Professional Documents

Culture Documents

TATA Painting Specification 40

Uploaded by

Suleman KhanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TATA Painting Specification 40

Uploaded by

Suleman KhanCopyright:

Available Formats

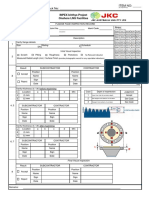

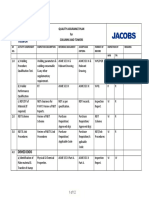

QAP No. TSL / New Fabrication-001/Rev.

0

TATA STEEL LIMITED QAP FOR SURFACE PREPARATIOPN & PAINT APPLICATION

Date:

Name of the Applicator: M/S .

Name of the Item to coated: Structural Steel Plates, Bulb Bars etc. Name of Paint Manufacturer:

Type of

Standards of Performed & Record No./

Sr. Parameters to be Acceptance Check(visual/ Qty/ Witnessed &

Compliances/Work Hold Points documented Inspection Remarks if Any

No. checked Criteria instrumental/ Frequency Recorded By

instruction by format

Both)

A ( QA necessary checks for product prequalification)

Coating Materials

Test Report with Individual Third party

Prequalification As per ISO12944 Part Prior to material Client Paint Test Verification & compliances to be

A01 compliance of Instrumental Paint Independent

Test Certificate 6 receive QC Mfg. Certificate ensured prior to supply

agreed QAP system Laboratory

from External lab

B ( QA necessary checks for material and corrosion control process)

Coating Materials Test Report with Blasting &

As per QAP Prior to material 100% for Client Paint Test Verification & compliances of self

B01 Batch Test compliance of Instrumental painting

agreement receive/issue every Batch QC Mfg. Certificate life to be ensured prior to use

Certificate agreed QAP Contractor

Non metallic

abrasives (copper

Copper refinery Blasting &

slag) test ISO 11126 Prior to issue 100% once Client Paint Test

BO2 slag / Metallic Both painting

certificate/ Metallic ISO11124 and its usage in every lot QC Mfg. Certificate

Steel Grit or Shot Contractor

abrasives test

certificate

Random

Blasting & Fine grade abrasive(Size-0.2 to

Abrasives size to ISO 11126 Aggregate=G or Prior to issue selection Client Paint Inspection

B03 Visual painting 1.5mm) to achieve 50-70micron

be check ISO11124 S and its usage once in QC Mfg. Records

Contractor surface profile

every lot

Prepared & Proposed By. TATA STEEL Ltd. Agreed & Approved By: M/s Committed By:

You might also like

- TATA Painting Specification 44Document1 pageTATA Painting Specification 44Suleman KhanNo ratings yet

- TATA Painting Specification 43Document1 pageTATA Painting Specification 43Suleman KhanNo ratings yet

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDocument3 pagesBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNo ratings yet

- SA MP LE: Company NameDocument4 pagesSA MP LE: Company NameAnonymous P8XHEXyIZLNo ratings yet

- 36 - Painting Procedure - Rev0Document21 pages36 - Painting Procedure - Rev0Duc ThinNo ratings yet

- Painting Maual For Power Sector ErectionDocument32 pagesPainting Maual For Power Sector Erectionnagarathinam82No ratings yet

- Pentadur 5540 (F6A)Document3 pagesPentadur 5540 (F6A)SiDdu Kalashetti0% (1)

- Surface Preparation & Painting Procedure Rev.0 PDFDocument17 pagesSurface Preparation & Painting Procedure Rev.0 PDFคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Chemical Resistance (LLDPE) PDFDocument24 pagesChemical Resistance (LLDPE) PDFrubyshreeNo ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFRadhakrishna VachaNo ratings yet

- Flange Face Inspection Record CCPP R5Document1 pageFlange Face Inspection Record CCPP R5asfaruk2556100% (1)

- TS4 - Project and Maintenance Coating PDFDocument26 pagesTS4 - Project and Maintenance Coating PDFmojgfdNo ratings yet

- Surface Preparation and PaintingDocument4 pagesSurface Preparation and PaintingSimbu ArasanNo ratings yet

- BOLT Torquing ReportDocument4 pagesBOLT Torquing ReportSumith Kumar S MNo ratings yet

- Coke Crusher - Lubrication Pumps Run in TestDocument26 pagesCoke Crusher - Lubrication Pumps Run in TestsayedNo ratings yet

- 2.8.2. Indicative QAP - ColumnsDocument12 pages2.8.2. Indicative QAP - ColumnsAshish Dhok0% (1)

- Stumpp Schuele & Somappa Springs Pvt. LTD.: Internal Particulate Cleanliness Analysis ReportDocument1 pageStumpp Schuele & Somappa Springs Pvt. LTD.: Internal Particulate Cleanliness Analysis ReportRajkumar KantiwalNo ratings yet

- NRP QapDocument10 pagesNRP QapKevin Mathew100% (1)

- External Pipe Wrapping - Inspection and Test Plan: Description of LocationDocument2 pagesExternal Pipe Wrapping - Inspection and Test Plan: Description of LocationDavidNo ratings yet

- Attachment D (SAEP 316)Document1 pageAttachment D (SAEP 316)imtiazNo ratings yet

- ITP For Piping SystemsDocument6 pagesITP For Piping SystemsGia Minh Tieu TuNo ratings yet

- Paint Coating Stainless SteelsDocument2 pagesPaint Coating Stainless SteelsSilva NumaNo ratings yet

- Tankguard 412 Jotun PaintDocument6 pagesTankguard 412 Jotun PaintGurdeep Sungh AroraNo ratings yet

- Work Method Statement FOR HSS PQTDocument6 pagesWork Method Statement FOR HSS PQTenels77No ratings yet

- Painting ProcedureDocument4 pagesPainting ProcedureRidoNo ratings yet

- ASTM D 714 - 87 r00Document6 pagesASTM D 714 - 87 r00Abi PutraNo ratings yet

- Adhesion Testing MethodDocument3 pagesAdhesion Testing MethodMohd Effiezool YaserNo ratings yet

- MS For Fabrication of Above-Ground Storage TankDocument8 pagesMS For Fabrication of Above-Ground Storage Tankdadz mingiNo ratings yet

- Grouting Format Report (Electrical Panel)Document1 pageGrouting Format Report (Electrical Panel)Anas PratamaNo ratings yet

- Aban Constructions Pvt. LTD: Procedure For PaintingDocument4 pagesAban Constructions Pvt. LTD: Procedure For PaintingAkhilesh KumarNo ratings yet

- Pull Off Test Report RefinaryDocument3 pagesPull Off Test Report RefinaryZaid Raslan AyoubNo ratings yet

- Saudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Document1 pageSaudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Mohammed Hamed BaganNo ratings yet

- INSPECTION TEST PLAN For Pole Production - Doc1Document8 pagesINSPECTION TEST PLAN For Pole Production - Doc1OGBONNAYA MARTINSNo ratings yet

- Reliance Industries Limited Line History Sheet For CS Piping Without PWHTDocument1 pageReliance Industries Limited Line History Sheet For CS Piping Without PWHTRavi ShankarNo ratings yet

- Itp Vessel PDFDocument4 pagesItp Vessel PDFBUDAPESNo ratings yet

- ITP For Mild Steel Pipe WorksDocument4 pagesITP For Mild Steel Pipe WorksKumar AbhishekNo ratings yet

- CPVC ChecklistDocument1 pageCPVC Checklistchakravarthi kanugulaNo ratings yet

- FAT Precedure - R 072 Nitrogen PackageDocument10 pagesFAT Precedure - R 072 Nitrogen PackageBudi UtomoNo ratings yet

- GS-09 (Painting) PDFDocument22 pagesGS-09 (Painting) PDFSarbendu PaulNo ratings yet

- Painting Inspection Report-534 - GALVACOATDocument1 pagePainting Inspection Report-534 - GALVACOATRahul MoottolikandyNo ratings yet

- Prorox WM 960 Sa PDFDocument1 pageProrox WM 960 Sa PDFr afriantoNo ratings yet

- Approved Itp-Dss - 28 Sep 2016Document4 pagesApproved Itp-Dss - 28 Sep 2016Selvakumar SubramanianNo ratings yet

- DFT Measurement Worksheet: Paint InspectionDocument1 pageDFT Measurement Worksheet: Paint Inspectionjay nathNo ratings yet

- Method Statement Installation Os Static Equipment and InternalsDocument24 pagesMethod Statement Installation Os Static Equipment and InternalsAjin SNo ratings yet

- Eadips Manual Engl PDFDocument390 pagesEadips Manual Engl PDFbkarabasevicNo ratings yet

- Interseal 670HDocument2 pagesInterseal 670Hmadmax_mfpNo ratings yet

- Epimastic 5200: Product DescriptionDocument2 pagesEpimastic 5200: Product DescriptionsreeNo ratings yet

- Astm A179 PDFDocument1 pageAstm A179 PDFgaminNo ratings yet

- Hydrotest QI304-sampleDocument3 pagesHydrotest QI304-sampleHanuman Rao100% (1)

- P68 M13 Painting Documents PDFDocument708 pagesP68 M13 Painting Documents PDFJohn TerryNo ratings yet

- Attachment: Painting ProcedureDocument79 pagesAttachment: Painting ProcedureOmar Wardeh100% (2)

- NPK 000 N1 GS 6001 K Rev 3 Spesification For Painting and CoatingDocument33 pagesNPK 000 N1 GS 6001 K Rev 3 Spesification For Painting and CoatingDangolNo ratings yet

- Procedure For Handling, Storage & Transportations of Bare & Coated PipesDocument6 pagesProcedure For Handling, Storage & Transportations of Bare & Coated Pipeskbpatel123No ratings yet

- PTDocument7 pagesPTMohdHuzairiRusliNo ratings yet

- Inspection report-GRVE BlankDocument2 pagesInspection report-GRVE BlankJoseph Perez100% (1)

- QAP For Conical StrainerDocument2 pagesQAP For Conical StrainersatishchidrewarNo ratings yet

- Coating Specification: 1. ScopeDocument4 pagesCoating Specification: 1. ScopeThaiminh Vo100% (2)

- Field Joint Coating Procedure Rev.1Document33 pagesField Joint Coating Procedure Rev.1gst ajahNo ratings yet

- QAP New Customer Nov23Document1 pageQAP New Customer Nov23RND DRAWNo ratings yet

- Inspection and Test Plan For Surface Preparation and PaintingDocument2 pagesInspection and Test Plan For Surface Preparation and PaintingNoor Rose Eka RoseNo ratings yet

- Sheet Metal Bending: A. ElbadanDocument24 pagesSheet Metal Bending: A. ElbadanSuleman KhanNo ratings yet

- B2 - Hardy SpicerDocument136 pagesB2 - Hardy SpicerSuleman KhanNo ratings yet

- Production Engineering 1 Year Marine FallDocument27 pagesProduction Engineering 1 Year Marine FallSuleman KhanNo ratings yet

- Production Engineering 1 Year Marine: Fall 2007Document12 pagesProduction Engineering 1 Year Marine: Fall 2007Suleman KhanNo ratings yet

- Production Engineering 1 Year Marine: Fall 2007Document26 pagesProduction Engineering 1 Year Marine: Fall 2007Suleman KhanNo ratings yet

- Inspection Report - RollerDocument1 pageInspection Report - RollerSuleman Khan100% (1)

- Engineers To Healthcare Industry®: Quality Assurance Protocol (QAP)Document9 pagesEngineers To Healthcare Industry®: Quality Assurance Protocol (QAP)Suleman KhanNo ratings yet

- NS - QAP-001 - Quality Assurance Provisions (QAPs) v6 - 0Document36 pagesNS - QAP-001 - Quality Assurance Provisions (QAPs) v6 - 0Suleman KhanNo ratings yet

- MITRE BEND-oldDocument5 pagesMITRE BEND-oldSuleman KhanNo ratings yet

- AREVA NP Inc. Quality Assurance Plan (QAP) For Design Certification of The U.S. EPR™ Topical ReportDocument116 pagesAREVA NP Inc. Quality Assurance Plan (QAP) For Design Certification of The U.S. EPR™ Topical ReportSuleman KhanNo ratings yet

- Surface Defects in Powder CoatingsDocument3 pagesSurface Defects in Powder CoatingsSuleman KhanNo ratings yet

- Heav Y-Duty Conveyor Roller Series 3950: Product Selection Product DescriptionDocument2 pagesHeav Y-Duty Conveyor Roller Series 3950: Product Selection Product DescriptionSuleman KhanNo ratings yet

- Conveyor Equipment Manufacturers Association: 2019 Cema Engineering Conference Bulk Handling SectionDocument8 pagesConveyor Equipment Manufacturers Association: 2019 Cema Engineering Conference Bulk Handling SectionSuleman KhanNo ratings yet

- Katalog - Gumenih - Traka - TRANSPORTNI TRAKI REMA TIP TOP ELECTROLUX MACEDONIA ENDocument65 pagesKatalog - Gumenih - Traka - TRANSPORTNI TRAKI REMA TIP TOP ELECTROLUX MACEDONIA ENSuleman KhanNo ratings yet

- Supplier Quality Development - A Review of Literature and Industry PracticesDocument24 pagesSupplier Quality Development - A Review of Literature and Industry PracticesSuleman KhanNo ratings yet

- ISRO EOT Crane QAPDocument17 pagesISRO EOT Crane QAPSuleman Khan100% (1)

- Certified Supplier Quality ProfessionalDocument12 pagesCertified Supplier Quality ProfessionalSuleman KhanNo ratings yet

- Bircher DWSK Profile & Rail - E PDFDocument2 pagesBircher DWSK Profile & Rail - E PDFSuleman KhanNo ratings yet

- Wampfler Power RailDocument28 pagesWampfler Power RailSuleman KhanNo ratings yet

- BRAUER 385 - Polyurethane Tyred Wheels SectionDocument6 pagesBRAUER 385 - Polyurethane Tyred Wheels SectionSuleman KhanNo ratings yet

- TB 600 v1Document106 pagesTB 600 v1Saud Affan100% (1)

- 802.11 A/G Ofdm Phy: 802.11 Wireless Networks, Chapter 11 Ofdm Wireless Lans, Part of Chapter 3Document21 pages802.11 A/G Ofdm Phy: 802.11 Wireless Networks, Chapter 11 Ofdm Wireless Lans, Part of Chapter 3Jack VuNo ratings yet

- Zed-3 Se150 QSG LenDocument6 pagesZed-3 Se150 QSG LenClaudia TituañaNo ratings yet

- ENERCON - BrizuelaDocument13 pagesENERCON - BrizuelaEzekiel Brizuela100% (1)

- Spatial Reference ManualDocument150 pagesSpatial Reference ManualRao FarhanNo ratings yet

- Process Communication Unit PCU400 MR9Document27 pagesProcess Communication Unit PCU400 MR9sahil4INDNo ratings yet

- 132 KV Transmission System AustraliaDocument67 pages132 KV Transmission System AustraliaistenicNo ratings yet

- D-Dome System: Mounting Systems For Solar TechnologyDocument22 pagesD-Dome System: Mounting Systems For Solar TechnologyArianit ZeqiriNo ratings yet

- An SAP Consultant - ABAP - Infotype Record Creation - HR - INFOTYPE - OPERATIONDocument2 pagesAn SAP Consultant - ABAP - Infotype Record Creation - HR - INFOTYPE - OPERATIONarunNo ratings yet

- Crane HazardsDocument218 pagesCrane HazardsSanjana Ganesh100% (5)

- Cobas B 221 Interface Manual PDFDocument70 pagesCobas B 221 Interface Manual PDFReach Business Software Pvt LtdNo ratings yet

- Thermoplastics Pipes and Associated Fittings For Hot and Cold Water For Domestic Purposes and Heating Installations in BuildingsDocument30 pagesThermoplastics Pipes and Associated Fittings For Hot and Cold Water For Domestic Purposes and Heating Installations in BuildingsFatty-bom-bomNo ratings yet

- BIW - Points Discussed With The CustomerDocument9 pagesBIW - Points Discussed With The CustomerJyoti Kale100% (1)

- 25 Towing With A MotorhomeDocument4 pages25 Towing With A MotorhomeBill jonesNo ratings yet

- Kasemake SoftwareDocument2 pagesKasemake SoftwareDlareme Nella OllitsacNo ratings yet

- Medium Voltage Isolated Phase Bus Guide Specification v0Document4 pagesMedium Voltage Isolated Phase Bus Guide Specification v0abu thahirNo ratings yet

- 2021 10 29 - LogDocument114 pages2021 10 29 - LogRizkySyahrizalNo ratings yet

- Open LdapDocument74 pagesOpen Ldapsollun3No ratings yet

- QMS Chapter 32 ReportingDocument10 pagesQMS Chapter 32 ReportingHannah Mae Mayol - EntrolizoNo ratings yet

- Most Important Selenium Interview QuestionsDocument14 pagesMost Important Selenium Interview Questionsnagub100% (2)

- Toyota Production SystemDocument55 pagesToyota Production SystemCrina SimionNo ratings yet

- Cassion FoundationDocument18 pagesCassion FoundationRavi Malik0% (1)

- KLCP Codec LogDocument4 pagesKLCP Codec Logkln258No ratings yet

- RaiBlocks Whitepaper EnglishDocument8 pagesRaiBlocks Whitepaper EnglishKenji J.No ratings yet

- Block RetráctilDocument1 pageBlock RetráctilInspector de Seguridad ParagshaNo ratings yet

- Ethernet Communication ModuleDocument11 pagesEthernet Communication Modulemuneeb.irfan9873No ratings yet

- Bassoon Fingering ChartDocument4 pagesBassoon Fingering ChartDerek100% (1)

- Normality - Questionnaire SampleDocument6 pagesNormality - Questionnaire SampleFatin NurNo ratings yet

- CCcam - CFG SimpleDocument3 pagesCCcam - CFG SimpleSadia KanwalNo ratings yet

- Sfhas Replication Admin 601 SolDocument552 pagesSfhas Replication Admin 601 SolNitin KanojiaNo ratings yet