Professional Documents

Culture Documents

AccuMove Flyer

Uploaded by

Mohd Asri TaipCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AccuMove Flyer

Uploaded by

Mohd Asri TaipCopyright:

Available Formats

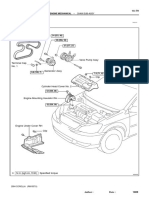

AccuMove™ 17 Tooth The Spotlight is on

Precision with

NOMINAL

L

A

AccuMove

2.89

(17) Tooth TM

1.265

(32.13) .5

(12.7)

AccuMove™ 25 Tooth

W + 2.04

(51.8)

L + 1 NOMINAL

(25.4) A

3.39

(25) Tooth

Order Belt Width (A) Nominal

W

Width Inches (mm) Conveyor Length (L)

02 1.97 (50) 2.5 Inches (mm) 1. Drawings do not show optional dual “T” slot rails.

03 2.95 (75) 3.25 24" (610)

04 3.94 (100) 4.5 36" (914) 2. If Part Holders are supplied

overall length increases.

06 5.91 (150) 6.0 48" (1219)

07 7.40 (188) 7.5 60" (1524) 3. Optional lengths available.

12 11.81 (300) 12.0 72" (1829)

U.S. Patent No.: 6,170,645

18 17.72 (450) 18.0 120" (3048)

FlexLoc™

U.S. Patent No.: 6,321,904

Part Holder Length - See Table “A”

Part Holder Pitch - Must Be

in 10mm Increments

for AccuMove™

Types

75mm MAX.

Table A

AccuMove™ Flat Belt

Order

Part Holder Part Holder

Width

Length (mm) Length (mm)

02 (63) (46)

03 (82) (65)

04 (114) (97)

06 (152) (135)

07 (190) (173)

12 (302) (287)

18 (454) (440)

Conveyor Technologies Ltd. Conveyor Technologies Ltd.

440 Milford Parkway, Milford, OH 45150

(513) 248-0663 www.ConveyorTechLtd.com (513) 248-0663 www.ConveyorTechLtd.com

Conveyor Technologies Ltd. (513) 248-0663 www.ConveyorTechLtd.com Conveyor Technologies Ltd. (513) 248-0663 www.ConveyorTechLtd.com

AccuMove TM Timing Belt Conveyor U.S. Patent No.: 6,170,645 FlexLoc TM Convertible Holder System U.S. Patent No.: 6,321,904

17 TOOTH LOW PROFILE PART POSITIONING ACCURACY

Minimum Torque Requirements Various factors effect (4) axes part positioning accuracy.

Minimum Inertia Values Lateral belt positioning, belt tooth clearance, drive system,

Lower Height welded profile position, and the holder itself can all

Greater Accuracy influence accuracy. FlexLoc™ addresses

Lower Cost all these for a typical part positioning accuracy

of ±.01”. Contact factory for accuracy values for

your specific application.

25 TOOTH LOW PROFILE

Permits Larger Welded Profiles

Preferred for Side Load / Unload

Suitable for Magnetic Applications

Recommended for Multiple Belts - Higher Speeds

GUIDED PART HOLDERS

Utilizes standard belting which retains full load rating.

Sub-Plate permits attachment of user supplied Part Holders.

Holders and Sub-Plates can be rapidly removed without tools.

FlexLoc™ reduces joint stress, and permits low inertia pulleys.

Part Holders feature a preloaded mounting with a Guided Travel.

Accuracy, Versatility and Durability are greatly improved with FlexLoc™.

SPECIFICATIONS o PART HOLDER TYPES

Perpendicularity ±1 Part

Precision tension calibration. Holder Guided

Standard belt widths from 50 to 450 mm. by Adjustable

Compatible with our standard Drives and Accessories. Side Rails

Standard lengths 2 - 10 feet. (Special lengths available.)

All units utilize (1) of (3) different methods of belt self-tracking.

Sealed for life Bearings eliminate lubricant contamination of product.

Indexing Drives utilize Stepper, Servo or Brushless D.C. motors, all with position verification. +.01” ±.005”

Powder Coated single piece 10 GA. steel frame. (Available with dual “T” slots on each side.) Height

-.02” Height

Solid Urethane Timing belts with steel or Kevlar tension members and Nylon coating for reduced friction and wear.

Pitch Tolerance ±.02” Pitch Tolerance ±.02” Pitch Tolerance ±.02”

(Longitudinal Spacing)

TYPE - 1 TYPE - 2 TYPE - 3

FUNCTIONS APPLICATIONS Conventional FlexLoc™ FlexLoc™

Fixed Urethane Profile Removable Removable Machined

Precision Indexing and 4-Axes Positioning Assembly

Holder (Welded Type) Machined Holder Holder / Sub-Plate

Synchronous movement of multiple Conveyors Vision Inspection

High cyclic rates Laser Imprinting Eliminates Perpendicular Error Eliminates Perpendicular Error

Reversing Pharmaceutical Greatly improves height tolerance Greatly improves height tolerance

Heavy Loads Packaging Minimizes pitch (longitudinal spacing) error

Side load / Unload Machine Integration Minimizes any Skew induced by pitch

High speeds (2000’/min.) FlexLoc™ is suitable for both timing and flat belts variation across belt width

Available in Standard, Welded Profile, Removable Holder, Magnetic, Typical Part Positioning Tolerance of ±.01” is not effected

Vacuum, and Wash-Down on Special Order, in English or Metric versions. by Pitch Tolerance when using C.T.L. Index Drives.

Conveyor Technologies Ltd. (513) 248-0663 www.ConveyorTechLtd.com Conveyor Technologies Ltd. (513) 248-0663 www.ConveyorTechLtd.com

AccuMove TM Timing Belt Conveyor U.S. Patent No.: 6,170,645 FlexLoc TM Convertible Holder System U.S. Patent No.: 6,321,904

17 TOOTH LOW PROFILE PART POSITIONING ACCURACY

Minimum Torque Requirements Various factors effect (4) axes part positioning accuracy.

Minimum Inertia Values Lateral belt positioning, belt tooth clearance, drive system,

Lower Height welded profile position, and the holder itself can all

Greater Accuracy influence accuracy. FlexLoc™ addresses

Lower Cost all these for a typical part positioning accuracy

of ±.01”. Contact factory for accuracy values for

your specific application.

25 TOOTH LOW PROFILE

Permits Larger Welded Profiles

Preferred for Side Load / Unload

Suitable for Magnetic Applications

Recommended for Multiple Belts - Higher Speeds

GUIDED PART HOLDERS

Utilizes standard belting which retains full load rating.

Sub-Plate permits attachment of user supplied Part Holders.

Holders and Sub-Plates can be rapidly removed without tools.

FlexLoc™ reduces joint stress, and permits low inertia pulleys.

Part Holders feature a preloaded mounting with a Guided Travel.

Accuracy, Versatility and Durability are greatly improved with FlexLoc™.

SPECIFICATIONS o PART HOLDER TYPES

Perpendicularity ±1 Part

Precision tension calibration. Holder Guided

Standard belt widths from 50 to 450 mm. by Adjustable

Compatible with our standard Drives and Accessories. Side Rails

Standard lengths 2 - 10 feet. (Special lengths available.)

All units utilize (1) of (3) different methods of belt self-tracking.

Sealed for life Bearings eliminate lubricant contamination of product.

Indexing Drives utilize Stepper, Servo or Brushless D.C. motors, all with position verification. +.01” ±.005”

Powder Coated single piece 10 GA. steel frame. (Available with dual “T” slots on each side.) Height

-.02” Height

Solid Urethane Timing belts with steel or Kevlar tension members and Nylon coating for reduced friction and wear.

Pitch Tolerance ±.02” Pitch Tolerance ±.02” Pitch Tolerance ±.02”

(Longitudinal Spacing)

TYPE - 1 TYPE - 2 TYPE - 3

FUNCTIONS APPLICATIONS Conventional FlexLoc™ FlexLoc™

Fixed Urethane Profile Removable Removable Machined

Precision Indexing and 4-Axes Positioning Assembly

Holder (Welded Type) Machined Holder Holder / Sub-Plate

Synchronous movement of multiple Conveyors Vision Inspection

High cyclic rates Laser Imprinting Eliminates Perpendicular Error Eliminates Perpendicular Error

Reversing Pharmaceutical Greatly improves height tolerance Greatly improves height tolerance

Heavy Loads Packaging Minimizes pitch (longitudinal spacing) error

Side load / Unload Machine Integration Minimizes any Skew induced by pitch

High speeds (2000’/min.) FlexLoc™ is suitable for both timing and flat belts variation across belt width

Available in Standard, Welded Profile, Removable Holder, Magnetic, Typical Part Positioning Tolerance of ±.01” is not effected

Vacuum, and Wash-Down on Special Order, in English or Metric versions. by Pitch Tolerance when using C.T.L. Index Drives.

AccuMove™ 17 Tooth The Spotlight is on

Precision with

NOMINAL

L

A

AccuMove

2.89

(17) Tooth TM

1.265

(32.13) .5

(12.7)

AccuMove™ 25 Tooth

W + 2.04

(51.8)

L + 1 NOMINAL

(25.4) A

3.39

(25) Tooth

Order Belt Width (A) Nominal

W

Width Inches (mm) Conveyor Length (L)

02 1.97 (50) 2.5 Inches (mm) 1. Drawings do not show optional dual “T” slot rails.

03 2.95 (75) 3.25 24" (610)

04 3.94 (100) 4.5 36" (914) 2. If Part Holders are supplied

overall length increases.

06 5.91 (150) 6.0 48" (1219)

07 7.40 (188) 7.5 60" (1524) 3. Optional lengths available.

12 11.81 (300) 12.0 72" (1829)

U.S. Patent No.: 6,170,645

18 17.72 (450) 18.0 120" (3048)

FlexLoc™

U.S. Patent No.: 6,321,904

Part Holder Length - See Table “A”

Part Holder Pitch - Must Be

in 10mm Increments

for AccuMove™

Types

75mm MAX.

Table A

AccuMove™ Flat Belt

Order

Part Holder Part Holder

Width

Length (mm) Length (mm)

02 (63) (46)

03 (82) (65)

04 (114) (97)

06 (152) (135)

07 (190) (173)

12 (302) (287)

18 (454) (440)

Conveyor Technologies Ltd. Conveyor Technologies Ltd.

440 Milford Parkway, Milford, OH 45150

(513) 248-0663 www.ConveyorTechLtd.com (513) 248-0663 www.ConveyorTechLtd.com

You might also like

- Conveyor Technologies LTD.: A World of Modular ConveyorsDocument24 pagesConveyor Technologies LTD.: A World of Modular Conveyorspaul napizaNo ratings yet

- B EJS SpecialityExpansionJointSys000 BRO v063-WEBDocument8 pagesB EJS SpecialityExpansionJointSys000 BRO v063-WEBGUILLERMO OTERO PRECIADONo ratings yet

- Medium Voltage Vacuum Circuit-Breaker With Mechanical Operating MechanismDocument2 pagesMedium Voltage Vacuum Circuit-Breaker With Mechanical Operating MechanismMahyar MashayekhiNo ratings yet

- Manual Transaxle Assy: ComponentsDocument2 pagesManual Transaxle Assy: Componentsjeremih alhegnNo ratings yet

- Case Cx75sr Cx80 Crawler Excavator Shop ManualDocument20 pagesCase Cx75sr Cx80 Crawler Excavator Shop Manualjamie100% (47)

- Body Builder Instructions: Chassis Propeller Shafts FM, FH Version2Document8 pagesBody Builder Instructions: Chassis Propeller Shafts FM, FH Version2Manuel CastroNo ratings yet

- DF150 175 SetupDocument16 pagesDF150 175 SetupElvin HernándezNo ratings yet

- Chain Sub Assembly1Document3 pagesChain Sub Assembly1jeremih alhegnNo ratings yet

- 40-01 Automatic Transaxle Assy (Atm) PrecautionsDocument2 pages40-01 Automatic Transaxle Assy (Atm) PrecautionsCelso BidinotiNo ratings yet

- Operator Instructions: ITD-19.0-001 ITD-19.0-001Document4 pagesOperator Instructions: ITD-19.0-001 ITD-19.0-001Ney HoraNo ratings yet

- Powerflex 523 Adjustable Frequency Ac Drive: Product InformationDocument2 pagesPowerflex 523 Adjustable Frequency Ac Drive: Product Informationelecrical gresikNo ratings yet

- PXM4/6/8K Meter Advanced Color Touchscreen Display Quick Start GuideDocument6 pagesPXM4/6/8K Meter Advanced Color Touchscreen Display Quick Start Guides.ganapathy RamanNo ratings yet

- D05 Standard Flow Parallel ManifoldDocument2 pagesD05 Standard Flow Parallel ManifoldYuriPasenkoNo ratings yet

- Catalogo Accesorios PilotesDocument69 pagesCatalogo Accesorios Piloteseleon07No ratings yet

- Starters Alternators Technical DataDocument10 pagesStarters Alternators Technical DataJoshua SanchezNo ratings yet

- Supplementary Service Manual: For '03 ModelDocument20 pagesSupplementary Service Manual: For '03 Modeljose martinezNo ratings yet

- New Easycarb Brochure 2020 Draft 7Document2 pagesNew Easycarb Brochure 2020 Draft 7api-542746165No ratings yet

- Corksport Install Instr For Axleback Muffler CX5!6!102-10-WEBDocument9 pagesCorksport Install Instr For Axleback Muffler CX5!6!102-10-WEBhutz5000No ratings yet

- Automatic Transaxle1 PDFDocument2 pagesAutomatic Transaxle1 PDFluisNo ratings yet

- 9056 Vocational Axles BrochureDocument18 pages9056 Vocational Axles BrochureAbdelhamid HaramiNo ratings yet

- 1983-SDEE - Foundation Vibrations STATE of The ARTDocument16 pages1983-SDEE - Foundation Vibrations STATE of The ARTJaime GuamanNo ratings yet

- Bomag BW211-40Document1 pageBomag BW211-40Felipe MenesesNo ratings yet

- TMS500 2 - ProductGuide ComboDocument32 pagesTMS500 2 - ProductGuide ComboArnold HernandezNo ratings yet

- Sales Manual of VESTA-1300 (7.0)Document63 pagesSales Manual of VESTA-1300 (7.0)Văn Duy ĐinhNo ratings yet

- MAJOR TECHNICAL SPECIFICATIONS 70 SeriesDocument7 pagesMAJOR TECHNICAL SPECIFICATIONS 70 SeriesAlzieNo ratings yet

- MACKDocument4 pagesMACKGurpreetNo ratings yet

- Doosan D35S-5 Forklift Kubota V3800 in US PDFDocument2 pagesDoosan D35S-5 Forklift Kubota V3800 in US PDFAditi DasNo ratings yet

- Ups Up-Pw1245 Panasonic PDFDocument2 pagesUps Up-Pw1245 Panasonic PDFPurnomo NugrohoNo ratings yet

- ISMC Weight and Dimension Chart - Grow MechanicalDocument7 pagesISMC Weight and Dimension Chart - Grow Mechanicalvishallrr7No ratings yet

- Cat XT ES Hose: The New Standard in Hose PerformanceDocument2 pagesCat XT ES Hose: The New Standard in Hose PerformanceJuan ValdesNo ratings yet

- Shimpo STH Series FlierDocument2 pagesShimpo STH Series Fliercoty burghyNo ratings yet

- V Series: Vertical / Linear WayDocument2 pagesV Series: Vertical / Linear WayPablo Santiago CampoverdeNo ratings yet

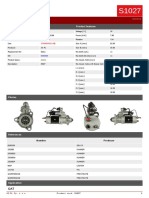

- S1027 PDFDocument2 pagesS1027 PDFHanNo ratings yet

- Grove RT 540 e Manuel TechniqueDocument16 pagesGrove RT 540 e Manuel TechniqueMohamedNo ratings yet

- RT540E ProductGuide Imperial 01 2020Document16 pagesRT540E ProductGuide Imperial 01 2020Leonardo LiraNo ratings yet

- Ipe 400 To Concrete ColumnDocument30 pagesIpe 400 To Concrete ColumnMoustafaNo ratings yet

- PTB TrussDocument158 pagesPTB TrussRAJKOT AIRPORTNo ratings yet

- RT530E 2 Product Guide Imperial PDFDocument16 pagesRT530E 2 Product Guide Imperial PDFsergio blandon lNo ratings yet

- Ze215e Ze210e Ze215e 10Document2 pagesZe215e Ze210e Ze215e 10Winarto100% (3)

- Movex 2015 L PDFDocument356 pagesMovex 2015 L PDFLuis Angel BecerrilNo ratings yet

- Jf'Ol TBQJ'LK: Underwater Mateable Miniature ConnectorsDocument6 pagesJf'Ol TBQJ'LK: Underwater Mateable Miniature ConnectorsJonathan RiveraNo ratings yet

- 1 BP1Document24 pages1 BP1kheang amgNo ratings yet

- Technical Procedure: Trailer Suspension SystemsDocument1 pageTechnical Procedure: Trailer Suspension SystemsAldair de Luis MoralesNo ratings yet

- Heavy Duty Safety Switches - H364ADocument4 pagesHeavy Duty Safety Switches - H364AFRANCISCO HINOJOSANo ratings yet

- ATA Ispec 2200 OverviewDocument35 pagesATA Ispec 2200 Overviewfreewill233% (3)

- Product Guide: FeaturesDocument16 pagesProduct Guide: FeaturesJavier Ignacio MacíasNo ratings yet

- MIQ Technical Data Table Technical Information ASSET DOC LOC 7258698Document1 pageMIQ Technical Data Table Technical Information ASSET DOC LOC 7258698Laura LNo ratings yet

- Im Supplement Torque Tube Identification 249 Sensors Fisher en 126696Document2 pagesIm Supplement Torque Tube Identification 249 Sensors Fisher en 126696Rachmat MaulanaNo ratings yet

- Toyota Camry 2002 2006 Workshop ManualDocument20 pagesToyota Camry 2002 2006 Workshop Manualbelinda100% (43)

- Pressure Gauge CalibrationDocument9 pagesPressure Gauge CalibrationShaikh sohilNo ratings yet

- Linde EN Ds x20 x35 1252 en A 0621 ViewDocument8 pagesLinde EN Ds x20 x35 1252 en A 0621 ViewNadeem AhmedNo ratings yet

- "Big Red" TX-280M - TX-300M - TX-330M - Taylor Machine WorksDocument4 pages"Big Red" TX-280M - TX-300M - TX-330M - Taylor Machine WorksIvan ManuelNo ratings yet

- ARKA SERIES WSMD 515 545 WEL E and PD 515 545 144 MP HC 08 10 04 2023 63a1cb9b97Document2 pagesARKA SERIES WSMD 515 545 WEL E and PD 515 545 144 MP HC 08 10 04 2023 63a1cb9b97Bharat GouripurNo ratings yet

- Eg5010 0 1Document4 pagesEg5010 0 1Victor SanchezNo ratings yet

- HN Amphenol Plugs & JacksDocument1 pageHN Amphenol Plugs & Jackshafidz asyrafNo ratings yet

- 372SSL20V3 Service Master Components PDFDocument2 pages372SSL20V3 Service Master Components PDFAnthony PozoNo ratings yet

- Flextable: Pipe TableDocument1 pageFlextable: Pipe TableSalva MezaNo ratings yet

- RobotbasketballDocument11 pagesRobotbasketballMohd Asri TaipNo ratings yet

- Active Control of A Robotic Arm With Pneumatic Artificial Muscle ActuatorDocument4 pagesActive Control of A Robotic Arm With Pneumatic Artificial Muscle ActuatorMohd Asri TaipNo ratings yet

- Yasir Amzad Ali MFKE2009Document113 pagesYasir Amzad Ali MFKE2009Mohd Asri TaipNo ratings yet

- Hungarian Moon RobotDocument2 pagesHungarian Moon RobotMohd Asri TaipNo ratings yet

- Lego RoboticsDocument6 pagesLego RoboticsMohd Asri TaipNo ratings yet

- Robot Edu Inner CityDocument8 pagesRobot Edu Inner CityMohd Asri TaipNo ratings yet

- Robotic Material HandlingDocument2 pagesRobotic Material HandlingMohd Asri TaipNo ratings yet

- L010416 - PCL501 Product SheetDocument1 pageL010416 - PCL501 Product SheetMohd Asri TaipNo ratings yet

- SRP (435 450) Bma HV - 166 - enDocument2 pagesSRP (435 450) Bma HV - 166 - enMohd Asri TaipNo ratings yet

- CAMCO General Service Manual 0061-1008Document26 pagesCAMCO General Service Manual 0061-1008Mohd Asri TaipNo ratings yet

- Speed SwitchDocument3 pagesSpeed SwitchMohd Asri TaipNo ratings yet

- Thread CheckingDocument1 pageThread CheckingMohd Asri TaipNo ratings yet

- AN-0110, Eddy Current Thread Quality Signature AnalysisDocument4 pagesAN-0110, Eddy Current Thread Quality Signature AnalysisMohd Asri TaipNo ratings yet

- L010719 - BLWR23MDA Series Spec SheetDocument2 pagesL010719 - BLWR23MDA Series Spec SheetMohd Asri TaipNo ratings yet

- Harmonic Blet Driven Linear DriveDocument1 pageHarmonic Blet Driven Linear DriveMohd Asri TaipNo ratings yet

- Geared e 4Document2 pagesGeared e 4Mohd Asri TaipNo ratings yet

- L010644 - PCL451 Spec SheetDocument2 pagesL010644 - PCL451 Spec SheetMohd Asri TaipNo ratings yet

- RPA004 Pneumatic Safety Systems and Cylinder Speed ControlDocument4 pagesRPA004 Pneumatic Safety Systems and Cylinder Speed ControlMohd Asri TaipNo ratings yet

- Aluminium Insight 2010-09 Expert-Midgely EMPDocument2 pagesAluminium Insight 2010-09 Expert-Midgely EMPMohd Asri TaipNo ratings yet

- FS-N40 Series: User's ManualDocument24 pagesFS-N40 Series: User's ManualMohd Asri TaipNo ratings yet

- EON-XR Marketplace UserguideDocument15 pagesEON-XR Marketplace UserguideMohd Asri TaipNo ratings yet

- CAMCO QuickStart 0157Document2 pagesCAMCO QuickStart 0157Mohd Asri TaipNo ratings yet

- Triton SU VGT AT ADV 4N 2017Document1 pageTriton SU VGT AT ADV 4N 2017Mohd Asri TaipNo ratings yet

- Fichea4 Inroof en 2021Document2 pagesFichea4 Inroof en 2021Mohd Asri TaipNo ratings yet

- IR EN MI-v11.3-4Document34 pagesIR EN MI-v11.3-4Mohd Asri TaipNo ratings yet

- FS-N40 Series: Instruction ManualDocument4 pagesFS-N40 Series: Instruction ManualMohd Asri TaipNo ratings yet

- Low Cost PVC CrutchesDocument2 pagesLow Cost PVC CrutchesMohd Asri TaipNo ratings yet

- Sketch Constraints Full SheetDocument1 pageSketch Constraints Full SheetMohd Asri TaipNo ratings yet

- CA-DBW13 DatasheetDocument2 pagesCA-DBW13 DatasheetMohd Asri TaipNo ratings yet

- Ir en PLDocument24 pagesIr en PLMohd Asri TaipNo ratings yet

- Tda 8175Document4 pagesTda 8175miniecateNo ratings yet

- Profile: SS Intellectual Property Neeti Consultancy LLPDocument13 pagesProfile: SS Intellectual Property Neeti Consultancy LLPAmit PandeyNo ratings yet

- Internet Piracy and CounterfeitingDocument36 pagesInternet Piracy and CounterfeitingRajeshwar NandanNo ratings yet

- The Book of The Thousand Nights and A Night - Volume 13 by AnonymousDocument357 pagesThe Book of The Thousand Nights and A Night - Volume 13 by AnonymousGutenberg.orgNo ratings yet

- 04-10X SALES PAGES - The Value Prism PDFDocument4 pages04-10X SALES PAGES - The Value Prism PDFDikesh ShahNo ratings yet

- Agile Practice GuideDocument3 pagesAgile Practice GuideJuwalNo ratings yet

- Nirvana - About A GirlDocument3 pagesNirvana - About A GirlLuca0% (1)

- US7090312Endless Track For High Speed Multi-Terrain VehiclesDocument16 pagesUS7090312Endless Track For High Speed Multi-Terrain Vehicles임학진No ratings yet

- Wesley Magnet Vibration GenERATORDocument71 pagesWesley Magnet Vibration GenERATORChad Ashley Vandenberg100% (1)

- Astm A389 A389m (1998)Document3 pagesAstm A389 A389m (1998)ibrahim780No ratings yet

- Country Kids 'N City Slicks, Inc. v. Vicki Sheen, Bill Sheen, Ladawn Bragg, and Flake Wells, Doing Business As Carousel Kids, 77 F.3d 1280, 10th Cir. (1996)Document12 pagesCountry Kids 'N City Slicks, Inc. v. Vicki Sheen, Bill Sheen, Ladawn Bragg, and Flake Wells, Doing Business As Carousel Kids, 77 F.3d 1280, 10th Cir. (1996)Scribd Government DocsNo ratings yet

- English Test B1 PDFDocument12 pagesEnglish Test B1 PDFAnh-Tuan TranNo ratings yet

- Practices - Section 1 Part 0: Download The Jdk8 and Netbeans Ide BundleDocument4 pagesPractices - Section 1 Part 0: Download The Jdk8 and Netbeans Ide BundleJonathan PhandanyNo ratings yet

- Captain Drake's Revenge: by Samuel WoodsDocument15 pagesCaptain Drake's Revenge: by Samuel WoodswyrmboyNo ratings yet

- Tds Bonderite C-Ic 4450 TPBDocument4 pagesTds Bonderite C-Ic 4450 TPBBugs MartínezNo ratings yet

- Chapter 8Document24 pagesChapter 8Donna Mae HernandezNo ratings yet

- MOMENTIVE Silicone in Coating Textile BrochureDocument12 pagesMOMENTIVE Silicone in Coating Textile Brochureoverlord5555100% (1)

- G.R. No. 194307 Birkenstock Orthopaedie Vs Phil. SHoe ExpoDocument16 pagesG.R. No. 194307 Birkenstock Orthopaedie Vs Phil. SHoe ExpoChatNo ratings yet

- Group: Roll No. 130 To 143 Div B: Media Law Workshop February 4, 2012Document6 pagesGroup: Roll No. 130 To 143 Div B: Media Law Workshop February 4, 2012MrinalBhatnagarNo ratings yet

- Technical Data Sheet: Product Saphira Blanket Premier Characteristics Saphira Blanket Premier Is A Blanket ForDocument1 pageTechnical Data Sheet: Product Saphira Blanket Premier Characteristics Saphira Blanket Premier Is A Blanket ForcaaelestisNo ratings yet

- 2024 ART COMPETITION Guidelines FINAL 03222024Document8 pages2024 ART COMPETITION Guidelines FINAL 03222024francy100% (1)

- Manual Vistron 95403 T 140Document116 pagesManual Vistron 95403 T 140brian100% (1)

- Manual de Operacion Consola GroveDocument63 pagesManual de Operacion Consola GroveTeofilo Flores100% (3)

- MFC-19G 2008 PDFDocument273 pagesMFC-19G 2008 PDFAdilbekMursaliyev100% (1)

- Intangibles Formative AssessmentDocument2 pagesIntangibles Formative AssessmentStephanie gasparNo ratings yet

- WBPDocument426 pagesWBPahmed_497959294No ratings yet

- Tacho SoftDocument8 pagesTacho SoftFurueiNo ratings yet

- Seri Somboonsakdikul V. Orlane S.A.: GR No. 188996, 2017-02-01Document6 pagesSeri Somboonsakdikul V. Orlane S.A.: GR No. 188996, 2017-02-01hartneyNo ratings yet

- Gallery Artist AgreementDocument1 pageGallery Artist AgreementVan JazminNo ratings yet

- Chordu Piano Chords Musikalisai Puisi Doa Karya Chairil Anwar MTSN 3 Kuningan 9 1 Chordsheet Id GNRYhk17VLcDocument2 pagesChordu Piano Chords Musikalisai Puisi Doa Karya Chairil Anwar MTSN 3 Kuningan 9 1 Chordsheet Id GNRYhk17VLcRatih Zata YumniNo ratings yet