Professional Documents

Culture Documents

Wsc2015 Tp10 TP Iso A Rev Pre

Uploaded by

Cristyan ReisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wsc2015 Tp10 TP Iso A Rev Pre

Uploaded by

Cristyan ReisCopyright:

Available Formats

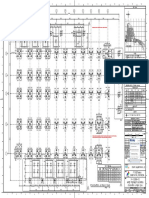

1 2 3 4 5 6 7 8 9 10

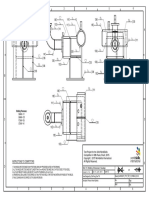

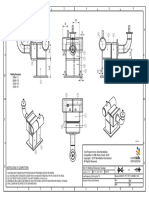

TEST PIPE 1B: TEST PIPE 1C:

HOLD 12:00 (IF WELDED WITH PH(5G) OR H-L045(6G) POSITIONS)

MATERIAL: CARBON STEEL PLATE MATERIAL: CARBON STEEL PLATE

THICKNESS: 10 mm. THICKNESS: 16 mm.

A A

A

B

NTS = NOT TO SCALE

X HOLD POINT

X= YOUR CHOICE

AREA OF STOP AND

RESTART IN FINAL CAP

A B PASS

X = YOUR CHOICE X XX

XX

B B

XX

XX

70

TEST PIPE 1A: EVALUATION:

MATERIAL: CARBON STEEL PIPE 1. VISUAL

2 PCS 114.3 X 8.56 WALL X 115 LONG 2. X-RAY ENTIRE WELD JOINT XX

XX

C

C WELDING POSITION: NOTE: WELDING POSITION: EVALUATION:

C

EVALUATION:

C

THE NUMBER OF TACKS IS TO BE WELDING POSITION:

ROOT PASS:___________ LIMITED WITH A MAXIMUM 4 TACKS. ROOT PASS:___________ 1. VISUAL

ROOT PASS:___________ 1. VISUAL

FILL & CAP:____________ FILL & CAP:____________ 2. X-RAY ENTIRE WELD JOINT

FILL & CAP:____________ 2. X-RAY ENTIRE WELD JOINT

TEST PLATE 1D: NOTE:

1. ANY PROCESS AND ANY POSITION MAY BE USED FOR TACKWELDING.

MATERIAL: CARBON STEEL PLATE

2. ALL TACK WELDS EXCEPT CENTRE OF FILLET WELDS ARE TO BE NOT LONGER THAN 15 mm. A MAXIMUM OF 4 TACKS ARE TO BE MADE FOR TEST PIPE.

THICKNESS: 12 mm

3. ALL PLATES OR PIPES ARE TO BE TACKWELDED BEFORE ANY WELDING COMMENCES.

D WELDING PROCESS:_____________ 4. PROCESS INDICATED FOR ROOT WELD TO BE USED ONLY FOR ONE RUN, NOT FOR SECOND AND SUBSEQUENT PASSES. D

WELDING POSITION:_____________ ID E 5. TEST PLATES OR PIPES MUST BE WELDED IN THE POSITION AS INDICATED FOR EACH TEST.

KS

TACK IN CENTRE BAC

(25 mm LENGTH MAXIMUM) 6. GRINDING IS NOT ALLOWED FOR THE CLEANING OF THE FINAL SURFACES OF BOTH CAP AND ROOT WELDS.

7. XXXX= COMPETITOR'S I.D. (WORKING BOOTH)

NOTE: ROOT FACE YOUR CHOICE

1. DEPOSIT A FILLET WELD ON THE FRONT SIDE OF THE TACK EACH END

X 30°

XXX E 1 CARBON STEEL PLATE 250 X 100 X 12

JOINT WITH A 10 mm (+2.0/-0) mm LEG LENGTH.

D 1 CARBON STEEL PLATE 250 X 125 X 12

8.56 (A)

2. WELD TO BE DEPOSITED WITH A MINIMUM OF 2 RUNS

16 (C)

10(B)

E AND A MAXIMUM OF 3 RUNS.

C

B

2

2

CARBON STEEL

CARBON STEEL

PLATE 250 X 125 X 16

PLATE 250 X 100 X 10

30 deg. MILLED BEVEL

30 deg. MILLED BEVEL E

3. EDGE PREPARATION MUST REMAIN AT 90° TO THE 115(A)

STOP/RESTART OF ROOT PASS IN THIS AREA A 2 CARBON STEEL PIPE OD 114.3 X 8.56 WALL X 110 LONG 30 deg. TURNED BEVEL

PLATE FACE. NO CHAMFER AND GAP ALLOWED. (ONLY FOR ROOT PASS) 100 (B) ITEM Q'TY MATERIAL DESCRIPTIONS REMARKS

12 75 125 (C)

Test Project for the 43rd WorldSkills

E FRONT SIDE Competition in São Paulo, Brazil 2015.

DETAIL OF MILLED BEVEL Copyright◎ 2015 Worldskills International

DISCARD

All Rights Reserved.

DISCARD

100

Ref.

D 10 NOTE Skill: 10. Welding, Schweisser, Soudage, Soldagem

F OR

F

Date: 07. Oct. 2014 Paper: A3

12

Scale: N. T. S

25 25 25 Designed/Drawn by: Chih-Peng Chen TW Drawing No: TP10_43BR_DAY1_GENERIC

125 ALL DIMENSIONS IN MILLIMETRES

BUT DO NOT SCALE DRAWING Description: TEST PLATES/PIPE Rev. 1 Page: 1 of 1

1 2 3 4 5 6 7 8 9 10

You might also like

- The Rough Guide to Beijing (Travel Guide eBook)From EverandThe Rough Guide to Beijing (Travel Guide eBook)Rating: 2 out of 5 stars2/5 (1)

- Identify The Areas Ex Transformer Area, Substation Area EtcDocument1 pageIdentify The Areas Ex Transformer Area, Substation Area EtcrendraNo ratings yet

- Additional Hydraulics Fitting Device LR 1400Document3 pagesAdditional Hydraulics Fitting Device LR 1400Anonymous VqTus7QAwNo ratings yet

- Templates 15Document2 pagesTemplates 15j3ark0No ratings yet

- Templates 1125Document2 pagesTemplates 1125j3ark0No ratings yet

- Azucar-Alto SaxDocument2 pagesAzucar-Alto SaxMauricio BautistaNo ratings yet

- Cws Pharmacy BLSTDocument1 pageCws Pharmacy BLSTShemin T JohnNo ratings yet

- Anand Vihar Rrts Station: Cut and CoverDocument1 pageAnand Vihar Rrts Station: Cut and CoverAnonymous USbc7XzsA6No ratings yet

- Sandwich Plates Porting Patterns To DIN 24340 Form A and ISO 440Document44 pagesSandwich Plates Porting Patterns To DIN 24340 Form A and ISO 440Александр БулдыгинNo ratings yet

- Rfi 8Document17 pagesRfi 8Muhamad BagusNo ratings yet

- Closing Ceremonies FileDocument22 pagesClosing Ceremonies FileEvent Safety Management ServiceNo ratings yet

- 01a Foundation Compound WallDocument1 page01a Foundation Compound Walljigarshah21No ratings yet

- Plano Ubic PlotDocument1 pagePlano Ubic Plotantony_3_31No ratings yet

- 120 West 41ST Cellar - C-1Document1 page120 West 41ST Cellar - C-1Shabbir LokhandwalaNo ratings yet

- Trommel Frame 2000 Diax2800 LGDocument3 pagesTrommel Frame 2000 Diax2800 LGFelipe Ignacio100% (1)

- CA01-L-ZL (84) 84CW95.003 - 3.0 - Isometric CA01-L-ZLDocument1 pageCA01-L-ZL (84) 84CW95.003 - 3.0 - Isometric CA01-L-ZLKreshna Wisnu BrataNo ratings yet

- Footing Reinforcement DetailsDocument1 pageFooting Reinforcement DetailsMurthy GunaNo ratings yet

- E-EB-126-rev1 (Deck Plate) - Model.1Document1 pageE-EB-126-rev1 (Deck Plate) - Model.1Joy FernandezNo ratings yet

- CH-BB-DET-EL-33-Transfer Station - Cabling Layout and InterfacesDocument1 pageCH-BB-DET-EL-33-Transfer Station - Cabling Layout and InterfacesMahmoud HusseinNo ratings yet

- Welding Drawing SampleDocument1 pageWelding Drawing Samplerafaellos19No ratings yet

- Kran ProgramDocument1 pageKran ProgramWojciechNo ratings yet

- Floor Area 49.0 SQ.M: A Perspective ViewDocument1 pageFloor Area 49.0 SQ.M: A Perspective ViewAlexis LlarenaNo ratings yet

- Spare Parts Catalog: Pearl DrumsDocument26 pagesSpare Parts Catalog: Pearl Drumsgabriel hongNo ratings yet

- Planos Electricos Del MV 1000Document13 pagesPlanos Electricos Del MV 1000jhon.lunavNo ratings yet

- Sheet No: Sheet Content: Project Owner: Project Title: Project Engineer: Civil Engineer As Shown A 2 Two Storey Residential With Fence BLK 5 Lot 28 Mr&Mrs Joemel A PeradillaDocument1 pageSheet No: Sheet Content: Project Owner: Project Title: Project Engineer: Civil Engineer As Shown A 2 Two Storey Residential With Fence BLK 5 Lot 28 Mr&Mrs Joemel A PeradillaJan Felix DonsalNo ratings yet

- CA01-L-ZL (84) 84CW94.003 - 3.0 - Isometric CA01-L-ZLDocument1 pageCA01-L-ZL (84) 84CW94.003 - 3.0 - Isometric CA01-L-ZLKreshna Wisnu BrataNo ratings yet

- Spo10 Spoa10 Spoa10nb (200 Series) Parts BreakdownDocument4 pagesSpo10 Spoa10 Spoa10nb (200 Series) Parts BreakdownGerardo Del CarpioNo ratings yet

- Hazard Map of CayareDocument1 pageHazard Map of CayareMardainze LabacladoNo ratings yet

- Structural DetailsDocument1 pageStructural DetailsGsUpretiNo ratings yet

- Panel LP8-10Document7 pagesPanel LP8-10electra munasirNo ratings yet

- FT 101NH Celda S AceroDocument1 pageFT 101NH Celda S Acerojesusoriano2008No ratings yet

- Campus Parking MapDocument1 pageCampus Parking MapXunyi LiaoNo ratings yet

- Typical Main Gate Sunshade DetailDocument1 pageTypical Main Gate Sunshade Detailkafoury80No ratings yet

- E-EB-126-rev1 (Deck Plate) - Model1Document1 pageE-EB-126-rev1 (Deck Plate) - Model1Joy FernandezNo ratings yet

- Area 2 Area 1 Area 3: OD ODDocument21 pagesArea 2 Area 1 Area 3: OD ODHNmaichoiNo ratings yet

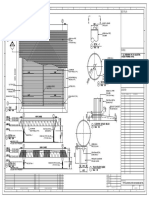

- 40 MLD SBR Air Blower Break Tank - R1, Sheet-2Document1 page40 MLD SBR Air Blower Break Tank - R1, Sheet-2pratikNo ratings yet

- Painted Panels: Ventilation HoleDocument2 pagesPainted Panels: Ventilation HoleAli ZubairNo ratings yet

- PB 950 A WB: The Netherlands Tel.: (+31) 854 868 200 Palfinger Boats BV Pasteurdijk 8 3846 BS HarderwijkDocument1 pagePB 950 A WB: The Netherlands Tel.: (+31) 854 868 200 Palfinger Boats BV Pasteurdijk 8 3846 BS HarderwijkAhmet GelişliNo ratings yet

- 5 STRTLLStorey Yang ModelDocument1 page5 STRTLLStorey Yang ModelKessler BiatingoNo ratings yet

- UCONNParade Routeand Parking 2011 NEWDocument1 pageUCONNParade Routeand Parking 2011 NEWJeff BustraanNo ratings yet

- Site Plan: Jl. Trans Tolitoli-PaluDocument1 pageSite Plan: Jl. Trans Tolitoli-PaluHaryo TantularNo ratings yet

- 01 Setting Stub Dd2 BorepileDocument1 page01 Setting Stub Dd2 BorepileAwii YunusNo ratings yet

- Lighting Layout All 27-01-2023 - Updated Final-ModelDocument1 pageLighting Layout All 27-01-2023 - Updated Final-ModelOmer SharifNo ratings yet

- ISOMETRIC - 10in-W-60348-C086100F2-A - (T)Document1 pageISOMETRIC - 10in-W-60348-C086100F2-A - (T)Jason UchennnaNo ratings yet

- Typical Road Cross Section: Typical Box Culvert DetailsDocument1 pageTypical Road Cross Section: Typical Box Culvert DetailsSam GalangNo ratings yet

- Paint Workshop-3: Braced Bay Braced BayDocument1 pagePaint Workshop-3: Braced Bay Braced BayZarkKhanNo ratings yet

- Belt Drive LH: Projectionsmeth.1 ISO5456-2Document1 pageBelt Drive LH: Projectionsmeth.1 ISO5456-2Traian SerbanNo ratings yet

- 940.00-C-001 - Typical Detail Fence Detail - r4Document1 page940.00-C-001 - Typical Detail Fence Detail - r4Teresa DspNo ratings yet

- Rahul Sardana - JEE Advanced Physics-Waves and Thermodynamics-Pearson India Education Services Pvt. LTDocument934 pagesRahul Sardana - JEE Advanced Physics-Waves and Thermodynamics-Pearson India Education Services Pvt. LTaeroenthusiastaltalt100% (1)

- Page 1Document1 pagePage 1JUN JUN ANCHETANo ratings yet

- Manhole Detail. Proposal 2Document1 pageManhole Detail. Proposal 2Mohammed BasheeruddinNo ratings yet

- C03 CRF-0050: Ac Markup Pump & Tank Room LGB01Document1 pageC03 CRF-0050: Ac Markup Pump & Tank Room LGB01Hermogenes Mejia Jr.No ratings yet

- KompresorDocument1 pageKompresorVraja DasiNo ratings yet

- Lote Señora Olinda Alvarez (1) - Medio PliegoDocument1 pageLote Señora Olinda Alvarez (1) - Medio PliegoAlfredo VareloNo ratings yet

- T Ird Rpan: A B C 7 D EDocument1 pageT Ird Rpan: A B C 7 D EJOHN CARLO AZORESNo ratings yet

- Practice 7-3: PXM WAL by SASDocument1 pagePractice 7-3: PXM WAL by SASsarayaNo ratings yet

- 2 - GRE - EEC.D.99.CO.P.15853.16.071.00 - ApantallamientoDocument6 pages2 - GRE - EEC.D.99.CO.P.15853.16.071.00 - ApantallamientoJuan Camilo Corena GómezNo ratings yet

- Opusk SalesKit Print 021122-13Document1 pageOpusk SalesKit Print 021122-13trungNo ratings yet

- Book ADocument2 pagesBook ABetchay TuazonNo ratings yet

- Mri Revised Upper Basement ModelDocument1 pageMri Revised Upper Basement ModelPinaky GuhaNo ratings yet

- Oceans ViolãoDocument3 pagesOceans ViolãoCristyan ReisNo ratings yet

- AnunciaçãoDocument1 pageAnunciaçãoCristyan ReisNo ratings yet

- Oceans AcoustDocument3 pagesOceans AcoustCristyan ReisNo ratings yet

- Oceanos OceansDocument6 pagesOceanos OceansCristyan ReisNo ratings yet

- Wsc2015 Tp10 Ss Us Isoe PreDocument1 pageWsc2015 Tp10 Ss Us Isoe PreCristyan ReisNo ratings yet

- Wsc2015 Tp10 PV TW Symbols Iso e PreDocument1 pageWsc2015 Tp10 PV TW Symbols Iso e PreCristyan ReisNo ratings yet

- Wsc2015 Tp10 Ss Us Isoa PreDocument1 pageWsc2015 Tp10 Ss Us Isoa PreCristyan ReisNo ratings yet

- Wsc2015 Tp10 PV TW Assembly Iso e PreDocument1 pageWsc2015 Tp10 PV TW Assembly Iso e PreCristyan ReisNo ratings yet

- Wsc2015 Tp10 Al TW Iso A PreDocument1 pageWsc2015 Tp10 Al TW Iso A PreCristyan ReisNo ratings yet

- Wsc2015 Tp10 PV TW Symbols Iso A PreDocument1 pageWsc2015 Tp10 PV TW Symbols Iso A PreCristyan ReisNo ratings yet

- Wsc2015 Tp10 PV TW Partslist Iso A PreDocument1 pageWsc2015 Tp10 PV TW Partslist Iso A PreCristyan ReisNo ratings yet

- Wsc2015 Tp10 Al TW Iso e PreDocument1 pageWsc2015 Tp10 Al TW Iso e PreCristyan ReisNo ratings yet

- Wsc2015 Tp10 PV TW Assembly Iso A PreDocument1 pageWsc2015 Tp10 PV TW Assembly Iso A PreCristyan ReisNo ratings yet

- Catalog Ore Tent or ADocument24 pagesCatalog Ore Tent or ACristyan ReisNo ratings yet

- Advanced Oil Gas Accounting International Petroleum Accounting International Petroleum Operations MSC Postgraduate Diploma Intensive Full TimeDocument70 pagesAdvanced Oil Gas Accounting International Petroleum Accounting International Petroleum Operations MSC Postgraduate Diploma Intensive Full TimeMoheieldeen SamehNo ratings yet

- Flight Data Recorder Rule ChangeDocument7 pagesFlight Data Recorder Rule ChangeIgnacio ZupaNo ratings yet

- Gobekli TepeDocument2 pagesGobekli TepeCarl Feagans100% (1)

- Ppap - 2556 PDFDocument7 pagesPpap - 2556 PDFMohamed ElmakkyNo ratings yet

- MEMORANDUM OF AGREEMENT DraftsDocument3 pagesMEMORANDUM OF AGREEMENT DraftsRichard Colunga80% (5)

- Lab Science of Materis ReportDocument22 pagesLab Science of Materis ReportKarl ToddNo ratings yet

- P01 - PT in Building & Its AdvantagesDocument11 pagesP01 - PT in Building & Its AdvantagesPartha Pratim RoyNo ratings yet

- Fce Use of English 1 Teacher S Book PDFDocument2 pagesFce Use of English 1 Teacher S Book PDFOrestis GkaloNo ratings yet

- Session 10. Value Proposition.Document69 pagesSession 10. Value Proposition.Bibhu R. TuladharNo ratings yet

- Joomag 2020 06 12 27485398153Document2 pagesJoomag 2020 06 12 27485398153Vincent Deodath Bang'araNo ratings yet

- Dependent ClauseDocument28 pagesDependent ClauseAndi Febryan RamadhaniNo ratings yet

- 5 Ways To Foster A Global Mindset in Your CompanyDocument5 pages5 Ways To Foster A Global Mindset in Your CompanyGurmeet Singh KapoorNo ratings yet

- Sheetal PatilDocument4 pagesSheetal PatilsheetalNo ratings yet

- Rapp 2011 TEREOS GBDocument58 pagesRapp 2011 TEREOS GBNeda PazaninNo ratings yet

- PCM Cables: What Is PCM Cable? Why PCM Cables? Application?Document14 pagesPCM Cables: What Is PCM Cable? Why PCM Cables? Application?sidd_mgrNo ratings yet

- 4039-Texto Del Artículo-12948-3-10-20211123Document14 pages4039-Texto Del Artículo-12948-3-10-20211123Ricardo ApazaNo ratings yet

- Clinical Skills TrainingDocument12 pagesClinical Skills TrainingSri Wahyuni SahirNo ratings yet

- Institutions and StrategyDocument28 pagesInstitutions and StrategyFatin Fatin Atiqah100% (1)

- Blackbook 2Document94 pagesBlackbook 2yogesh kumbharNo ratings yet

- Sociology A Brief Introduction Canadian Canadian 5th Edition Schaefer Test Bank DownloadDocument44 pagesSociology A Brief Introduction Canadian Canadian 5th Edition Schaefer Test Bank DownloadJohn Blackburn100% (20)

- 2015 NSPC Proposed Changes Book PDFDocument268 pages2015 NSPC Proposed Changes Book PDFMichelle Pinohermoso JabatNo ratings yet

- Thermodynamics WorksheetDocument5 pagesThermodynamics WorksheetMalcolmJustMalcolmNo ratings yet

- What Is The PCB Shelf Life Extending The Life of PCBsDocument9 pagesWhat Is The PCB Shelf Life Extending The Life of PCBsjackNo ratings yet

- Writ Petition 21992 of 2019 FinalDocument22 pagesWrit Petition 21992 of 2019 FinalNANDANI kumariNo ratings yet

- The DIRKS Methodology: A User GuideDocument285 pagesThe DIRKS Methodology: A User GuideJesus Frontera100% (2)

- Study Notes - Google Project Management Professional CertificateDocument4 pagesStudy Notes - Google Project Management Professional CertificateSWAPNIL100% (1)

- 15 Miscellaneous Bacteria PDFDocument2 pages15 Miscellaneous Bacteria PDFAnne MorenoNo ratings yet

- DBM Uv W ChartDocument2 pagesDBM Uv W ChartEddie FastNo ratings yet

- Bharti Airtel Strategy FinalDocument39 pagesBharti Airtel Strategy FinalniksforloveuNo ratings yet

- SHS G11 Reading and Writing Q3 Week 1 2 V1Document15 pagesSHS G11 Reading and Writing Q3 Week 1 2 V1Romeo Espinosa Carmona JrNo ratings yet