Professional Documents

Culture Documents

Leaded Nickel Silver

Uploaded by

mp87_ingCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Leaded Nickel Silver

Uploaded by

mp87_ingCopyright:

Available Formats

Leaded Nickel Silver

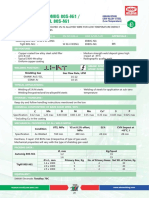

Copper alloys for Specialized Applications

Nickel Silver offering an optimal compromise between cold forming and

Applications and Characteristics: machining. Typical applications: Screws, Jewelry, Silver ware, Writing

Instruments, Eyeglass components & Elevator decoration.

European Material Symbol - -

Designation Number CuNi10Zn42Pb2 -

France CuNi10Zn42Pb2 -

Germany DIN 17660 CuNi10Zn42Pb2 -

Nearest National Equivalents

UK BS 2872/2874 NS 101 -

USA UNS C798 C797

Cu 45,5 - 48,5 46,0 - 48,0

Pb 1,5 - 2,5 1,5 - 2,5

Al - -

Fe 0,25 -

Mn 1,5 - 2,5 1,5 - 2,5

Nominal Composition (%)

Ni 9,0 - 11,0 6,5 - 8,5

Si - -

Sn - -

Zn Remainder Remainder

Others - -

Machinability index* (%) 30 -

Cold working good -

Manufacturing

Hot working good -

Hot working temp. (°C) - -

Tensile strength (N/mm²) min. 485 -

Typical Mechanical Properties 0,5% Proof strength (N/mm²) min. 260 -

Elongation (%) min. 18 -

Density (kg/dm³) 8,54 -

Modulos of elasticity (kN/mm²) 102 -

Melting range (°C) 910-1030 -

Coefficient of linear - -

Typical Physical Properties

Expansion x10 K (20-300°C) 18 -

Thermal conductivity (W/mK) 36 -

Electrical resitivity (μΩm) 0,246 -

Electrical conductivity (%IACS) 7 -

EN 12163: Rod for

- -

general purposes

EN 12164: Rod for free

x -

machining purposes

EN 12165: Wrought and

Relevant European Standards x -

unwrought forging stock

EN 12167: Profiles and rectan-

x -

gular bar for general purposes

EN 12168: Hollow rod for free

- -

machining purposes

LDM B.V.

Lipsstraat 44, 5151 RP Drunen, The Netherlands

PO Box 42 , 5150 AA Drunen, The Netherlands

tel.: +31 416 389 911 - fax: +31 416 378 655

www.ldmbrass.com

sales.ldm@ldmbrass.com

You might also like

- Hass English LatheDocument318 pagesHass English LathePrabhu Subbiah RamdossNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Virtual Reality Technology and Applications-Springer Netherlands (2014)Document236 pagesVirtual Reality Technology and Applications-Springer Netherlands (2014)Keyser SozeNo ratings yet

- On Oxygen-Induced Corrosion of An Oil Refinery Condensate Fraction at Ion UnitDocument17 pagesOn Oxygen-Induced Corrosion of An Oil Refinery Condensate Fraction at Ion UnitAzmi Mohammed NorNo ratings yet

- SANDVIK Understanding Cemented Carbide PDFDocument20 pagesSANDVIK Understanding Cemented Carbide PDFmp87_ingNo ratings yet

- Metering - Manual - Eastern - RegionDocument65 pagesMetering - Manual - Eastern - RegionAmit PathakNo ratings yet

- 1697 Dzyan Kitabi Qedim Qutsal Oghreti Bilim Arashdirma Qurupu 1971 61sDocument67 pages1697 Dzyan Kitabi Qedim Qutsal Oghreti Bilim Arashdirma Qurupu 1971 61strametesa100% (1)

- Cox MerzDocument4 pagesCox MerzJohnNo ratings yet

- Metco 16C 10-040Document8 pagesMetco 16C 10-040JSH100No ratings yet

- Dry Room in Battery PlantDocument36 pagesDry Room in Battery Plantcostas matsangosNo ratings yet

- Burst Strength of PaperDocument10 pagesBurst Strength of PaperHariHaran RajendranNo ratings yet

- MCQ 4 GroundwaterDocument6 pagesMCQ 4 GroundwaterAnonymous EvbW4o1U7100% (4)

- DZR BrassDocument1 pageDZR BrasssmrdojeNo ratings yet

- Silicon Bronze PDFDocument1 pageSilicon Bronze PDFFabian Andres Pinilla CarballoNo ratings yet

- Naval BrassDocument1 pageNaval BrassAugusto Gabriel Flores ManzanedaNo ratings yet

- Automig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060Document1 pageAutomig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060satnamNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Jonathan Getial CruzNo ratings yet

- En 0011 1312 00 Ed5Document2 pagesEn 0011 1312 00 Ed5cybula.michalNo ratings yet

- Cw008a Cu-Of Version1Document1 pageCw008a Cu-Of Version1Gaka RtaNo ratings yet

- P91TPDocument37 pagesP91TPPhong ĐỗNo ratings yet

- Nickel Alloys: Alloy 825 (UNS N08825)Document1 pageNickel Alloys: Alloy 825 (UNS N08825)joceth3632No ratings yet

- Technical Report: Thermocouple Extension & Compensating Cable Thermocouple Extension & Compensating CableDocument3 pagesTechnical Report: Thermocouple Extension & Compensating Cable Thermocouple Extension & Compensating CableIsioma1No ratings yet

- Werkstoffdatenblatt: Cw614N (Cuzn39Pb3 - 2.0401)Document1 pageWerkstoffdatenblatt: Cw614N (Cuzn39Pb3 - 2.0401)tapanNo ratings yet

- Key Facts Typical Wire Analysis: - Bossweld 71T-1Document1 pageKey Facts Typical Wire Analysis: - Bossweld 71T-1cj elec techNo ratings yet

- Materials CourseworkDocument21 pagesMaterials CourseworkGeorge RoydenNo ratings yet

- Ficha Tecnica Superaleaciones Ni - SuperalloysDocument5 pagesFicha Tecnica Superaleaciones Ni - SuperalloysANDRES DOMINGUEZNo ratings yet

- 18crnimo7-6: Steel GradeDocument4 pages18crnimo7-6: Steel GradeFINNING CATNo ratings yet

- TNI2TIDocument2 pagesTNI2TIKureiNo ratings yet

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADocument1 pageAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNo ratings yet

- A320l7 L7M - A320l7 A320l7m EngDocument1 pageA320l7 L7M - A320l7 A320l7m EngNarimane BentyNo ratings yet

- C2700Document6 pagesC2700Andrew TanNo ratings yet

- item11-LNT NiCroMo 59.23Document1 pageitem11-LNT NiCroMo 59.23VVan TanNo ratings yet

- A.S.T.M. B584-09a: WWW - Okendo.mxDocument4 pagesA.S.T.M. B584-09a: WWW - Okendo.mxShariq KhanNo ratings yet

- Alluminium Proto MaterialDocument75 pagesAlluminium Proto MaterialAnjani kumarNo ratings yet

- RK1B7 A193b7m - A193b7 A193b7m EngDocument1 pageRK1B7 A193b7m - A193b7 A193b7m EngNarimane BentyNo ratings yet

- 1.4401 1.4404 316 316L X2Crnimo17-12-2 S31603: en Designation Astm DesignationDocument2 pages1.4401 1.4404 316 316L X2Crnimo17-12-2 S31603: en Designation Astm Designation池边树No ratings yet

- Yellow: LM6 (EN 1706 AC-44100) Aluminium Casting AlloyDocument3 pagesYellow: LM6 (EN 1706 AC-44100) Aluminium Casting AlloySohail ShaikhNo ratings yet

- Consumables To Match Cast & Wrought Alloy 800: Astm Bs en & DinDocument3 pagesConsumables To Match Cast & Wrought Alloy 800: Astm Bs en & Dinankitniranjan1390No ratings yet

- Item5 LNT316LDocument1 pageItem5 LNT316LVVan TanNo ratings yet

- Cuzn37 Industrial RolledDocument6 pagesCuzn37 Industrial RolledcvgfgNo ratings yet

- En 1982 Copper and Copper Alloy Ingots and Castings - Compositions, Uses and Typical Properties-Table9Document1 pageEn 1982 Copper and Copper Alloy Ingots and Castings - Compositions, Uses and Typical Properties-Table9yw_oulalaNo ratings yet

- Ficha Técnica CarborodDocument1 pageFicha Técnica CarborodAndres NuñezNo ratings yet

- Piher PC16Document6 pagesPiher PC16marik2500No ratings yet

- En 353Document3 pagesEn 353anush_swaminathanNo ratings yet

- item8-LNT NiCro60.20Document1 pageitem8-LNT NiCro60.20VVan TanNo ratings yet

- Cu DHPDocument3 pagesCu DHPLUIGINo ratings yet

- Technical Datasheet: High Purity Solder AlloyDocument6 pagesTechnical Datasheet: High Purity Solder Alloyاوس محمد رؤوف لؤيNo ratings yet

- Data Table For Grades Stainless Steels 1Cr18Ni9Document3 pagesData Table For Grades Stainless Steels 1Cr18Ni9hmid007No ratings yet

- European Steel and Alloy Grades: Nicr22Fe18Mo (Dubl) (2.4665)Document2 pagesEuropean Steel and Alloy Grades: Nicr22Fe18Mo (Dubl) (2.4665)farshid KarpasandNo ratings yet

- Stellite 21Document2 pagesStellite 21Mohsen ParpinchiNo ratings yet

- A 553 Type 1 and Details of Low Temp ServicesDocument11 pagesA 553 Type 1 and Details of Low Temp Servicesروشان فاطمة روشانNo ratings yet

- Carbofil Crmo9 (G Crmo9)Document1 pageCarbofil Crmo9 (G Crmo9)brunizzaNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10207Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10207farshid KarpasandNo ratings yet

- 308H Tig: Category GMAW-GTAW Solid Wires Type ApplicationsDocument1 page308H Tig: Category GMAW-GTAW Solid Wires Type ApplicationsFilipe CordeiroNo ratings yet

- Alluminium GradesDocument4 pagesAlluminium GradesAnjani kumarNo ratings yet

- 1.4462 2205 X2Crnimon22-5-3 S31803 / S32205: en Designation Astm DesignationDocument2 pages1.4462 2205 X2Crnimon22-5-3 S31803 / S32205: en Designation Astm DesignationshravyaNo ratings yet

- 1.4462 2205 X2Crnimon22-5-3 S31803 / S32205: en Designation Astm DesignationDocument2 pages1.4462 2205 X2Crnimon22-5-3 S31803 / S32205: en Designation Astm DesignationCarlos SerranoNo ratings yet

- International Standard: Cu-ETP - CW004ADocument2 pagesInternational Standard: Cu-ETP - CW004AgnanasekarNo ratings yet

- Bourns LMNPLPDocument2 pagesBourns LMNPLPJc Valve RecordNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- 1.2003 Datasheet, 1.2003 Chemical, 1Document2 pages1.2003 Datasheet, 1.2003 Chemical, 1Slobodan NocajNo ratings yet

- Piher T-21Document6 pagesPiher T-21EanBombingNo ratings yet

- CuZn33 CatalogueDocument9 pagesCuZn33 CataloguefedericoNo ratings yet

- AUTOMIG 80S Ni1 - TIGFIL 80S Ni1Document1 pageAUTOMIG 80S Ni1 - TIGFIL 80S Ni1Kalyan Chakravathi A GNo ratings yet

- ASTM A297 Grade HHDocument1 pageASTM A297 Grade HHinfo.nulyproNo ratings yet

- 1.4521 444 X2Crmotinb18-2 S44400: C Si MN P S CR Mo Ti NBDocument1 page1.4521 444 X2Crmotinb18-2 S44400: C Si MN P S CR Mo Ti NBRodrigo TeodoroNo ratings yet

- Steel P235TR2Document2 pagesSteel P235TR2Moulham ShahinNo ratings yet

- L1 8515 en Diamondspark Ni1 MC CU05120F 3241743 ENDocument1 pageL1 8515 en Diamondspark Ni1 MC CU05120F 3241743 ENbrayanNo ratings yet

- Writing Big Script For Success AbroadDocument1 pageWriting Big Script For Success Abroadmp87_ingNo ratings yet

- Ball Pen in 4 Colours With Medium Point: Main FeaturesDocument1 pageBall Pen in 4 Colours With Medium Point: Main Featuresmp87_ingNo ratings yet

- Usefulness of Ambulatory Glucose Profile (AGP) in Diabetes CareDocument6 pagesUsefulness of Ambulatory Glucose Profile (AGP) in Diabetes Caremp87_ingNo ratings yet

- Competing in The Gray ZoneDocument83 pagesCompeting in The Gray Zonemp87_ingNo ratings yet

- LDM CuNi7Zn39Pb3Mn2 MSDSDocument4 pagesLDM CuNi7Zn39Pb3Mn2 MSDSmp87_ingNo ratings yet

- The First Four Things I Check When A Project Is in TroubleDocument12 pagesThe First Four Things I Check When A Project Is in Troublemp87_ingNo ratings yet

- Using The Power Law Model To Quantify Shear Thinning Behavior On A Rotational RheometerDocument7 pagesUsing The Power Law Model To Quantify Shear Thinning Behavior On A Rotational Rheometermp87_ingNo ratings yet

- Pub 94 Equilibrium Diagrams PDFDocument36 pagesPub 94 Equilibrium Diagrams PDFmariaNo ratings yet

- I018e PDFDocument68 pagesI018e PDFasjdkfjskaldjf;klasdfNo ratings yet

- Corrosion Por Acidos NaftenicosDocument19 pagesCorrosion Por Acidos NaftenicosUlisesNo ratings yet

- Overview of Factors Contributing To Steel Spring Performance and FailureDocument48 pagesOverview of Factors Contributing To Steel Spring Performance and Failuremp87_ingNo ratings yet

- Nestle Low-Sulfur Marine FuelsDocument5 pagesNestle Low-Sulfur Marine Fuelsmp87_ingNo ratings yet

- Strategies For Eliminating DecarburizationDocument3 pagesStrategies For Eliminating Decarburizationmp87_ingNo ratings yet

- Intro To Basic UTDocument41 pagesIntro To Basic UTgirish310100% (1)

- CDA Benzotriazole Corrosion Inhibitor For Copper Alloys PDFDocument10 pagesCDA Benzotriazole Corrosion Inhibitor For Copper Alloys PDFmp87_ingNo ratings yet

- An Inside Look at The Chinese Forging IndustryDocument5 pagesAn Inside Look at The Chinese Forging Industrymp87_ingNo ratings yet

- WearResistantBearings PDFDocument18 pagesWearResistantBearings PDFmp87_ing100% (1)

- JIS G4805:1999 High Carbon Chromium Bearing SteelsDocument34 pagesJIS G4805:1999 High Carbon Chromium Bearing Steelsmp87_ingNo ratings yet

- Abrasion ResistanceDocument1 pageAbrasion ResistanceWahyu VidyoNo ratings yet

- Fatigue, Static Tensile Strength and Stress Corrosion of Aircraft Materials and StructuresDocument232 pagesFatigue, Static Tensile Strength and Stress Corrosion of Aircraft Materials and Structuresmp87_ing100% (1)

- Alloy CarbidesDocument2 pagesAlloy Carbidesmp87_ing100% (1)

- NagoyaDocument16 pagesNagoyasoheila225No ratings yet

- Offshore Structures Surface TreatmentDocument11 pagesOffshore Structures Surface Treatmentmp87_ingNo ratings yet

- Understanding Magnesium Heat TreatmentDocument2 pagesUnderstanding Magnesium Heat Treatmentmp87_ingNo ratings yet

- Revealing Prior-Austenite Grain Boundaries in Heat-Treated SteelsDocument5 pagesRevealing Prior-Austenite Grain Boundaries in Heat-Treated Steelsmp87_ingNo ratings yet

- Heat-Resistant Materials: Alloy SystemsDocument2 pagesHeat-Resistant Materials: Alloy Systemsmp87_ingNo ratings yet

- XI - Science Class Routine 2019: Xi-Isc - I Rm. 234 Xi - Isc-Ii Rm. 334Document2 pagesXI - Science Class Routine 2019: Xi-Isc - I Rm. 234 Xi - Isc-Ii Rm. 334Koushik MajumderNo ratings yet

- Experimental Investigation On Mechanical Performance of Aluminium CompositeDocument10 pagesExperimental Investigation On Mechanical Performance of Aluminium CompositeMadhu KotlaNo ratings yet

- Rajshahi University of Engineering and Technology, RajshahiDocument9 pagesRajshahi University of Engineering and Technology, RajshahiShakil Ahmed100% (1)

- Chemistry Folio Soap and DetergentDocument13 pagesChemistry Folio Soap and DetergentMarinda YieNo ratings yet

- Chemsheets As 1005 Ionisation EnergiesDocument2 pagesChemsheets As 1005 Ionisation Energiesangel ranaNo ratings yet

- Calculating The Heating Value of BiogasDocument5 pagesCalculating The Heating Value of BiogasAnonymous MVHQ97KEoPNo ratings yet

- Topic 4. Binary DistillationDocument123 pagesTopic 4. Binary DistillationAngela Lorena DíazNo ratings yet

- EO Using Small Satellites CapabilitiesDocument36 pagesEO Using Small Satellites CapabilitiesМРязанскийNo ratings yet

- Logarithms PDFDocument1 pageLogarithms PDFtwanda bryanNo ratings yet

- The Avio 200 ICP-OES: A Unique Double-Monochromator Optical SystemDocument2 pagesThe Avio 200 ICP-OES: A Unique Double-Monochromator Optical SystemUswatul HasanahNo ratings yet

- Hiten Parmar: Physics byDocument5 pagesHiten Parmar: Physics byKailas ArunNo ratings yet

- Old-Examination-Questions-Ch.#17 (Dr. Gondal - Phys102) : at One End, Are Approximately: (Ans: 170 and 510 HZ)Document5 pagesOld-Examination-Questions-Ch.#17 (Dr. Gondal - Phys102) : at One End, Are Approximately: (Ans: 170 and 510 HZ)Alexandro Andra PizzaroNo ratings yet

- Experiment No.1 (DSP Lab)Document9 pagesExperiment No.1 (DSP Lab)Omer SheikhNo ratings yet

- BiwaveletDocument29 pagesBiwaveletThiago MelquíadesNo ratings yet

- Analysis of Shear Walls For Multi-Storey Timber BuildingsDocument54 pagesAnalysis of Shear Walls For Multi-Storey Timber BuildingsrahimmullaNo ratings yet

- Data SheetDocument5 pagesData SheetMubashir HasanNo ratings yet

- Crystallinity in Polymers-1Document19 pagesCrystallinity in Polymers-1anbuchelvanNo ratings yet

- Theory of Elasticity and Plasticity. (CVL 622) M.Tech. CE Term-2 (2017-18)Document2 pagesTheory of Elasticity and Plasticity. (CVL 622) M.Tech. CE Term-2 (2017-18)er.praveenraj30No ratings yet

- E 777 - Gidarakos 2005 - Ultimate - C and HDocument5 pagesE 777 - Gidarakos 2005 - Ultimate - C and HTamara Aulia RachimNo ratings yet

- 750 Multilin Feeder Management Relay ManualDocument446 pages750 Multilin Feeder Management Relay ManualFerdinandja100% (1)

- Wave Motion Demonstrator: Instruction ManualDocument17 pagesWave Motion Demonstrator: Instruction ManualScience HouseNo ratings yet

- TemptDocument13 pagesTemptJhun Lerry TayanNo ratings yet

- 17 Capacitors and Inductors in AC CircuitsDocument12 pages17 Capacitors and Inductors in AC CircuitsAbhijit PattnaikNo ratings yet