Professional Documents

Culture Documents

POWERFUL MODELS IN A FLEXIBLE RANGE OF SIZES - Kelvion

Uploaded by

Hakkı YılmazOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

POWERFUL MODELS IN A FLEXIBLE RANGE OF SIZES - Kelvion

Uploaded by

Hakkı YılmazCopyright:

Available Formats

Brazed

plate heat exchangers

GBS-Series

POWERFUL MODELS

IN A FLEXIBLE RANGE OF SIZES

GBS-Series Always a suitable solution at hand

Heat Exchangers of the GBS-Series are the solid all-rounders The brazed plate heat exchangers from Kelvion offer tailor-

among all brazed plate heat exchangers from Klevion. The made solutions for the widest range of application. We configure

latest technology and decades of experience of successful the most economically favorable model for you from the wide

applications guarantee highest quality, cost efficiency and reli- range of available sizes and the numerous optional features. We

ability. Equipped with the proven technical features like Safety adapt this with individually positioned connections to meet your

Chamber TM , Delta InjectionTM and Full Flow SystemTM the units specific requirements.

are ideal for applications of all sizes with max. 200°C / 392°F and

up to 40 bar / 580 psi. Example:

• heating water and industrial water systems

The product range also offers the widest variety and flexibility • underfloor heating

in terms of sizes, different connections, flow arrangements and • subcoolers and condensers

accessories. Thus heat exchangers of the GBS-series always • economizer

serve the right solution for your operating conditions. • refrigerant evaporators

• oil coolers

Your advantages at a glance:

• highest flexibility

• compact design

• wide range of applications

• solid construction

A

C

We need following information to select your

optimum heat exchanger

B D • required temperature range

• flow rates or required heat load

• maximal permitted pressure drop

• required working conditions

L

(Litres/

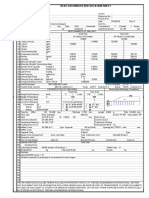

Type (bar) Standard dimensions (mm) (mm) (kg)

Channel)

L-Dimension Mass Max.

Plate heat exchanger Pressure A B C D N = number of N = number of Volume number of

plates plates plates

GBS 100M 31 74 204 40 170 8.00+2.23xN 0.70+0.050xN 0.025 50

GBS 200H 31 90 231 43 182 10.00+2.24xN 1.10+0.060xN 0.030 50

GBS 220H 31 90 328 43 279 10.00+2.22xN 1.30+0.080xN 0.046 50

GBS 240H 31 91 464 43 415 10.00+2.20xN 2.04+0.140xN 0.070 50

GBS 300H 31 124 173 73 120 10.00+2.22xN 1.20+0.060xN 0.030 50

GBS 400H 31 124 335 73 281 9.50+2.24xN 1.60+0.130xN 0.065 100

GBS 418L/M 40 127 282 84 239 9.00+2.05xN 1.35+0.118xN 0.055 50

GBS 420L 31 127 282 68 223 9.00+2.76xN 1.35+0.118xN 0.076 150

GBS 500H 31 124 532 73 478 9.50+2.23xN 1.76+0.210xN 0.100 100

GBS 525L/M/H 36/34 118 525 69 476 9.00+2.58xN 2.55+0.210xN 0.125 100

GBS 700L/M 31 271 532 200 460 11.00+2.25xN 9.60+0.540xN 0.230 150

GBS 757L/M/H 35 281 543 198 460 11.50+2.65xN 13.20+0.500xN 0.310 160

GBS 760L 27/20 257 519 138 416 13.50+3.45xN 12.60+0.400xN 0.410 150

GBS 800H 31 271 532 161 421 11.50+2.34xN 10.00+0.540xN 0.221 260

GBS 900H 31 271 802 161 690 11.30+2.31xN 11.50+0.800xN 0.399 260

GBS 910M 36/32 318 783 225 690 14.00+2.54xN 20.00+0.853xN 0.480 200

GBS 1000M/H 31 386 875 237 723 20.30+2.31xN 39.50+1.250xN 0.600 360

GBS 1000L 31/16 386 875 237 723 22.65+2.35xN 39.50+1.250xN 0.466/0.733 360

Also available as an advanced evaporator with a special „Delta InjectionTM“ distribution system for the refrigerant inlet.

GBS 400H-AE 31 124 335 73 281 9.50+2.24xN 1.60+0.130xN 0.065 100

GBS 500H-AE 31 124 532 73 478 9.50+2.23xN 1.76+0.210xN 0.100 100

GBS 700M-AE 31 271 532 200 460 11.00+2.25xN 9.60+0.540xN 0.230 150

GBS 800H-AE 31 271 532 161 421 11.50+2.34xN 10.00+0.540xN 0.221 260

GBS 900H-AE 31 271 802 161 690 11.30+2.31xN 11.50+0.800xN 0.399 260

GBS 1000H-AE 31 386 875 237 723 20.30+2.31xN 39.50+1.250xN 0.600 360

GBS-Series: Specifications

• plate material: Stainless steel AISI 316L / 1.4404

• brazing material: Copper

Features

• Safety Chamber TM (model 700, 757, 800, 900, 1000)

• Delta InjectionTM (model 400, 500, 700M, 800, 900, 1000H)

© Kelvion Brazed PHE GmbH | All rights reserved. GBS-UK04/18

• Full Flow SystemTM (model 100, 200, 220, 240, 300, 400, 500)

Performance limits

• working temperature: -196°C to +200°C / -321°F to +392°F

• working pressure: up to 40 bar / 580psi

Approval

• PED (CE), ASME VIII-1, UL

The specifications contained in this brochure are intended only to serve the non-binding description of our products and services and are not subject to guarantee.

Binding specifications, especially pertaining to performance data and suitability for specific operating purposes, are dependent upon the individual circumstances at

the operation location and can, therefore, only be made in terms of precise requests.

Kelvion Brazed PHE GmbH Kelvion PHE GmbH

Remsaer Straße 2a, 04603 Nobitz-Wilchwitz, Germany Karl-Schiller-Straße 1-3, 31157 Sarstedt, Germany

Phone +49 34 47 55 39-0 Phone +49 50 66 601-0

Fax +49 34 47 55 39-30 Fax +49 50 66 601-134

sales.nobitz@kelvion.com sarstedt@kelvion.com

www.kelvion.com

You might also like

- Lamina Brasado Bphe Produto GBHDocument2 pagesLamina Brasado Bphe Produto GBH伊藤 哲ウンベルト(Tabibito)No ratings yet

- High Wall Inverter: Yhkf 09 To 24 ZeebmhorxDocument2 pagesHigh Wall Inverter: Yhkf 09 To 24 ZeebmhorxmuratNo ratings yet

- Style 355 355PDocument10 pagesStyle 355 355PUmmes AhmedNo ratings yet

- HX 16-Data SheetDocument2 pagesHX 16-Data SheetRaul SebastiamNo ratings yet

- Stainless Steel Flexible Coupling Style 77S: 1.0 Product DescriptionDocument8 pagesStainless Steel Flexible Coupling Style 77S: 1.0 Product DescriptionMahmoudNo ratings yet

- Heatpipe Spec CCI FarnellDocument3 pagesHeatpipe Spec CCI FarnellcivicbladeNo ratings yet

- Shop Manual GD610, GD620, GD660, GD670 PDFDocument664 pagesShop Manual GD610, GD620, GD660, GD670 PDFAing LaingNo ratings yet

- MSS SP 58Document1 pageMSS SP 58octa aldyNo ratings yet

- GB Trelljet681Document1 pageGB Trelljet681magnavacchi serviceNo ratings yet

- Acople FlexibleDocument4 pagesAcople Flexiblejhoger2012No ratings yet

- CIPRIANI A5 Saldobrasati SCDocument4 pagesCIPRIANI A5 Saldobrasati SCSebastian MirandaNo ratings yet

- Parametros Agua StripDocument1 pageParametros Agua StripJose CaminoNo ratings yet

- Victaulic Duplex Grooved Couplings Style 77DX Duplex Stainless Steel Flexible CouplingDocument9 pagesVictaulic Duplex Grooved Couplings Style 77DX Duplex Stainless Steel Flexible Couplingגרבר פליקסNo ratings yet

- Kelvion K°Bloc: Welded Plate Heat ExchangerDocument50 pagesKelvion K°Bloc: Welded Plate Heat ExchangerDipankar KhawasNo ratings yet

- Actaris Gas Regulators SERusDocument2 pagesActaris Gas Regulators SERushendrik muellerNo ratings yet

- Silo Weight & Volume CalculationDocument18 pagesSilo Weight & Volume CalculationYogesh PatilNo ratings yet

- Pressure DropDocument36 pagesPressure DropdesignselvaNo ratings yet

- RXQ 32Document1 pageRXQ 32Surya LiemNo ratings yet

- Htri PDFDocument1 pageHtri PDFLuigy L-aNo ratings yet

- Catálogo Mola PratoDocument24 pagesCatálogo Mola PratoJan MartinsNo ratings yet

- DynaDrill (SLB) 7.25 IN 6-7 Lobe 10.7 STGDocument1 pageDynaDrill (SLB) 7.25 IN 6-7 Lobe 10.7 STGLeonardo BarriosNo ratings yet

- 2 Old Evaps LB and ELB Series PDFDocument28 pages2 Old Evaps LB and ELB Series PDFPreeti gulatiNo ratings yet

- Aquacal - TropicalDocument2 pagesAquacal - TropicalDebora MaryantiNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- Dimensions Victaulic ClampDocument12 pagesDimensions Victaulic ClampAries MunandarNo ratings yet

- Carrier Spec Sheet 38MHRBDocument4 pagesCarrier Spec Sheet 38MHRBZeroNo ratings yet

- Heat Exchanger Specification Sheet Thermal NEC UnitsDocument1 pageHeat Exchanger Specification Sheet Thermal NEC Unitsmohsen ranjbarNo ratings yet

- Goodman Gms9 SpecsDocument8 pagesGoodman Gms9 Specsdonzi7218No ratings yet

- Victaulic Carbon Steel Couplings and Grooved FittingsDocument16 pagesVictaulic Carbon Steel Couplings and Grooved FittingsAnonymous 7I5qQ0eAxgNo ratings yet

- DLGDocument2 pagesDLGJoseph BoshehNo ratings yet

- P P P P: Duplex 2205 Specifications: UNS S32205/S31803Document2 pagesP P P P: Duplex 2205 Specifications: UNS S32205/S31803Bagus AdiriantoNo ratings yet

- Bearing Selection ProcessDocument21 pagesBearing Selection Processarchie zambranoNo ratings yet

- K-Flex Offer - R1Document10 pagesK-Flex Offer - R1farhaNo ratings yet

- Ram Sons Viet MachinesDocument38 pagesRam Sons Viet MachinesDeepanNo ratings yet

- K-ML-KT20: K-TRON Product Specification Twin Screw Loss-in-Weight FeederDocument2 pagesK-ML-KT20: K-TRON Product Specification Twin Screw Loss-in-Weight FeederselvaNo ratings yet

- GEA PHE WP En-5.2Document2 pagesGEA PHE WP En-5.2Oscar CamposNo ratings yet

- Lec6 - Ce429 - Rebar Estimate and Cutting List PrepDocument65 pagesLec6 - Ce429 - Rebar Estimate and Cutting List Preparchweiss06No ratings yet

- For Maximum Load (Normal Case) : From Staad From STAAD With ImpactDocument4 pagesFor Maximum Load (Normal Case) : From Staad From STAAD With ImpactVasu Deva Rao ChilukuriNo ratings yet

- Weaver Heat Transfer Technologies DATA SHEET 1Document1 pageWeaver Heat Transfer Technologies DATA SHEET 1Bhavin PatelNo ratings yet

- Celsius SHS: Celsius Structural Hollow SectionsDocument13 pagesCelsius SHS: Celsius Structural Hollow SectionsDuarte CardosoNo ratings yet

- SAF 2205 DatasheetDocument11 pagesSAF 2205 DatasheetNitinNo ratings yet

- VRF ToshibaDocument2 pagesVRF ToshibaClima ShopNo ratings yet

- Manual Scotsman MXGM638AS (2 Páginas)Document3 pagesManual Scotsman MXGM638AS (2 Páginas)jose alberto marquez silvaNo ratings yet

- Heavy Industrial Pressure Transducer: The M5100Document7 pagesHeavy Industrial Pressure Transducer: The M5100Anh TranNo ratings yet

- Quickvic Flexible Coupling For Steel: Carbon Steel Pipe - Grooved CouplingsDocument4 pagesQuickvic Flexible Coupling For Steel: Carbon Steel Pipe - Grooved CouplingsMina MagdyNo ratings yet

- Grinnell Mechanical Products Flexible Coupling Technical Data General DescriptionDocument4 pagesGrinnell Mechanical Products Flexible Coupling Technical Data General DescriptionСергей КолесниковNo ratings yet

- Reboiler 1Document12 pagesReboiler 1kishna009No ratings yet

- Test4 PDFDocument1 pageTest4 PDFKevin DoNo ratings yet

- JZBFJZBS Series Semi Hermetic Compressor Condensing Units (Bitzer Compressor)Document5 pagesJZBFJZBS Series Semi Hermetic Compressor Condensing Units (Bitzer Compressor)Cool EquipmentNo ratings yet

- Ay-All Ss Sanitary Pressure GaugeDocument3 pagesAy-All Ss Sanitary Pressure Gaugepankaj doshiNo ratings yet

- Ball Valve - VictaulicDocument4 pagesBall Valve - VictaulicMF CHOONGNo ratings yet

- DIMO 42H - Prehardened CrMnMo-alloyed Steel in Holderblock Quality For The Construction of Plastic MoldsDocument4 pagesDIMO 42H - Prehardened CrMnMo-alloyed Steel in Holderblock Quality For The Construction of Plastic MoldsFernando LaraNo ratings yet

- Victaulic Snap-Joint Coupling Style 78: 1.0 Product DescriptionDocument6 pagesVictaulic Snap-Joint Coupling Style 78: 1.0 Product DescriptionFlori MovNo ratings yet

- Piston Seals: Technical DetailsDocument4 pagesPiston Seals: Technical DetailsRPINILLA (EICO S.A.)No ratings yet

- Druck PMP3700 Test Sensors For Aerospace Datasheet - ENDocument4 pagesDruck PMP3700 Test Sensors For Aerospace Datasheet - ENmoreauNo ratings yet

- 240-05-DTS-009 V-501 Air ReceiverDocument20 pages240-05-DTS-009 V-501 Air ReceiverEmran NazirNo ratings yet

- 240-05-DTS-010 V-400 Regenaration Gas SeperatorDocument20 pages240-05-DTS-010 V-400 Regenaration Gas SeperatorEmran NazirNo ratings yet

- RECAM Catalogue 2012Document83 pagesRECAM Catalogue 2012Maxmore Karumamupiyo100% (1)

- PSP 108 Alloy2507Document2 pagesPSP 108 Alloy2507Nitin KurupNo ratings yet

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- All NFPA Tables Fire Sprinklers & Fire Pump: Classification of OccupanciesDocument5 pagesAll NFPA Tables Fire Sprinklers & Fire Pump: Classification of OccupanciesEngFaisal AlraiNo ratings yet

- DW 145 - Guide To Good Practice For The Installation of Fire and Smoke DampersDocument50 pagesDW 145 - Guide To Good Practice For The Installation of Fire and Smoke DampersHakkı Yılmaz100% (4)

- TUF-2000H User ManualDocument52 pagesTUF-2000H User ManualHakkı YılmazNo ratings yet

- Geberit Price ListDocument3 pagesGeberit Price ListHakkı YılmazNo ratings yet

- Alnor 801 RVADocument13 pagesAlnor 801 RVAHakkı YılmazNo ratings yet

- EMP Candidate HandbookDocument38 pagesEMP Candidate HandbookHakkı YılmazNo ratings yet

- CxA Candidate HandbookDocument32 pagesCxA Candidate HandbookHakkı YılmazNo ratings yet

- Evaluation of An AHU Fault Detection Scheme Based On Finite State Machine Sequencing ControlDocument108 pagesEvaluation of An AHU Fault Detection Scheme Based On Finite State Machine Sequencing ControlNatarajNo ratings yet

- Results From Field Testing of Air Handling Unit and Variable Air Volume Box Fault Detection ToolsDocument33 pagesResults From Field Testing of Air Handling Unit and Variable Air Volume Box Fault Detection ToolsNatarajNo ratings yet

- BEAP Candidate Guidebook 9820Document43 pagesBEAP Candidate Guidebook 9820Hakkı YılmazNo ratings yet

- Fault Diagnosis of Components and Sensors in HVAC Air Handling Systems With New Types of FaultsDocument15 pagesFault Diagnosis of Components and Sensors in HVAC Air Handling Systems With New Types of FaultsHakkı YılmazNo ratings yet

- Sustainable Building Operation and Maintenance Guideline33420Document154 pagesSustainable Building Operation and Maintenance Guideline33420Hakkı YılmazNo ratings yet

- Link Profi̇l Hesap RaporuDocument3 pagesLink Profi̇l Hesap RaporuHakkı YılmazNo ratings yet

- Reflex Extwin TW 50 R, Micro Bubble-/ Dirt Separator, Flanged Connection Article-No.:8253400Document1 pageReflex Extwin TW 50 R, Micro Bubble-/ Dirt Separator, Flanged Connection Article-No.:8253400Hakkı YılmazNo ratings yet

- Missel Product List GB 2017 02 Fire Protection PDFDocument36 pagesMissel Product List GB 2017 02 Fire Protection PDFHakkı YılmazNo ratings yet

- 1-1-01 EN Frese OPTIMA Compact DN10-DN50Document15 pages1-1-01 EN Frese OPTIMA Compact DN10-DN50Hakkı YılmazNo ratings yet

- Link Profi̇l Hesap RaporuDocument3 pagesLink Profi̇l Hesap RaporuHakkı YılmazNo ratings yet

- Welding Process PDFDocument1 pageWelding Process PDFZainul Abedin SayedNo ratings yet

- Multilift MDDocument704 pagesMultilift MDHakkı Yılmaz100% (1)

- Kelvion HEXDocument2 pagesKelvion HEXHakkı YılmazNo ratings yet

- Memory Chart Set 1Document7 pagesMemory Chart Set 1Hakkı YılmazNo ratings yet

- Memory Chart Set 1Document7 pagesMemory Chart Set 1Hakkı YılmazNo ratings yet

- Omnirad 819 - EN PDS 2Document3 pagesOmnirad 819 - EN PDS 2brausenpaulNo ratings yet

- Asme Sec V A-15-2006Document4 pagesAsme Sec V A-15-2006Muhammed Abo-FandoodNo ratings yet

- Carbohydrates WorksheetDocument4 pagesCarbohydrates WorksheetNatalie Pemberton86% (7)

- Adiabatic Vs Isothermal ProcessDocument2 pagesAdiabatic Vs Isothermal ProcessRyanNo ratings yet

- STP 491-1971Document90 pagesSTP 491-1971Tim SchouwNo ratings yet

- 0237e CHBDocument1 page0237e CHBSaif Ahmed SiddiquiNo ratings yet

- Chem 1Document1 pageChem 1himanshupandit485No ratings yet

- Elec6063 Optoelectronics and Lightwave Technology: Part 2: Leds and Lasers - 1 (Leds)Document43 pagesElec6063 Optoelectronics and Lightwave Technology: Part 2: Leds and Lasers - 1 (Leds)wanxin zhouNo ratings yet

- Session1 Kroeger Beth PresDocument83 pagesSession1 Kroeger Beth PresMahesh GavasaneNo ratings yet

- REFRIGERANTSDocument72 pagesREFRIGERANTSSka dooshNo ratings yet

- Ammonia Piping Handbook PDFDocument55 pagesAmmonia Piping Handbook PDFadh3ckNo ratings yet

- Tmecc 0411Document6 pagesTmecc 0411Karen BenteoNo ratings yet

- Gas Laws Practice Test - Ans. KeyDocument4 pagesGas Laws Practice Test - Ans. Keycabbiemartinez100% (1)

- 8 B 829 B 1 Af 50 Aeb 45 D 91 DDocument6 pages8 B 829 B 1 Af 50 Aeb 45 D 91 Dapi-400268497No ratings yet

- Experiment No.1. (Monograph)Document3 pagesExperiment No.1. (Monograph)ayeza.sarwar2021No ratings yet

- Duncan Sobre EsmaltesDocument9 pagesDuncan Sobre EsmaltesLeland StanfordNo ratings yet

- Salama YoussefDocument1 pageSalama YoussefYoussef SalamaNo ratings yet

- DSM-0295.0 Al2O3 NiAl CermetDocument3 pagesDSM-0295.0 Al2O3 NiAl CermetApichitNo ratings yet

- Effect of Temperature On Sliding Wear of AISI 316 L (N) Stainless Steel  " Analysis of Measured Wear and Surface Roughness of Wear TracksDocument7 pagesEffect of Temperature On Sliding Wear of AISI 316 L (N) Stainless Steel  " Analysis of Measured Wear and Surface Roughness of Wear TracksSamir BoseNo ratings yet

- Stockmann 2016Document12 pagesStockmann 2016Barbara SilvaNo ratings yet

- STI - SP001-00 - Standard For Inspection of In-Service Shop Fabricated Aboveground Tanks For Storage of Combustible and Flammable LiquidsDocument20 pagesSTI - SP001-00 - Standard For Inspection of In-Service Shop Fabricated Aboveground Tanks For Storage of Combustible and Flammable LiquidsJoe BetkerNo ratings yet

- Method of Statement For FRP Lining TankDocument5 pagesMethod of Statement For FRP Lining Tankmoytabura96100% (3)

- Mathematics Arithmetic and Number Sense Algebra Geometry: (Answer Many Word Problems As Possible)Document5 pagesMathematics Arithmetic and Number Sense Algebra Geometry: (Answer Many Word Problems As Possible)DarleneNo ratings yet

- Separating Corn Starch From CornDocument3 pagesSeparating Corn Starch From CornJagna LannaoNo ratings yet

- Chapter 3 Propteries of Water HWDocument2 pagesChapter 3 Propteries of Water HWapi-521773978No ratings yet

- (A6) Durability of Concrete With Different Mineral Admixtures A ReviewDocument12 pages(A6) Durability of Concrete With Different Mineral Admixtures A ReviewAbd El-nour RamdNo ratings yet

- Furnace SoftwareDocument7 pagesFurnace SoftwareolaNo ratings yet

- Friction Coefficients of Some Common MaterialsDocument2 pagesFriction Coefficients of Some Common MaterialsWanda Hafiz NurzamanNo ratings yet

- Mep MainDocument57 pagesMep Mainravi_92No ratings yet