Professional Documents

Culture Documents

Date

Uploaded by

Lipika Gayen100%(1)100% found this document useful (1 vote)

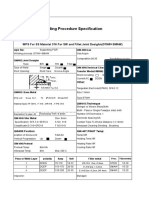

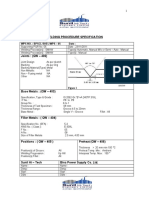

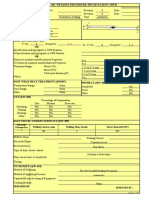

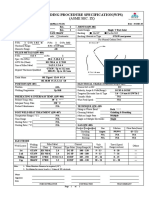

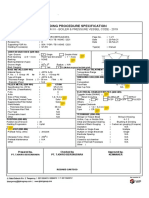

53 views1 pageThis welding procedure specification outlines the parameters for gas tungsten arc welding (GTAW) of carbon steel, low alloy steel, and stainless steel pipes and plates using an ER-80S-Ni1 filler metal. It specifies details such as joint design, base metal composition, preheat requirements, welding positions, parameters for multiple weld passes using direct current electrode negative polarity and a 1.6mm tungsten electrode. The WPS is intended to be used for single or multiple pass welds on materials up to 20mm thick in any welding position.

Original Description:

Hey

Original Title

4_6021560431213020219

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis welding procedure specification outlines the parameters for gas tungsten arc welding (GTAW) of carbon steel, low alloy steel, and stainless steel pipes and plates using an ER-80S-Ni1 filler metal. It specifies details such as joint design, base metal composition, preheat requirements, welding positions, parameters for multiple weld passes using direct current electrode negative polarity and a 1.6mm tungsten electrode. The WPS is intended to be used for single or multiple pass welds on materials up to 20mm thick in any welding position.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

53 views1 pageDate

Uploaded by

Lipika GayenThis welding procedure specification outlines the parameters for gas tungsten arc welding (GTAW) of carbon steel, low alloy steel, and stainless steel pipes and plates using an ER-80S-Ni1 filler metal. It specifies details such as joint design, base metal composition, preheat requirements, welding positions, parameters for multiple weld passes using direct current electrode negative polarity and a 1.6mm tungsten electrode. The WPS is intended to be used for single or multiple pass welds on materials up to 20mm thick in any welding position.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 1

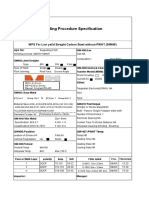

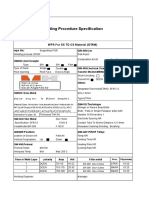

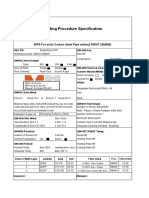

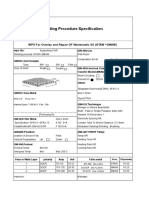

Welding Procedure Specification

WPS For LTCS (GTAW)

wps No: Supporting PQR: QW-408:Gas

Welding process: GTAW Gas:Argon

Composition:99.5 Flow Rate:6-12Lit/min

QW402:Joint Desighn

Type: BW SW Fillet

Type of Weld: Single Double QW-409:Electrical Characterist

Root Opening: Root Face: Groove Angle Transfer Mode(GMAW):

Short-Circuiting Glubular Spray

Current:AC DCEN DCEP

Other:

Tangestan Electrode(GTAW): SFA 5.12

QW403: Base Metal Size:1.6mm

[P,S] no:1 Group No:1 To [P,S] no: 1 Group No1,2 Type:ETWH

Material Spec:A106, A105,WPB,WCB,API5L(X42 X52,X56) QW410:Technique

, A283,A36,A53,A36,ST37, A672, A179,A178,WPHY42,LF2, Stringer or Weave Bead:Both

F52,A516GR,A515,A537,A333 GR(1,6,10), A671,A334 Multi - Pass or Single Pass(per side) both

Diametere For pipe: All Thickness:THK<20mm Number Of Electrodes: 1

QW-404:Filler Metal Dia< 6mm Electrode Spacing:NA

Specification: SFA 5.28+SFA5.1 A NO 2+2 Contact Tube To Worke Distance:14-16mm

Classificatin:ER-80S-Ni1+E-7018-1 F NO 6+4 Interpass Cleaning:Grinding , Brushing

QW405:Position QW-407:PWHT Temp:

position of Groove:All Fillet:All Temp:NA

Vertical Progression: Up Down Holding Time:NA

QW-406:Preheat Heating Rate: NA

Preheat Temp: Min:NA Cooling Rate:NA

Interpass Temp: Min: Max:250 C

Pass or Weld Layer polarity Amp Volt Filler metal Proc. TV(cm/min)

1 DCEN 70-110 18-22 ER-80S-Ni1 Dia =2.2mm GTAW 10-20

2 DCEN 110-170 20-30 ER-80S-Ni1 Dia =2.2mm GTAW 10-20

n DCEN 150-200 25-35 ER-80S-Ni1 Dia =2.2mm GTAW 10-20

Inspector: Manager:

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Welding Procedure Specification: WPS For Low Yeild Streght Carbon Steel With PWHT (SMAW)Document1 pageWelding Procedure Specification: WPS For Low Yeild Streght Carbon Steel With PWHT (SMAW)Lipika GayenNo ratings yet

- WPS for Low Carbon Steel SMAW WeldingDocument1 pageWPS for Low Carbon Steel SMAW WeldingLipika GayenNo ratings yet

- Welding Procedure Specification: WPS For SS TO CS Material (GTAW)Document1 pageWelding Procedure Specification: WPS For SS TO CS Material (GTAW)Lipika GayenNo ratings yet

- Welding Procedure Specification: WPS For Repair of Corrod Area (SMAW)Document1 pageWelding Procedure Specification: WPS For Repair of Corrod Area (SMAW)Lipika GayenNo ratings yet

- Welding Procedure Specification: Wps Forcarbon Steel For Fillet and SW Joint Desighn (Smaw)Document1 pageWelding Procedure Specification: Wps Forcarbon Steel For Fillet and SW Joint Desighn (Smaw)Lipika GayenNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- WPS for SS to CS WeldingDocument1 pageWPS for SS to CS WeldingLipika GayenNo ratings yet

- Welding Procedure Specification: WPS For Exist Carbon Steel Pipe Without PWHT (SMAW)Document1 pageWelding Procedure Specification: WPS For Exist Carbon Steel Pipe Without PWHT (SMAW)Lipika Gayen100% (1)

- Welding Procedure Specification: WPS For Overlay and Repair OF Martenzetic SS (GTAW +SMAW)Document1 pageWelding Procedure Specification: WPS For Overlay and Repair OF Martenzetic SS (GTAW +SMAW)Lipika GayenNo ratings yet

- Welding Procedure Specification for 316 Stainless Steel GTAW WeldsDocument1 pageWelding Procedure Specification for 316 Stainless Steel GTAW WeldsLipika GayenNo ratings yet

- Wps - Eni-Ci - Enife-ci-A (Gray Cast Iron)Document1 pageWps - Eni-Ci - Enife-ci-A (Gray Cast Iron)AminNo ratings yet

- Welding Procedure Specification: WPS For SS Material 304 (GTAW+SMAW)Document1 pageWelding Procedure Specification: WPS For SS Material 304 (GTAW+SMAW)Lipika GayenNo ratings yet

- Welding Procedure Specification: WPS For SS Material 316 For SW and Fillet Joint Desighn (GTAW+SMAW)Document1 pageWelding Procedure Specification: WPS For SS Material 316 For SW and Fillet Joint Desighn (GTAW+SMAW)Lipika GayenNo ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocument10 pagesWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- 4 2WPSDocument2 pages4 2WPSsaravanans18910% (1)

- GTAW Welding Process ParametersDocument12 pagesGTAW Welding Process Parametersmiteshpatel191No ratings yet

- Mechanical Engineering M.Abdul GhoziDocument4 pagesMechanical Engineering M.Abdul GhoziRizaldy PhoenksNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- WPS 10Document2 pagesWPS 10Arab WeldersNo ratings yet

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Document2 pagesWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- WPS for Manual SMAW Welding of 316L Stainless Steel Butt JointsDocument3 pagesWPS for Manual SMAW Welding of 316L Stainless Steel Butt JointsAmjad PathanNo ratings yet

- WPS, PQR, WPQ PoojaDocument10 pagesWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- Resistance Welding WpsDocument1 pageResistance Welding WpsQwertyNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNo ratings yet

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- Electrode Pressure Bar Welding Current, Amp Welding Time, Second Power Source (AC/DC)Document1 pageElectrode Pressure Bar Welding Current, Amp Welding Time, Second Power Source (AC/DC)Mohit TiwariNo ratings yet

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- WPS No. ST-CS-02-2Document1 pageWPS No. ST-CS-02-2Hussein JassimNo ratings yet

- WPS For Different Materail by BhelDocument176 pagesWPS For Different Materail by Bhelsaisssms911691% (46)

- Aic Asf PQR 133Document3 pagesAic Asf PQR 133AHMED MEDANYNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- 2G & 5GDocument2 pages2G & 5GRahul MoottolikandyNo ratings yet

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

- 1 5 1Document5 pages1 5 1daemsalNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 01 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 01 DateAmjad PathanNo ratings yet

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- Daewoo E & C: Welding Procedure Specification (WPS)Document2 pagesDaewoo E & C: Welding Procedure Specification (WPS)Jarus YdenapNo ratings yet

- WC9Document5 pagesWC9Suresh KrishnanNo ratings yet

- WPS Gtaw) - 47Document2 pagesWPS Gtaw) - 47Dharmendra BhardwajNo ratings yet

- WPS Gtaw+smawDocument2 pagesWPS Gtaw+smawAnand GNo ratings yet

- PQR Welding Procedure RecordDocument2 pagesPQR Welding Procedure RecordAtilio BarriosNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- 0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCDocument2 pages0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCAshish PatelNo ratings yet

- PT Alphacon's Single V Butt Joint WPSDocument20 pagesPT Alphacon's Single V Butt Joint WPScrys0% (1)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Aic Asf PQR 0122Document2 pagesAic Asf PQR 0122AHMED MEDANYNo ratings yet

- PRN005Document2 pagesPRN005beyNo ratings yet

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- LOGOS ENGINEERING WELDING PROCEDURE SPECIFICATIONDocument5 pagesLOGOS ENGINEERING WELDING PROCEDURE SPECIFICATIONKAMALNo ratings yet

- ASME Section IX Welding Procedure Specification for GTAW of ASTM A-36 SteelDocument3 pagesASME Section IX Welding Procedure Specification for GTAW of ASTM A-36 SteelBudi Setia RahmanNo ratings yet

- T-721 For MPTDocument1 pageT-721 For MPTLipika GayenNo ratings yet

- How Does A Steam Boiler Work?Document11 pagesHow Does A Steam Boiler Work?Lipika GayenNo ratings yet

- Table T-233.1 For RTDocument1 pageTable T-233.1 For RTLipika GayenNo ratings yet

- Table T-233.1 For RTDocument1 pageTable T-233.1 For RTLipika GayenNo ratings yet

- Axial Flow For Industry 1Document9 pagesAxial Flow For Industry 1Lipika GayenNo ratings yet

- CompressorDocument17 pagesCompressorLipika GayenNo ratings yet

- Impact Test Machine CalculationsDocument6 pagesImpact Test Machine CalculationsSoumadipta SenNo ratings yet

- Quality (1) Min. Yield Point (2) Tensile Strenght (3) Impact Strenght (4) Reh N/MM RM N/MM Temp °C Charpy VDocument1 pageQuality (1) Min. Yield Point (2) Tensile Strenght (3) Impact Strenght (4) Reh N/MM RM N/MM Temp °C Charpy VLipika Gayen100% (1)

- Ductile Pipe MFG ProcessDocument1 pageDuctile Pipe MFG ProcessLipika GayenNo ratings yet

- CompressorDocument17 pagesCompressorLipika GayenNo ratings yet

- Acceptance Criteria For Pipeline & WQT: South Pars Gas Field Development 9&10 Pipe Line Connecting Phase 1 To Phases 9&10Document4 pagesAcceptance Criteria For Pipeline & WQT: South Pars Gas Field Development 9&10 Pipe Line Connecting Phase 1 To Phases 9&10Lipika Gayen100% (1)

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design Calculationmail_younes659283% (29)

- Tee JointsDocument1 pageTee JointsLipika GayenNo ratings yet

- CompressorDocument6 pagesCompressorLipika GayenNo ratings yet

- CompressorDocument17 pagesCompressorLipika GayenNo ratings yet

- Test ConditionDocument1 pageTest ConditionLipika GayenNo ratings yet

- Third Party Inspection For Reciprocating Compressor - ProcedureDocument12 pagesThird Party Inspection For Reciprocating Compressor - ProcedureLipika GayenNo ratings yet

- Code for Gas Welding Process and ParametersDocument1 pageCode for Gas Welding Process and ParametersLipika GayenNo ratings yet

- Work permit details for IPDC project constructionDocument1 pageWork permit details for IPDC project constructionLipika GayenNo ratings yet

- Wa0000Document9 pagesWa0000Lipika GayenNo ratings yet

- Test ConditionDocument1 pageTest ConditionLipika GayenNo ratings yet

- Technical Tank Inspection Report TemplateDocument1 pageTechnical Tank Inspection Report TemplateLipika GayenNo ratings yet

- S.No. Hospital Code Hospital NameDocument20 pagesS.No. Hospital Code Hospital NameLipika GayenNo ratings yet

- API 650, 5.6.4, Calculation of Shell ThicknessDocument31 pagesAPI 650, 5.6.4, Calculation of Shell ThicknessalokbdasNo ratings yet

- Flange Dimensions and Pressure Ratings ChartDocument24 pagesFlange Dimensions and Pressure Ratings Chartgateauxboy100% (2)

- Tank Shell DesignDocument4 pagesTank Shell Designgon972001No ratings yet

- API 650 Datasheet 1Document16 pagesAPI 650 Datasheet 1alwacsNo ratings yet

- Tank Shell DesignDocument4 pagesTank Shell Designgon972001No ratings yet

- Standard Pipe Sizes and PropertiesDocument64 pagesStandard Pipe Sizes and PropertiesLipika GayenNo ratings yet

- Eritrea and Ethiopia Beyond The Impasse PDFDocument12 pagesEritrea and Ethiopia Beyond The Impasse PDFThe Ethiopian AffairNo ratings yet

- Academy Broadcasting Services Managerial MapDocument1 pageAcademy Broadcasting Services Managerial MapAnthony WinklesonNo ratings yet

- Aci 207.1Document38 pagesAci 207.1safak kahraman100% (7)

- Short Term Training Curriculum Handbook: General Duty AssistantDocument49 pagesShort Term Training Curriculum Handbook: General Duty AssistantASHISH BARAWALNo ratings yet

- AKTA MERGER (FINAL) - MND 05 07 2020 FNLDocument19 pagesAKTA MERGER (FINAL) - MND 05 07 2020 FNLNicoleNo ratings yet

- Make a Battery Level Indicator using LM339 ICDocument13 pagesMake a Battery Level Indicator using LM339 ICnelson100% (1)

- Conplast SP430 0407Document4 pagesConplast SP430 0407Harz IndNo ratings yet

- L-1 Linear Algebra Howard Anton Lectures Slides For StudentDocument19 pagesL-1 Linear Algebra Howard Anton Lectures Slides For StudentHasnain AbbasiNo ratings yet

- Theme Meal ReportDocument10 pagesTheme Meal Reportapi-434982019No ratings yet

- Question Paper Code: 31364Document3 pagesQuestion Paper Code: 31364vinovictory8571No ratings yet

- Entrepreneurship Style - MakerDocument1 pageEntrepreneurship Style - Makerhemanthreddy33% (3)

- Material Properties L2 Slides and NotesDocument41 pagesMaterial Properties L2 Slides and NotesjohnNo ratings yet

- Chapter 1 Qus OnlyDocument28 pagesChapter 1 Qus OnlySaksharNo ratings yet

- Self-Assessment On Accountability: I. QuestionsDocument2 pagesSelf-Assessment On Accountability: I. QuestionsAjit Kumar SahuNo ratings yet

- PS300-TM-330 Owners Manual PDFDocument55 pagesPS300-TM-330 Owners Manual PDFLester LouisNo ratings yet

- Tata Group's Global Expansion and Business StrategiesDocument23 pagesTata Group's Global Expansion and Business Strategiesvgl tamizhNo ratings yet

- Computers As Components 2nd Edi - Wayne WolfDocument815 pagesComputers As Components 2nd Edi - Wayne WolfShubham RajNo ratings yet

- Chapter 3: Elements of Demand and SupplyDocument19 pagesChapter 3: Elements of Demand and SupplySerrano EUNo ratings yet

- SyllabusDocument4 pagesSyllabusapi-105955784No ratings yet

- Code Description DSMCDocument35 pagesCode Description DSMCAnkit BansalNo ratings yet

- Battery Impedance Test Equipment: Biddle Bite 2PDocument4 pagesBattery Impedance Test Equipment: Biddle Bite 2PJorge PinzonNo ratings yet

- Venturi Meter and Orifice Meter Flow Rate CalculationsDocument2 pagesVenturi Meter and Orifice Meter Flow Rate CalculationsVoora GowthamNo ratings yet

- Ieee Research Papers On Software Testing PDFDocument5 pagesIeee Research Papers On Software Testing PDFfvgjcq6a100% (1)

- The Value of Repeat Biopsy in SLEDocument8 pagesThe Value of Repeat Biopsy in SLESergio CerpaNo ratings yet

- Denial and AR Basic Manual v2Document31 pagesDenial and AR Basic Manual v2Calvin PatrickNo ratings yet

- HI - 93703 Manual TurbidimetroDocument13 pagesHI - 93703 Manual Turbidimetrojesica31No ratings yet

- EFM2e, CH 03, SlidesDocument36 pagesEFM2e, CH 03, SlidesEricLiangtoNo ratings yet

- Dwnload Full International Monetary Financial Economics 1st Edition Daniels Solutions Manual PDFDocument36 pagesDwnload Full International Monetary Financial Economics 1st Edition Daniels Solutions Manual PDFelegiastepauleturc7u100% (16)

- Well Control Kill Sheet (Low Angle Wells)Document8 pagesWell Control Kill Sheet (Low Angle Wells)Tatita ValenciaNo ratings yet

- AnkitDocument24 pagesAnkitAnkit MalhotraNo ratings yet