Professional Documents

Culture Documents

BoxBeamBench PDF

Uploaded by

giacummoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BoxBeamBench PDF

Uploaded by

giacummoCopyright:

Available Formats

Box-Beam

Bench

A master's bench

that anyone can build.

by Tom Caspar

Inexpensive materials Rigid construction Absolutely flat top

A bunch of 2x4s, a little 3/4" poplar, one The base is a box that’s skinned with This is critical for a good bench, but not

sheet each of 3/4" MDF and 1/4" birch— plywood. (The ends and top are removed hard to make. The base is designed to

that’s all you’ll need. here). It won’t rack, bend or twist. keep the top from sagging.

30 AmericanWoodworker.com OCTOBER/NOVEMBER 2011

15630_ThriftyWorkBench_F.indd 30 8/2/11 4:58 PM

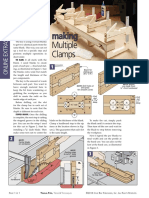

BUILDING A SERIOUS WORKBENCH Make a flat 1

is a rite of passage for many wood- assembly

workers. It’s usually an ambitious table—it’s

essential for

project requiring a lot of skill, lum-

building this

ber, time, money and tools—but it bench. A

doesn’t have to be that hard. Here’s hollow-core

an alternative. door placed

This bench is every bit as good as on a pair of

one that costs thousands of dollars. sawhorses

It’s rigid, heavy and dead flat. Its vises works well.

offer all the holding power you need. Screw some

But you can build it on a budget in a boards to one

short time. You don’t have to make corner to help

complicated joints or use big equip- keep your

work square.

ment. It’s a bench for everyone.

How tall should it be?

When you use a plane, a bench

should be about wrist height. When

you use a router or a sander, it should

ILLUSTRATION: FRANK ROHRBACH

be about two to three inches taller. Build a pair

of frames on 2

This bench works for both hand tools

the assembly

and power tools: You can easily raise

table. Clamp

or lower it with two removable riser their sides to

blocks (see center photo, below). It’s the corner

equally sturdy at both heights. pieces to

As designed, the bench is quite make sure

low—about right for a hand-tool each frame is

user who is 5' 8" tall. If you’re taller, square.

|

or if you don’t need a low, hand-

PHOTOGRAPHY: JASON ZENTNER

tool-friendly bench, just make the

feet twice as thick or add tall blocks

underneath them. (The bench's

base is made from a single sheet

of plywood, and is about as tall as

it can be without cutting into a sec-

ond sheet.)

Clamping room Adjustable height Storage option

The top has a big overhang so there’s To raise the bench for use with power You can add a drawer unit later on, if you

plenty of room for clamping. Its underside tools, just lift each end and scoot an wish. It passes right through the hollow

is flat, too—there’s no annoying lip. additional foot underneath. center of the base.

OCTOBER/NOVEMBER 2011 AmericanWoodworker.com 31

15630_ThriftyWorkBench_F.indd 31 8/2/11 4:59 PM

Fig. A Exploded View

C1

C3

C2 C8

C4

C6

C7

C5

2-1/2" L A3 A3 A5

#9 F.H., (TYP.)

A4

A 13

A7

B3

1-1/4" #8 SCREW (TYP.)

A9

B1

A 12

B2

B7 3/8" LAG SCREW

2-1/2" L. (TYP.)

A 10

B5 A2

A1

B6

B4

A 11

2-1/2" L

#9 F.H., (TYP.)

A6

A7

A8 For a closer look at this bench, and more

Fig. B Frame Detail information on adding a storage cabinet, go to

AmericanWoodworker.com/WebExtras

7/8"

3/8" DIA. HOLE Fig. C Cleat Detail

1-3/8"

2-1/2" L 1/2" 3 1

1- /8" DIA. COUNTERBORE, /2" DEEP

#9 F.H.,

(TYP.)

A5 A4 A3

2-1/2" L., 6" A7

#9 F.H. (TYP.)

32 AmericanWoodworker.com OCTOBER/NOVEMBER 2011

15630_ThriftyWorkBench_F.indd 32 8/2/11 4:59 PM

Materials Stiffen each 3

I’ve designed this bench to keep the frame with

cost way down—so you can afford an oversize

two very nice vises. All of the mate- skin of 1/4"

plywood. Glue

rials are available at a home center.

and screw

I’ve squeezed the sheetstock pieces the plywood

out of one sheet of 1/4" birch ply- to the frame,

wood and one sheet of 3/4" MDF. then rout the

Most of the solid-wood pieces can be plywood flush

made from fir 2x4s; the others are all around.

poplar 1x4s.

The 2x4s must be dry (6% to 8%

MC). Dimensional lumber doesn’t

come that dry, however; you’ll have

to plan ahead and wait at least six

months for the wood to dry out

before using it. In addition, the 2x4s

must be flat and straight. You’ll have

to joint or plane the wood after it’s

dry—the cutting list dimensions

allow for this. Make the

If you’d like to get started right cleats that will 4

tie the frames

away, there are two alternatives to

together. Glue

2x4s. First, you could glue poplar an extra-

1x4s together to make the 2x4 mate- wide spacer

rial; they’re dry enough straight from onto each

the store. (You wouldn’t have to joint piece, then

or plane them, either.) Second, you rout its sides

could buy 6/4 (1-1/2") kiln-dried flush with

yellow poplar and have a lumberyard a laminate

joint and plane it for you. Milling the trimmer.

lumber yourself usually yields the

best results, though.

If you have the budget and a

jointer and a planer, roughsawn

poplar would be the best choice for

building this bench. That’s what I

used in all the construction photos.

Build the base

Before you begin, buy the vises (see

Source, page 36). Make sure they’ll your tablesaw, cut rabbets on the

fit in the space allotted (Fig. F). Many ends of the rails (A1, Fig. B). Glue Shopping List

different vises will work, but some and screw the rails to the stiles (A2), Lumber

may require more room. If that’s the one corner at a time (Photo 2). • 50 linear feet 2x4

case, reposition a few bench parts to Make sure their faces are flush. Build • 1 sheet 3/4" MDF

free up more space. two of these frames. • 1 sheet 1/4" birch plywood

The key to successfully build- Cut the plywood panels (A9) • 8 linear feet of 3/4" x 4" hardwood,

ing this bench is to work on a large for the frames (Photo 3, Fig. D). not including vise faces

surface that is truly flat. I recom- Note that they’re slightly oversize.

mend using a 30" hollow-core door Place the panels on the frames and Hardware

• 2 boxes of 1-3/8" deck screws

(Photo 1). It’s inexpensive, easy to drill pilot holes for the screws, spac-

• 1 box of 2-1/2" deck screws

move and store, and will come in ing them about 5" to 6" apart. Glue • 8 lag screws, 3/8" x 2"

handy for building many other proj- and screw the panels to the frames. • 8 washers, 3/8" i.d.

ects. Fasten two boards to the sides After the glue dries, use a router and • 4 lag screws, 5/16" x 3" (for face vise)

of the door to form a square corner. a flush-trim bit to make the panels • 4 lag screws, 5/16" x 2-1/2" (for end vise)

Start by milling all the solid-wood even with the frames. • 16 washers, 5/16" i.d. (double them up)

parts for the base (A1–A8). Cut them Make the cleats (A3, A4 and A5) • 5 #14 x 2" FH screws (for face vise)

to final length. Using a dado set in and feet (A6) by gluing spacers (A7)

OCTOBER/NOVEMBER 2011 AmericanWoodworker.com 33

15630_ThriftyWorkBench_F.indd 33 8/2/11 4:59 PM

Cutting List Overall Dimensions: 32-7/8" H x 23" W x 59" L (35" H with optional riser) Fig. D 1/4" Plywood Cutting Diagram

Section Part Name Qty. Material Th x W x L

Base A1 Rail 4 2x4 1-3/8" x 3-1/4" x 43"

A2 Stile 4 2x4 1-3/8" x 3-1/4" x 25-3/8" A9

A3 Cleat 1 2 2x4 1-3/8" x 3-1/4" x 21"

A4 Cleat 2 1 2x4 1-3/8" x 3-1/4" x 18"

A5 Cleat 3 1 2x4 1-3/8" x 3-1/4" x 15" B7 B7

A6 Foot 2 2x4 1-3/8" x 3-1/4" x 21" C6 C6

A7 Spacer 6 3/4" hardwood 3/4" x 3-1/4" x 4-5/8" (a) A 14

A8 Pad 4 3/4" hardwood 3/4" x 3-1/4" x 4" (a)

A9 Front and back panel 2 1/4" birch ply 1/4" x 27-1/8" x 43" (b) A1 3 A1 1

A10 End panel 2 1/4" birch ply 1/4" x 11-5/8" x 29-7/8" (c) A10 A10

A11 Bottom panel 1 1/4" birch ply 1/4" x 11-5/8" x 36-1/2" (c) A1 2

A12 Top panel 1 1 1/4" birch ply 1/4" x 11-1/2" x 13"

A13 Top panel 2 1 1/4" birch ply 1/4" x 11-1/2" x 14-1/4"

A14 Top panel 3 1 1/4" birch ply 1/4" x 11-1/2" x 2-3/4"

Brace B1 Inner stile 1 2x4 1-3/8" x 3-1/4" x 27-1/8" A9

B2 Outer stile 1 2x4 1-3/8" x 3-1/4" x 19"

B3 Arm 1 2x4 1-3/8" x 3-1/4" x 11"

B4 Box top and bottom 2 2x4 1-3/8" x 2-3/4" x 2-3/4"

B5 Box side, short 1 2x4 1-3/8 x 2-3/4" x 10"

B6 Box side, long 1 2x4 1-3/8" x 2-3/4" x 12" Fig. E 3/4" MDF Cutting Diagram

B7 Face 2 1/4" birch ply 1/4" x 5-1/2" x 10" (b)

Top C1 Top 1 MDF 3/4" x 23" x 59"

C2 Center, end 2 MDF 3/4" x 12" x 23-1/4" (c) C2 C2

C3 Center, middle 2 MDF 3/4" x 11-5/8" x 35-1/4" (d)

C4 Bottom 1 MDF 3/4" x 23-1/4" x 59-1/4" (d) C3 C5

C5 Face vise platform 2 MDF 3/4" x 11-1/2" x 13-1/2" (d)

C6 End vise platform 2 1/4" birch ply 1/4" x 4-1/4" x 9-1/8" (d) C3 C5

C7 Face vise front 1 3/4" hardwood 3" x 6-1/4" x 15"

C8 End vise face 2 3/4" hardwood 3/4" x 3" x 7"

Riser D1 Foot 2 2x4 1-3/8" x 3-1/4" x 21"

D2 Spacer 2 3/4" hardwood 5/8" x 3-1/4" x 13"

D3 Pad 4 3/4" hardwood 3/4" x 3-1/4" x 4"

D4 Side 8 3/4" hardwood 3/4" x 2-3/4" x 4"

C1 C4

Notes:

a) Rip at 3-3/8" wide, then glue to mating piece.

b) This is the final size. Rough-cut 1/4" oversize in length and width. Glue to mating

surfaces, then rout flush.

c) Rough-cut 1/4" oversize in width only.

d) This is the rough-cut size. Glue to mating piece with 1/8" overhang, then rout flush.

Fig. F

Top View of Base 1"

3/8" 2-1/2"

VISE

PLATFORM

16-1/4" 3/4" DIA. DOG 6"

VISE HOLE (TYP.)

PLATFORM

16" AREA FOR

FACE VISE 5-1/2" (TYP.)

AREA FOR

END VISE 7-1/4"

3-3/4"

1"

1 1 - 3/8" 10-1/2"

SET BACK VISE HARDWARE

7/8" FROM FRONT EDGE

34 AmericanWoodworker.com OCTOBER/NOVEMBER 2011

15630_ThriftyWorkBench_F.indd 34 8/2/11 4:59 PM

to each piece (Fig. C). Be sure that Assemble the

box beam by

5

the spacers are positioned square to

the piece underneath. Trim the spac- gluing and

screwing the

ers flush (Photo 4). Drill holes in the

cleats to the

cleats for fastening them to the top frames. Again,

with lag screws. it’s essential

Drill and countersink pilot holes to do this on

in the cleats and feet (see Fig. F for the assembly

hole locations). Clamp up the base table, so the

without glue, making sure that the base stays flat.

ends of the frames are flush with

the sides of the outer cleats and feet.

Continue drilling the pilot holes into

the frames. Remove all four cleats,

then glue and screw the outer ones

only (Photo 5).

All of the pieces that support the

top of this bench must be level with

each other. If they’re not, the top will

eventually sag. (It’s made from MDF,

which isn’t as stiff as solid wood.)

Place the two middle cleats in posi-

tion and make sure they’re level with

the outer cleats (Photo 6). If your

frame members are straight, every-

thing should be fine. If the middle

cleats are low, shim them with paper;

if they’re high, sand or plane them

thinner. Glue the cleats in place.

Turn over the base and glue and

screw the feet. Glue and screw pads

(A8) under the feet, then trim them

flush. Cut the end panels (A10), glue

and screw them to the base, then

trim their sides flush. Cut the bottom

panel (A11). Glue and screw it to the Buy the book

base, then trim flush. Turn the base

over and add the top panels (A12,

“How to Make Workbenches and Shop Storage Solutions”

A13 and A14). at awbookstore.com

Add the brace on the left end of

the base. Cut all the solid wood parts Sight across

(B1–B6). Glue the box parts (B4, the top of the 6

B5 and B6). Cut the plywood faces box beam

(B7) and glue them to the box. Trim with the

flush. Glue and screw the box to the middle cleats

inner stile (B1). Screw the inner stile in place—

and box to the base; note that the before gluing

top of this part sits below the base them on.

by the thickness of the arm (B3, Fig. Everything

must be level.

A). Clamp the outer stile (B2) to the

box’s long side (B6). Place the arm

in position and adjust the outer stile

until the arm is level. Screw the outer

stile and arm in place.

Make the riser blocks (D1–D4,

Fig. G). You can make these any

height you wish. They should fit

tight, so the bench won’t wiggle.

OCTOBER/NOVEMBER 2011 AmericanWoodworker.com 35

15630_ThriftyWorkBench_F.indd 35 8/2/11 4:59 PM

7 Assemble the Build the top

top in stages. Cut all of the top pieces (C1–C6, Fig.

It’s composed E) to size. You’ll be building the top

of three layers in stages, upside down. Each layer

of MDF. Use is glued to the piece below using

lots of screws 1-1/4" screws as clamps (Photo 7).

as miniature To begin, place the top (C1) on the

clamps to

assembly table, then place the cen-

apply even

pressure when ter pieces (C2 and C3) in position

you glue and make sure they fit snug.

the pieces Draw grids on these pieces to

together. locate the screws; the lines should be

3/4" in from each edge and spaced

about 4" to 5" apart. Clamp the four

pieces to the top and pre-drill 1-1/4"

deep holes for all the screws. Coun-

tersink the holes. Remove the center

pieces and lightly countersink the

opposite side of the holes, plus the

holes in the top piece. This guaran-

8 Rout the tees that the pieces will lie flat when

pieces flush. you screw them together.

Remove the Glue and screw the center pieces,

screws, then one at a time. Apply the glue with

add the next a small paint roller. After the glue

layer. The dries, trim the edges flush (Photo 8).

result is a top Remove the screws and repeat the

that’s dead same process for the bottom piece

flat—and the (C4) and the platforms for the face

box-beam

vise (C5) and end vise (C6).

base will keep

it that way. Add the vises while the top is

upside down. One note on the

face vise: The front (C7) must be

tapered, top to bottom (Fig. H).

This ensures that the top of the vise

pinches first as it closes. Make the

taper by taping a 1/8" shim under

one side of the face, then run the

block through a planer.

The top of the face vise should

be flush with the top of the bench.

Fig. H End View of Vise’s Face Drill the mounting holes in the

For more information on buying 2-7/8"

a vise for your workbench, go to vise face so it sits about 1/16"

above the benchtop, then level the

AmericanWoodworker.com/WebExtras

vise’s top after it is installed. Follow

TOP the same procedure with the end

ROUND OVER ALL OF VISE

vise faces (C8).

INNER EDGES Fasten the top to the base. Drill

Fig. G Riser 6-1/4"

pilot holes 1/8" deeper than the full

length of the lag screws. Drill holes

D2 FRONT for the bench dog, making sure they

OF VISE

D1 don’t hit any of the cleats. (These

holes must be plumb; make a 1-3/8"

thick guide block and use a drill

2-3/4"

SOURCE press to drill a 3/4" hole through

Woodcraft Supply, woodcraft.com, it.) Finish the top with three coats

D4 800-225-1153, Large Front Vise, #144805, $76.99; Handle, of oil-based poly.

17E52, $6.99; 7" Quick Release Bench Vise, #152633, $99.99;

D3 Pinnacle Brass Bench Dogs, 3/4" dia., #151101, $29.99.

36 AmericanWoodworker.com OCTOBER/NOVEMBER 2011

15630_ThriftyWorkBench_F.indd 36 8/8/11 10:51 AM

You might also like

- Woodworker's Guide to Handplanes: How to Choose, Setup and Master the Most Useful Planes for Today's WorkshopFrom EverandWoodworker's Guide to Handplanes: How to Choose, Setup and Master the Most Useful Planes for Today's WorkshopRating: 5 out of 5 stars5/5 (3)

- Traditional Wooden Handplanes: How to Restore, Modify & Use Antique PlanesFrom EverandTraditional Wooden Handplanes: How to Restore, Modify & Use Antique PlanesRating: 5 out of 5 stars5/5 (1)

- The Pochade and Wet Panel Carrier Do It Yourself PlanFrom EverandThe Pochade and Wet Panel Carrier Do It Yourself PlanRating: 4 out of 5 stars4/5 (1)

- Make Your Own Toolbox: A Woodworker’s Guide to Building Chests, Cases & CabinetsFrom EverandMake Your Own Toolbox: A Woodworker’s Guide to Building Chests, Cases & CabinetsNo ratings yet

- Cabinet Making for Beginners - Tools, Joints, Cabinet Construction, Veneering and Inlaying, Drawing, Cutting Lists, Etc., Timber, Fittings, Typical DesignsFrom EverandCabinet Making for Beginners - Tools, Joints, Cabinet Construction, Veneering and Inlaying, Drawing, Cutting Lists, Etc., Timber, Fittings, Typical DesignsRating: 5 out of 5 stars5/5 (2)

- Classic Plan: Artist's EaselDocument5 pagesClassic Plan: Artist's Easelwhorne240% (1)

- Woodwork Joints: How They Are Set Out, How Made and Where UsedFrom EverandWoodwork Joints: How They Are Set Out, How Made and Where UsedNo ratings yet

- Panel Door 1Document67 pagesPanel Door 1bugsy77100% (1)

- HowWoodWords PDFDocument4 pagesHowWoodWords PDFJavier D100% (1)

- Lie-Nielsen Studio BenchDocument2 pagesLie-Nielsen Studio BenchSameh SamehNo ratings yet

- A Little Book of Vintage Designs and Instructions for Making Dainty Gifts from Wood. Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box: Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box.From EverandA Little Book of Vintage Designs and Instructions for Making Dainty Gifts from Wood. Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box: Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box.No ratings yet

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- Getting Started with Handplanes: How to Choose, Set Up, and Use Planes for Fantastic ResultsFrom EverandGetting Started with Handplanes: How to Choose, Set Up, and Use Planes for Fantastic ResultsRating: 1 out of 5 stars1/5 (1)

- 10 Best Handscrew TipsDocument5 pages10 Best Handscrew TipsMitnel Satory100% (1)

- Moxon's Ingenious Bench Vise: Jig JournalDocument2 pagesMoxon's Ingenious Bench Vise: Jig Journaloqab18100% (1)

- Woodworker's Journal - Vol.01 No.1 Jan-Feb 1977Document16 pagesWoodworker's Journal - Vol.01 No.1 Jan-Feb 1977BeingNo ratings yet

- The Woodwright's Workbook: Further Explorations in Traditional WoodcraftFrom EverandThe Woodwright's Workbook: Further Explorations in Traditional WoodcraftRating: 4.5 out of 5 stars4.5/5 (4)

- Making A Wooden MalletDocument11 pagesMaking A Wooden MalletKoki MostafaNo ratings yet

- Handwork Issue 5Document131 pagesHandwork Issue 5andrew_phelps100% (1)

- Good Woodworking - February 2017Document92 pagesGood Woodworking - February 2017Omer Cetinkaya100% (1)

- The Woodwright's Apprentice: Twenty Favorite Projects From The Woodwright's ShopFrom EverandThe Woodwright's Apprentice: Twenty Favorite Projects From The Woodwright's ShopRating: 4.5 out of 5 stars4.5/5 (6)

- How To Saw Log For Woodturning BlanksDocument5 pagesHow To Saw Log For Woodturning Blankscadman013100% (2)

- Roy Underhill's The Woodwright's Shop Classic Collection, Omnibus E-book: Includes The Woodwright's Shop, The Woodwright's Companion, and The Woodwright's WorkbookFrom EverandRoy Underhill's The Woodwright's Shop Classic Collection, Omnibus E-book: Includes The Woodwright's Shop, The Woodwright's Companion, and The Woodwright's WorkbookRating: 4 out of 5 stars4/5 (1)

- Popular Woodworking - 016 - 1984 PDFDocument52 pagesPopular Woodworking - 016 - 1984 PDFKawchhar Ahammed100% (1)

- Woodworker's Journal 41-03 (June 2017)Document88 pagesWoodworker's Journal 41-03 (June 2017)davidsternleader5768100% (1)

- The Essential Handsaw Book: Projects & Techniques for Mastering a Timeless Hand ToolFrom EverandThe Essential Handsaw Book: Projects & Techniques for Mastering a Timeless Hand ToolNo ratings yet

- Drawer Book-Runners Guides KickersDocument12 pagesDrawer Book-Runners Guides KickersDillon HartsykerNo ratings yet

- Bandsaw Circle JigDocument3 pagesBandsaw Circle Jigphilipisaia100% (1)

- DPROJ02Document13 pagesDPROJ02VhomBoris75% (4)

- Good Woodworking July 2015 PDFDocument92 pagesGood Woodworking July 2015 PDFJd DiazNo ratings yet

- Principles & Practice of Ornamental or Complex TurningFrom EverandPrinciples & Practice of Ornamental or Complex TurningNo ratings yet

- Woodcarving Illustrated Issue 42 Spring 2008From EverandWoodcarving Illustrated Issue 42 Spring 2008No ratings yet

- American Woodworker No 112 January 2005Document66 pagesAmerican Woodworker No 112 January 2005sibalde100% (1)

- Wooden Utensils from the Bandsaw: 60+ Patterns for Spatulas, Spoons, Spreaders & MoreFrom EverandWooden Utensils from the Bandsaw: 60+ Patterns for Spatulas, Spoons, Spreaders & MoreNo ratings yet

- American Woodworker - 079-2000-04Document74 pagesAmerican Woodworker - 079-2000-04api-19759721100% (3)

- The Woodworker Woodturner - January 2020Document102 pagesThe Woodworker Woodturner - January 2020carlos latreNo ratings yet

- Breadboard EndsDocument5 pagesBreadboard Endssamwise garimella100% (1)

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Comfort in A Morris Chair: Craftsman-StyleDocument5 pagesComfort in A Morris Chair: Craftsman-Stylegromov.kirill1No ratings yet

- 10 Best Table Saw AccessoriesDocument6 pages10 Best Table Saw AccessoriesAntônio Castro100% (2)

- Portable Dovetail Jig WorkcenterDocument8 pagesPortable Dovetail Jig Workcentergmand6850% (2)

- American Woodworker - 101-2003-07Document62 pagesAmerican Woodworker - 101-2003-07api-19759721100% (2)

- How to Build Garden Furniture: Plans and Complete Instructions for Making Lawn Chairs, Benches, Settees and a Chaise Longue, Tables, Dinettes and Picnic Sets, Portable and Folding Pieces of All Kinds for Outdoor UseFrom EverandHow to Build Garden Furniture: Plans and Complete Instructions for Making Lawn Chairs, Benches, Settees and a Chaise Longue, Tables, Dinettes and Picnic Sets, Portable and Folding Pieces of All Kinds for Outdoor UseNo ratings yet

- A Guide to the Carpentry Skills Needed in Historic Aircraft Construction - A Step by Step Guide for the Amateur CarpenterFrom EverandA Guide to the Carpentry Skills Needed in Historic Aircraft Construction - A Step by Step Guide for the Amateur CarpenterNo ratings yet

- Jig Maker's Toolkit: Stock Up On This Ti Me-Saving Collecti On of Important IngredientsDocument6 pagesJig Maker's Toolkit: Stock Up On This Ti Me-Saving Collecti On of Important IngredientsJd Diaz100% (1)

- Circular Saw Cutting GuidesDocument1 pageCircular Saw Cutting Guidesava_lana100% (1)

- Traditional Country Woodworking Projects: Plans for 18 Practical Indoor and Outdoor ProjectsFrom EverandTraditional Country Woodworking Projects: Plans for 18 Practical Indoor and Outdoor ProjectsNo ratings yet

- The Woodworker Amp Woodturner - May 2022Document102 pagesThe Woodworker Amp Woodturner - May 2022Pere Ferran AndugarNo ratings yet

- W0 Odshop N3 Ws November 2016Document76 pagesW0 Odshop N3 Ws November 2016starpulseNo ratings yet

- Canadian Woodworking 015 (December 2001-January 2002) PDFDocument44 pagesCanadian Woodworking 015 (December 2001-January 2002) PDFluis murilloNo ratings yet

- Lee Valley - A Deluxe Chisel CabinetDocument6 pagesLee Valley - A Deluxe Chisel Cabinetzedric100% (1)

- Kepler Bottom Bracket Friction Drive For Sale (Finally) - Endless SphereDocument34 pagesKepler Bottom Bracket Friction Drive For Sale (Finally) - Endless SpheregiacummoNo ratings yet

- Flint: A Boat For Oars, Sail, and Small OutboardDocument11 pagesFlint: A Boat For Oars, Sail, and Small OutboardgiacummoNo ratings yet

- How DNA Replicates: by Matthew Meselson and Frank StahlDocument30 pagesHow DNA Replicates: by Matthew Meselson and Frank StahlgiacummoNo ratings yet

- CRISPR Cas Bacterial Adaptive ImmunityDocument50 pagesCRISPR Cas Bacterial Adaptive ImmunitygiacummoNo ratings yet

- PocketShip Study Plans 1A9322Document10 pagesPocketShip Study Plans 1A9322giacummo100% (1)

- Synthetic Guide RNA For CRISPR Genome EditingDocument9 pagesSynthetic Guide RNA For CRISPR Genome EditinggiacummoNo ratings yet

- 3.7 Farr Sail - Original MoelDocument1 page3.7 Farr Sail - Original MoelgiacummoNo ratings yet

- Russia in Space Part IIIDocument6 pagesRussia in Space Part IIIgiacummoNo ratings yet

- Russia in Space Part IIIDocument6 pagesRussia in Space Part IIIgiacummoNo ratings yet

- Drum Sander Plans - WoodArchivistDocument9 pagesDrum Sander Plans - WoodArchivistErics100% (1)

- Jig-Fixture DesignDocument11 pagesJig-Fixture DesignVikramChauhanNo ratings yet

- Sonai ProjectDocument1 pageSonai Projectrahulgalande005No ratings yet

- 8th Grade Safety TestDocument5 pages8th Grade Safety TestcankuhnNo ratings yet

- Homemade Bandsaw Plans - YouTubeDocument3 pagesHomemade Bandsaw Plans - YouTubeStaroth Gonz Rodr100% (4)

- Lecture 2 - Week 3 - Hand ToolsDocument23 pagesLecture 2 - Week 3 - Hand ToolsSarahNo ratings yet

- Circular Home MadeDocument96 pagesCircular Home MadeFlorinNo ratings yet

- Smart Shop in A One Car GarageDocument7 pagesSmart Shop in A One Car GarageEmilio Ge100% (1)

- Machine Shop ManualDocument6 pagesMachine Shop ManualManoj KumarNo ratings yet

- Lathe Is A Machine, Which Removes The Metal From A Piece of Work To The Required Shape &sizeDocument14 pagesLathe Is A Machine, Which Removes The Metal From A Piece of Work To The Required Shape &sizeabuziad1234No ratings yet

- 5 Shop Made Clamps - SSCDocument1 page5 Shop Made Clamps - SSCjuan olivaNo ratings yet

- Machine Shop ReportDocument8 pagesMachine Shop ReportNazib Ul Islam Sazib78% (9)

- Proxxon Pricelist 2016Document5 pagesProxxon Pricelist 2016Joe JoeNo ratings yet

- Classification of ToolsDocument73 pagesClassification of ToolsNathaniel Pili De Jesus100% (1)

- Common G and M Codes For CNC MachinesDocument2 pagesCommon G and M Codes For CNC MachinesSiddhrajsinh ZalaNo ratings yet

- Armeg Product Guide Low ResDocument141 pagesArmeg Product Guide Low ResKoekieNo ratings yet

- SDS Drill Bits ExplainedDocument2 pagesSDS Drill Bits Explainedsdsbits100% (2)

- 10 Quick and Easy Woodworking Gift IdeasDocument50 pages10 Quick and Easy Woodworking Gift Ideaspavel100% (1)

- 2 B.TECH EXPERIMENT'S SEM IV - Wire DrawingDocument3 pages2 B.TECH EXPERIMENT'S SEM IV - Wire DrawingNeelNo ratings yet

- J S Auto Cast Foundry India PVT LTD.,: Tool LayoutDocument24 pagesJ S Auto Cast Foundry India PVT LTD.,: Tool Layoutkishore RavindranNo ratings yet

- Belt GrinderDocument37 pagesBelt GrindermecanicaycompeticionNo ratings yet

- Carpentry Tools: Submitted By: Suchit Bhansali Batch: H-3, Mechanical Submitted To: Prof. Deepak MehraDocument19 pagesCarpentry Tools: Submitted By: Suchit Bhansali Batch: H-3, Mechanical Submitted To: Prof. Deepak MehraSuchit Bhansali100% (1)

- Sop - Drill MachineDocument2 pagesSop - Drill MachineprojectssuyashcorpNo ratings yet

- Declaration: by Yohannes, Migbaru, Yalew &masrie (Wukiot)Document63 pagesDeclaration: by Yohannes, Migbaru, Yalew &masrie (Wukiot)Sibhat GebregziabherNo ratings yet

- Plansnow Tablesaw JointingDocument3 pagesPlansnow Tablesaw JointingShawn BrinkmanNo ratings yet

- Metal LatheDocument10 pagesMetal LatheDinesh KumarNo ratings yet

- Lec2 Lathe MachineDocument70 pagesLec2 Lathe MachineFELIX KEUYANo ratings yet

- Wood #203 2011Document96 pagesWood #203 2011Mike Papa100% (4)

- Tools AND Equipment: Submitted byDocument4 pagesTools AND Equipment: Submitted byChan Chan GamoNo ratings yet

- Taper JigDocument9 pagesTaper JigAustinPalmer100% (1)