Professional Documents

Culture Documents

TS 16949 Standard in One Page

Uploaded by

pkd1963100%(3)100% found this document useful (3 votes)

805 views1 pageQuality Management Systems 4. General Requirements 4.1. General 4.2. Engineering Specifications 4.2. Control of documents 4.2.3. Control of Records 4.2.4. Records retention Management Responsibility 5. Management Commitment 5.1. Process Efficiency 5. Customer Focus 5. Quality Policy 5. Planning 5. Responsibility,Authority and Communication 5.5. Responsibility and Authority 5.5.1. Responsibility for quality 5.5. Management representative 5.5.2. Customer representative 5.5. Internal Communication 5. Review Input 5.6.2. Review Input - Supplemental 5.6. Review Output Resource Management 6.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentQuality Management Systems 4. General Requirements 4.1. General 4.2. Engineering Specifications 4.2. Control of documents 4.2.3. Control of Records 4.2.4. Records retention Management Responsibility 5. Management Commitment 5.1. Process Efficiency 5. Customer Focus 5. Quality Policy 5. Planning 5. Responsibility,Authority and Communication 5.5. Responsibility and Authority 5.5.1. Responsibility for quality 5.5. Management representative 5.5.2. Customer representative 5.5. Internal Communication 5. Review Input 5.6.2. Review Input - Supplemental 5.6. Review Output Resource Management 6.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

100%(3)100% found this document useful (3 votes)

805 views1 pageTS 16949 Standard in One Page

Uploaded by

pkd1963Quality Management Systems 4. General Requirements 4.1. General 4.2. Engineering Specifications 4.2. Control of documents 4.2.3. Control of Records 4.2.4. Records retention Management Responsibility 5. Management Commitment 5.1. Process Efficiency 5. Customer Focus 5. Quality Policy 5. Planning 5. Responsibility,Authority and Communication 5.5. Responsibility and Authority 5.5.1. Responsibility for quality 5.5. Management representative 5.5.2. Customer representative 5.5. Internal Communication 5. Review Input 5.6.2. Review Input - Supplemental 5.6. Review Output Resource Management 6.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

4.0 Quality Management Systems 7.3.

6 Design and Development Validation

4.1 General Requirements 7.3.6.1 Design and Development Validation – Supplemental

4.1.1 General Requirements – Supplements 7.6.3.2 Prototype Programme

4.2 Documentation Requirements 7.3.6.3 Product approval process

4.2.1 General 7.3.7 Control of design and development changes

4.2.2 Quality Manual 7.4 Purchasing

4.2.3 Control of documents 7.4.1 Purchasing process

4.2.3.1 Engineering Specifications 7.4.1.1 Regulatory conformity

4.2.4 Control of Records 7.4.1.2 Supplier quality management system development

4.2.4.1 Records retention 7.4.1.3 Customer approved sources

Management Responsibility 7.4.2 Purchasing information

5.1 Management Commitment 7.4.3 Verification of product quality

5.1.1 Process Efficiency 7.4.3.1 Incoming product quality

5.2 Customer Focus 7.4.3.2 Supplier monitoring

5.3 Quality Policy 7.5 Production and service provision

5.4 Planning 7.5.1 Control of production and service provision

5.4.1 Quality Objectives 7.5.1.1 Control plan

5.4.1.1 Quality Objectives - Supplemental 7.5.1.2 Work instructions

5.4.2 Quality Management System Planning 7.5.1.3 Verification of job set-ups

5.5 Responsibility,Authority and Communication 7.5.1.4 Preventive and predictive maintenance

5.5.1 Responsibility and Authority 7.5.1.5 Management of production tooling

5.5.1.1 Responsibility for Quality 7.5.1.6 Production scheduling

5.5.2 Management representative 7.5.1.7 Feedback of information from service

5.5.2.1 Customer representative 7.5.1.8 Service agreement with customer

5.5.3 Internal Communication 7.5.2 Validation of processes for prodn. and service provision

5.6 Management Review 7.5.2.1 Validation of processes for …. - Supplemental

5.6.1 General 7.5.3 Identification and traceability

5.6.1.1 Quality Management System Performance 7.5.3.1 Identification and traceability - Supplemental

5.6.2 Review Input 7.5.4 Customer property

5.6.2.1 Review input - Supplemental 7.5.4.1 Customer -owned production tooling

5.6.3 Review Output 7.5.5 Preservation of product

Resource Management 7.5.5.1 Storage and inventory

6.1 Provision of Resources 7.6 Control of monitoring and measuring devices

6.2 Human resources 7.6.1 Measurement system analysis

6.2.1 General 7.6.2 Calibration / verification records

6.2.2 Competence, Awareness and Training 7.6.3 Laboratory requirements

6.2.2.1 Product Design Skill 7.6.3.1 Internal laboratory

6.2.2.2 Training 7.6.3.2 External laboratory

6.2.2.3 Training on the job Measurement , Analysis and Improvement

6.2.2.4 Employee Motivation and Empowerment. 8.1 General

6.3 Infrastructure 8.1.1 Identification of statistical tools

6.3.1 Plant, Facility and equipment planning 8.1.2 Knowledge of basic statistical concepts

6.3.2 Contingency Plans 8.2 Monitoring and measurement

6.4 Work Environment 8.2.1 Customer satisfaction

6.4.1 Personnel safety to achieve product quality 8.2.1.1 Customer satisfaction - supplemental

6.4.2 Cleanliness of premises 8.2.2 Internal audit

7.0 Product Realization 8.2.2.1 Quality management system audit

7.1 Planning of Product Realization 8.2.2.2 Manufacturing process audit

7.1.1 Planning of Product Realization - Supplemental 8.2.2.3 Product audit

7.1.2 Acceptance Criteria 8.2.2.4 Internal audit plan

7.1.3 Confidentiality 8.2.2.5 Internal auditor qualification

7.1.4 Change Control 8.2.3 Monitoring and measurement of processes

7.2 Customer Related processes 8.2.3.1 Monitoring and measurement of manufacturing processes

7.2.1 Determination of rqmnts. related to the product 8.2.4 Monitoring and measurement of product

7.2.1.1 Customer designated special characteristics 8.2.4.1 Layout inspection and functional testing

7.2.2 Review of Requirements related to the product 8.2.4.2 Appearance items

7.2.2.1 Review of Requirements …….- Supplemental 8.3 Control of nonconforming product

7.2.2.2 Organisation manufacturing feasibility 8.3.1 Control of nonconforming product - supplemental

7.2.3 Customer Communication 8.3.2 Control of reworked product

7.2.3.1 Customer Communication – Supplemental 8.3.3 Customer information

7.3 Design and Development 8.3.4 Customer waiver

7.3.1 Design and Development Planning 8.4 Analysis of data

7.3.1.1 Multidisciplinary approach 8.4.1 Analysis and use of data

7.3.2 Design and Development inputs 8.5 Improvement

7.3.2.1 Product Design Input 8.5.1 Continual improvement

7.3.2.2 Manufacturing process design input 8.5.1.1 Continual improvement of the organisation

7.3.2.3 Special characteristics 8.5.1.2 Manufacturing process improvement

7.3.3 Design and development outputs 8.5.2 Corrective action

7.3.3.1 Product design Outputs - Supplemental 8.5.2.1 Problem solving

7.3.3.2 Manufacturing process design output 8.5.2.2 Error- proofing

7.3.4 Design and Development Review 8.5.2.3 Corrective action impact

7.3.4.1 Monitoring 8.5.2.4 Rejected product test / analysis

7.3.5 Design and Development Verification 8.5.3 Preventive action

You might also like

- Processaudit VDA 6.3 - RecentDocument34 pagesProcessaudit VDA 6.3 - Recentavinash_k007No ratings yet

- IATF 16949 Mandatory Documents ListDocument2 pagesIATF 16949 Mandatory Documents ListLuis Alejandro60% (5)

- Turtle Diagram Rev'01Document2 pagesTurtle Diagram Rev'01Ankur Parshav100% (6)

- TurtlesDocument15 pagesTurtlesshobhit2310100% (4)

- 2 Handout IATF 16949 Clause Map 2016 To 2009 PDFDocument5 pages2 Handout IATF 16949 Clause Map 2016 To 2009 PDFMohini Marathe100% (2)

- Aum Prasad Casting PVT LTD: 1. Types of Audit 2. Objectives Overview 3. Introduction To Clauses. 4. Conducting AuditDocument24 pagesAum Prasad Casting PVT LTD: 1. Types of Audit 2. Objectives Overview 3. Introduction To Clauses. 4. Conducting AuditpraveenNo ratings yet

- ISO 9001 Quality Procedure Context of the OrganizationDocument1 pageISO 9001 Quality Procedure Context of the OrganizationKarim HakimNo ratings yet

- Clausul IATFDocument8 pagesClausul IATFAhmad ZainuddinNo ratings yet

- First Article Inspection Report: Purchase Order Number Supplier NameDocument8 pagesFirst Article Inspection Report: Purchase Order Number Supplier NameTuff qualityNo ratings yet

- ISO 9001 Requirements WorkbookDocument27 pagesISO 9001 Requirements WorkbookMahkota Jaya Raya KarawangNo ratings yet

- Layered Audit ChecklistDocument4 pagesLayered Audit ChecklistNavnath TamhaneNo ratings yet

- Daimler-Chrysler LPA Training at SRAFDocument27 pagesDaimler-Chrysler LPA Training at SRAFMarcela Gonçalves100% (3)

- ISO-TS 16949 IQA Course MaterialDocument31 pagesISO-TS 16949 IQA Course Materialazadsingh1No ratings yet

- T12 Core Tools - The Alphabet Soup of APQP, PPAP, FMEA, SPC and MSA - JD Marhevko PDFDocument70 pagesT12 Core Tools - The Alphabet Soup of APQP, PPAP, FMEA, SPC and MSA - JD Marhevko PDFrakshithNo ratings yet

- Product Audit FormDocument2 pagesProduct Audit Formcong da0% (1)

- KEMET Quality Manual outlines standards for electronic componentsDocument43 pagesKEMET Quality Manual outlines standards for electronic componentsAvyan KelanNo ratings yet

- APQP Process AssessmentDocument3 pagesAPQP Process AssessmentSergio ArellanoNo ratings yet

- Supplier Quality Assurance Manual - Rev. 06Document40 pagesSupplier Quality Assurance Manual - Rev. 06Sundaramoorthy ArumugamNo ratings yet

- Process Management for Quality AssuranceDocument22 pagesProcess Management for Quality AssuranceVikas0% (1)

- Supplier Deviation Request FormDocument1 pageSupplier Deviation Request FormBESNo ratings yet

- Summary of New QMS Documents With References To ISO 9001 & IATF 16949 ClausesDocument8 pagesSummary of New QMS Documents With References To ISO 9001 & IATF 16949 ClausesStephen Lim Kean Jin100% (2)

- IATF Additional Requirement LocationsDocument6 pagesIATF Additional Requirement LocationsSudhagar50% (2)

- Company Name: Engineering Location: Customer Name: Model Year / PlatformDocument45 pagesCompany Name: Engineering Location: Customer Name: Model Year / Platformsuresh kumar0% (1)

- Questionnaire IATF 16949-2016Document6 pagesQuestionnaire IATF 16949-2016shelke1010100% (1)

- MAstering IATFDocument20 pagesMAstering IATFGyanesh_DBNo ratings yet

- Pecb Iatf 16949 Lead Auditor Exam Preparation GuideDocument14 pagesPecb Iatf 16949 Lead Auditor Exam Preparation GuideR.BALASUBRAMANI100% (1)

- IATF 16949:2016 IntroductionDocument20 pagesIATF 16949:2016 IntroductionDisha Shah100% (4)

- Bliss Manufacturing Lab ScopeDocument2 pagesBliss Manufacturing Lab ScopesachNo ratings yet

- IATF16949 Transition Audit Document Review Draft V5 Final Points EnglishDocument6 pagesIATF16949 Transition Audit Document Review Draft V5 Final Points EnglishSudhagarNo ratings yet

- CS Customer - Plant Turtle Diagram 07Document1 pageCS Customer - Plant Turtle Diagram 07Alex100% (1)

- D1 - Problem Solving TeamDocument2 pagesD1 - Problem Solving TeamMuthusamy Ayyanapillai100% (1)

- ISO/TS16949-Self Audit ChecklistDocument14 pagesISO/TS16949-Self Audit ChecklistBharathNo ratings yet

- Apqp Status LogDocument1 pageApqp Status Logsathyabalaraman67% (3)

- AS9100D to AS9100C Clause Map ComparisonDocument3 pagesAS9100D to AS9100C Clause Map ComparisonVasudevan GovindarajNo ratings yet

- Sop-Special Characteristics IdentificationDocument3 pagesSop-Special Characteristics IdentificationSaravana kumar NagarajanNo ratings yet

- Advanced Product Quality Planning (APQP)Document22 pagesAdvanced Product Quality Planning (APQP)mjapmgNo ratings yet

- IATF 16949 QMS Requirements MatrixDocument1 pageIATF 16949 QMS Requirements MatrixJOECOOL67100% (5)

- Competence For Internal AuditorsDocument2 pagesCompetence For Internal AuditorsSachin Ramdurg100% (1)

- IATF 16949 Webinar Slides 3.7.17 Final PDFDocument47 pagesIATF 16949 Webinar Slides 3.7.17 Final PDFwanphen kawnawanichNo ratings yet

- The Process Approach QuestionsDocument6 pagesThe Process Approach QuestionsDwinanda SeptiadhiNo ratings yet

- FAI - SH0071 - Rev 21 - 14oct19Document33 pagesFAI - SH0071 - Rev 21 - 14oct19anon_958736733100% (1)

- APQP Phases ActivitiesDocument1 pageAPQP Phases Activitiesaorto3919No ratings yet

- With What (Infrastructure) With Who (Personnel) Risk Assessment ModelDocument3 pagesWith What (Infrastructure) With Who (Personnel) Risk Assessment Model80ALLA86i100% (2)

- Project Checklist For IATF 16949:2016 Implementation: Implementation Phases Tasks DoneDocument2 pagesProject Checklist For IATF 16949:2016 Implementation: Implementation Phases Tasks DoneNikita Fatah EntingNo ratings yet

- IATF 16949 2016 Implementation Process Diagram enDocument1 pageIATF 16949 2016 Implementation Process Diagram enisolongNo ratings yet

- Process Turtle Diagram - Assignment EngineeringDocument1 pageProcess Turtle Diagram - Assignment EngineeringShara Jane DelmoNo ratings yet

- SPC ProcedureDocument5 pagesSPC ProcedureKrunal Pandya100% (1)

- ISO 13485 Quality Management System A Complete Guide - 2021 EditionFrom EverandISO 13485 Quality Management System A Complete Guide - 2021 EditionNo ratings yet

- Iso 9001:2015 To Iso 9001:2008 Correlation Matrix: Tüv Süd Akademie GMBHDocument4 pagesIso 9001:2015 To Iso 9001:2008 Correlation Matrix: Tüv Süd Akademie GMBHNgọc ThiênNo ratings yet

- AS9100 REV. D AS9100 REV. C: 4 Context of The Organization 1 ScopeDocument3 pagesAS9100 REV. D AS9100 REV. C: 4 Context of The Organization 1 ScopeMiguelAngelSanchezPueblaNo ratings yet

- 2S Audit Daily ChecklistDocument2 pages2S Audit Daily Checklistpkd1963No ratings yet

- 2S Audit Daily ChecklistDocument2 pages2S Audit Daily Checklistpkd1963No ratings yet

- ToyotaA3Template 1Document1 pageToyotaA3Template 1pkd1963No ratings yet

- DEMING Application Guide2010Document53 pagesDEMING Application Guide2010pkd1963No ratings yet

- Catalog DuctingDocument9 pagesCatalog DuctingchristiadiargaNo ratings yet

- Effects of Cryogenic Cooling on Grinding Forces, Temperature and Residual StressesDocument9 pagesEffects of Cryogenic Cooling on Grinding Forces, Temperature and Residual StressesChirag JainNo ratings yet

- Geotech Final ReportDocument38 pagesGeotech Final Reportapi-320590292No ratings yet

- Laboratory Design GuideDocument110 pagesLaboratory Design Guidejuly lang100% (5)

- AWS CWI For NSRP at NSRP PDFDocument7 pagesAWS CWI For NSRP at NSRP PDFTuấn PhạmNo ratings yet

- Singly Linked Lists AlgorithmDocument18 pagesSingly Linked Lists AlgorithmGSX-R 1100No ratings yet

- White Paper c11 737101Document13 pagesWhite Paper c11 737101Aleksandar PopovicNo ratings yet

- Silent Sound TechnologyDocument22 pagesSilent Sound TechnologyPurnima K100% (2)

- CS153 111017Document29 pagesCS153 111017Sethu RamanNo ratings yet

- 2021 International Construction Benchmark Yearbook SAMPLE 1Document10 pages2021 International Construction Benchmark Yearbook SAMPLE 1Familia GonzalezNo ratings yet

- Sangshad BhabanDocument21 pagesSangshad Bhabanuniqueboy6050% (2)

- Net Positive Suction HeadDocument4 pagesNet Positive Suction Headjorge alarconNo ratings yet

- Connector CatalogDocument60 pagesConnector CatalogYadira De De Ciam100% (1)

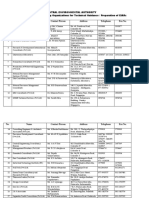

- New Consultant List 20177 For Cea Website 10.02.2016Document4 pagesNew Consultant List 20177 For Cea Website 10.02.2016hxian.y9333No ratings yet

- Catalogue Cable Tray RevDocument40 pagesCatalogue Cable Tray RevhardiyantodonniNo ratings yet

- Farris 2700 ManualDocument12 pagesFarris 2700 ManualNelson AlvarezNo ratings yet

- Pneumatic Actuator Eb-Syd, Double Acting Pneumatic Actuator Eb-Syd, Double ActingDocument4 pagesPneumatic Actuator Eb-Syd, Double Acting Pneumatic Actuator Eb-Syd, Double ActingYi WUNo ratings yet

- Competency-Check-H e I ADocument20 pagesCompetency-Check-H e I Abaldo yellow4No ratings yet

- Diamond Pin Locator and V Blocks 1Document8 pagesDiamond Pin Locator and V Blocks 1pratik thakareNo ratings yet

- ULSADO-JSA-Demolation Existing Concrete FoundationDocument2 pagesULSADO-JSA-Demolation Existing Concrete FoundationKelvin Tan75% (4)

- AP238 PS09 ManualDocument28 pagesAP238 PS09 ManualEuro-Kitchen, Inc.100% (4)

- Ce1a3q E1a3qDocument5 pagesCe1a3q E1a3qapi-239041842No ratings yet

- PNG382 FT en 11Document2 pagesPNG382 FT en 11Misu1983No ratings yet

- Part - I (MCQ) (Compulsory) : M A A ADocument4 pagesPart - I (MCQ) (Compulsory) : M A A AAfzaal GhaziNo ratings yet

- Absolute-Pressure Sensors: Micromechanics, Hybrid DesignDocument3 pagesAbsolute-Pressure Sensors: Micromechanics, Hybrid Designc20get100% (2)

- Everyday Vocabulary Telephone TestDocument3 pagesEveryday Vocabulary Telephone TestzdravkamajkicNo ratings yet

- Tsi 20040109 PDFDocument2 pagesTsi 20040109 PDFenache_marian0% (1)

- (Developments in Geotechnical Engineering 75) Sven Hansbo (Eds.) - Foundation Engineering-Academic Press, Elsevier (1994) PDFDocument534 pages(Developments in Geotechnical Engineering 75) Sven Hansbo (Eds.) - Foundation Engineering-Academic Press, Elsevier (1994) PDFপ্রিয়দীপ প্রিয়মNo ratings yet

- Profile Correction of A Helical Gear Shaping CutterDocument11 pagesProfile Correction of A Helical Gear Shaping Cutterdanielk32No ratings yet

- Sewing 04-Needle Class 118 of Groz-Beckert For Union Special FlatseamersDocument6 pagesSewing 04-Needle Class 118 of Groz-Beckert For Union Special Flatseamersfriendztoall4351No ratings yet