity........................T 201

TESTING

Absolute viscosity .........................T 202

2.1 The cut-back asphalt shall show no

separation or curdling prior to use and 4.1 Sampling and testing cut-back asphalt

(rapid-curing type) shall be in accordance

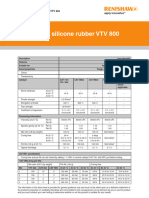

TABLE I

RC-70 RC-250 RC-800 RC-3000

Min Max Min Max Min Max Min Max

Kinematic viscosity at 60°C (140°F) (See Note 1) mr2/s 70 140 250 500 800 1600 3000 6000

Flash point (Tag, open-cup), degrees C (F) - - 27 (80) - 27 (80) - 27 (80) -

Water, percent - 0.2 - 0.2 - 0.2 - 0.2

Distillation test:

Distillate, percentage by volume of total distillate to

360°C (680°F)

to 190°C (374°F) 10 - - - - - - -

to 225°C (437°F) 50 - 35 - 15 - - -

to 260°C (500ºF) 70 - 60 - 45 - 25 -

to 315°C (600°F) 85 - 80 - 75 - 70 -

Residue from distillation to 360°C (680°F) volume

55 - 65 - 75 - 80 -

percentage of sample by difference

Tests on residue from distillation:

Absolute viscosity at 60°C (140°F) (See Note 3) Pa•s 60 240 60 240 60 240 60 240

(poises) (600) (2400) (600) (2400) (600) (2400) (600) (2400)

Ductility, 5 cm/min at 25°C (77°F) cm 100 - 100 - 100 - 100 -

Solubility percent 99.0 - 99.0 - 99.0 - 99.0 -

Spot test (See Note 2) with

Standard naphtha Negative for all grades

Naphtha-xylene solvent, percent xylene Negative for all grades

Heptane-xylene solvent, percent xylene Negative for all grades

NOTE 1-As an alternate, Saybolt-Furol viscosities may be specified as follows:

Grade RC-70-Furol viscosity at 50°C (122°F)-60 to 120 s.

Grade RC-250-Furol viscosity at 60°C (140°F)-125 to 250 s.

Grade RC-800-Furol viscosity at 82.2°C (180°F)-100 to 200 s.

Grade RC-3000-Furol viscosity at 82.2'C (I 80°F)-300 to 600 s.

NOTE 2-The use of the spot test is optional. When specified, the engineer shall indicate whether the standard naphtha solvent, the naphtha-xylene

solvent or the heptanexylene solvent will be used in determining compliance with the requirement, and also, in the case of the xylene solvents, the

percentage of xylene to be used.

NOTE 3-In lieu of viscosity of the residue, the specifying agency, at its option, can specify penetration at 100 g: 5 s at 25°C (77°F) of 80-120 for

Grades RC-70, RC-250, RC-800. and RC-3000. However, in no case will both be required.

59

You might also like

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- M82Document1 pageM82FRANZ RICHARD SARDINAS MALLCO100% (1)

- Cutback Asphalt (Rapid-Curing Type) : Standard Specification ForDocument2 pagesCutback Asphalt (Rapid-Curing Type) : Standard Specification Fordong ganNo ratings yet

- M20Document1 pageM20FRANZ RICHARD SARDINAS MALLCO75% (4)

- m20 PDF FreeDocument1 pagem20 PDF FreeDede NurcahyadiNo ratings yet

- Cutback Asphalt (Rapid-Curing Type) : AashloDocument3 pagesCutback Asphalt (Rapid-Curing Type) : AashloNacer KisyNo ratings yet

- 3.4 Bituminous Materials: 3.4.1 DescriptionDocument5 pages3.4 Bituminous Materials: 3.4.1 DescriptionSujon AhmmedNo ratings yet

- Viscosity-Graded Asphalt Cement: Standard Specification ForDocument4 pagesViscosity-Graded Asphalt Cement: Standard Specification Formohammed karasnehNo ratings yet

- Cutback Asphalt (Medium-Curing Type) : Standard Specification ForDocument2 pagesCutback Asphalt (Medium-Curing Type) : Standard Specification ForROHITNo ratings yet

- Tests Astm Test Method Requirements Min. MaxDocument12 pagesTests Astm Test Method Requirements Min. Maxhisham gawishNo ratings yet

- TM500E-2 Pist Pump InfoDocument32 pagesTM500E-2 Pist Pump InfoFredy QuispeNo ratings yet

- K3VLTechnical Brochure PDFDocument32 pagesK3VLTechnical Brochure PDFanon_485665212No ratings yet

- M 82-75 (2004) Cutback Asphalt (MC Type)Document2 pagesM 82-75 (2004) Cutback Asphalt (MC Type)WalticoZegarraHerrera100% (1)

- Viscosity ClassificationsDocument4 pagesViscosity ClassificationsKhin Aung ShweNo ratings yet

- Cutback Asphalt (Slow-Curing Type) : Standard Specification ForDocument2 pagesCutback Asphalt (Slow-Curing Type) : Standard Specification ForFrengkiNo ratings yet

- Product: Penetration Grade Bitumen Cutback MC 70 Packing: New Steel Drum 180 5Kgs / BulkDocument2 pagesProduct: Penetration Grade Bitumen Cutback MC 70 Packing: New Steel Drum 180 5Kgs / BulkvinayaiyappaNo ratings yet

- D 977 - 98 Rdk3ny1sruqDocument4 pagesD 977 - 98 Rdk3ny1sruqRufo CascoNo ratings yet

- Texaco Meropa 320 Eng M0010Document2 pagesTexaco Meropa 320 Eng M0010Ady MihailaNo ratings yet

- Product Data Sheet SP-6888Document5 pagesProduct Data Sheet SP-6888rmfpereiraNo ratings yet

- Medium Curing Cutback Asphalts Product Data Sheet: Description and Physical PropertiesDocument1 pageMedium Curing Cutback Asphalts Product Data Sheet: Description and Physical PropertiesEsrom AbebeNo ratings yet

- Flash & Fire Point Test For Asphalt by Cleveland Open Cup Tester.Document8 pagesFlash & Fire Point Test For Asphalt by Cleveland Open Cup Tester.Shaheer AhmadNo ratings yet

- RC-250 Product Data Sheet: Quality Emulsion For Every ApplicationDocument1 pageRC-250 Product Data Sheet: Quality Emulsion For Every ApplicationVictor LunaNo ratings yet

- Ipol Rubber Process Oil 501 PDFDocument5 pagesIpol Rubber Process Oil 501 PDFvinoth kumar SanthanamNo ratings yet

- Chevron Meropa EP PDSDocument2 pagesChevron Meropa EP PDSArie'f Armand ArsyatNo ratings yet

- RC - 2Document1 pageRC - 2miguelNo ratings yet

- Emulsified Asphalt: Standard Specification ForDocument3 pagesEmulsified Asphalt: Standard Specification Forsebastian novoaNo ratings yet

- Renolin Ac Compressor Oils: Product InformationDocument2 pagesRenolin Ac Compressor Oils: Product InformationSoporte Técnico RyRNo ratings yet

- Construction & Quality Control of Flexible Pavement: Dr. N.K.S. Pundhir Senior Principal Scientist E-MailDocument84 pagesConstruction & Quality Control of Flexible Pavement: Dr. N.K.S. Pundhir Senior Principal Scientist E-MailMohd Ali100% (1)

- Product Data Sheet SP-8888Document7 pagesProduct Data Sheet SP-8888pablo gonzalezNo ratings yet

- Maker Tauro enDocument2 pagesMaker Tauro enibrahim maulanaNo ratings yet

- AMPD Data Sheet Silicone Rubber VTV 800Document2 pagesAMPD Data Sheet Silicone Rubber VTV 800scribduser071No ratings yet

- Standard Specification For: ScopeDocument2 pagesStandard Specification For: Scopedong ganNo ratings yet

- QALCO Syntholube GX 220Document1 pageQALCO Syntholube GX 220Deepak JoyNo ratings yet

- PDS Intergard 906Document4 pagesPDS Intergard 906SUBHOMOYNo ratings yet

- Afm120 794 Faa Section02Document24 pagesAfm120 794 Faa Section02Beka KarumidzeNo ratings yet

- Hy GardDocument2 pagesHy GardGustavo GonzalezNo ratings yet

- Epofine 740 - Finehard 5200Document4 pagesEpofine 740 - Finehard 5200Karishma PrabhuNo ratings yet

- MC3000 Technical Datasheet Cutback BitumenDocument2 pagesMC3000 Technical Datasheet Cutback BitumenlearnafrenNo ratings yet

- Oil Specs Silver State BrandDocument1 pageOil Specs Silver State BrandAllen WilburNo ratings yet

- Tecnical R 802Document16 pagesTecnical R 802Dyah Ayu100% (1)

- Cutback Asphalt (Slow-Curing Type) : Standard Specification ForDocument2 pagesCutback Asphalt (Slow-Curing Type) : Standard Specification ForShaker QaidiNo ratings yet

- Kapton HN Data SheetDocument5 pagesKapton HN Data Sheet谢朋亨No ratings yet

- Asphalt Binder Basics Specifications, History and FutureDocument40 pagesAsphalt Binder Basics Specifications, History and FutureEdmundo Jaita CuellarNo ratings yet

- Amercoat 56E Polyamide Epoxy High Solids Tank LiningDocument4 pagesAmercoat 56E Polyamide Epoxy High Solids Tank LiningMuhammad MustahsinNo ratings yet

- Nevastane SLDocument4 pagesNevastane SLronnysiguasNo ratings yet

- Parthan Ep: Industrial Gearbox OilsDocument1 pageParthan Ep: Industrial Gearbox OilsHesham MahdyNo ratings yet

- Pureblu Hydraulic Oil: With Leak Detection FormulationDocument2 pagesPureblu Hydraulic Oil: With Leak Detection FormulationDavid RamosNo ratings yet

- Epofine 556 - Finehard 22962Document5 pagesEpofine 556 - Finehard 22962Karishma PrabhuNo ratings yet

- CA 602 Maintenance M602enDocument37 pagesCA 602 Maintenance M602enMohamed AbodaifNo ratings yet

- Couplant Feature Comparison Chart: N/A N/ADocument1 pageCouplant Feature Comparison Chart: N/A N/AdantegimenezNo ratings yet

- AV138M Araldite HV998 HardDocument6 pagesAV138M Araldite HV998 HardFilipe Alberto De MagalhãesNo ratings yet

- BG Universal Synthetic ATFDocument1 pageBG Universal Synthetic ATFroeiweissNo ratings yet

- Sigma Fluid PDFDocument2 pagesSigma Fluid PDFHubertt Chacon AntonioNo ratings yet

- General Discussions On Lubricating OilsDocument59 pagesGeneral Discussions On Lubricating OilsHari PurwadiNo ratings yet

- Axial Piston Pumps For Open Circuits in Mobile, Industrial and Marine ApplicationsDocument36 pagesAxial Piston Pumps For Open Circuits in Mobile, Industrial and Marine ApplicationsKamal Solanki100% (1)

- M 226-80 (2004) Viscosity-Graded Asphalt PDFDocument3 pagesM 226-80 (2004) Viscosity-Graded Asphalt PDFWalticoZegarraHerreraNo ratings yet

- Astm D 2026Document2 pagesAstm D 2026Juan Carlos MejiaNo ratings yet

- Energol SHF-HV RangeDocument2 pagesEnergol SHF-HV RangeArthur Sanda LayukNo ratings yet

- Kaeser Sigma 8000 S 100 150 PDFDocument1 pageKaeser Sigma 8000 S 100 150 PDFJan HendriksNo ratings yet

- MilDocument9 pagesMilDanielSantos0% (1)

- Astm D979-12 PDFDocument3 pagesAstm D979-12 PDFErwinBascon100% (1)

- M 269Document11 pagesM 269Katerin HernandezNo ratings yet

- Astm D6934-04Document2 pagesAstm D6934-04Katerin HernandezNo ratings yet

- Xylene-Insoluble Matter in Creosote: Aashto Designation: T 81-87Document1 pageXylene-Insoluble Matter in Creosote: Aashto Designation: T 81-87Katerin HernandezNo ratings yet

- Astm D 3515 PDFDocument5 pagesAstm D 3515 PDFJulio Cesar Rojas Apaza100% (1)

- Resistance To Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in The Los Angeles MachineDocument3 pagesResistance To Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in The Los Angeles MachineKaterin HernandezNo ratings yet

- Mineral Filler For Bituminous Paving Mixtures: M17 Specifications For MaterialsDocument1 pageMineral Filler For Bituminous Paving Mixtures: M17 Specifications For MaterialsKaterin HernandezNo ratings yet

- M 147Document2 pagesM 147Katerin HernandezNo ratings yet

- Lightweight Aggregates For Structural ConcreteDocument3 pagesLightweight Aggregates For Structural ConcreteKaterin HernandezNo ratings yet

- Fine Aggregate For Portland Cement ConcreteDocument2 pagesFine Aggregate For Portland Cement ConcreteKaterin HernandezNo ratings yet

- Corrugated Steel Pipe, Metallic-Coated, For Sewers and DrainsDocument10 pagesCorrugated Steel Pipe, Metallic-Coated, For Sewers and DrainsKaterin HernandezNo ratings yet

- M 259MDocument17 pagesM 259MKaterin Hernandez100% (2)

- T 48Document3 pagesT 48Katerin HernandezNo ratings yet

- Reinforced Concrete Arch Culvert Storm Drain, and Sewer Pipe (Metric)Document7 pagesReinforced Concrete Arch Culvert Storm Drain, and Sewer Pipe (Metric)Katerin HernandezNo ratings yet

- Lightweight Aggregates For Structural ConcreteDocument3 pagesLightweight Aggregates For Structural ConcreteKaterin HernandezNo ratings yet

- Materials Finer Than 75 - M (Nº 200) Sieve in Mineral Aggregates by WashingDocument3 pagesMaterials Finer Than 75 - M (Nº 200) Sieve in Mineral Aggregates by WashingKaterin HernandezNo ratings yet

- Diamond Core Drilling For Site Investigation: Standard Method of Test ForDocument3 pagesDiamond Core Drilling For Site Investigation: Standard Method of Test ForKaterin HernandezNo ratings yet

- T119Document2 pagesT119Katerin HernandezNo ratings yet

- Quality of Water To Be Used in Concrete: Aashto Designation: T 26-79Document2 pagesQuality of Water To Be Used in Concrete: Aashto Designation: T 26-79Katerin HernandezNo ratings yet

- M 145Document4 pagesM 145Katerin HernandezNo ratings yet

- M 170MDocument10 pagesM 170MKaterin HernandezNo ratings yet

- Carbon and Alloy Steel Nuts For Bolts For High-Pressure and High-Temperature ServiceDocument8 pagesCarbon and Alloy Steel Nuts For Bolts For High-Pressure and High-Temperature ServiceKaterin HernandezNo ratings yet

- Frictional Properties of Paved Surfaces Using A Full-Scale TireDocument4 pagesFrictional Properties of Paved Surfaces Using A Full-Scale TireKaterin HernandezNo ratings yet

- Asphalt Cement Content of Asphalt Concrete Mixtures by The Nuclear MethodDocument3 pagesAsphalt Cement Content of Asphalt Concrete Mixtures by The Nuclear MethodKaterin HernandezNo ratings yet

- Rail-Steel Deformed and Plain Bars For Concrete ReinforcementDocument4 pagesRail-Steel Deformed and Plain Bars For Concrete ReinforcementKaterin HernandezNo ratings yet

- T155Document4 pagesT155Katerin HernandezNo ratings yet

- T 70Document1 pageT 70Katerin HernandezNo ratings yet

- M 168Document2 pagesM 168Katerin Hernandez50% (2)

- M 237Document4 pagesM 237Katerin Hernandez0% (1)

- 485 Ass1 Exampes PDFDocument375 pages485 Ass1 Exampes PDFfgh fghfghfNo ratings yet

- IEEE 118 Color PDFDocument35 pagesIEEE 118 Color PDFcarlos patrickNo ratings yet

- UntitledDocument37 pagesUntitledVenkatesh KinneraNo ratings yet

- Chem 1Document12 pagesChem 1Ellaine NacisNo ratings yet

- Change of Standard Gibbs Free Energy For The Decomposition of Sodium Hydrogen CarbonaDocument13 pagesChange of Standard Gibbs Free Energy For The Decomposition of Sodium Hydrogen CarbonaEuphoria V KhosaNo ratings yet

- Answers 1dkinematics PacketDocument28 pagesAnswers 1dkinematics PacketAbdalla MhrzNo ratings yet

- General Chemistry 1: Quarter 2 - Module 2 The Chemical BondingDocument17 pagesGeneral Chemistry 1: Quarter 2 - Module 2 The Chemical BondingKaren de los Reyes100% (1)

- List of FormulasDocument1 pageList of FormulasKenzy Waleed SolimanNo ratings yet

- 11 Heat Part1 Formula Sheets Getmarks AppDocument5 pages11 Heat Part1 Formula Sheets Getmarks AppVansh GuptaNo ratings yet

- PHARMACY, 8 (1), 87-109: 1983 by Marcel Dekker. IncDocument23 pagesPHARMACY, 8 (1), 87-109: 1983 by Marcel Dekker. Inchicham1963No ratings yet

- Magnetic Leakage FieldDocument13 pagesMagnetic Leakage FieldNjkt CADNo ratings yet

- Math Formula ListDocument3 pagesMath Formula ListKumaravel PadmaroopaNo ratings yet

- IEC 61400-3 EdDocument17 pagesIEC 61400-3 EdDaniel Ghersi0% (4)

- Alternator, (20000929-20031130) DatasheetDocument2 pagesAlternator, (20000929-20031130) DatasheetSales support TechnicalNo ratings yet

- Class X Science Multiple Choice Questions 1Document1 pageClass X Science Multiple Choice Questions 1rayi17198467% (12)

- QRT 4 Gen Chemistry Week 3 4Document26 pagesQRT 4 Gen Chemistry Week 3 4Quijano, Stephanie L.No ratings yet

- Introduction To FTIR SpectrosDocument12 pagesIntroduction To FTIR SpectrosĐào Văn HoạtNo ratings yet

- Structural Panels in Shear Through-the-Thickness: Standard Test Methods ForDocument10 pagesStructural Panels in Shear Through-the-Thickness: Standard Test Methods ForAnvit GadkarNo ratings yet

- Comparison of Different Evaluation Methods To Determine Stray Load Losses in Induction Machines With Eh-Star MethodDocument8 pagesComparison of Different Evaluation Methods To Determine Stray Load Losses in Induction Machines With Eh-Star MethodBorislav BrnjadaNo ratings yet

- Data Ncrp151Document17 pagesData Ncrp151Ibtissam ZazgadNo ratings yet

- Homework 3 SolutionDocument12 pagesHomework 3 SolutionTACN-2T?-19ACN Nguyen Dieu Huong LyNo ratings yet

- gr6 & 7 RoboDocument2 pagesgr6 & 7 RoboPriya Origin internationalNo ratings yet

- Basic Perspective DrawingDocument32 pagesBasic Perspective DrawingRegino GonzagaNo ratings yet

- LED 36W 2X2 Panel Light: Halonix Technologies Private LimitedDocument1 pageLED 36W 2X2 Panel Light: Halonix Technologies Private Limitedamitthakur2006No ratings yet

- Sir Alan Cottrell and The Dislocation Mechanics of FracturingDocument34 pagesSir Alan Cottrell and The Dislocation Mechanics of FracturingGood & GoodNo ratings yet

- Stellar SR33 Series Basic Soft Starters: Advantages Standards & ApprovalsDocument7 pagesStellar SR33 Series Basic Soft Starters: Advantages Standards & ApprovalsJOHAN RICARDO REINA FLORIDONo ratings yet

- Science: Quarter 2 - The "Magnifier"Document23 pagesScience: Quarter 2 - The "Magnifier"ShengNo ratings yet

- Kawasaki Jetski 800 SX R 2003 Service ManualDocument3 pagesKawasaki Jetski 800 SX R 2003 Service ManualPaul MartinNo ratings yet

- Device Corrosion: Enumerate The Electrical Contact Degradation and The Types of Mechanism Involved in ItDocument10 pagesDevice Corrosion: Enumerate The Electrical Contact Degradation and The Types of Mechanism Involved in ItSreekanth KrishnamurthyNo ratings yet