Professional Documents

Culture Documents

Form U-Dr-1 User'S Design Requirements For Single Chamber Pressure Vessels

Uploaded by

ssOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Form U-Dr-1 User'S Design Requirements For Single Chamber Pressure Vessels

Uploaded by

ssCopyright:

Available Formats

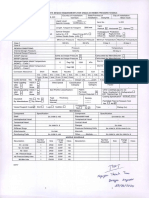

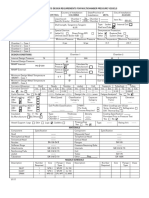

FORM U-DR-1 USER'S DESIGN REQUIREMENTS FOR SINGLE CHAMBER PRESSURE VESSELS

Owner: OMAN DRYDOCK Operator; Country of Installation: State / Province of Installation: City of Installation:

COMPANY -- Not Known -- Not Known

Service: Liquid Level: Full Item No:

AIR Specific Gravity : 1.1 Kg/m3 V-01

Diameter (in): 950 mm (ID) Length, Tan line - to - Tan line: Type:

1500 mm Vertical: Horizontal: Sphere

National Board Canadian Special Service: No Over Pressure Protection:

Registration Required Registration Required Lethal (L) Direct Firing (DF) Valve Rapture Disk

Yes No Yes No Unfired Steam Boiler (UB). Other System Design

Operating Conditions: Minimum Pressure Maximum Pressure Minimum Temperature Maximum Temperature

Case-1 - 0.90 Mpa - 50 ºC

Case-2

Design Conditions: Pressure Temperature

Internal Design Pressure: 1.0 Mpa 125 ºC

External Design Pressure:

MAWP Internal: Same as Design Pressure Calculated by Manufacturer:

MAWP External: Same as Design Pressure N/A Calculated by Manufacturer:

Minimum Design Metal Temperature 0 Deg @ 1.0 Mpa Due to: Process Other

(MDMT) - Case 1 Ambient Temperature

Minimum Design Metal Temperature Deg @ Due to: Process Other

-- --

(MDMT) - Case 2 Ambient Temperature

Corrosion Allowance: Shell Heads Nozzles Jacket Coil Supports Internals Corrosive

Serivce ?

Int. Ext. Int. Ext. Int. Ext. Int. Ext. Int. Ext. Int. Ext. Int. Ext. Yes No

1.0 -- 1.0 -- 1.0 -- -- -- -- -- -- -- -- --

Cyclic Service: Yes No ______ Cycles Per _______ Design Life Years Fatigue Analysis: Yes No

Wind Loading: ASCE Wind Speed Classification Ctegory Exposure Category Topographic Factor Elevation

UBC IBC

Others None 120 KMPH C -- -- --

Seismic Loading : ASCE Soil Prof Classification PWHT Other Loading per UG-22

UBC IBC Per Code: Temp. Gradients Deflagration

Others None Sd Process Required Diff. Thermal Exp.

Insulated: Yes No Type -- Thickness Density: Coating Specification:

By Manufacturer By Others External: -- -- Permitted prior to Pressure Test

Internal: _ -- -- Yes No

Vessel Support: Legs Skirt Lugs Saddles Fire Proofing: Type Rating (Hrs)

Yes No -- --

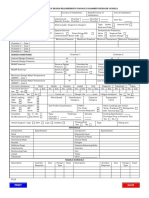

MATERIALS

Component Specification Component Specification

Shell SA 516 M GR. 485 Elipsoidal Head SA 516 M GR. 485

Hemispherical Head -- Torispherical Head --

Toriconical Head -- Conical Head --

Nozzles (Pipes) SA 106M Gr. B Flanges SA 105 M (N)

Stiffener Rings -- Pressure Retaining Bolts -

Attachments -- Internals --

Reinforcing Pad Others (Couplings) SA 105 M

NOZZLE SCHEDULE

Description Number Req. Size Flange Type Class Description Number Req. Size Flange Type Class

INLET (N1) 1 1+1/2" Full Coupling 6000# VENT (N5) 1 1+1/2" SO-RF 150#

SPARE (N2) 1 1+1/2" Full Coupling 6000# INSPECTION OPENING 1 6" SO-RF 150#

OUTLET (N3) 1 1+1/2" SO-RF 150# INSPECTION OPENING 1 6" SO-RF 150#

DRAIN (N4) 1 1+1/2" SO-RF 150#

WELD PRESSURE JOINT REQUIREMENT

Design Basis Shell & Cone Thickness Based On: Head Thickness Based On:

Joint Efficiency E: 0.85 Joint Efficiency E : 0.85

JOINT LOCATION TYPE OF JOINT NDE WITH COMMENTS

UW-3

(RT Category: RT3)

Category - A Shell Longitudinal Seam Type 1 as per UW 12 Cloumn (b) Spot RT

Wld

Head to Shell Type 1 as per UW 12 Cloumn (B) Spot RT

Category - B

Other --

Body Flanges N/A

Category - C

Nozzle Flanges Type 7 as per UW 12 Cloumn (a) None

Category D Type 7 as per UW 12 Cloumn (a) None

BODY FLANGE REQUIREMENTS

Description Type Facing / Surface Finish Gasket Type Joint Assembly

-- -- -- -- --

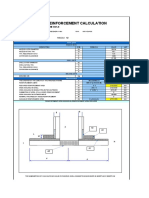

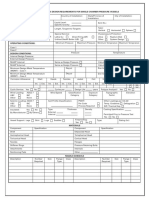

SKETCH

For More Details Ref. DWG No: ODC-U-AR-VS-001

GENERAL NOTES

Nozzles N2 is to be supplied with Hexagonal Plug.

CERTIFICATION

We Certify that the statement made in this form are accurate and represent all details of design as per the user or

his designated agent..

Date:

User:

Signed:

Registration Identification:

You might also like

- Form U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsDocument2 pagesForm U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsAmit Sharma100% (1)

- Toriconical Head Ver 1.1Document4 pagesToriconical Head Ver 1.1Iqbal AhmadsNo ratings yet

- Minimum Distance Between Two Circumferential PipeDocument7 pagesMinimum Distance Between Two Circumferential PipeAbdulrahmanNo ratings yet

- Asme B31.8 Nozzles CalcDocument16 pagesAsme B31.8 Nozzles CalcSAMER OSMANNo ratings yet

- DRP001 Ouf Pro U 000 001 B4Document58 pagesDRP001 Ouf Pro U 000 001 B4ss50% (2)

- MetallurgyDocument2 pagesMetallurgygjabyNo ratings yet

- SHELLDocument6 pagesSHELLSalz EngineeringNo ratings yet

- BPVC Viii-1 Udr-2Document2 pagesBPVC Viii-1 Udr-2asniff08No ratings yet

- Spectacle Blind FlangeDocument3 pagesSpectacle Blind Flangel kishoreNo ratings yet

- ABC QC ManualDocument45 pagesABC QC ManualFanny McWinkerbeanNo ratings yet

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Document15 pagesFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaNo ratings yet

- PFHT & PWHT ASME InterpretationDocument2 pagesPFHT & PWHT ASME InterpretationypatelsNo ratings yet

- Asme VIII Div1 2010-2011a PDFDocument86 pagesAsme VIII Div1 2010-2011a PDFJohan ConradieNo ratings yet

- TBE-Pressure Vessel Standard TemplateDocument4 pagesTBE-Pressure Vessel Standard TemplateSiva baalanNo ratings yet

- Straddle Principle For FlangesDocument1 pageStraddle Principle For Flangesameybarve67% (3)

- PD5500 - 133 - RectangularFlange CalculationDocument9 pagesPD5500 - 133 - RectangularFlange CalculationDarshan PanchalNo ratings yet

- What Is An ASME Appendix 2 Flange Design PDFDocument1 pageWhat Is An ASME Appendix 2 Flange Design PDFMangesh BanaleNo ratings yet

- AutoPipe Vessel PresentationDocument32 pagesAutoPipe Vessel PresentationRUDHRA DHANASEKARNo ratings yet

- Nozzle Design CalculationDocument1 pageNozzle Design CalculationSachin55860% (1)

- Sa 420Document10 pagesSa 420Widya widyaNo ratings yet

- TDC For Pipes - Sa 106 GR.BDocument2 pagesTDC For Pipes - Sa 106 GR.BRenny DevassyNo ratings yet

- Tank Baffle Thickness Calculation: Baffle Provided Thickness Is Greater Than Require Thickness Hecnc Design Is SafeDocument1 pageTank Baffle Thickness Calculation: Baffle Provided Thickness Is Greater Than Require Thickness Hecnc Design Is SafeABIDEEN BAMNENo ratings yet

- Pipes. Pressure and Wall Thickness Equations and Data For A Straight Pipe. ASME B31.1 and B31.3.odsDocument100 pagesPipes. Pressure and Wall Thickness Equations and Data For A Straight Pipe. ASME B31.1 and B31.3.odsNaufal FirmansyahNo ratings yet

- Branch Reinforcement Pad Requirement CalculationDocument1 pageBranch Reinforcement Pad Requirement Calculations.mladinNo ratings yet

- Narrow Face Flange - Slip On Hub TypeDocument17 pagesNarrow Face Flange - Slip On Hub TypeEng-CalculationsNo ratings yet

- Table UW-12 Maximum Allowable Joint Efficiencies For Arc and Gas Welded JointsDocument1 pageTable UW-12 Maximum Allowable Joint Efficiencies For Arc and Gas Welded Jointsluis armandoNo ratings yet

- Nozzle Interference Error SolvingDocument2 pagesNozzle Interference Error SolvingSakthi VelNo ratings yet

- Comparision of Piping CodeDocument14 pagesComparision of Piping CodeAnonymous J1vjrU2No ratings yet

- Auto PipeDocument18 pagesAuto PipeAdi SutardiNo ratings yet

- CASE 2901: Inquiry: Under What Requirements May External Loads (Forces and Bending Moments) Be Evaluated ForDocument2 pagesCASE 2901: Inquiry: Under What Requirements May External Loads (Forces and Bending Moments) Be Evaluated ForDijin MaroliNo ratings yet

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDocument5 pagesASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaNo ratings yet

- Skirt To Dish Joint PDFDocument64 pagesSkirt To Dish Joint PDFPrajwal ShettyNo ratings yet

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Document32 pagesPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNo ratings yet

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Document1 pagePipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadNo ratings yet

- UG-100 Pneumatic TestDocument2 pagesUG-100 Pneumatic TestInaamNo ratings yet

- How To Consider Sea Transportation LoadDocument7 pagesHow To Consider Sea Transportation LoadSharun SureshNo ratings yet

- WRC-107 Lifting Lugs - Vert. Vessel Vertical LiftDocument5 pagesWRC-107 Lifting Lugs - Vert. Vessel Vertical LiftManoj MulikNo ratings yet

- PV Elite Vessel Analysis Program HorizontalDocument55 pagesPV Elite Vessel Analysis Program HorizontalMarizta Perdani PutriNo ratings yet

- D:/dont Delete User/Downloads/ (Flange Analysis NC-3658-3)Document1 pageD:/dont Delete User/Downloads/ (Flange Analysis NC-3658-3)deepakNo ratings yet

- Code Case 2695 in PV Elite - How To Use It PDFDocument2 pagesCode Case 2695 in PV Elite - How To Use It PDFMukeshChopra100% (1)

- Static Equipment Generator 2019 BrochureDocument4 pagesStatic Equipment Generator 2019 BrochureDennis RaymondNo ratings yet

- Fatigue Analysis in PV EliteDocument3 pagesFatigue Analysis in PV EliteCostynhaNo ratings yet

- Oil Gas Construction Factory L.L.CDocument2 pagesOil Gas Construction Factory L.L.CRenny DevassyNo ratings yet

- 2 PN40 (WCB)Document2 pages2 PN40 (WCB)siddhesh_guessNo ratings yet

- EJMA Calculation Report For Cryostat DNB 7HL9UC v1 3Document25 pagesEJMA Calculation Report For Cryostat DNB 7HL9UC v1 3zstNo ratings yet

- Methods For WRC 107 and WRC 297 Checking in Caesar IIDocument8 pagesMethods For WRC 107 and WRC 297 Checking in Caesar IIRomner CordovaNo ratings yet

- HAJ-AR-UDR-001 Rev.0 - 1.08.2023Document4 pagesHAJ-AR-UDR-001 Rev.0 - 1.08.2023divakar.panigrahiNo ratings yet

- Company UDR Format - REV.0Document3 pagesCompany UDR Format - REV.0Shaheen Andre ChikkuNo ratings yet

- U Stamp - KK Form - SampleDocument5 pagesU Stamp - KK Form - SampleshazanNo ratings yet

- UDR-1 Excel FileDocument5 pagesUDR-1 Excel FileshazanNo ratings yet

- Ngurv Ter - : de en Ow06/002.0Document2 pagesNgurv Ter - : de en Ow06/002.0tranhonghakd5533No ratings yet

- BPVC Viii-1 Udr-2Document2 pagesBPVC Viii-1 Udr-2Carlos Anibal OrtizNo ratings yet

- BPVC Viii 1 U DR 1Document2 pagesBPVC Viii 1 U DR 1gahaind0518No ratings yet

- Operating Conditions:: Form Kk3-U-DrDocument2 pagesOperating Conditions:: Form Kk3-U-DrshazanNo ratings yet

- Form U-Dr-1 User, S Design Requirement For Single Chamber Pressure VesselsDocument4 pagesForm U-Dr-1 User, S Design Requirement For Single Chamber Pressure VesselsAmit SharmaNo ratings yet

- Udr 1Document2 pagesUdr 1shazanNo ratings yet

- BPVC - Viii-1 - U-Dr - GASDocument2 pagesBPVC - Viii-1 - U-Dr - GASRodolfoNo ratings yet

- SESMACOL BPVC - Viii-1 - U-Dr-1 ASME Rev 0Document2 pagesSESMACOL BPVC - Viii-1 - U-Dr-1 ASME Rev 0Jairo Andres Romero QuirogaNo ratings yet

- 31220098Document9 pages31220098Muhammad AliNo ratings yet

- Tank Manual CalculationsDocument19 pagesTank Manual Calculationsbhavanamadhuri itapuNo ratings yet

- Wps Smaw3g Smaw B-U2 (Vacio)Document1 pageWps Smaw3g Smaw B-U2 (Vacio)Richard Gonzales CapchiNo ratings yet

- TWI UT Level IIDocument7 pagesTWI UT Level IIssNo ratings yet

- MRIR FOrmDocument1 pageMRIR FOrmssNo ratings yet

- Material Receiving Report FormDocument2 pagesMaterial Receiving Report FormssNo ratings yet

- DFG GTRFCDocument38 pagesDFG GTRFCssNo ratings yet

- AUdit Schedule 2018Document1 pageAUdit Schedule 2018ssNo ratings yet

- Inco-Weld 725NDUR Filler MetalDocument1 pageInco-Weld 725NDUR Filler MetalssNo ratings yet

- Cast Iron Weld RepairDocument1 pageCast Iron Weld RepairssNo ratings yet

- PWHTDocument57 pagesPWHTssNo ratings yet

- Hull and Machinery Steel Castings W8Document6 pagesHull and Machinery Steel Castings W8ssNo ratings yet

- WPS ChecklistDocument1 pageWPS ChecklistssNo ratings yet

- 103 Ohsas 18001 2007 IngDocument1 page103 Ohsas 18001 2007 IngssNo ratings yet

- Velosi Lessens LearnedDocument33 pagesVelosi Lessens LearnedssNo ratings yet

- Ballast Water Management: A Comparative Analysis of Todim and ThorDocument54 pagesBallast Water Management: A Comparative Analysis of Todim and ThorssNo ratings yet

- Dial Thermometer Shape For Powerpoint: Edit Text HereDocument5 pagesDial Thermometer Shape For Powerpoint: Edit Text HeressNo ratings yet

- Investigating Anglo-Saxon Population Movement Using Strontium Stable Isotope AnalysisDocument58 pagesInvestigating Anglo-Saxon Population Movement Using Strontium Stable Isotope AnalysisAnnemieke DoornbosNo ratings yet

- 9701 w03 QP 3Document8 pages9701 w03 QP 3Hubbak KhanNo ratings yet

- Bresle Kit Chloride Test Kit Sp7310 d44Document3 pagesBresle Kit Chloride Test Kit Sp7310 d44sanmartinjNo ratings yet

- Shell Omala SW 150Document1 pageShell Omala SW 150Anonymous TvZMMT5No ratings yet

- Worksheet 26 CombineDocument24 pagesWorksheet 26 CombineCleo Poulos0% (1)

- RT Procedure 10.09.16Document9 pagesRT Procedure 10.09.16mukeshsingh6No ratings yet

- Sceng 818Document25 pagesSceng 818Arslan UmarNo ratings yet

- Epoxy Formulations Using JEFFAMINE MinesDocument105 pagesEpoxy Formulations Using JEFFAMINE Mineszamanzingo97100% (1)

- SC Sample Paper 23 UnsolvedDocument12 pagesSC Sample Paper 23 UnsolvedjessievijayNo ratings yet

- Extended SurfacesDocument13 pagesExtended SurfacesDirkMyburghNo ratings yet

- Cerium: 1. Devina Dwi Astari 2. Marchia Marthalena MarintaDocument13 pagesCerium: 1. Devina Dwi Astari 2. Marchia Marthalena MarintaastariNo ratings yet

- Sika Injection 20Document3 pagesSika Injection 20the pilotNo ratings yet

- Hopping Technology On Lager Beer Flavor and Flavor StabilityDocument249 pagesHopping Technology On Lager Beer Flavor and Flavor StabilityKrishna ChaudhariNo ratings yet

- What Is 21 CFR Part 11Document26 pagesWhat Is 21 CFR Part 11chemtabNo ratings yet

- 1314 Lab - Single Replacement Lab As Inquiry BasedDocument2 pages1314 Lab - Single Replacement Lab As Inquiry Basedapi-239433858No ratings yet

- BAKER Drilling - Products Fluid End Expandable Parts PDFDocument56 pagesBAKER Drilling - Products Fluid End Expandable Parts PDFAnonymous GjCOVlgNo ratings yet

- ASTM 547 Extraction Replica TechniquesDocument6 pagesASTM 547 Extraction Replica Techniquesdeweyj1100% (1)

- 2012-3 National Chemistry OlympiadDocument14 pages2012-3 National Chemistry OlympiadRSLNo ratings yet

- SP-1246 Part 1 Technical RequirementsDocument27 pagesSP-1246 Part 1 Technical RequirementsBurning TrainNo ratings yet

- Allosteric EnzymeDocument22 pagesAllosteric EnzymeAhmed ImranNo ratings yet

- Sterilization of WaterDocument21 pagesSterilization of WaterYASHWIN RAMESHNo ratings yet

- EBook ListDocument61 pagesEBook Listayakashimajorin100% (1)

- 7 Elements in The Human BodyDocument2 pages7 Elements in The Human BodyCris CorsinoNo ratings yet

- Astm E945 - 12Document4 pagesAstm E945 - 12ChristianNo ratings yet

- A Course On Reciprocating PumpDocument11 pagesA Course On Reciprocating PumpSwami VedatitanandaNo ratings yet

- Troubleshooting Turbine Steam Path Damage MechanismsDocument40 pagesTroubleshooting Turbine Steam Path Damage MechanismsMas Zuhad100% (1)

- Psych Ro MetricDocument11 pagesPsych Ro MetricLucia Kara Chance100% (1)

- Spectrophotometric Determination of Salicylamide and ParacetamolDocument6 pagesSpectrophotometric Determination of Salicylamide and Paracetamoliabureid7460No ratings yet