Professional Documents

Culture Documents

Frame Design Using Web-Tapered Members: Problem

Uploaded by

W SOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Frame Design Using Web-Tapered Members: Problem

Uploaded by

W SCopyright:

Available Formats

Module 6 Gabled Frame Example D.

White 2011

D. White

FRAME DESIGN USING

WEB-TAPERED MEMBERS

MODULE 6

BASIC GABLED FRAME EXAMPLE USING THE DM

Problem

Check the adequacy of a clear-span gable frame

with a mezzanine level using the DM

15 ft

30 ft

16 ft

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 1

Module 6 Gabled Frame Example D. White 2011

Problem

15 ft

30 ft

Compare to the results obtained by the ELM

16 ft

Problem Features 1

Representative interior clear-span gable frame

supporting a mezzanine level

Geometry typical of fabricated metal building

moment frames, but using wide-flange sections

All moment frame members are W30x116 A992 steel

W30x116 sections are cut as shown to form

haunches at the knees of the moment frame

(very common practice in the UK)

Specific checking of stability of the knee region is

not considered in this study

All column bases are a typical 4-bolt detail & are

idealized as pins for the analysis UNO

Mezzanine level contains only gravity framing

Typical outset purlin, girt & eave strut layouts

4

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 2

Module 6 Gabled Frame Example D. White 2011

Problem Features 2

The rafters are braced out-of-plane at their top

(outside) flange by the purlins

Diagonal braces are provided intermittently from the

purlins to the inside flange as shown in the drawing

The left-hand column of the moment frame is braced

out-of-plane by the girts at its outside flange

Diagonal struts are provided to the inside flange at

16 and 24.75 ft above the column base

Both flanges of the right-hand column of the moment

frame are braced out-of-plane at the level of the

connection to the mezzanine, at the bottom of the

haunch, and at the bottom of the column

In addition, the outside flange of this column is

braced out-of-plane by girts at 8 ft above its base

5

Problem Features 3

The stability design solution for this frame is not

immediately obvious due to:

The non-rectangular geometry

The variation of the axial load along the members

The effects of the mezzanine on the right-hand

column of the moment frame

The tendency of the gable frame knees to spread

apart under application of the gravity loads and

potentially in the buckling mode of the frame

The influence of axial compression in the rafters on

the frame stability

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 3

Module 6 Gabled Frame Example D. White 2011

Problem Features 4

Explicit o/L = 0.002 used instead of notional loads

Sidesway amplification limit checked based on

weighted average column drifts

Pn = QPy utilized where e / > 10

Use of deep wide-flange sections requiring consider-

ation of web local buckling under axial compression

Handling of gravity load eccentricity at simple shear

connections into a column flange

Discussion of the importance of unbalanced snow

loads on gable moment frames

Potential member limit states involving constrained-

axis torsional buckling about the centroid of the

purlins & girts

Influence of partial base fixity on service drift

7

Loadings

Dead load, including the self-weight of the primary

framing, is taken as 9 psf over the projected

horizontal area of the roof

Nominal Live load on mezzanine = 100 psf,

reduced to 50 psf based on ASCE 7-05 for

influence area of 3600 ft2

Representative snow load per ASCE 7-05, including

unbalanced snow on the gable roof

Ground snow load taken as pg = 30 psf, ps = 21 psf

Representative wind load per ASCE 7-05 Method 2

Basic wind speed = 85 mph

All loads modeled as uniformly distributed line

loads

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 4

Module 6 Gabled Frame Example D. White 2011

Loadings (cont’d)

Dead & Live loading calculated using the area

within the building envelope (120 ft – 2 x 10 in =

118.3 ft width)

Snow & wind loading calculated using the full roof

area including the outset dimensions of the

building envelope (120 ft building width & 30 ft

eave height)

ASCE 7 Strength Load Combinations

1) 1.4D

2-1) 1.2D + 1.6Lreduced + 0.5Sbalanced

2-2) 1.2D + 1.6Lreduced + 0.5SunbalancedRight

3-1) 1.2D + 1.6Sbalanced + 0.5Lreduced (governs)

3-2) 1.2D + 1.6Sbalanced + 0.8WtoLeft

3-3) 1.2D + 1.6SunbalancedRight + 0.5Lreduced

3-4) 1.2D + 1.6SunbalancedRight + 0.8WtoLeft

4-1) 1.2D + 1.6WtoLeft + 0.5Lreduced + 0.5Sbalanced

4-2) 1.2D + 1.6WtoLeft + 0.5Lreduced + 0.5SunbalancedRight

5) 0.9D + 1.6WtoLeft

Earthquake loading is assumed not to govern relative

to the wind loading

10

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 5

Module 6 Gabled Frame Example D. White 2011

ASCE 7-05 Unbalanced Snow Load

24.5 psf rectangular surcharge

ps = 21 psf

0.3 ps = 6.3 psf

15 ft

11

ASCE 7-05 Wind Load

12

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 6

Module 6 Gabled Frame Example D. White 2011

ASCE 7 Service Load Combinations

1) 1.0D + 0.5Sbalanced + 0.5Lreduced

2) 1.0D + 0.5SunbalancedRight + 0.5Lreduced

3) 1.0D + 0.5SunbalancedRight + 0.5Lreduced + 0.7WtoLeft

4) 1.0D + 1.0Lreduced

Service Deflection Design Criteria:

Column drifts < L/100

Roof girder vertical deflections < Span/240

13

DM ANALYSIS CALCULATIONS

14

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 7

Module 6 Gabled Frame Example D. White 2011

Second-Order Analysis 1

Although amplified 1st-order analysis procedures

can be applied to this type of frame, their accuracy

in capturing all of the stability attributes is

relatively uncertain

Therefore, the analysis of this frame is conducted

using a general purpose 2nd-order analysis that

includes both P- & P- effects in the element

formulation

Both flexural and shear deformations are included

in the analysis, although the influence of shear

deformations is relatively small here

15

Second-Order Analysis 2

Joint size is included in determining the lean-on

& connection eccentricity effects of the gravity

framing, & in setting the “member end” locations

The rigid-zone size of all the joints is taken as zero

The haunch is modeled using a tapered frame elem.

Panel zone deformations at the haunch are

considered in a coarse fashion via the use of a zero

rigid-zone size

The moment frame connections are assumed to be

Fully-Restrained (FR)

16

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 8

Module 6 Gabled Frame Example D. White 2011

Second-Order Analysis 3

Reduced modulus of 0.8 E = 23,200 ksi employed in

all the DM strength analysis calculations

Out-of-plumbness of 0.002 to the left explicitly

modeled in strength analysis calculations

– Initial out-of-plumb nodal displacements = 0.002 x

vertical coordinate above the base

Nominal modulus of E = 29,000 ksi employed in all

the service load analysis calculations

Perfect frame geometry assumed in all the service

load analysis calculations

17

Out-of-Plumbness Imperfections

18

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 9

Module 6 Gabled Frame Example D. White 2011

Equivalent Notional Lateral Loads

19

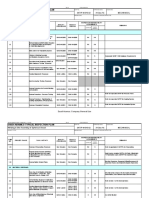

Strength LC (3-1) Results

0.1959(80) 0.1329(52 133 )

1st 0.0336 inches

80 52 133 2nd

1.16 1.70

1st

0.1919 (80 ) 0.1390 (52 133 )

2nd 0.0391 inches

80 52 133

20

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 10

Module 6 Gabled Frame Example D. White 2011

Strength LC (3-1) Results

The sidesway amplification is relatively

small (1.16 vs the 1.70 limit)

However, this is a gravity-only load

combination

Therefore, the out-of-plumbness (or

notional lateral load) still must be included

21

Strength LC (3-1) Results

Axial Force (kips)

Moment (ft-kips)

22

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 11

Module 6 Gabled Frame Example D. White 2011

Out-of-Plumbness to the Right

Given the deflected geometry of the mezzanine for

the critical strength LC (3-1), it is apparent that out-

of-plumbness to the right may have a larger

destabilizing effect for this load combination

With OOP to the right, the axial forces are essentially

unchanged, the max. moments on the rhs increase

by approximately 10 to 13 ft-kips & the moments on

the lhs decrease by the same amount

23

DM RESISTANCE

CALCULATIONS

24

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 12

Module 6 Gabled Frame Example D. White 2011

Determine cPnx

The maximum Pu, Pumax = 133 kips, is in the bottom

portion of the column on the rhs

Lx = 24.75 ft

Pex = 2 (29000) (4930)/ (24.75)2/144 = 16,000 kips

Pumax/Pex = 133/16,000 = 0.0083 << 0.1

cPnx may be taken as cQPy

From Table 6-1, p. 6-29 of the AISC Manual,

cQPy = 1/p = 1000/0.713 = 1403 kips

25

Determine cPnx

Note, for the rafters, Lx should generally be taken as

the on-slope length from column to column

Lx = 129.5 ft

However, AISC DG 25 explains that in-plane non-

sway buckling of the rafters is fully addressed by the

DM for cases where mid-span work point is offset

above the rafter chord by Lchord / 50 or more

Pex = 2 (29000) (4930)/ (129.5)2/144 = 584 kips

doesn’t need to be considered

26

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 13

Module 6 Gabled Frame Example D. White 2011

Determine cPnCAT

The out-of-plane axial resistance in the bottom

segments of both the rhs and lhs columns is

governed by Constrained-Axis Torsional (CAT)

Buckling

Conservatively take the length between the points

where twisting is prevented as LT = 16 ft

27

Determine cPnCAT

The equation for the theoretical column elastic CAT

buckling is…

2E(C w Iy a 2s ) 1

PeCAT GJ 2 2

rx ry ac

2 2

LT

28

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 14

Module 6 Gabled Frame Example D. White 2011

Determine cPnCAT

E = 29,000 ksi, G = E/2.6

Cw = 34,900 in6, Iy = 164 in4, J = 6.43 in4,

A = 34.2 in2, rx = 12.0 in, ry = 2.19 in

PeCAT = 1550 kips

FeCAT = PeCAT / A = 45.4 ksi

Pumax / PeCAT = 133 /1550 = 0.086 < 0.1

cPnCAT may be taken as cQPy = 1403 kips

29

Determine cPny

The largest unsupported length for minor-axis

flexural buckling is Ly = 8.75 ft

Pey = 2 (29000) (164)/ (8.75)2/144 = 4258 kips

Pu/Pey = 80.1/4258 = 0.0019 << 0.1 on lhs column

cPny may be taken as cQPy = 1403 kips

30

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 15

Module 6 Gabled Frame Example D. White 2011

Synthesis… cPn

When using the DM, cPn may be taken as

cQPy = 1403 kips for any location within this frame

By recognizing that the largest value of Pu/cQPy is

0.095 throughout the frame, it is clear that the

most critical segments will be the ones with the

largest Mu/bMn

31

Strength LC (3-1), OOP to Left

Axial Force (kips)

Moment (ft-kips)

32

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 16

Module 6 Gabled Frame Example D. White 2011

Identifying the critical strength UC

By comparing LC (3-1) with out-of-plumbness to

the left to the other load combinations, ….

It appears that the lhs column is likely to be the

critical component in this structure

This is in spite of the long on-slope length of the

rafters or the larger axial compression in the

bottom of the rhs column

33

Critical column & rafter loadings

1.2D + 1.6Sbalanced + 0.5Lreduced

34

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 17

Module 6 Gabled Frame Example D. White 2011

Determine bMn

Consider the top unbraced segment of the lhs

column, Lb = 8.75 ft

From Table 3-10 of the AISC Manual, p. 3-107,

bMn1 = 1377 ft-kips for uniform bending (Cb = 1)

M2 = 1078 ft-kips, M1 = 696 ft-kips

Cb = 1.75 – 1.05 (M1/M2) + 0.3 (M1/M2)2 = 1.2

bMn = min(Cb bMn1, bMp) = 1420 ft-kips

35

Determine bMn

Consider the left-most unbraced segment of the

lhs rafter, Lb = 15 ft

From Table 3-10 of the AISC Manual, p. 3-111,

bMn1 = 1148 ft-kips for uniform bending (Cb = 1)

M2 = 747.6 ft-kips, M1 = 238.4 ft-kips

Cb = 1.75 – 1.05 (M1/M2) + 0.3 (M1/M2)2 = 1.4

bMn = min(Cb bMn1, bMp) = 1420 ft-kips

36

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 18

Module 6 Gabled Frame Example D. White 2011

Synthesis… bMn

The flexural resistance may be taken as the

“plateau strength” bMn = 1420 ft-kips for all of the

potentially critical unbraced lengths in this frame

37

Critical Beam-Column Unity Checks

Top segment of the lhs column:

Pu/2cPn + Mu/ bMn =

80.1/ 2 / 1403 + 1078 / 1420 = 0.03 + 0.76 = 0.79

Left-most segment of the lhs rafter:

Pu/2cPn + Mu/ bMn =

49.4/ 2 / 1403 + 747.6 / 1420 = 0.02 + 0.53 = 0.54

38

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 19

Module 6 Gabled Frame Example D. White 2011

Service Deflection Checks

Using…

– Nominal elastic stiffness (E = 29,000 ksi)

– No geometric imperfections

39

Critical Service Deflection Checks

Vertical deflection of roof

SLC1: 1.0D + 0.5Sbalanced + 0.5Lreduced

2.63 in = Span / 529

2.42 in = Span / 574 using G = 10 < Span / 240, ok

base restraint, Krot = 0.6EIc / Lc

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 20

Module 6 Gabled Frame Example D. White 2011

Critical Service Deflection Checks

Lateral deflection at eaves

SLC3: 1.0D + 0.5SunbalancedRight + 0.5Lreduced + 0.7WtoLeft

1.38 in = L / 233 2.63 in = Span / 529

< L / 100, ok 0.98 in = L / 329 using G = 10

base restraint, Krot = 0.6EIc / Lc

41

Critical Service Deflection Checks

Lateral deflection at mezzanine floor

SLC5 (new case considered “after the fact”):

1.0D + 0.5SunbalancedLeft + 0.7WtoRight

0.77 in = L / 230

0.57 in = L / 310 using G = 10

base restraint, Krot = 0.6EIc / Lc

< L / 100, ok

Assuming no interior partitions, no brittle exterior walls & no frame

mounted equipment

42

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 21

Module 6 Gabled Frame Example D. White 2011

Critical Service Deflection Checks

Vertical deflection at mezzanine floor

SLC4: 1.0D + 1.0L

4.02 in = Span / 175

> L / 240, NG

Deflection under 1.0 L is L/280 > L/360

Increase girder size to a W36x135 section

43

ELM CALCULATIONS

44

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 22

Module 6 Gabled Frame Example D. White 2011

ELM Strength Checks

The key in applying the Effective Length Method to

this type of frame is in determining the appropriate

member buckling load Pex

K is ALWAYS (implicitly, or explicitly) determined by

equating the load in the member at buckling to the

Euler buckling load based on KLx …

i.e., [Pex = ex Pu] = 2 EIx/(KLx)2 …

and back-solving for K … K = { [2 EIx/Lx2 ]/Pex }0.5

Pex can be determined by any legitimate buckling

calculation

Note: in the end, the column strength for in-plane

buckling is based on Pex, not K …

Once we have a value for Pex, K isn’t necessary

45

ELM Strength Checks

For this frame, the column strengths in the ELM

may be based on an eigenvalue linear buckling

analysis of the full structure under LC 3-1

(1.2D + 1.6Sbalanced + 0.5Lreduced )…

ex = 11.02

Pex = ex Pu

= 11.02 (80.1)

= 883 kips

But Pu / Pex = 1 / ex = 0.09 < 0.1, so lets use cPnx = cQPy = 1403 kips

46

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 23

Module 6 Gabled Frame Example D. White 2011

ELM Strength Checks

Analyze using ….

– Perfect geometry

– Nominal elastic stiffness

From LC (3-1), Mu = 1069 ft-kips

Versus 1078 ft-kips in the DM Analysis

Versus 1057 ft-kips from a linear elastic analysis

bMn = 1420 ft-kips

Pu/2cPn + Mu/bMn

= 80.1/2/1403 + 1069/ 1420 = 0.78

(0.81 if we calculate Pn using KLx)

Versus 0.79 from the DM Calculations

47

ELM Strength Checks

Note:

1/(1 – 1/ex) = 1 / (1 – 1/ 11.02) = 1.10

is also a reasonable check of the sidesway

amplification limit for the ELM ( < 1.5) for this

frame

We would obtain 1.13 using the weighted average

1st & 2nd-order deflections as illustrated previously

48

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 24

Module 6 Gabled Frame Example D. White 2011

ELM Strength Checks

The rafters clearly “go along for the ride”

and predominantly serve to provide

rotational restraint to the tops of the

columns in the above buckling mode

Therefore, use of the above buckling

solution for the rafters can be very

conservative

49

ELM Strength Checks

For this frame, the rafter strengths in the ELM may

be based on the next highest buckling mode in an

eigenvalue linear buckling analysis of the full

structure under LC 3-3, the critical combination for

the lhs rafter (1.2D + 1.6SunbalancedRight + 0.5Lreduced )

ex = 55.0

Pex = ex Pu

= 55.0 (49.3)

= 2712 kips

But Pu / Pex = 1 / ex = 0.018 << 0.1, so lets use cPnx = cQPy = 1403 kips

50

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 25

Module 6 Gabled Frame Example D. White 2011

ELM Strength Checks

For the critical rafter strength check, we obtain

UC = 0.54

UC = 0.54 also if the column strength is based on

the critical elastic PeCAT value for the 15 ft rafter

unsupported segment (LT = 15 ft)

We also obtained UC = 0.54 using the DM

51

Observations

Frames with more complex geometries such

as the example clear-span gable structure

are certainly solveable using the ELM

However …

The DM is simpler and it gives internal

forces and deflections that are more

representative of the true strength

responses

Clear-span gable frames rarely have

substantial overall stability effects

Use the DM

52

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 26

Module 6 Gabled Frame Example D. White 2011

D. White

FRAME DESIGN USING

WEB-TAPERED MEMBERS

END MODULE 6

BASIC GABLED FRAME EXAMPLE USING THE DM

Overview of AISC Design Guide 25

Frame Design Using Web-Tapered Members 27

You might also like

- Plate Stresses in STAADDocument7 pagesPlate Stresses in STAADARYANo ratings yet

- Sand Heap AnalogyDocument23 pagesSand Heap AnalogyTatyGendadeReynosoNo ratings yet

- Non-Shrink GroutDocument7 pagesNon-Shrink GroutIm ChinithNo ratings yet

- MonorailDocument14 pagesMonorailZain AndabloNo ratings yet

- Castellated Beams STAAD-Pro2004Document13 pagesCastellated Beams STAAD-Pro2004Lukman Nul HakimNo ratings yet

- ACI 350.3-06 ERRATA Seismic Design of Liquid-Containing Concrete Structures and CommentaryDocument2 pagesACI 350.3-06 ERRATA Seismic Design of Liquid-Containing Concrete Structures and CommentarynunezalbertoNo ratings yet

- Mathcad - Tank Foundation Design Actions - 2611-501 & 502 - Rougher WMS Feed Tank 1 & 2Document15 pagesMathcad - Tank Foundation Design Actions - 2611-501 & 502 - Rougher WMS Feed Tank 1 & 2shashank sharmaNo ratings yet

- Steel-Tables 2 PDFDocument110 pagesSteel-Tables 2 PDFMahmoud AllamNo ratings yet

- Corbel Design ACI 318 PDFDocument2 pagesCorbel Design ACI 318 PDFShamim Ahsan ZuberyNo ratings yet

- Partial Fixity in ETABSDocument3 pagesPartial Fixity in ETABSErnest NavarroNo ratings yet

- 15.lattice (Cage) Beam Design and Finite Element Analysis of Gantry CraneDocument3 pages15.lattice (Cage) Beam Design and Finite Element Analysis of Gantry CraneravirajNo ratings yet

- Joint Shear Check Using RCDCDocument10 pagesJoint Shear Check Using RCDCmat_1141No ratings yet

- 45 Degree Cone MethodDocument3 pages45 Degree Cone Methodundf25No ratings yet

- SmartBeamNon CompositeCastellatedDesignDocument3 pagesSmartBeamNon CompositeCastellatedDesignKiboyNo ratings yet

- Runway Beam Esdep Lecture Note (Wg14)Document19 pagesRunway Beam Esdep Lecture Note (Wg14)kayakeras3335No ratings yet

- Design of Continuous Footing-1 PDFDocument8 pagesDesign of Continuous Footing-1 PDFSamuel Antobam100% (2)

- Insert Plate CheckDocument6 pagesInsert Plate CheckSatish KumarNo ratings yet

- Bar Bending Schedule OF Box CulvertDocument1 pageBar Bending Schedule OF Box CulvertvishalNo ratings yet

- Checklist For Concrete Shear Wall (ACI 318-14)Document5 pagesChecklist For Concrete Shear Wall (ACI 318-14)renzo1221No ratings yet

- Division III-WIND DESIGN Section 1615 - General Section 1617 - Symbols and NotationsDocument13 pagesDivision III-WIND DESIGN Section 1615 - General Section 1617 - Symbols and NotationsjirongNo ratings yet

- Bitexco Article To UseDocument9 pagesBitexco Article To Useyamibarisonzi100% (1)

- Dome Structures. Saldome 2Document6 pagesDome Structures. Saldome 2Lidhia Fairuz HarlyNo ratings yet

- Ibc 2003 - Poles Footings DesignDocument4 pagesIbc 2003 - Poles Footings DesignAhmed ALiNo ratings yet

- PRYING9 - AISC 9th ED. PRYING ACTION ANALYSIS PROGRAMDocument5 pagesPRYING9 - AISC 9th ED. PRYING ACTION ANALYSIS PROGRAMCarlos Valverde PortillaNo ratings yet

- WeldDocument7 pagesWeldMuhammad Akbar Faereza NugrahaNo ratings yet

- Cell / Model Name Description DateDocument19 pagesCell / Model Name Description DateHemanthNo ratings yet

- Detailed Composite Beam Design AISCDocument20 pagesDetailed Composite Beam Design AISCRaveendra Babu CherukuriNo ratings yet

- AASHTO-2009 Highway Signs 159 PDFDocument1 pageAASHTO-2009 Highway Signs 159 PDFer_rahmansNo ratings yet

- Din 4024Document13 pagesDin 4024Muhammad HassanNo ratings yet

- Shear Lug Verification Example 12Document1 pageShear Lug Verification Example 12Nasrul AdliNo ratings yet

- IBC 2006 SEISMIC PARAMETER For StaadDocument22 pagesIBC 2006 SEISMIC PARAMETER For Staadutoy032367No ratings yet

- Corrugated Steel Pipe, Metallic-Coated, For Sewers and DrainsDocument10 pagesCorrugated Steel Pipe, Metallic-Coated, For Sewers and DrainsFRANZ RICHARD SARDINAS MALLCONo ratings yet

- Huong Dan MegafloorDocument11 pagesHuong Dan Megafloortrung1983No ratings yet

- Hilti Rebar 2Document69 pagesHilti Rebar 2Jeevan ShendreNo ratings yet

- Seismic Load Calc: Equivalent Lateral Force Analysis: InputDocument5 pagesSeismic Load Calc: Equivalent Lateral Force Analysis: InputMohammed Saleem Syed KhaderNo ratings yet

- Col - Stiff Properties - SAFE - CSIDocument1 pageCol - Stiff Properties - SAFE - CSIkilmasterNo ratings yet

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part3-Pull Out Strength in TensionDocument4 pagesConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part3-Pull Out Strength in TensionVenu GopalNo ratings yet

- Structure Engineer CertificateDocument1 pageStructure Engineer CertificateSantosh100% (2)

- Universal Beams To BS4 Part 1 - 1993Document3 pagesUniversal Beams To BS4 Part 1 - 1993Aristotle MedinaNo ratings yet

- AMETank Product BrochureDocument6 pagesAMETank Product BrochureSYedZYnAleNo ratings yet

- AASHTO - Rigid Pavement DesignDocument83 pagesAASHTO - Rigid Pavement DesignBenedict OgbaghaNo ratings yet

- Design of Reinforced Concrete: University of Wasit-College of Engineering Civil Engineering DepartmentDocument12 pagesDesign of Reinforced Concrete: University of Wasit-College of Engineering Civil Engineering DepartmentSomaNo ratings yet

- Ladder CalculationDocument25 pagesLadder CalculationYash SutharNo ratings yet

- BoqDocument24 pagesBoqDilshad AhemadNo ratings yet

- Duct Runs Through Open Web JoistDocument11 pagesDuct Runs Through Open Web JoistWilliam GrecoNo ratings yet

- Pile Cap Theory - BentleyDocument4 pagesPile Cap Theory - BentleyParameswaran GanesanNo ratings yet

- Steel Connections: Research in Building Tech 3Document10 pagesSteel Connections: Research in Building Tech 3Angelica Marie AzucenaNo ratings yet

- Detailed Design of TrussesDocument131 pagesDetailed Design of TrussesMohammed DanaNo ratings yet

- Plate Girder DesignDocument109 pagesPlate Girder Designhasib100% (3)

- CSE 513-5 TubularDocument29 pagesCSE 513-5 TubularVincent YeungNo ratings yet

- Design of Plate GirdersDocument109 pagesDesign of Plate GirdersFahd Abdul RahmanNo ratings yet

- Design of Plate GirderDocument109 pagesDesign of Plate GirderFAR_A_DAYNo ratings yet

- Design Example 4 Reinforced Concrete Parking Garage: 2012 IBC SEAOC Structural/Seismic Design Manual, Vol. 3Document21 pagesDesign Example 4 Reinforced Concrete Parking Garage: 2012 IBC SEAOC Structural/Seismic Design Manual, Vol. 3Mofasa ENo ratings yet

- AISC - Design Guide 10 - Errata - Erection Bracing of Low - Rise Structural Steel Buildings PDFDocument2 pagesAISC - Design Guide 10 - Errata - Erection Bracing of Low - Rise Structural Steel Buildings PDFapuhapuh_153349No ratings yet

- IESL Technicalpaper EngK - JeyamohanDocument5 pagesIESL Technicalpaper EngK - Jeyamohanאסמעיל מצארווהNo ratings yet

- Beam Frame Example of A Parking Structure International Version TN461-SI PDFDocument30 pagesBeam Frame Example of A Parking Structure International Version TN461-SI PDFLau Kim HwaNo ratings yet

- Insulated Concrete Forms (ICF) Walls Analysis and DesignDocument23 pagesInsulated Concrete Forms (ICF) Walls Analysis and DesignLakshay BansalNo ratings yet

- Chapter 5 Post-Tensioned SlabDocument19 pagesChapter 5 Post-Tensioned SlabSharan BvpNo ratings yet

- Preprints202110 0412 v1Document32 pagesPreprints202110 0412 v1W SNo ratings yet

- Numerical Modelling For Synthetic Fibre Mooring Lines Taking Elongation and Contraction Into AccountDocument20 pagesNumerical Modelling For Synthetic Fibre Mooring Lines Taking Elongation and Contraction Into AccountW SNo ratings yet

- Determination of P-Y Curves For Offshore PilesDocument8 pagesDetermination of P-Y Curves For Offshore PilesRamanathan GnanasambandamNo ratings yet

- Nhi 14006Document149 pagesNhi 14006W SNo ratings yet

- Guide Specifications For Bridges Vulnerable To Coastal StormsDocument4 pagesGuide Specifications For Bridges Vulnerable To Coastal StormsRodrigo LameirasNo ratings yet

- Evaluation Design Report 112315 Revised 080116 CleanDocument98 pagesEvaluation Design Report 112315 Revised 080116 CleanW SNo ratings yet

- VOL 04 Runway-24-EMAS PDFDocument21 pagesVOL 04 Runway-24-EMAS PDFW SNo ratings yet

- Fdot Design Standards: 292 1 Standard Precast Concrete Box CulvertsDocument14 pagesFdot Design Standards: 292 1 Standard Precast Concrete Box CulvertsW SNo ratings yet

- Experience With Asphalt Pavement On The Heavy Loaded Port Area of The "Niedersachsenkai"Document10 pagesExperience With Asphalt Pavement On The Heavy Loaded Port Area of The "Niedersachsenkai"W SNo ratings yet

- Fishing HarbourDocument351 pagesFishing HarbournongvandenNo ratings yet

- Fdot Design Standards: 292 1 Standard Precast Concrete Box CulvertsDocument14 pagesFdot Design Standards: 292 1 Standard Precast Concrete Box CulvertsnelsonsainzNo ratings yet

- Design of Structural Steel and Concrete Elements PDFDocument153 pagesDesign of Structural Steel and Concrete Elements PDFW S100% (1)

- 5 Cross Section Classification HandoutDocument2 pages5 Cross Section Classification HandoutThananchayan MaheshNo ratings yet

- Breasting, Mooring Dolphin, & Main Jetty (Version 1) PDFDocument48 pagesBreasting, Mooring Dolphin, & Main Jetty (Version 1) PDFjuraganiwal100% (10)

- Design Calculation For Prestressed BeamDocument20 pagesDesign Calculation For Prestressed BeamW SNo ratings yet

- A Comparison of U.S. and European Bridge Loadings: Eugene J Obrien, Cathal Leahy & Bernard EnrightDocument39 pagesA Comparison of U.S. and European Bridge Loadings: Eugene J Obrien, Cathal Leahy & Bernard EnrightW SNo ratings yet

- New Asce Seismic Design Standards For Piers and WharvesDocument51 pagesNew Asce Seismic Design Standards For Piers and Wharveskkkelvin100% (2)

- AISC - Design Guide 12 - Errata - Modification of Existing Welded Steel Moment Frame Connections For Seismic Resistance PDFDocument2 pagesAISC - Design Guide 12 - Errata - Modification of Existing Welded Steel Moment Frame Connections For Seismic Resistance PDFapuhapuh_153349No ratings yet

- California Building Code - Matrix Adoption Table Chapter 31F - Marine Oil TerminalsDocument80 pagesCalifornia Building Code - Matrix Adoption Table Chapter 31F - Marine Oil TerminalsW SNo ratings yet

- New Pianc Guidelines For Marine Oil & Petrochemical Terminal DesignDocument33 pagesNew Pianc Guidelines For Marine Oil & Petrochemical Terminal DesignW S0% (1)

- AISC Design Guide 16 Errata - Flush and Extend Multiple-Row Moment End-Plate Connections PDFDocument4 pagesAISC Design Guide 16 Errata - Flush and Extend Multiple-Row Moment End-Plate Connections PDFFernando Gutiérrez UrzúaNo ratings yet

- AISC - Design Guide 10 - Errata - Erection Bracing of Low - Rise Structural Steel Buildings PDFDocument2 pagesAISC - Design Guide 10 - Errata - Erection Bracing of Low - Rise Structural Steel Buildings PDFapuhapuh_153349No ratings yet

- Disputes in Managing Projects - A Case Study of Construction Industry in VietnamDocument10 pagesDisputes in Managing Projects - A Case Study of Construction Industry in VietnamIna AriffinNo ratings yet

- Astm A1078Document5 pagesAstm A1078mmendez11333% (3)

- Copia de Ficha Tecnica 2021-2022 AA 12,18,24,36 T. Solo Frio 410WHIDocument6 pagesCopia de Ficha Tecnica 2021-2022 AA 12,18,24,36 T. Solo Frio 410WHIUlisesSoliherNo ratings yet

- My MBA ProjectDocument93 pagesMy MBA ProjectVivek Nambiar70% (10)

- Vibration Pads: Mason Industries, IncDocument2 pagesVibration Pads: Mason Industries, Incbman0051401No ratings yet

- Nse Technical Report and Post Graduate Experience Format - 2Document85 pagesNse Technical Report and Post Graduate Experience Format - 2Orjinta Victor100% (3)

- INTRODUCTION Steel StructureDocument2 pagesINTRODUCTION Steel StructureSyamil NordinNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalpravinNo ratings yet

- ADMC040EN VersaGlazeDocument112 pagesADMC040EN VersaGlazeMeeNo ratings yet

- ETI Part BooksDocument63 pagesETI Part Booksyugopuspoyo100% (1)

- SKF Bearing BasicsDocument28 pagesSKF Bearing Basicshibhavu0% (1)

- BPVCDocument2 pagesBPVCdaverich86No ratings yet

- Eaton Fuller RTO 14613 Transmission Parts ManualDocument49 pagesEaton Fuller RTO 14613 Transmission Parts ManualDiego AlvarezNo ratings yet

- Pompa Lincoln AnginDocument8 pagesPompa Lincoln AnginGuntur SoebankNo ratings yet

- Prediction of Movements For Braced Cuts in ClayDocument19 pagesPrediction of Movements For Braced Cuts in Clayvanness hoNo ratings yet

- Sumithva DeveloperDocument2 pagesSumithva DeveloperSachin KothvalNo ratings yet

- A Clay BrickDocument3 pagesA Clay Brickbarik.biswaranjan1666No ratings yet

- Mill ManualDocument57 pagesMill ManualsatishflsNo ratings yet

- Fhwa Nhi-Mechanically Stabilized Earth Walls and Reinforced Soil Slopes Design & Construction GuidelinesDocument418 pagesFhwa Nhi-Mechanically Stabilized Earth Walls and Reinforced Soil Slopes Design & Construction GuidelinessallymazeeraNo ratings yet

- IGB010.E2-Axial Flow Fan - TDA-TDF-TBE-TDB-TDS - New PDFDocument10 pagesIGB010.E2-Axial Flow Fan - TDA-TDF-TBE-TDB-TDS - New PDFโจ้ สแปร์แร็คNo ratings yet

- Brushbond RFX PDFDocument2 pagesBrushbond RFX PDFpiyu114No ratings yet

- Mooring BuoyDocument3 pagesMooring BuoyGermán AguirrezabalaNo ratings yet

- CH 11 - Rocker Arm Assembly, Camshaft Assembly, Tappets & Push RodsDocument46 pagesCH 11 - Rocker Arm Assembly, Camshaft Assembly, Tappets & Push RodsEnrrique LaraNo ratings yet

- Hvac Book 2009.en - Must EditDocument12 pagesHvac Book 2009.en - Must Editmiddle_inn1230No ratings yet

- Express-Fab System Guide: Modular CabinetsDocument8 pagesExpress-Fab System Guide: Modular CabinetsDiego SánchezNo ratings yet

- (01 32 16) Construction Schedule Critical Path Method-CPMDocument7 pages(01 32 16) Construction Schedule Critical Path Method-CPMAmeer JoshiNo ratings yet

- Engineering Guide Woodfram PDFDocument18 pagesEngineering Guide Woodfram PDFJimmy Hernandez35% (20)

- Finite Element Analysis of Delamination in Laminated Composite PlatesDocument44 pagesFinite Element Analysis of Delamination in Laminated Composite PlatesSrini RaoNo ratings yet

- White Collar FactoryDocument14 pagesWhite Collar FactoryAnder AndersenNo ratings yet

- JCT Standards Specs - NOT CompleteDocument87 pagesJCT Standards Specs - NOT Completemicana88No ratings yet