Professional Documents

Culture Documents

410 Welding Wire and Rod

Uploaded by

JenderalKancil0 ratings0% found this document useful (0 votes)

36 views1 page410 filler electrode

Original Title

410

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document410 filler electrode

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

36 views1 page410 Welding Wire and Rod

Uploaded by

JenderalKancil410 filler electrode

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

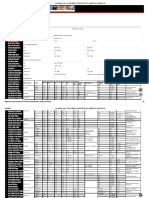

U.S. ALLOY CO.

410 dba Washington Alloy

7010-G Reames Rd.

Welding Wire and Rod Charlotte, NC 28216

www.weldingwire.com

WASHINGTON ALLOY’S Quality

Management System is

Certified to ISO 9001:2008 ALLOY DESCRIPTION AND APPLICATION;

Cert # 05-R0925

USA 410 stainless steel welding wire is used to weld straight

chromium steels such as AISI types 403, 405, 410, 414 and 416. It is also

used as an overlay on carbon steels to give added resistance against corrosion and abrasion.

Preheat / interpass of 350-500°F and postheat treatment of 1350-1400°F for 1hour per inch

with slow cool may be required. (Tri-mix gas = 90%He+7.5%Ar+2.5%CO 2)

TYPICAL GMAW WELDING PROCEDURES; DCEP Short Circuit

Wire Diameter Wire Speed (ipm) Amps Volts Electrical Stick-out Tri-mix (cfh)

0.023 180-400 30-85 14-19 3/8-1/2” 20-25

0.030 150-350 45-125 15-20 3/8-1/2” 20-25

0.035 120-330 60-150 16-22 3/8-1/2” 20-30

0.045 100-280 90-210 17-22 3/8-1/2” 25-30

(1)

Spray 0.030 280-600 160-220 24-28 3/8-1/2” 25-35

(1)

0.035 250-470 170-295 23-29 1/2-3/4” 25-35 (1) 98%Ar

(1) 2%O 2

0.045 200-385 195-360 24-30 1/2-3/4” 30-35

(1)

1/16” 110-200 210-380 25-31 1/2-3/4” 35-40

TYPICAL GTAW WELDING PROCEDURES; DCEN with EWTh-2 truncated conical tip

Filler Wire Size Tungsten Amps Volts Gas Cup Size Argon (cfh) Base thickness

1/16” 1/16” 80-150 12 3/8” 20 1/16-1/8”

3/32” 3/32” 150-250 12 3/8” 20 1/8- 3/16”

1/8” 1/8” 200-375 12 1/2” 25 1/4-1/2”

Procedures may vary with change in position, base metals, filler metals, equipment and other changes.

Pre-heat & postheat recommended

TYPICAL WIRE CHEMISTRY (%) & WELD METAL PROPERTIES*

Carbon 0.08 Tensile Strength (psi) 80,000

Manganese 0.50 Yield Strength (psi) 44,000

Silicon 0.40 Elongation 26 %

Molybdenum 0.15

Sulfur 0.03 * Pre-heat & post heat required

Chromium 12.90

Nickel 0.40

AVAILABLE SIZES: TS 410= Spools of 030, 035, 045, 1/16, 3/32

TT 410 = Cut lengths of 030, 035, 045, 1/16, 3/32, 1/8, 3/16

Other sizes available – please inquire

SPECIFICATIONS; ANSI/AWS A5.9 ER410

ASME SFA 5.9 ER410

EAST COAST GULF COAST WEST COAST

7010-G Reames Rd 4755 Alpine Drive #100A 8535 Utica Ave

Charlotte, NC 28216 Stafford, TX 77477 Rancho Cucamonga, CA 91730 2012 DC

Tel (888) 522-8296 Tel (877) 711-9274 Tel(800)830-9033

Fax (704)598-6673 Fax (281)313-6332 Fax (909)291-4586

Warehouse Distribution Center – Dayton, Ohio Head Office – Puyallup, Washington

Washington Alloy Company believes that all information and data given is correct. Use this information to assist in making your

own evaluations or decisions and this information should not be mistaken as an expressed or implied warranty. U.S. ALLOY CO.

assumes no liability for results or damages incurred from the use of any information contained herein, in whole or in part.

You might also like

- Kompresor Part and KIT ServiceDocument557 pagesKompresor Part and KIT ServiceJenderalKancil100% (2)

- Aircraft RivetsDocument50 pagesAircraft RivetsPranjal DograNo ratings yet

- Star Core 6Document2 pagesStar Core 6jmur10No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Atpdt 9 Vcu 20103Document158 pagesAtpdt 9 Vcu 20103JenderalKancilNo ratings yet

- SS 309 All PropertiesDocument1 pageSS 309 All Propertiessharafudheen_sNo ratings yet

- 4340 Wire For Low Alloy SteelsDocument1 page4340 Wire For Low Alloy SteelsPankaj KumbhareNo ratings yet

- USA 110S-1 Welding Wire and Rod: Cert # 05-R0925Document1 pageUSA 110S-1 Welding Wire and Rod: Cert # 05-R0925javadmohammadiNo ratings yet

- 1100 Aluminum Welding Wire: Dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216Document1 page1100 Aluminum Welding Wire: Dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216Ilham Alwi KhunaefiNo ratings yet

- Filler Metal 70s-6Document1 pageFiller Metal 70s-6Hugo RodriguezNo ratings yet

- USA 70S-B2L Welding Wire and Rod: Cert # 05-R0925Document1 pageUSA 70S-B2L Welding Wire and Rod: Cert # 05-R0925Nhien ManNo ratings yet

- 71t 1cDocument1 page71t 1cSuthan M RNo ratings yet

- Ficha Tecnica ER-316LDocument1 pageFicha Tecnica ER-316LOscar ZavaletaNo ratings yet

- USA 309L-16 Coated Electrode: Alloy Description and ApplicationDocument1 pageUSA 309L-16 Coated Electrode: Alloy Description and ApplicationRaju ChaudharyNo ratings yet

- Er70S-6 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-6 Carbon Steel Welding Wire: Technical Specification Sheetrizviabbas2012No ratings yet

- 4140 Electrode PDFDocument1 page4140 Electrode PDFweerasinghekNo ratings yet

- Er70S-3 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-3 Carbon Steel Welding Wire: Technical Specification Sheetrizviabbas2012No ratings yet

- Er 70s2 PDFDocument1 pageEr 70s2 PDFtaravindnagarajNo ratings yet

- 7018 Wa - Alloy 2Document1 page7018 Wa - Alloy 2Khaled A MarashliNo ratings yet

- Er70S-2 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-2 Carbon Steel Welding Wire: Technical Specification Sheetrizviabbas2012No ratings yet

- 230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505Document1 page230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505mohamed AdelNo ratings yet

- Er70S-3 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-3 Carbon Steel Welding Wire: Technical Specification SheetShaneNo ratings yet

- ER80S B2CRMOSpec PDFDocument2 pagesER80S B2CRMOSpec PDFIsrael BenavidesNo ratings yet

- ESPECIFICACIÓN DE E317lLT1-1Document1 pageESPECIFICACIÓN DE E317lLT1-1Nj Nelson JavierNo ratings yet

- ER4043Document1 pageER4043Luis Fidel Ramírez LópezNo ratings yet

- USA 6010 Coated Electrode: Alloy Description and ApplicationDocument1 pageUSA 6010 Coated Electrode: Alloy Description and Applicationmateo zamoraNo ratings yet

- Alloy 4047 Weld Data Sheet: Typical ApplicationsDocument2 pagesAlloy 4047 Weld Data Sheet: Typical ApplicationsMarcoAntonioNo ratings yet

- Stainless Steel Flux Cored Tig: Alloy Description and ApplicationDocument1 pageStainless Steel Flux Cored Tig: Alloy Description and ApplicationNGUYEN VINHNo ratings yet

- 9015-B9, 9018-B9 Low-Alloy Steel Electrode: Dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216Document1 page9015-B9, 9018-B9 Low-Alloy Steel Electrode: Dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216m s sankar raoNo ratings yet

- 8018-B2L Low-Alloy Steel Electrode: Cert # 05-R0925Document1 page8018-B2L Low-Alloy Steel Electrode: Cert # 05-R0925Ehab AhmedNo ratings yet

- SmawDocument56 pagesSmawFakhar WindratamaNo ratings yet

- Hobart Maxal 1100Document2 pagesHobart Maxal 1100jclenerNo ratings yet

- 5183 Aluminum Welding WireDocument1 page5183 Aluminum Welding Wiresank79No ratings yet

- Kawat Las Carbon Steel ER 70S-3Document2 pagesKawat Las Carbon Steel ER 70S-3Nyoman RakaNo ratings yet

- Applications: TYPE: Basic (Lime)Document1 pageApplications: TYPE: Basic (Lime)Tran van VuongNo ratings yet

- Standar Elektroda PDFDocument182 pagesStandar Elektroda PDFFakhar WindratamaNo ratings yet

- USA 316L-17 Coated Electrode: Alloy Description and ApplicationDocument1 pageUSA 316L-17 Coated Electrode: Alloy Description and ApplicationKaliyaperumal DhanapalNo ratings yet

- Alloy C-4300MDocument1 pageAlloy C-4300Malex diazNo ratings yet

- 1100 Data SheetDocument1 page1100 Data SheetMuhammad Whisnu NugrahaNo ratings yet

- Typical Mechanical Properties (As Welded) : Do Not Breathe Fumes!Document20 pagesTypical Mechanical Properties (As Welded) : Do Not Breathe Fumes!Samuel LatumahinaNo ratings yet

- SOW 09380SB2T SpecSheetDocument2 pagesSOW 09380SB2T SpecSheetAi NayNo ratings yet

- Steel Grade Indian StandardsDocument5 pagesSteel Grade Indian StandardsPriyanathan ThayalanNo ratings yet

- Reaming Speeds and Feeds PDFDocument1 pageReaming Speeds and Feeds PDFWarrior TempurNo ratings yet

- 253 MA Flux-Cored Wire: Alloy Description and ApplicationDocument1 page253 MA Flux-Cored Wire: Alloy Description and ApplicationGuilherme AugustoNo ratings yet

- A 2319 TdsDocument2 pagesA 2319 TdsSyam NathNo ratings yet

- E7018 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE7018 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Hobart Maxal 4943Document2 pagesHobart Maxal 4943brunizzaNo ratings yet

- Product Description Wire RodDocument3 pagesProduct Description Wire RodEngr Farrukh RehanNo ratings yet

- INDIA - Hot Rolled Coils - ROLEX METAL DISTRIBUTORS - A - SA516-70, A - SA515-70Document6 pagesINDIA - Hot Rolled Coils - ROLEX METAL DISTRIBUTORS - A - SA516-70, A - SA515-70Roberto AlvarezNo ratings yet

- Stainless Steel Grade 304 Vs 304LDocument3 pagesStainless Steel Grade 304 Vs 304Lrudi setiawanNo ratings yet

- TDSWE 5356 Wire TSDocument2 pagesTDSWE 5356 Wire TSbalamuruganNo ratings yet

- Pinnacle Alloys ENiCrFe 3 12.16Document2 pagesPinnacle Alloys ENiCrFe 3 12.16satnamNo ratings yet

- Table A Commonly Used Material Specification Reference ChartDocument1 pageTable A Commonly Used Material Specification Reference ChartPhong TongNo ratings yet

- Trevi Benne CS Shear Appetite GuideDocument1 pageTrevi Benne CS Shear Appetite GuideKarikalan JayNo ratings yet

- Atom Arc 8018: Features Typical Mechanical PropertiesDocument2 pagesAtom Arc 8018: Features Typical Mechanical PropertiesFranklin Aranda ChacónNo ratings yet

- WELDING SPREADER Electrode KALMAR PDFDocument1 pageWELDING SPREADER Electrode KALMAR PDFArtin HykoNo ratings yet

- Selectalloy 307cDocument1 pageSelectalloy 307cJuan Carlos RodriguezNo ratings yet

- Böhler Fox Eti: Rutile Stick Electrode, UnalloyedDocument1 pageBöhler Fox Eti: Rutile Stick Electrode, UnalloyedMiroslav MiladinovićNo ratings yet

- HSS Carbide Reamers Speeds Feeds p497 498Document2 pagesHSS Carbide Reamers Speeds Feeds p497 498Ravi DahiwalaNo ratings yet

- E7014 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE7014 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Stainless Steel Properties PDFDocument8 pagesStainless Steel Properties PDFprajash007No ratings yet

- Chemical CompositionDocument13 pagesChemical Compositionssharma3474No ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Isoria 10Document34 pagesIsoria 10JenderalKancilNo ratings yet

- 1600 Bro enDocument2 pages1600 Bro enJenderalKancilNo ratings yet

- 11 FanDocument5 pages11 Faniso026No ratings yet

- BalancingDocument19 pagesBalancingJenderalKancilNo ratings yet

- CU AT LUB - 4th - 12 12 PDFDocument8 pagesCU AT LUB - 4th - 12 12 PDFJenderalKancilNo ratings yet

- Mindjet Large Scale Deployment GuideDocument59 pagesMindjet Large Scale Deployment GuideJenderalKancilNo ratings yet

- Water97 v13Document8 pagesWater97 v13techkasambaNo ratings yet

- Boiler Operators Handbook - RefractoryDocument4 pagesBoiler Operators Handbook - RefractoryJenderalKancilNo ratings yet

- Thank YouDocument1 pageThank YouJenderalKancilNo ratings yet

- Corrosion and RustDocument9 pagesCorrosion and RustahmedNo ratings yet

- Aalco Metals LTD - Aluminium Alloy 5083 H32 Sheet - 140 PDFDocument2 pagesAalco Metals LTD - Aluminium Alloy 5083 H32 Sheet - 140 PDFAhmad Renaldy Jurais0% (1)

- Revision Chapter 1, 2020 - WatermarkDocument14 pagesRevision Chapter 1, 2020 - Watermarkrabab elkomyNo ratings yet

- FulltextDocument145 pagesFulltextMedina CikeuNo ratings yet

- Chapter17 FinalDocument47 pagesChapter17 FinalAnahAlhabshiNo ratings yet

- Metallic Implant MaterialsDocument39 pagesMetallic Implant MaterialsRecep VatanseverNo ratings yet

- Colour ChartDocument1 pageColour ChartgawaNo ratings yet

- 5.MMC, CMC, CCCDocument22 pages5.MMC, CMC, CCCwladimir ramrezNo ratings yet

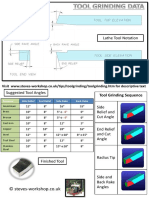

- Lathe Tool Notation: © Steves-Workshop - Co.ukDocument1 pageLathe Tool Notation: © Steves-Workshop - Co.ukArtur MeierNo ratings yet

- Basic Principles of Heat TreatmentDocument26 pagesBasic Principles of Heat TreatmentYaser Mohamed AbasNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile Propertiescorsini999No ratings yet

- Hes A1002-01 Selection Reference of Steel Bolt MaterialsDocument5 pagesHes A1002-01 Selection Reference of Steel Bolt MaterialsPreetam KumarNo ratings yet

- Din 1623-05Document11 pagesDin 1623-05dietersimaNo ratings yet

- Question BankDocument27 pagesQuestion BankselvaNo ratings yet

- Day 1 Part 3 PDFDocument72 pagesDay 1 Part 3 PDFEdukondalu PentapatiNo ratings yet

- Haynes 230 Alloy: Principal FeaturesDocument28 pagesHaynes 230 Alloy: Principal FeaturesMatheus DominguesNo ratings yet

- Copper Recovery Flotation: Slag Composition Loses Priority To Controlled Cooling of The SlagDocument6 pagesCopper Recovery Flotation: Slag Composition Loses Priority To Controlled Cooling of The SlagBenito Quispe A.No ratings yet

- 1 s2.0 S2238785421003227 MainDocument18 pages1 s2.0 S2238785421003227 MainManikandan ChinnachamyNo ratings yet

- MINERALSDocument15 pagesMINERALSBea Dacillo BautistaNo ratings yet

- Colville 1970Document5 pagesColville 1970Jorge Álef Estevam Lau BomfimNo ratings yet

- AP 08 Ps em 04 Q A Metals and Non MetalsDocument3 pagesAP 08 Ps em 04 Q A Metals and Non Metalslakkysep16No ratings yet

- Gear Materials and Heat TreatmentsDocument2 pagesGear Materials and Heat TreatmentsLazaras Benny INo ratings yet

- 4.solid State, Heat Treatment, Tarnish N CorrosionDocument72 pages4.solid State, Heat Treatment, Tarnish N Corrosionsaloni singhNo ratings yet

- Asme2b SB 446Document8 pagesAsme2b SB 446Marjan SubanNo ratings yet

- RoastingDocument2 pagesRoastingRon Estolano0% (1)

- Zincalume® G550 Technical Datasheet MalaysiaDocument2 pagesZincalume® G550 Technical Datasheet MalaysiaJeffrey RonquilloNo ratings yet

- QC General NotesDocument21 pagesQC General NotesBilly Kurniawan100% (2)

- TMI17 TP6continuacionDocument312 pagesTMI17 TP6continuacionMaria Hernaiz PerezNo ratings yet