Professional Documents

Culture Documents

Docking Load Dist

Uploaded by

swathi viswanathanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Docking Load Dist

Uploaded by

swathi viswanathanCopyright:

Available Formats

ince the keel blocks bear the weight of the ship, the load distribution curve for

the keel blocks is derived from the weight curve of the ship, which is comprised of

a combination of distributed and concentrated weights. The weight of the hull

girder and superstructure are distributed along the ship�s length. But weights like

that of machinery, equipment, transverse bulkheads, fuel oil, fresh water are

considered as concentrated weights.

The bilge keel extends as an appendage from the sides of the hull. The distance

from the bilge keel to the ship�s centerline must be specified in the docking plan.

The height of the bilge keel from the ship�s keel is used to ensure there is

sufficient vertical clearance available during docking and undocking

The keel profile shows the elevation of the keel line along the ship�s length. This

profile is used to determine the height of the keel blocks at each longitudinal

position, taking into consideration the load distribution curve of the ship.

Sufficient clearance should be ensured between the propeller tip and the dock

floor. There should also be adequate longitudinal and transverse clearances for

enabling removal of the propeller. It is due to this reason, the cross sectional

view of the propeller (usually looking forward) is provided in the dock plans. The

centerline of the ship, centerline of the propeller disc, distance between the

ship�s centerline and the propeller centerline, and keel line of the amidship is

also shown in the same diagram, as illustrated below

The plan view would show the location of the keel blocks along the centerline of

the ship. Most large ships with wide beam are also placed on a series of side

blocks, and the layout of the same is laid out in the plan view. The position of

every hull opening and hull protrusions (both, above and below the waterline) are

also marked in this drawing, in order to make sure they do not interfere with the

dock blocks.

The elevation view of the docking drawing gives the following information:

Location of the Longitudinal Reference Point (LRP), i.e. the point from which all

the longitudinal dimensions are measured.

Location of Aft Perpendicular and Forward Perpendicular.

Location of the end of skeg.

Frame spacing.

Longitudinal clearance required for removal of shaft.

Longitudinal clearance required for removal of rudder.

Location of draft marks along the ship.

Location of the first and last keel blocks.

The first few hydrostatics that must be checked before a ship enters a dry dock

are:

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Stairway To Heaven SoloDocument2 pagesStairway To Heaven SoloJakob FrandsenNo ratings yet

- Kylie MinogueDocument2 pagesKylie MinogueJhon Ray Ganton RabaraNo ratings yet

- Medieval Concept of GodDocument13 pagesMedieval Concept of GodEJ JoseNo ratings yet

- Article CssDocument3 pagesArticle Cssshalini0220No ratings yet

- Genigraphics Poster Template TitleLeft 44x44Document1 pageGenigraphics Poster Template TitleLeft 44x44KatherynNo ratings yet

- Alphabet Song Classic LyricDocument1 pageAlphabet Song Classic LyricMaíta Medeiros e SilvaNo ratings yet

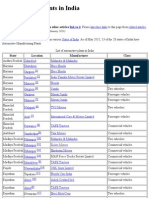

- List of Vehicle Plants in India - Wikipedia, The Free EncyclopediaDocument3 pagesList of Vehicle Plants in India - Wikipedia, The Free EncyclopediaAjay Marya50% (2)

- Timgad CityDocument27 pagesTimgad Cityfularisagar3599No ratings yet

- 424 Riv-04Document2 pages424 Riv-04Maurice DavisNo ratings yet

- L12 - Thin Shells (Compatibility Mode)Document30 pagesL12 - Thin Shells (Compatibility Mode)Raja ShekarNo ratings yet

- Total Recovery - Benny Hinn PDFDocument70 pagesTotal Recovery - Benny Hinn PDFcahuen89% (9)

- Datasheet of DS-2DE5225IW-AE (C)Document6 pagesDatasheet of DS-2DE5225IW-AE (C)nvnakumNo ratings yet

- Waterina BrochureDocument14 pagesWaterina BrochureThuận Văn ThuậnNo ratings yet

- Features/Principles of Indian EthosDocument16 pagesFeatures/Principles of Indian EthosSIDDHANT TYAGI100% (1)

- You Want A Confederate Monument My Body Is A Confederate MonumentDocument4 pagesYou Want A Confederate Monument My Body Is A Confederate MonumentmusabNo ratings yet

- Bach - 6f.embellishments VIIDocument8 pagesBach - 6f.embellishments VIIPailo76No ratings yet

- Complete Music Theory Cheat Sheetpdf PDFDocument15 pagesComplete Music Theory Cheat Sheetpdf PDFhack_by_yuriNo ratings yet

- MGH SRM 1 2Document473 pagesMGH SRM 1 2Julia VershininaNo ratings yet

- Theodoret, Commentator On The PsalmsDocument17 pagesTheodoret, Commentator On The PsalmsFabio AraujoNo ratings yet

- EENADU No 1 NewspaperDocument25 pagesEENADU No 1 NewspaperPradip PandaNo ratings yet

- BAGL 6-1 Watt PDFDocument12 pagesBAGL 6-1 Watt PDFguillermoisedetNo ratings yet

- JCR Vol. 08 No. 02: Symposium On The AtonementDocument245 pagesJCR Vol. 08 No. 02: Symposium On The AtonementChalcedon Foundation100% (2)

- Belgrade City ProfileDocument11 pagesBelgrade City ProfileIvana Lukic DjekovicNo ratings yet

- November 2020 Newsletter - FCCEDocument5 pagesNovember 2020 Newsletter - FCCEFirst Congregational Church of EvanstonNo ratings yet

- Dr. Quinn Medicine Woman Pilot ScriptDocument86 pagesDr. Quinn Medicine Woman Pilot ScriptMohammad Muji Paliwala100% (4)

- Semi ColonDocument21 pagesSemi ColonJopax CanedaNo ratings yet

- Calinawan Re - Ed.NOT DONEDocument5 pagesCalinawan Re - Ed.NOT DONERichard Jr CalinawanNo ratings yet

- Dawn of Darkness: First BookDocument13 pagesDawn of Darkness: First BookGodwin A.udo-akanNo ratings yet

- Liturgy Guide (Songs W CHORDS Latest) With Prayers 2Document33 pagesLiturgy Guide (Songs W CHORDS Latest) With Prayers 2Keiyth Joemarie BernalesNo ratings yet

- Dystopian Project PDFDocument3 pagesDystopian Project PDFTejas RegeNo ratings yet