Professional Documents

Culture Documents

S1F Non-Metallic Pump: Technical Data Sheet

Uploaded by

spattacutOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S1F Non-Metallic Pump: Technical Data Sheet

Uploaded by

spattacutCopyright:

Available Formats

S1F NON-METALLIC PUMP

TECHNICAL DATA SHEET

SERIES

STANDARD DUTY BALL VALVE PUMPS

Offering the widest range of performance and application capabilities

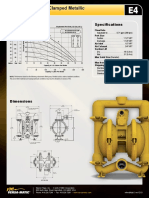

PERFORMANCE

SUCTION / DISCHARGE PORT SIZE HEADS UP TO

• 1” ANSI Flange or • 100 psi or 231 ft. of water

PN10 25mm DIN Flange (7 bar or 70 meters)

CAPACITY MAXIMUM OPERATING PRESSURE

• 0 to 53 gallons per minute • 100 psi (7 bar)

(0 to 200 liters per minute DISPLACEMENT/STROKE

AIR DISTRIBUTION VALVE • .19 Gallon / .72 liter

• No-lube, no-stall design WEIGHTS

SOLIDS-HANDLING • Polypropylene 42 lbs. (19kg)

• Up to .25 in. (6 mm) • PVDF 54 lbs. (24kg)

• Conductive Polypropylene 40 lbs. (18kg)

BAR

PSI

10 (17) Performance based on water at ambient temperature.

7 100 5 (9) 15 (26)

100 AIR CONSUMPTION IN SCFM

PSI AIR PRESSURE IN PSI

(6.8 20 (34)

Bar

6 )

25 (43)

80

80 P 30 (51)

SI (5

5 .44 B

ar)

NPSHR

35 (60)

60

HEAD

4 60 P 40 (68)

SI (4

.08 B

ar)

Meters

3

40

Feet

40 PS

I (2.72

Bar) 30 9.1

2

25 7.6

20 20 6

1 20 PSI 15 4.5

(1.36 B

ar) Air 10 3

Inlet Pre

ssure

5 1.5

0

0 5 10 15 20 25 30 35 40 45 50 55 GPM

0 25 50 75 100 125 150 175 200 LPM

CAPACITY

5 YEAR LIMITED PRODUCT WARRANTY USE ONLY GENUINE SANDPIPER PARTS

EX

CLUSIVE

5 Year Guarantee for defects in material or workmanship. See All certification, standards, guarantees & warranties

FE

sandpiperpump.com/content/warranty-certifications originally supplied with this pump will be invalidated by the use of

AT U R E

for complete warranty, including terms and conditions, limitations service parts not identified as “Genuine

and exclusions. SANDPIPER Parts.”

Warren Rupp, Inc. • A Unit of IDEX Corporation

II 2G EEx m c T5

800 N. Main St., Mansfield, Ohio 44902 USA

II 2D c IP65 T100°C ISO 9001 Certified

S A N D P I P E R P U M P. C O M Telephone 419.524.8388 • Fax 419.522.7867 ISO 14001 Certified

DIMENSIONS

S1F Non-Metallic Inline Ported Option- Polypropylene Wet End Models ONLY

Dimensions in inches (metric dimensions in brackets). Dimensional Tolerance .125" (3mm).

DISCHARGE PORT (OPTIONAL) A

1" FNPT

4.96 126

19.94 506

2X 2.15 55

STANDARD INTEGRAL MUFF

DISCHARGE PORT

1" FNPT

AIR INLET

1/2 FNPT

18.18 462 4.06 103

17.12 435

2.50 64 9.81 249 4X .53 13

MTG. SLOT

10.09 256

SUCTION PORT SUCTION PORT (OPTIONAL)

1" FNPT 1" FNPT

GENERAL NOTES .50 13

Mesh & Sound

Standard Integral Dampening Muffler

1. OPTIONAL SUCTION & DISCHARGE SIDE PORTS WILL BE PLUGGED AT Muffler Option

FACTORY, NOT SHOWN Option

2. STANDARD INTEGRAL MUFFLER (SHOWN) COVERS 1" FNPT EXHAUST PORT A 11.81 [300] 13.50 [343]

FOR OPTIONAL MUFFLER STYLES OR PIPING EXHAUST AIR IN SUBMERGED

APPLICATIONS

S1F Non-Metallic Side Ported Options

Dimensions in inches (metric dimensions in brackets). Dimensional Tolerance .125" (3mm).

DISCHARGE PORT

.56 X .69 SLOTTED BOLTING CONFIGURATION

FITS TO EITHER:

1" ANSI 125# FLANGE CONNECTION OR

A

PN10 25mm DIN FLANGE CONNECTION

17.04 433

4.96 126

3.62 92

MANIFOLD CAN ROTATE 90

FROM VERTICAL CENTERLINE STANDARD INTEGRAL MUFFLER

AIR INLET 4.00 102

1/2 FNPT

20.75 527

17.12 435

4X .44

MTG. SLOT

9.81 249

10.19 259

2.50 64

SUCTION PORT

.56 X .69 SLOTTED BOLTING CONFIGURATION .50 13 Mesh & Sound

FITS TO EITHER: 3.63 92

Standard Integral Dampening Muffler

1" ANSI 125# FLANGE CONNECTION OR Muffler Option

PN10 25mm DIN FLANGE CONNECTION Option

A 11.81 [300] 13.50 [343]

GENERAL NOTES

1. STANDARD INTEGRAL MUFFLER (SHOWN) COVERS 1" FNPT EXHAUST PORT

FOR OPTIONAL MUFFLER STYLES OR PIPING EXHAUST AIR IN SUBMERGED

Warren Rupp, Inc. • A Unit of IDEX Corporation APPLICATIONS

800 N. Main St., Mansfield, Ohio 44902 USA

S A N D P I P E R P U M P. C O M Telephone 419.524.8388 • Fax 419.522.7867

EXPLANATION OF PUMP NOMENCLATURE

S

Your Model

#: __ ____ __ __ __ __ __ __ __ __ __ ____

(fill in from

pump nameplate)

Pump Pump Check Design Wetted Diaphragm/ Check Valve

Non-Wetted Porting Pump Pump Kit

Config. Size Valve Level Material Check Valve Seat Material Options Style Options Options

Model #: S XX X X X X X X X X X XX

PUMP BRAND CHECK VALVE SEAT P0. 10.30VDC Pulse Output Kit

S SANDPIPER® K PVDF P1. Intrinsically-Safe 5.30VDC,

P Polypropylene 110/120VAC 220/240 VAC

PUMP SIZE Pulse Output Kit

1F 1” Full Flow NON-WETTED MATERIAL OPTIONS P2. 110/120 or 220/240VAC

P Polypropylene

CHECK VALVE TYPE 1 40% Glass Filled Polypropylene Pulse Output Kit

B Ball with PTFE hardware KIT OPTIONS (CONT.)

DESIGN LEVEL C Conductive Polypropylene

E0. Solenoid Kit with 24VDC Coil

3 Design Level PORTING OPTIONS E1. Solenoid Kit with 24VDC

WETTED MATERIAL N NPT Thread Explosion-Proof Coil

K PVDF U Universal (Fits ANSI and DIN) E2. Solenoid Kit with 24VAC/12VDC Coil

P Polypropylene 7 Dual Porting (ANSI) E3. Solenoid Kit with 12VDC

C Conductive Polypropylene 8 Top Dual Porting (ANSI) Explosion-Proof Coil

V Conductive PVDF 9 Bottom Dual Porting (ANSI) E4. Solenoid Kit with 110VAC Coil

E5. Solenoid Kit with 110VAC

DIAPHRAGM/CHECK VALVE MATERIALS PUMP STYLE Explosion-Proof Coil

1 Santoprene/Santoprene D With Electronic Leak E6. Solenoid Kit with 220VAC Coil

2 PTFE Santoprene Backup/PTFE Detection (110 V) E7. Solenoid Kit with 220VAC

3 PTFE Pumping, PTFE-Santoprene E With Electronic Leak Explosion-Proof Coil

Backup Driver/PTFE Detection (220V) E8. Solenoid Kit with 110VAC, 50 Hz

4 Santoprene Pumping/Santoprene I Inline Porting NPT Threads Explosion-Proof Coil

B Nitrile/Nitrile M With Mechanical E9. Solenoid Kit with 230VAC, 50 Hz

G PTFE-Neoprene Backup/PTFE Leak Detection Explosion-Proof Coil

M Santoprene/PTFE S Standard SP. Stroke Indicator Pins

N Neoprene/Neoprene V With Visual Leak Detection

V FKM/FKM A1. Solenoid Kit with 12 VDC

PUMP OPTIONS ATEX Compliant Coil

Y PTFE Pumping/One-Piece Bonded 0 None

Driver/PTFE A2. Solenoid Kit with 24 VDC

6 Metal Muffler ATEX Compliant Coil

Z One-Piece Bonded/PTFE

KIT OPTIONS A3. Solenoid Kit with 110/120 VAC

00. None 50/60 Hz ATEX Compliant Coil

MATERIALS

A4. Solenoid Kit with 220/240 VAC

50/60 Hz ATEX Compliant Coil

Material Profile: Operating

Temperatures:

POLYPROPYLENE: A thermoplastic polymer. Moderate tensile

and flex strength. Resists stong acids and alkali. Attacked by

180°F

82°C

32°F

0°C

CAUTION! Operating temperature limitations are as follows: chlorine, fuming nitric acid and other strong oxidizing agents.

Max. Min.

PVDF: (Polyvinylidene Fluoride) A durable fluoroplastic with 250°F 0°F

CONDUCTIVE ACETAL: Tough, impact resistant, ductile. Good 190°F -20°F

excellent chemical resistance. Excellent for UV applications. 121°C -18°C

abrasion resistance and low friction surface. Generally inert, 88°C -29°C

High tensile strength and impact resistance.

with good chemical resistance except for strong acids and

oxidizing agents. SANTOPRENE®: Injection molded thermoplastic elastomer with 275°F -40°F

no fabric layer. Long mechanical flex life. Excellent abrasion 135°C -40°C

EPDM: Shows very good water and chemical resistance. Has 280°F -40°F

resistance.

poor resistance to oils and solvents, but is fair in ketones and 138°C -40°C

alcohols. UHMW PE: A thermoplastic that is highly resistant to a broad 180°F -35°F

range of chemicals. Exhibits outstanding abrasion and impact 82°C -37°C

FKM (FLUOROCARBON): Shows good resistance to a wide 350°F -40°F

resistance, along with environmental stress-cracking resistance.

range of oils and solvents; especially all aliphatic, aromatic and 177°C -40°C

halogenated hydrocarbons, acids, animal and vegetable oils. URETHANE: Shows good resistance to abrasives. Has poor 150°F 32°F

Hot water or hot aqueous solutions (over 70°F(21°C)) will attack resistance to most solvents and oils. 66°C 0°C

FKM.

VIRGIN PTFE: (PFA/TFE) Chemically inert, virtually impervious. 220°F -35°F

HYTREL®: Good on acids, bases, amines and glycols at room 220°F -20°F Very few chemicals are known to chemically react with PTFE; 104°C -37°C

temperatures only. 104°C -29°C molten alkali metals, turbulent liquid or gaseous fluorine and a few

fluoro-chemicals such as chlorine trifluoride or oxygen difluoride

NEOPRENE: All purpose. Resistance to vegetable oils. Gener- 200°F -10°F

which readily liberate free fluorine at elevated temperatures.

ally not affected by moderate chemicals, fats, greases and 93°C -23°C

many oils and solvents. Generally attacked by strong oxidizing Maximum and Minimum Temperatures are the limits for which these materials can be

acids, ketones, esters and nitro hydrocarbons and chlorinated operated. Temperatures coupled with pressure affect the longevity of diaphragm pump

aromatic hydrocarbons. components. Maximum life should not be expected at the extreme limits of the

temperature ranges.

NITRILE: General purpose, oil-resistant. Shows good solvent, 190°F -10°F

oil, water and hydraulic fluid resistance. Should not be used with

highly polar solvents like acetone and MEK, ozone, chlorinated

88°C -23°C

Metals:

hydrocarbons and nitro hydrocarbons. ALLOY C: Equal to ASTM494 CW-12M-1 specification for nickel and nickel alloy.

NYLON: 6/6 High strength and toughness over a wide tem- 180°F 32°F STAINLESS STEEL: Equal to or exceeding ASTM specification A743 CF-8M for corro-

perature range. Moderate to good resistance to fuels, oils and 82°C 0°C sion resistant iron chromium, iron chromium nickel and nickel based alloy castings for

chemicals. general applications. Commonly referred to as 316 Stainless Steel in the pump industry.

For specific applications, always consult the Chemical Resistance Chart.

II 2G EEx m c T5

II 2D c IP65 T100°C

Warren Rupp, Inc. • A Unit of IDEX Corporation

800 N. Main St., Mansfield, Ohio 44902 USA

NOTE: See service manual for ATEX details.

S A N D P I P E R P U M P. C O M Telephone 419.524.8388 • Fax 419.522.7867 SP_DS_TemplateDataSheet_0817

You might also like

- Sandpiper s1f PumpDocument3 pagesSandpiper s1f PumpAdi PurnomoNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- pb025 NM STANDARDDocument3 pagespb025 NM STANDARDAlvaro Iparraguirre NavarroNo ratings yet

- s05 M StandardDocument3 pagess05 M Standardlaura.diazNo ratings yet

- Sandpiper S15 Bomba NeumaticaDocument3 pagesSandpiper S15 Bomba NeumaticaAlejandro AdriasolaNo ratings yet

- S30 Non-Metallic Containment Duty Pump: Technical Data SheetDocument2 pagesS30 Non-Metallic Containment Duty Pump: Technical Data SheetMuhamad nurul aminNo ratings yet

- Sandpiper s30nmdl2dsDocument4 pagesSandpiper s30nmdl2dsYongfeng QianNo ratings yet

- s30 SMetallic Data SheetDocument5 pagess30 SMetallic Data Sheetluis miguel velarde manriqueNo ratings yet

- Metallic Design Level 1 Ball Valve: Air-Powered Double-Diaphragm PumpDocument6 pagesMetallic Design Level 1 Ball Valve: Air-Powered Double-Diaphragm PumpCarlos Alberto OspinaNo ratings yet

- s20 Metalik Data Sheet Rev0817Document2 pagess20 Metalik Data Sheet Rev0817STEPF cryptoNo ratings yet

- Sump PumpDocument2 pagesSump PumpRAM SANNo ratings yet

- Bomba Neumatica Sandpiper Metalica Modelo S20Document8 pagesBomba Neumatica Sandpiper Metalica Modelo S20Edgar EncinaNo ratings yet

- HDF1 M HdflapDocument2 pagesHDF1 M HdflapAlvaro Iparraguirre NavarroNo ratings yet

- S07nmdl1ds ENDocument5 pagesS07nmdl1ds ENYongfeng QianNo ratings yet

- Eaton 421 Pump Sheet Vers-BDocument2 pagesEaton 421 Pump Sheet Vers-Bdzakky syahputraNo ratings yet

- Binks AX260L Air Motor BreakdownDocument11 pagesBinks AX260L Air Motor BreakdownAryo KamandanuNo ratings yet

- Sandpiper Standard Duty Metallic Pumps s30 Data SheetDocument3 pagesSandpiper Standard Duty Metallic Pumps s30 Data Sheetjose manuel alvarez rodriguezNo ratings yet

- S20 Metallic Pump: Technical Data SheetDocument3 pagesS20 Metallic Pump: Technical Data SheetDang LucNo ratings yet

- Typical Performance Curve SRU3/038/ (Sru3Wls) With Hyclean SealDocument6 pagesTypical Performance Curve SRU3/038/ (Sru3Wls) With Hyclean SealSonia Marcela AriasNo ratings yet

- WD Bredel 25 32 enDocument2 pagesWD Bredel 25 32 enMario CalvisiNo ratings yet

- Bomba de Agua Shurflo 8007-593-836 Sup SH 12V 35 MTSDocument2 pagesBomba de Agua Shurflo 8007-593-836 Sup SH 12V 35 MTSrocilic114No ratings yet

- Typical Performance Curve Sru5Wld (Sru5/168) With Hyclean SealDocument1 pageTypical Performance Curve Sru5Wld (Sru5/168) With Hyclean Sealdanielagomezga_45545No ratings yet

- 6000 - Spec BooterDocument2 pages6000 - Spec BooterCasanova FernandoNo ratings yet

- Bulldog 43:1 Air-Powered Pump: Ideal For Blowout Preventor SystemsDocument2 pagesBulldog 43:1 Air-Powered Pump: Ideal For Blowout Preventor Systemsangel benito PortilloNo ratings yet

- Operating Instructions: 1" Elima-Matic Bolted PumpDocument13 pagesOperating Instructions: 1" Elima-Matic Bolted PumpJOSE INESNo ratings yet

- WD Duconite 25 32 GB 03Document2 pagesWD Duconite 25 32 GB 03Jorge Luis BriceñoNo ratings yet

- Scanjet Datasheet Bio7SBDocument2 pagesScanjet Datasheet Bio7SBGabriel TravassosNo ratings yet

- Flojet Industrial Pump N5100-020Document4 pagesFlojet Industrial Pump N5100-020Felipe Frutuoso0% (1)

- SBKP - Sid Rnav Isevu 1a Rwy 33 - Sid - 20171012Document1 pageSBKP - Sid Rnav Isevu 1a Rwy 33 - Sid - 20171012Matheus BrandtNo ratings yet

- Filtro Carbon ActivoDocument1 pageFiltro Carbon ActivoZzmangostazZNo ratings yet

- 10US 50 Ssu CurveDocument1 page10US 50 Ssu CurveHermanto penjolbaeNo ratings yet

- Directional Control Valve: V20 SeriesDocument8 pagesDirectional Control Valve: V20 SeriesRAYNo ratings yet

- Classic Dripline With Flat Dripper and Long Labyrinth: Ideal For Orchards!Document2 pagesClassic Dripline With Flat Dripper and Long Labyrinth: Ideal For Orchards!Mk TouamiNo ratings yet

- Technical Specifications: CV / CL Series FiltersDocument2 pagesTechnical Specifications: CV / CL Series FiltersEmanuel MurilloNo ratings yet

- Barometric, Gage or Absolute Pressure Ranges: PX2700 SeriesDocument2 pagesBarometric, Gage or Absolute Pressure Ranges: PX2700 SeriesicsNo ratings yet

- Datasheet Bredel - 40 50Document2 pagesDatasheet Bredel - 40 50Giorgi GhambashidzeNo ratings yet

- VM Sludgemaster Rev1222Document15 pagesVM Sludgemaster Rev1222Pkk Siam Rayong co-saleNo ratings yet

- Sru5 168 HDDocument1 pageSru5 168 HDvicenteNo ratings yet

- CP340-1 Flow DividerDocument1 pageCP340-1 Flow DividerRonaldNo ratings yet

- Series B10-2 - Technical Information General Description Performance CurveDocument2 pagesSeries B10-2 - Technical Information General Description Performance CurveLuis Fernando Ramírez PromotorNo ratings yet

- SB 930Document8 pagesSB 930Mauricio Hermosilla OrellanaNo ratings yet

- CP340-1/CP340-1S Flow Divider/Combiner: Flow Control Valves Technical InformationDocument1 pageCP340-1/CP340-1S Flow Divider/Combiner: Flow Control Valves Technical InformationmatheusNo ratings yet

- 1 1/2" Elima-Matic Clamped Metallic: Performance SpecificationsDocument1 page1 1/2" Elima-Matic Clamped Metallic: Performance SpecificationsAldy DankersNo ratings yet

- Compressor/Vacuum Pumps For Liquid Waste Tankers: Truck SeriesDocument4 pagesCompressor/Vacuum Pumps For Liquid Waste Tankers: Truck Seriessourov mutsuddyNo ratings yet

- Water 639,0 MM (D1) : Termo Paipa Cooling Water Pumps SJM CWP Bsm650-1SDocument1 pageWater 639,0 MM (D1) : Termo Paipa Cooling Water Pumps SJM CWP Bsm650-1SAlexander PinedaNo ratings yet

- ADC3010 AF 484 Series RegulatorDocument3 pagesADC3010 AF 484 Series RegulatormiguesobeNo ratings yet

- Bravo: Technical Catalogue Compressor - CSL 40BR/250L 2 STAGES - 175 PsigDocument4 pagesBravo: Technical Catalogue Compressor - CSL 40BR/250L 2 STAGES - 175 PsigALINE CARDOSONo ratings yet

- Pressure ControlsDocument56 pagesPressure Controlsapi-3854910100% (1)

- Needle Valves: Flow ControlsDocument2 pagesNeedle Valves: Flow ControlsyorisfmNo ratings yet

- R73G, R73R: Technical DataDocument4 pagesR73G, R73R: Technical DataEnrique Arellano HidalgoNo ratings yet

- Estandar Disolucion LevoDocument5 pagesEstandar Disolucion LevoBrendapaez3No ratings yet

- CHDS Fchmber 141002 PDFDocument4 pagesCHDS Fchmber 141002 PDFVils ArabadzhievaNo ratings yet

- DBB8666 Fuel Filter Data SheetDocument2 pagesDBB8666 Fuel Filter Data SheetJamyansuren TseveendorjNo ratings yet

- Ficha Tecnica Surflo 8090-212-246Document2 pagesFicha Tecnica Surflo 8090-212-246Fernando YepezNo ratings yet

- 152 Series RegulatorsDocument1 page152 Series RegulatorsScientific EquipmentNo ratings yet

- Mindman Maf200Document1 pageMindman Maf200Alejandro ZapataNo ratings yet

- High Pressure Check Valves: SHCV SeriesDocument8 pagesHigh Pressure Check Valves: SHCV SeriesToty DzNo ratings yet

- 1PF2G42X Ra 10042Document6 pages1PF2G42X Ra 10042aminNo ratings yet

- Cvsection cvh081pDocument1 pageCvsection cvh081pVentas Control HidráulicoNo ratings yet

- Surface PretreatmentDocument48 pagesSurface PretreatmentAnonymous 6tg80e6BqANo ratings yet

- WaterDocument40 pagesWaterhimanshuchawla654No ratings yet

- Lead Fire-Assay: Method Code Gravimetric Determination of Gold and SilverDocument5 pagesLead Fire-Assay: Method Code Gravimetric Determination of Gold and SilverAnonymous FfIxH2o9No ratings yet

- Secrets of Good Peak Shape in HPLCDocument44 pagesSecrets of Good Peak Shape in HPLCWan Ton100% (1)

- FTIR Spectroscopy MontmorilloniteDocument6 pagesFTIR Spectroscopy MontmorilloniteAdrian VolceanovNo ratings yet

- 22.2 - Alkanes, Cycloalkanes, Alkenes, Alkynes, and Aromatics - Chemistry LibreTextsDocument1 page22.2 - Alkanes, Cycloalkanes, Alkenes, Alkynes, and Aromatics - Chemistry LibreTextsbrettNo ratings yet

- FILE NO 3 Exercise 2 Chemical Formula Writing and Naming of Compounds RevDocument2 pagesFILE NO 3 Exercise 2 Chemical Formula Writing and Naming of Compounds RevEJ TaylanNo ratings yet

- CHM131 - Chapter 1 - Atoms - Molecules Ions - Chemical EqDocument106 pagesCHM131 - Chapter 1 - Atoms - Molecules Ions - Chemical EqLeo PietroNo ratings yet

- Laporan Metil Salisilat 2018Document12 pagesLaporan Metil Salisilat 2018Novia KurbaniaNo ratings yet

- Exercise No. 08 - Chloramphenicol PalmitateDocument5 pagesExercise No. 08 - Chloramphenicol PalmitatepharmaebooksNo ratings yet

- Astm C150Document9 pagesAstm C150alexintel100% (3)

- Aldehyde, Ketone & Carboxylic Acid CHEMHACKDocument12 pagesAldehyde, Ketone & Carboxylic Acid CHEMHACKplightpixelNo ratings yet

- Precipitated SulfurDocument1 pagePrecipitated SulfurArvin Jonathan Cua0% (2)

- Química de CoordinacionDocument107 pagesQuímica de CoordinacionEMMANUEL ALEJANDRO FERNANDEZ GAVIRIANo ratings yet

- 3 Woda 2016 Woda 5 10062016Document14 pages3 Woda 2016 Woda 5 10062016AdrianoNo ratings yet

- Tpoic 3Document12 pagesTpoic 3Marvin EusebioNo ratings yet

- Acid Base CatalysisDocument13 pagesAcid Base CatalysisKaran Jeswani100% (2)

- Carbonato de Calcio-2015 PDFDocument2 pagesCarbonato de Calcio-2015 PDFVictor Manuel Contreras HernandezNo ratings yet

- Biodiesel Puri Fication and Upgrading Technologies: Hbateni@iastate - EduDocument44 pagesBiodiesel Puri Fication and Upgrading Technologies: Hbateni@iastate - EduRyan FebrinoNo ratings yet

- 152 809 2 PBDocument12 pages152 809 2 PBsujal jhaNo ratings yet

- Mock #8Document45 pagesMock #8tonetoNo ratings yet

- Kataoka 1996Document16 pagesKataoka 1996alonrabNo ratings yet

- 1 Theory2Document16 pages1 Theory2Tushar RajNo ratings yet

- Best AnswerDocument11 pagesBest AnswerEdwin Lan100% (1)

- Volatile Chemicals From Thermal Degradation of Less Volatile Coffee ComponentsDocument7 pagesVolatile Chemicals From Thermal Degradation of Less Volatile Coffee ComponentsemiliaNo ratings yet

- Chapter 2 Atoms IonsDocument42 pagesChapter 2 Atoms IonsJunaid AlamNo ratings yet

- Qualitative Analysis LabDocument4 pagesQualitative Analysis LabScottyNo ratings yet

- Haloalakne and HaloarenesDocument2 pagesHaloalakne and HaloarenesJasmin 10115No ratings yet

- SUMMATIVE ASSESSMENT 2021 - Paper 1Document4 pagesSUMMATIVE ASSESSMENT 2021 - Paper 1brianNo ratings yet

- UtsDocument2 pagesUtsIstiqomah RahmawatiNo ratings yet