Professional Documents

Culture Documents

Sand FM Details

Uploaded by

V Venkata NarayanaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sand FM Details

Uploaded by

V Venkata NarayanaCopyright:

Available Formats

THE IMPORTANCE OF CALCULATION OF FINENESS

FITNESS MODULUS MODULUS (FM) FOR FINE AGGREGATE

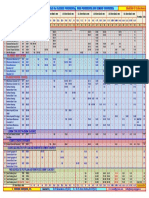

By Bruce Suprenant SIEVE WEIGHT INDIVIDUAL TOTAL SUM TO

RETAINED PERCENT PERCENT CALCULATE

I

n 1925, Duff Abrams introduced (GRAMS) RETAINED, % RETAINED, % F.M.

the concept of fineness modulus

(FM) for estimating the propor- No. 4 9.2 2 2 Yes

tions of fine and coarse aggregates in No. 8 67.6 13 15 Yes

concrete mixtures. The premise: No. 16 101.2 20 35 Yes

“aggregate of the same fineness mod-

No. 30 102.2 20 55 Yes

ulus will require the same quantity of

water to produce a mix of the same No. 50 120.5 24 79 Yes

consistency and give a concrete of the No. 100 93.1 18 97 Yes

same strength.” Over the years, many No. 200 10.2 2 99 Yes

ready mix producers have verified the

Pan 4.5 1 100 No

wisdom of Abram’s premise.

ASTM C 33 “Standard Specification Total 508.5 100 FM = 283/100 = 2.83

for Concrete Aggregates” specifies

requirements for the FM of fine aggre-

gate, and ACI 211 “Standard Practice fine aggregate are No. 4, 8, 16, 30, 50, strength. In general, manufactured

for Selecting Proportions for Normal, and 100. The No. 200 sieve is included sands require more fines than natural

Heavyweight, and Mass Concrete” in a standard sieve analysis, but is not sands for equal workability.

uses FM to select the amount of coarse used to calculate FM.

aggregates for trial mix designs. ASTM C 33 requires the FM of fine CHECK FOR AGGREGATE VARIATIONS

Because FM is such a widely used aggregate to be between 2.3 and 3.1. Because changes in fine aggregate

index for aggregate proportioning, The higher the FM, the coarser the can significantly affect concrete prop-

most testing labs report the FM for aggregate. FM doesn’t define the erties, FM variations should be close-

fine aggregate with each sieve analy- grading curve, however, since differ- ly monitored.

sis. ent gradings can have the same FM. Concrete is proportioned using a

base fineness modulus determined

CALCULATING FM HOW AGGREGATE FINENESS AFFECTS from previous tests or, if no previous

Before calculating FM, lab techni- CONCRETE PROPERTIES tests exist, from the average of the FM

cians perform a sieve analysis to Fine aggregate affects many con- values for the first 10 aggregate sam-

determine the particle size distribu- crete properties, including workabili- ples tested. Aggregates delivered

tion, or grading, of the aggregate sam- ty and finishability. Experience has with a different FM than the base

ple. To obtain a grading, the aggregate shown that very coarse sand or very value may require an adjustment in

is shaken through a series of sieves, fine sand produces poor concrete the concrete mix.

nested one above the other in order of mixes. Coarse sand results in harsh For shipments of fine aggregate

size. The sieve with the largest open- concrete mixes prone to bleeding and from a given source, the FM shouldn’t

ings is on top and the one with the segregation. Fine sand requires a vary more than 0.2 from the base

smallest openings is on the bottom. A comparatively large amount of water value. (The purchaser may agree,

pan placed beneath the sieves catches to achieve the desired concrete work- however, to accept a greater base

material passing through the smallest ability, is prone to segregation, and value variation from a specific aggre-

sieve. may require higher cement contents. gate source.) If the fineness modulus

Coarse and fine aggregate usually Figure 1 shows that decreasing FM varies by 0.2, adjust the proportions of

are sieved separately. That portion of for a sand used in mortar requires con- fine and coarse aggregate. As the FM

an aggregate sample passing the No. siderably more cement content when decreases (aggregate becomes finer),

4 sieve is fine aggregate. After sieving, the water-cement ratio and slump are use a lower percentage of sand in the

a scale is used to weigh material held constant. However, a changing FM total aggregate or increase the amount

retained on each sieve and on the pan. has little influence on the cement con- of coarse aggregate.

FM is the sum of the total percentages tent required in concrete.

retained on each specified sieve divid- Usually, a lower FM results in more

ed by 100 (Table 1). The lower limit of paste, making concrete easier to finish.

the specified sieves is the No. 100 For the high cement contents used in

sieve and the actual size of the open- the production of high-strength con-

ings in each larger sieve is twice that crete, coarse sand with an FM around PUBLICATION #J940107

of the sieve below. The most common 3.0 produces concrete with the best Copyright © 1994, The Aberdeen Group

sieve sizes for calculating the FM of workability and highest compressive All rights reserved

You might also like

- Sec 400 (Most Version)Document37 pagesSec 400 (Most Version)abhijit_xpNo ratings yet

- MoRTH Specifications Pocket Book 09.04.2019 FinalDocument92 pagesMoRTH Specifications Pocket Book 09.04.2019 FinalsombansNo ratings yet

- EBOOK Integrated Details of Roads For The Year 2014 - 15Document84 pagesEBOOK Integrated Details of Roads For The Year 2014 - 15V Venkata Narayana100% (3)

- Failure of Government Buildings at Early AgeDocument21 pagesFailure of Government Buildings at Early AgeV Venkata Narayana100% (3)

- Layers of Flexible PavementDocument52 pagesLayers of Flexible Pavementsavan chavanNo ratings yet

- Irc 063-1976Document9 pagesIrc 063-1976kruttika_apNo ratings yet

- Pavement Design, Construction and Maintenance For Bituminous RoadsDocument47 pagesPavement Design, Construction and Maintenance For Bituminous RoadsMadhavpokaleNo ratings yet

- TOR TOT Preparation of Detailed Project Report On Physical Condition of The National Highways StretchesDocument6 pagesTOR TOT Preparation of Detailed Project Report On Physical Condition of The National Highways StretchesSuyog GoreNo ratings yet

- Irc 120 2015 PDFDocument72 pagesIrc 120 2015 PDFrameshsrprsNo ratings yet

- Earth Work Guide Lines As Per GE 0014 in Indian RailwaysDocument92 pagesEarth Work Guide Lines As Per GE 0014 in Indian RailwaysRamojiNaikNo ratings yet

- Pavement Design Report 07-03-2020Document18 pagesPavement Design Report 07-03-2020Chandan Kumar Das50% (2)

- IRC-73 Rural High Ways TablesDocument9 pagesIRC-73 Rural High Ways TablesV Venkata Narayana100% (1)

- INTERVIEWDocument5 pagesINTERVIEWMRITYUNJAY PANDEYNo ratings yet

- 6 - Irc SP 85 PDFDocument44 pages6 - Irc SP 85 PDFJoselin LeoNo ratings yet

- NHAI Calendar Low ResDocument13 pagesNHAI Calendar Low Resদেবীসা দুর্গা সিনহা100% (1)

- 1 Introduction To Highway EngineeringDocument19 pages1 Introduction To Highway EngineeringLynas Beh TahanNo ratings yet

- WMM Mix DesignDocument22 pagesWMM Mix DesignDivyesh AhirNo ratings yet

- Axle Load Survey FormatDocument2 pagesAxle Load Survey FormatSatish BhairanattiNo ratings yet

- Test Report Volume - 2 PDFDocument495 pagesTest Report Volume - 2 PDFakilan100% (1)

- Proposed Revisions To MORTH Specifications For Roads (Fifth Edition Dated 2013) by Prof. KandhalDocument14 pagesProposed Revisions To MORTH Specifications For Roads (Fifth Edition Dated 2013) by Prof. KandhalProf. Prithvi Singh KandhalNo ratings yet

- SDBC-Job Mix FinalDocument31 pagesSDBC-Job Mix FinalAchintya DasNo ratings yet

- (With Flyash) : M-20 KERBDocument8 pages(With Flyash) : M-20 KERBNaveen SinghNo ratings yet

- 40mm Aggregate For Concrete Flakiness Elongation IndicesDocument147 pages40mm Aggregate For Concrete Flakiness Elongation IndicesV Venkata Narayana100% (6)

- Right of Way:: 120' 36 .00 MDocument4 pagesRight of Way:: 120' 36 .00 MV Venkata NarayanaNo ratings yet

- 57 - MoRTH 5th RVN What Is Where and Where Is What - Venkata Narayana - PrintDocument4 pages57 - MoRTH 5th RVN What Is Where and Where Is What - Venkata Narayana - PrintV Venkata Narayana100% (2)

- Bituminous Mix DesignDocument62 pagesBituminous Mix DesignShaim RehanNo ratings yet

- Final BC Grade 2 With VG 40 Honeywell Titan Polymer 56 HMP 1 Lime and 0.8 PolymerDocument15 pagesFinal BC Grade 2 With VG 40 Honeywell Titan Polymer 56 HMP 1 Lime and 0.8 PolymerSunil BoseNo ratings yet

- Irc SP 20Document64 pagesIrc SP 20Prasad Chowdry100% (1)

- KSR Job Mix DBM II - pdf-1Document6 pagesKSR Job Mix DBM II - pdf-1Ankur BarsainyaNo ratings yet

- By: Hiralal Agrawal: Executive EngineerDocument38 pagesBy: Hiralal Agrawal: Executive EngineerCheng EngiNo ratings yet

- Design of Rigid Pavement For TunnelsDocument19 pagesDesign of Rigid Pavement For TunnelsHemant YesajiNo ratings yet

- Embankment & Sub-Grade LayerDocument9 pagesEmbankment & Sub-Grade LayerPathankot MandiNo ratings yet

- Lesson 4: Hot Mix Asphalt - Mix Design: CEE 595 Construction Materials Winter 2008Document37 pagesLesson 4: Hot Mix Asphalt - Mix Design: CEE 595 Construction Materials Winter 2008akmeez100% (1)

- Letter To Highway Colleagues in India On Use of "Third Class" Bitumen Emulsion For Prime CoatDocument4 pagesLetter To Highway Colleagues in India On Use of "Third Class" Bitumen Emulsion For Prime CoatProf. Prithvi Singh Kandhal100% (1)

- WMM Gradation3Examples PDFDocument32 pagesWMM Gradation3Examples PDFV Venkata Narayana100% (4)

- QA in Highway Sector-Part-4Document10 pagesQA in Highway Sector-Part-4boomiNo ratings yet

- A Report On: Sub-Soil Investigation For The Proposed Construction of Minor Bridge Over Chora Nala at Ch. KM 4.000Document30 pagesA Report On: Sub-Soil Investigation For The Proposed Construction of Minor Bridge Over Chora Nala at Ch. KM 4.000Manvendra NigamNo ratings yet

- Flexible Pavement (Bituminous Road) : Compacted Soil SubgradeDocument3 pagesFlexible Pavement (Bituminous Road) : Compacted Soil SubgradeDinesh Kumar PatelNo ratings yet

- Asphtlatoseal NewDocument41 pagesAsphtlatoseal Newnagaraj_qce3499100% (1)

- Work Program For Consolidated COS Work 13.09.2019Document46 pagesWork Program For Consolidated COS Work 13.09.2019hardikNo ratings yet

- GSB (SOURCE - BATHU UNA QUARRY) Grade - IIIDocument27 pagesGSB (SOURCE - BATHU UNA QUARRY) Grade - IIIjitendra100% (1)

- IRC CatalogueDocument12 pagesIRC CatalogueMohnish Kaushal100% (1)

- CENG 6305 Ch3 Soil StabilizationDocument62 pagesCENG 6305 Ch3 Soil StabilizationsamiNo ratings yet

- FlexiblePavements QCTablesDocument22 pagesFlexiblePavements QCTablesV Venkata Narayana100% (2)

- Irc 115 2014 FWDDocument44 pagesIrc 115 2014 FWDp09tp451No ratings yet

- Pmgsy Circular About Rural Road GeometryDocument16 pagesPmgsy Circular About Rural Road Geometryprasadnn2001100% (1)

- CBR ProjectDocument46 pagesCBR ProjectChau Suktana EnlingNo ratings yet

- VDF CalculationDocument4 pagesVDF CalculationswarupmandalNo ratings yet

- Prof M A Reddy Part 1Document29 pagesProf M A Reddy Part 1najuka ghodvindeNo ratings yet

- Semana 03 O - The Importance of Fineness ModulusDocument1 pageSemana 03 O - The Importance of Fineness ModulusGuillermo AlcantaraNo ratings yet

- The Concrete Producer Article PDF - Mix Designs For Concrete Block PDFDocument4 pagesThe Concrete Producer Article PDF - Mix Designs For Concrete Block PDFMa'rufSamuderaPasaiNo ratings yet

- Coarse and Fine Aggregates: Presented byDocument26 pagesCoarse and Fine Aggregates: Presented byKhan AaghaNo ratings yet

- Effect of Fineness of SandDocument8 pagesEffect of Fineness of SandRamBinodSharmaNo ratings yet

- Avances en La GeotecniaDocument6 pagesAvances en La GeotecniaKarla AlarconNo ratings yet

- Bce (Class 5) - Material - 1843692 - 2023 - 06 - 09 - 22 - 24Document13 pagesBce (Class 5) - Material - 1843692 - 2023 - 06 - 09 - 22 - 24witnessNo ratings yet

- Models Relating Mixture Composition To The Density and Strength of Foam Concrete Using Response Surface Methodology - Nambiar & Ramamurthy 2006 PDFDocument9 pagesModels Relating Mixture Composition To The Density and Strength of Foam Concrete Using Response Surface Methodology - Nambiar & Ramamurthy 2006 PDFalexnlima852No ratings yet

- Concrete Mix DesignDocument67 pagesConcrete Mix DesignAnket PandeyNo ratings yet

- Proportions and Quantities: Strength Reduction, When Using Air-EntrainDocument6 pagesProportions and Quantities: Strength Reduction, When Using Air-EntrainLuyanda SilangweNo ratings yet

- Chapter-3 Highway Pavement MaterialsDocument47 pagesChapter-3 Highway Pavement MaterialsZemichael AbaynehNo ratings yet

- Road Safety Measures On Stretches of National Highways - RegardingDocument4 pagesRoad Safety Measures On Stretches of National Highways - RegardingDhiren PatelNo ratings yet

- Venkat Rigid Pavement Tables of Joints and SteelDocument2 pagesVenkat Rigid Pavement Tables of Joints and SteelV Venkata NarayanaNo ratings yet

- VenkatBox Cell Structuresa at Glance GraphicDocument3 pagesVenkatBox Cell Structuresa at Glance GraphicV Venkata NarayanaNo ratings yet

- VenkatBox Cell Structuresa at Glance GraphicDocument3 pagesVenkatBox Cell Structuresa at Glance GraphicV Venkata NarayanaNo ratings yet

- Venkats Interpretation On Configuration of MORTHDocument29 pagesVenkats Interpretation On Configuration of MORTHV Venkata Narayana100% (3)

- Venkat Master SemiLog CurvesPlainDocument28 pagesVenkat Master SemiLog CurvesPlainV Venkata NarayanaNo ratings yet

- Venkat Rigid Pavement Tables of Joints and Steel PDFDocument2 pagesVenkat Rigid Pavement Tables of Joints and Steel PDFV Venkata NarayanaNo ratings yet

- 60 - Master Gradation Table of All Aggregates For Pavements and Cement ConcretesDocument1 page60 - Master Gradation Table of All Aggregates For Pavements and Cement ConcretesV Venkata Narayana100% (3)

- 60 - Master Gradation Table of All Aggregates For Pavements and Cement ConcretesDocument1 page60 - Master Gradation Table of All Aggregates For Pavements and Cement ConcretesV Venkata Narayana100% (3)

- 57 - MoRTH 5th RVN What Is Where and Where Is What - Venkata Narayana - PrintDocument4 pages57 - MoRTH 5th RVN What Is Where and Where Is What - Venkata Narayana - PrintV Venkata Narayana100% (2)

- 57 - MoRTH 5th RVN What Is Where and Where Is What - Venkata Narayana - PrintDocument4 pages57 - MoRTH 5th RVN What Is Where and Where Is What - Venkata Narayana - PrintV Venkata Narayana100% (2)

- Venkat - MoRTH 5th Revision Essential Tables For Highway Field EngineersDocument68 pagesVenkat - MoRTH 5th Revision Essential Tables For Highway Field EngineersV Venkata Narayana96% (28)

- 56 - Venkat - MoRTH 5th Revision Essential Tables For Highway Field Engineers PrintDocument34 pages56 - Venkat - MoRTH 5th Revision Essential Tables For Highway Field Engineers PrintV Venkata Narayana100% (4)

- Venkat Master SemiLog CurvesPlainDocument28 pagesVenkat Master SemiLog CurvesPlainV Venkata NarayanaNo ratings yet

- IRC 85 1983 Part2 PDFDocument11 pagesIRC 85 1983 Part2 PDFV Venkata NarayanaNo ratings yet

- VenkatBox Box Culverts AbstractDocument1 pageVenkatBox Box Culverts AbstractV Venkata Narayana0% (1)

- Morth400 Sub-Bases and Bases Tables of Gradation Tests LimitsDocument5 pagesMorth400 Sub-Bases and Bases Tables of Gradation Tests LimitsV Venkata Narayana100% (2)

- Venkat Master Semi-Log Curves For Metal GradationDocument28 pagesVenkat Master Semi-Log Curves For Metal GradationV Venkata Narayana100% (1)

- Standard Data Book (Roads & Bridges)Document353 pagesStandard Data Book (Roads & Bridges)shariqabideen81% (63)

- Membership Form A-1Document2 pagesMembership Form A-1V Venkata NarayanaNo ratings yet

- The Modern Asphalt Pavement 1904 PDFDocument617 pagesThe Modern Asphalt Pavement 1904 PDFV Venkata NarayanaNo ratings yet

- APPROACH SLABS Venkata NarayanaDocument9 pagesAPPROACH SLABS Venkata NarayanaV Venkata Narayana100% (1)

- Bituminous Mixtures in Roads - 1Document586 pagesBituminous Mixtures in Roads - 1V Venkata Narayana100% (1)

- 1904Document24 pages1904Palani KumarNo ratings yet

- Fundamentals of Concrete ADocument174 pagesFundamentals of Concrete AV Venkata Narayana100% (1)

- Approach Slabs - For BRIDGES VenkatDocument3 pagesApproach Slabs - For BRIDGES VenkatV Venkata Narayana0% (1)

- d36 Softening Point Test Ring and BallDocument5 pagesd36 Softening Point Test Ring and BallNurul RizalNo ratings yet

- Go 94Document36 pagesGo 94Pasha100% (5)

- Aiwa RM-77 Service ManualDocument9 pagesAiwa RM-77 Service Manualcristianhumberto_reyesaguileraNo ratings yet

- Model Space & Layout (Paper) SpaceDocument7 pagesModel Space & Layout (Paper) SpaceIonela Lioara TutaNo ratings yet

- Swot Analysis of PTCLDocument5 pagesSwot Analysis of PTCLM Aqeel Akhtar JajjaNo ratings yet

- EE 303 Tutorial 1Document19 pagesEE 303 Tutorial 1Syama SameekshaNo ratings yet

- Valve Face To Face Dimension ComparisonDocument12 pagesValve Face To Face Dimension ComparisonRagul NNo ratings yet

- Tech Datasheet AXTT 2VDocument2 pagesTech Datasheet AXTT 2VALEX MATHEUS DA SILVA FERRAZNo ratings yet

- On The Job Winter 2013Document3 pagesOn The Job Winter 2013alanhynesNo ratings yet

- Ecen 607 CMFB-2011Document44 pagesEcen 607 CMFB-2011Girish K NathNo ratings yet

- Tips On Printing Half-Sheet PDF Booklets: 1. Print 1 Page of A Booklet To A Full Sheet of PaperDocument3 pagesTips On Printing Half-Sheet PDF Booklets: 1. Print 1 Page of A Booklet To A Full Sheet of Papermyco samNo ratings yet

- Revista Stiinte Politice Issue 42Document264 pagesRevista Stiinte Politice Issue 42Costel111No ratings yet

- Improvements in Offshore Pipeline Cathodic ProtectionDocument6 pagesImprovements in Offshore Pipeline Cathodic ProtectionEddy Norman Benites DelgadoNo ratings yet

- Opoc Engine ReportDocument34 pagesOpoc Engine Reportapi-32792277367% (3)

- Case Study of Improving Productivity in Warehouse WorkDocument5 pagesCase Study of Improving Productivity in Warehouse WorkRohan SharmaNo ratings yet

- MARINO WORLD MAGAZINE July-August IssueDocument52 pagesMARINO WORLD MAGAZINE July-August IssueNhal LopezNo ratings yet

- 22KW Hydraulic Power Unit GADocument1 page22KW Hydraulic Power Unit GAGabi GabrielNo ratings yet

- Truwater - TCM SeriesDocument12 pagesTruwater - TCM SeriesnkhhhNo ratings yet

- 10 A103 SiteDocument112 pages10 A103 SiteGovindaraju HSNo ratings yet

- 01 Getting StartedDocument44 pages01 Getting StartedAsbokid SeniorNo ratings yet

- Chapter 3 - Bending MembersDocument41 pagesChapter 3 - Bending MembersSuhailah SuhaimiNo ratings yet

- Loupe S Dental Brochure Sur 6351Document16 pagesLoupe S Dental Brochure Sur 6351bernadinadwiNo ratings yet

- Arni AdvertisementDocument2 pagesArni AdvertisementHemanthNo ratings yet

- Active Suspension System of Quarter CarDocument70 pagesActive Suspension System of Quarter CarMarcu SorinNo ratings yet

- SSMT Solution ManualDocument12 pagesSSMT Solution ManualPraahas Amin0% (1)

- Creating Flight Plan and User Waypoint Files For The Flight1 GTNDocument6 pagesCreating Flight Plan and User Waypoint Files For The Flight1 GTNJosé A. Montiel QuirósNo ratings yet

- Unit I - Shafts: Single ElementDocument7 pagesUnit I - Shafts: Single Elementchelam101100% (1)

- Core Insights: Advances in 12G-SDIDocument3 pagesCore Insights: Advances in 12G-SDIHedsdasNo ratings yet

- ILO - Working Conditions of Contract Workers in The Oil and Gas IndustriesDocument106 pagesILO - Working Conditions of Contract Workers in The Oil and Gas IndustriesLuís Augusto Lopes100% (1)

- Lexmark-E 321 Service ManualDocument184 pagesLexmark-E 321 Service ManualRemysNo ratings yet

- CS-Z25XKEW - 1, Evaporator Specification SheetDocument1 pageCS-Z25XKEW - 1, Evaporator Specification SheetpaulNo ratings yet

- Mail Scanner - Community Ubuntu DocumentationDocument4 pagesMail Scanner - Community Ubuntu DocumentationAjith PathiranaNo ratings yet