Professional Documents

Culture Documents

Byers Et Al-1967-AIChE Journal

Uploaded by

SamarthJaiswalCopyright

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentByers Et Al-1967-AIChE Journal

Uploaded by

SamarthJaiswalGas-Liquid Mass Transfer with a

Tangentially Moving Interface: Part 1. Theory

CHARLES H. BYERS and C. JUDSON KING

University of California, Berkeley, California

A theoretical investigation has been made of the effect of a moving interface upon gas-liquid

mass transfer, where the control of the mass transfer i s entirely within the gas phase and

where the control is distributed between the two phases. An analytical model is proposed for

laminar interphase mass transfer in infinite media. Computer solutions have been obtained

for gas-liquid mass transfer in confined phases. A cocurrent moving interface increases mars

transfer coefficients over what they would be for the same flow rate without interfacial motion.

Many simple models have been suggested for the anal- in the absence or suppression of resistance in the other

ysis of mass transfer between immiscible fluid phases. Most phase. Their use in Equation (1) implies that the value

of these models ne lect the effect of the fluid mechanics of each individual phase coefficient is unaltered by changes

5

of one phase upon t ose of the other phase. For example,

penetration or surface renewal models are often employed

in the coefficient in the other phase. The use of a in Equa-

tion (1) implies that H and kG/kL are both constant

to describe liquid phase mass transfer near a across the entire contacting interface. The limitations of

.

liquid interface (10, 22, 23, etc.) Such models Equation (1) have been discussed by King (12,1 3 ) ; its

no gradient of velocity in the liquid adjacent to applicability to single cocurrent or countercurrent fluid

r

face; this is general1 a good assumption, since the viscos-

ity of a gas is usua Iy orders of ma nitude less than that

of a liquid. In situations where 8e

liquid flows as a

exposures is explored further in the present work.

Although the ensuing discussion is carried out in the

terminology of mass transfer, it applies as well to heat

r

laminar la er over B solid surface, it is usually presumed

that the ree surface velocit for use in a penetration

Y

model is 3/2 the average ve ocity. Strictly speaking this

transfer between a gas and a liquid. Mass transfer consid-

erations are restricted to low concentration levels and low

net fluxes of mass. Presumably this restriction precludes

is true only when there is zero drag at the interface. When any possibility of dynamic instabilities (Marangoni effect,

there is a relatively high gas flow rate near the interface, etc.) enterin the analysis. It is also assumed that the fluid

the drag upon the interface may alter the interfacial veloc-

ity to an appreciable extent. As is shown below, this factor

P

interface is ree in the sense that no surfactant layer is

present to hamper flow. It is found in Part 11 of this work

can assume importance. that this assumption is obeyed in many systems, but that

Similarly, most models and correlations which have been for some cases of horizontal contacting, notably in aqueous

proposed for gas hase resistance in as li uid contacting systems, it is not obeyed.

K fq- 8

apparatus ignore t e influence of the i ui surface veloc-

ity (7,19, etc.). At least two theoretica papers have ana-

Interphase heat and mass transfer in confined systems

has been considered in a similar fashion by Nunge, Gill,

lyzed mass transfer near a moving surface (1, 2 ) ; how- and Stein (16 to 18, 2 0 ) . The difference between the

ever no concepts obtained from these works have been present work and theirs lies in the motion of the inter-

employed for the analysis of experimental mass transfer face. The present work is concerned with situations where

data. The influence of a moving interface is explored fur- there is tangential interfacial motion, such as in direct

ther in this paper and in Part 11. fluid-fluid contacting. The analyses of Nunge, Gill, and

It is also common practice to ignore the interaction Stein are concerned with situations where there is no in-

between the resistances to mass transfer offered by each terfacial motion, such as for heat exchange between fluids

of two contacting fluid phases, just as the interaction of across a metallic dividing surface.

the fluid mechanics is often i nored. The overall resistance

B

to mass transfer is usually o tained from an equation of Flow Between Flat Plates

the form

1 1 H . .

x

Consider a gas and a li uid in parallel, laminar, strati-

fied flow between two para el flat plates. The velocity pro-

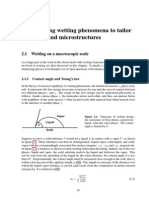

files for this situation are shown in Figure 1. For general-

ity it will be presumed that the flow rates of the

The asterisks denote mass transfer coefficients measured

liquid streams can be set independently; this c o d occur 8"

and

if, for example, part or all of the impetus for liquid flow

came from gravity. The two phases may be in cocurrent

flow ( U G m and U Lboth ~ positive) or countercurrent flow

Charles H. Byers is with the University of Rochester, Rochester, New

York. ( U G m and U L m with different signs).

Page 628 AlChE Journal July, 1967

uo 6(1+%)

Gas 6

4 - + - s2cy: + 3

Liquid b b L

The interfacial velocity is 3/2 the average liquid velocity

3

t- L only if 8 2 p ~= P ~ LIf . s 2 p ~> b2pL, UO< 2 U L ~and-

;

Fig. 1. Flow and interphase mass transfer between two flat plates.

3

if P ~ <

G b2pL, Uo >-

2

ULm. For phases of equal thick-

The equation of motion may be solved for this two-

ness with p~ = 50 p ~ UO

, = 1.71 ULm-

dimensional case with the boundary conditions of zero

velocity at y = +b and -8, U G = UL at y = 0, and PHASES OF INFINITE EXTENT

J L L G ( ~ ~ G / ~=Y )pL(dUL/dy) at y = 0, giving For mass transfer during brief exposures of a gas and a

liquid in confined flow, it is permissible to consider only

UG

-= the region very near the interface and to neglect the ef-

UGm fect of the confining walls upon the mass transfer process.

The following sections will consider mass transfer between

gas and liquid phases which are in fully developed cocur-

rent parallel flow and are infinite in extent. Cases consid-

ered include gas phase-controlled mass transfer,

phase-controlled mass transfer, and the general

case where the resistances of both phases are important.

Even though the models consider phases of infinite extent,

they are applicable to many cases of confined flow. The

extent to which unconfined models are applicable to con-

fined cases is discussed below.

Gas Phase-Controlled Mass Transfer

The velocity profile near the gas-liquid interface may

be taken to be linear for cases of brief exposures where

the concentration changes due to mass transfer do not

penetrate the gas deeply. A general model for the mass

( 3) transfer process in this situation is shown in Figure 2.

The ratio of the surface velocity to the average liquid In this case the velocity profile is

velocity is

bpL UGm

UG = UO + ay (7)

uo

-=- 3 (,+-I ULm (4)

Therefore the diffusive transport equation reduces to

ULn, 2

<2+4

Thus the surface velocity is 3/2 the average liquid veloc- with the boundary conditions

ity only if UGm = ULm. For cocurrent flow with Ucm > at y= 0 CA = CAS

3

UL,, Uo > -

2

ULm; for cocurrent flow with UGm < ULm x= 0

y= 00

cA=

cA=

CAO

CAO

(9)

3

or for countercurrent flow, Uo < - ULm. This problem has been solved by Beek and Bakker ( 2 ) by

2 Laplace transformation. Two asymptotic solutions were

For many systems used in mass transfer pL is about found for the local mass transfer coefficients based upon

fifty times pG. If 8 = b, U G =~ - U L ~will correspond to the initial driving force. For short exposures (a2& x/UoS

Uo = 1.44 ULm, U G =~ 2ULm will correspond to Uo = << I ) , the solution is

1.53 UGm, and UGm = 10 ULm will correspond to Uo =

1.76 U L ~The. changes in the ratio of surface velocity to

average liquid velocity become more severe as the gas

P ase becomes thinner in relation to the liquid. Thus for

/8 = 0.2 and p L / p G = 50, the ratios for the three

previous situations become 1.23, 1.64, and 2.00, respec-

while for long exposures (@DGx/U03 >> 1)

tively.

For the special case of true horizontal two-phase flow,

the pressure drop serves as the sole impetus of flow for

both gas and liquid. A derivation similar to that given by

Bird et al. (3) yields

Gos

w cA= A.

Slope = a

Fig. 2. The Beek and Bakker model for mass transfer to an infinite

and medium with an interfacial velocity.

Vol. 13, No. 4 AIChE Journal Page 629

[ 1 + 0.375 ( x)

LT~DGX '.-"]

(11) -4

0.5

Beek and Bakker used interpolation to approximate the

solution in the intermediate region (a2DcX/Uo3 on the $

-

order of the 1 ) . An exact solution in this region is desir- ~ 0.4

able because it must be used in estimating average mass Y

transfer coefficients for all but the shortest exposures. A

0.3

numerical digital computer solution was made of the lo3 I d2 16' I

roblem by using a Crank-Nickolson six-point implicit a2S, x / U:

Formula to approximate the parabolic partial differential

Fig. 4. Solution for mass transfer to a phase with a negative slope

equation. It was necessary to calculate local mass transfer

coefficients by means of a numerical differentiation of the

-- -

in the velocity profile: asymptotic solution,-

concentration profile at the interface. An unsymmetrical

---

exact sofution, penetration model.

five-point formula provided the necessary accuracy. It

was found that the correct solution in the intermediate re-

gion is the one shown in Figure 3 as a solid line. The removal of mass resulting from the finite velocit at the

hatched curves are the asymptotic solutions [Equations

tration and Leveque models underestimate the mass trans-

K

interface itself. Therefore, it is logical that both t e pene-

(10) and ( l l ) ] .The exact solution lies below the two

asymptotic solutions rather than between them, as was fer coefficient.

originally estimated by Beek and Bakker (compare Figure The Beek and Bakker model assumes that the slope of

3 of reference 2). the velocity profile in the medium in question is positive.

For short exposures, where the slope in the velocity There are a number of situations where the slope is nega-

profile becomes unimportant compared to the interfacial tive, and therefore it is of considerable interest to carry

velocity, the solution approaches the penetration model: through such a solution. Strictly speaking, one may not

postulate an infinite phase for the case of a negative slope

of the velocity profile, since a flow reversal must occur at

some distance from the interface. This in turn would

necessitate the provision of initial concentrations at both

For higher values of the abscissa, where the interfacial ends of the exposure (at x = 0 and x = L in Figure 2).

velocity is small compared with velocities a short distance However, if the value of U ~ D , X / U ,is , ~ sufficiently small,

in the gas, the solution approaches the Leveque the solution should not be sensitive to the flow reversal. If

aw7

mo el for transfer from a stagnant surface into a fluid

with a linear velocity profile:

we carry out the soIution for a short-exposure asymptote,

the result is

In the intermediate region, however, the mass transfer For any physically significant case the long-exposure

coefficient is higher than predicted by either of these two asymptote with Equation (9) as boundary conditions is

limiting models. Near an abscissa of 1.0 both limiting meaningless. It is evident that E uation (14) is a mirror

models are in error by 30%. The physical basis for this

behavior is clear enough: The penetration model allows

1

image of Equation (10) about t e penetration solution.

Equation (14) is shown as the hatched line in Figure 4.

for the interfacial velocity, but neglects the increased The dotted line is the penetration model, while the solid

convective removal of mass resulting from the increase in line is the exact solution of this problem, which was car-

velocity with distance away from the surface. The Le- ried out numerically by computer methods.

v&que model allows for the increase in velocity with dis- The solution for a negative velocity gradient allows

tance away from the interface, but neglects the convective some qualitative remarks concerning two important situ-

ations. In most cases where a gas and a liquid are in co-

current motion, the gas is moving sufficiently quickly to

cause some drag upon the liquid interface, which in turn

causes a small negative slope in the liquid phase velocity.

With this solution we are able to say that if the value

of a2DLx/Va3is less than the penetration theory is

--q obeyed to within 2 % . The other important case is when a

gas and a liquid are in countercurrent flow. Here there

will be a negative slope in the velocity profile in gas at

the interface. While Equation (14) is invalid for most

countercurrent problems, it is interesting that the solution

does predict that the negative slope causes a decrease in

the mass transfer coefficient. This fact was confirmed ex-

- perimentally in Part I1 of the present work. Equation

(14) could not be a plied directly in that study, since the

0.3' flow reversal p l a y e l a n important role in all the experi-

0.0 I 0. I

a*Bt[,x/ UXI .o 10.0 100.0 ments.

Fig. 3. Solution for mass transfer to on infinite medium with an Liquid Phase-Controlled Moss Transfer

- -

interfocial velocity: - -

asymptotic solutions, Strictly speaking, a model similar to that developed for

---

exact solution, limiting solutions. the gas phase would apply to the mass transfer resistance

Page 630 AlChE Journal July, 1967

of an adjacent liquid. However, since the drag of the gas constant to be determined by the application of the in-

on the liquid is relatively small and since liquid diffusivi- terfacial conditions.

ties are low, one is almost invariably located on the The gas phase solution is carried out by the same

penetration asymptote of Figure 3. Hence, no features of method as the solution of Beek and Bakker (2, 5 ) . The

the liquid velocity profile need be considered for mass solution in the Laplace domain to this portion of the

transfer purposes aside from the velocity of the interface problem is

itself. If a liquid with a constant velocity Uo is exposed

to a medium which imparts to its interface a constant con-

centration different from that in the entering bulk, the

transport equation reduces to

The local mass transfer coefficient based upon the initial

driving force will be

kcL = (D L U o / m ) (18)

For flow between parallel plates Uo would be calculated

by means of Equation ( 3 ) . This form of the penetration

model has been shown to be appropriate in many liquid

phase-controlled situations (8, 21, 23, etc.) .

lnterphase Mass Transfer where 6 is a constant. The two constants A and 0 are

A model for interphase mass transfer in fully developed obtained by the simultaneous application of the two in-

flow is shown in Figure 5. Two infinite phases-a gas with terfacial conditions [Equations (19) and (ZO)] to the

an interfacial velocit Uo and a velocity profile with a solutions in the Laplace domain.

constant slope a, a n 8 a liquid with constant velocity Uo

-are contacted for a length L. The convective transport

equation for the gas phase is the same as Equation ( S ) ,

while in the liquid phase the equation is the same as

Equation ( 15). The boundary conditions are

At x=O Y>O CG=CGO} (17)

x=o y <0 CL = CLO AC

0=--

At y = + ~ S

Y=-W CL = CLO

The interfacial conditions at y = 0 are

CG = 51 CL (20)

The first equation is the continuity of fluxes across the in-

terface, while the second is the assumption of Henry’s law CGO

as the equilibrium interfacial condition. The constant H is &=-- CLO (27)

H

dimensionless ( H / R T ). and

The problem is solved by Laplace transformation. In

the Laplace domain the liquid phase solution is the solu- 2= -

2

3

f s1/2 (28)

tion for penetration into a stream with constant velocity

It is obvious that concentration profiles would be quite

difficult to generate, As a result only a solution for the

mass transfer coefficient is sought. The local overall mass

transfer coefficient based on the initial driving force is de-

fined in the Laplace domain as

where s is the Laplace transform variable and A is a

and is found to be

Gas

d

No simple general solution is available for this problem.

However it is possible to find asymptotic solutions for

short and long exposures. For large values of Z, the fol-

lowing simple form may be given to the Bessel’s function

of the second kind:

WO? L

Fig. 5. Model for interphase mass transfer with control distributed (31)

between gas and liquid.

Vol. 13, No. 4 AlChE Journal Page 631

where R, and S, are series in n and x given b Carslaw

and Jaeger ( 6 ) . If this approximation is inclu ed in the

solution and the binomial in the denominator is expanded

B

in a series, the result is

% o = La [ (f) +(:+A)(,) 1 2

455

”> (f>l + ....]

where

y = 2 .NUo2/3 a

(32)

t I

i

a=uN+l

8=

5-7(a.N+

72

1) } (33)

lo-) ’ “ “ “ l

--

’ p l ” ’ l ’ ’ 1 ” 1 1 ’ 1 ’ l i ’ ’ l i

uw= 2.0

I ”“”

This series may be inverted term by term. The overall 10-2 10-1 10 102 10’

mass transfer coefficient based upon the gas phase is O‘OOx/uO‘

-

Fig. 6. Interphase mass transfer solution for unbounded media:

analytic solution, ---

computer solution.

Rearrangement gives King (12) has shown that the addition of resistances

principle [Equation (1)J should be closely obeyed for co-

current flow. This will be particularly true to the extent

that the independently measured individual phase mass

transfer coefficients tend to vary with the same power of

the distance since the start of an exposure. The addition

of resistances principle should therefore be effective

for the prediction of the results shown in Figure 6, since

The solution for low values of z is not quite as satis- for liquid phase-controlled mass transfer the coefficient

factory. For small values of x varies as x - ~ ’ ~while

, for gas phase-controlled mass trans-

K p ( x ) = 2”-’ ( p - l ) !x-p (36) fer, the coefficient varies as x - ~ / Z for very short times

with the exponent increasing toward -1/3 at longer times.

For this case Equation (30) becomes Addition of resistances for the independently measured

local coefficients at all points yields

(37)

where

F = 2-’i3(- 2/3)f/(- 1/3)! (38)

A solution is difficult in this case so that we seek a solution

only for the situation where

UH > F zY3 (41)

Let The penetration model is employed for the liquid phase,

7=-

Us1

F

and the gas phase mass transfer group kCG ->,,’is

(DIU0

Then if taken from Figure 3.

z1/a/r << 1 The solution using the additivity of resistances was

- compared with the analytical solution where it is applic-

KCG = (1- ~1/3/7 + z2/3/7 . . . .) (39) able and the computer solution in the remainder of the

re ion. It was found that the deviations of the additivity

The solution is inverted and rearranged. Finally the coeffi-

cients are evaluated, resulting in P

so ution were greatest in the region where aH is near

unity, that is, where control is evenly divided between

phases. Also the deviation tends to increase as a2D~X/Uo3

increases, but the maximum deviation is less than 2% for

any reasonable value of the length group (<lOO,OOO) .

The use of the addition of resistances with average coeffi-

cients is similarly effective.

CONFINED PHASES

Interphase mass transfer situations generally involve

The results of this solution are shown graphically in confined fluid phases; hence it is important to analyze

Figure 6. A presentation of &G(X/UODG)’/~ as a func- the rates of mass transfer which are to be expected in

tion of a 2 D ~ x / U o 3is made for different values of the confined flows. Such analyses are particularly needed for

parameter uH. The solid Iine represents the analyticaI the interpretation of the experimental measurements re-

solution, while the dotted line shows results of a com- ported in Part 11. The prediction of mass transfer coeffi-

puter solution of the same problem in the regions where cients is simpler for fluids of infinite extent. It is there-

the analytic solution is not valid. This computer solution fore important to compare the unbounded models with

is discussed in detail elsewhere ( 5 ) . the corresponding confined flow solutions in order to

Page 632 AlChE Journal July, 1967

identify the degree of equilibration or duration of surface

exposure for which the former are valid.

Mass Transfer Controlled by a Single Phase

The hydrodynamic simplicity of laminar flow in a circu-

lar tube made the prediction of mass and heat transfer

coefficients for that case a relatively simple task. Since the

original solution by Graetz (9) for uniform walI tempera-

ture or concentrations, there have been several solutions

made of this problem for various boundary conditions.

Mass transfer to laminar flow between two infinitely wide

flat plates is similar to the Graetz problem. The constants

generated by this solution are of course somewhat differ-

ent from those in the original Graetz solution.

The problem of mass transfer to a stream flowing be-

tween two flat plates has been solved by Butler and I I 1 1 J

Plewes ( 4 ) for the case of a constant solute concentration 0.32 0.64 0.96 1.28 I.60

Graetz ,number (DL/U, b21

at one wall, different from that in the entering fluid stream,

and a zero flux at the other wall. A modification of their Fig. 8. Mean fraction saturation as a function of the Graetz num-

velocity profile is needed for the present study. The wall ber for different values of the parameter U d U o .

at which the mass transfer takes place is a fluid interface

which is in motion with a velocity UOrelative to the fixed

wall. The physical situation is illustrated in Figure 7. The used. A listing of the Fortran programs written for this

fluid enters with a solute concentration CAOand is con- solution along with all the other programs mentioned in

tacted with an immiscible fluid which holds the concentra- the present discussion may be found elsewhere ( 5 ) .

tion at the interface constant at C A ~The . velocity profile The results were given directly in the form of graphs

may be expressed as on the digital plotter. Figure 8 shows the average (cup

U G = ~ O (6Ucm-44uo)

+ y/b+ ( ~ U O - ~ U G ~ ) (5) 2

mixing) fraction saturation [(CA- CAo)/(CAs - CAo)]Av,

as a function of the Graetz number DGx/U,bz for the

(42) seven values of the parameter U,/Uo which were consid-

ered. The solution was verified by comparison with the

The profile is also applicable to the liquid, in which case two pertinent analytical solutions available. The solution

UL is expressed as a function of UO,UL,, and y/& The by Butler and Plewes almost perfectly matched the solu-

transport equation for this case may be written nondi- tion for the highest value of U,/Uo (100) over the entire

mensionally as range for which the former is valid. Pigford (11) has

ac a2c

[1 + (6V - 4)Y + ( 3 - 6V)Y2] -

dX

=-

aY2

(43)

solved for the case of li uid flow down a plane, where

V,/Uo is 2/3. Again in %IS case the present solution al-

The boundary conditions are most perfectIy matched the earlier solution from a frac-

tion saturation of 0.20 to 1.00. At values of the average

x=o c=o fraction saturation below 0.2, insufficient terms are avail-

Y=O C=l (44) able for the analytical solution.

Y=1 ac/ar = o The effect of the interfacial velocity upon the mass

transfer process is uite clearly shown in Figure 8. For

The velocity profile is parabolic and the problem could

be solved by a method of separation of variables in the 1

a given system, if t e average velocity of the gas phase

U , is kept constant and the interfacial velocity Uo is al-

same way as Butler and Plewes solved for the case of zero

interfacial motion. The present situation must be solved

for a wide range of values of the arameter V. As a result,

the generation of constants was found to be impractical, 3.0

and the equation was solved directly on the computer for

seven values of the parameter V = U,/Uo. These range

from 0.5 to 100, the latter figure being essentially equiv- . _.

alent to the solution of Butler and Plewes. Equation (43)

is a arabolic partial differential equation and therefore

may e! put in finite-difference form by the application of I 1

the Crank-Nicholson six-point implicit formula. The re-

sulting tridiagonal matrix may be solved directly by a

Thomas method (14)and corrected by means of a Gauss-

Seidell procedure with a successive overrelaxation factor

- 3.0

- 4.0 - 3.0 -2.0 -1.0 0 1.0

Log,, (Groetz number)

Fig. 9. A logarithmic representation of the local Sherwood number

Fig. 7. Mass transfer to a fluid in laminar flow between two parallel as a function of the Graetz number for different values of the

walls, one of which is in cocurrent motion. parameter Um/Uo.

Vol. 13, No. 4 AlChE Journal Page 633

lowed to increase from zero to a high value, one moves Finally, concentration profiles were generated for all of

vertically upward on the graph. It is obvious that there the values of Um/Uo mentioned above. Figure 10 is a

is a considerable increase in the mass transfer coefficient typical set of profiles for U,/Uo = 2/3. The profiles for

merely because of the fact that the interface is in motion. the other cases are reported elsewhere ( 5 ) . The dimen-

For example at a Graetz number of 0.32, the average frac- sionless concentration C is plotted as a function of the

tion saturation corresponding to no interfacial motion ( V fractional distance from the interface with the Graetz

= 100) is 0.58, while for V = 0.5 this increases to 0.78. number as a parameter. This series of profiles is of par-

The local Sherwood number (Nusselt number for mass ticular interest since it is the solution to mass transfer into

transfer) based upon the initial driving force was com- a liquid flowing down a plane where there is no drag

puted, using an unsymmetrical five-point formula to esti- upon the interface. For this case, it is normal to use the

mate the local mass transfer flux. For very short exposures penetration model in the estimation of the mass transfer

numerically estimated derivatives are inaccurate, and coefficients and concentration profiles. When the exact

therefore only values of the Sherwood number for values solution is compared with the penetration model, it is

of the Graetz number greater than 10-4 are shown in Fig- found that the latter is a close approximation up to an

ure 9. This figure is a logarithmic plot of the local Sher- average fraction saturation of about 0.60 for estimating

wood number as a function of the Graetz number, for the the average mass transfer coefficient. The concentration

same seven values of the velocity parameter. The curves profiles are in agreement up to a Graetz number of 0.04.

cross at a Graetz number of about 0.2, since at higher Another comparison which is of interest is between the

interfacial velocities saturation is achieved at a lower infinite phase model with a positive slope in velocit and

Graetz number. The fact that the curves all cross at one

point appears to be a coincidence.

the confined flow solution. For this comparison a va ue of

Um/Uo of 2.0 was chosen for the confined case. The con-

7

centration profiles coincide only up to a Graetz number

of 0.01 (average fraction saturation of 0.125). On the

other hand, the average mass transfer coefficient was valid

to within 10% up to a Graetz number of 0.2, which rep-

resents an average fraction saturation of about 50%.

Interphase Mass Transfer

When a third component passes from a solvent to an

inert carrier gas, the resistance to mass transfer is in

era1 distributed between the two phases. In the anaytic

solution to the unbounded problem it was found that the

r-

degree of control which is resident in either phase is de-

.

pendent upon the parameter ( D G / D L ) ( H / R T ) In the

confined flow case this group serves the same purpose. The

convective transport equation was solved for two different

cases of confined interphase mass transfer. The experi-

mental study which accompanied this theoretical work

had the geometry shown in Figure 1. Therefore, the first

solution involves transfer between two confined phases,

both of which have parabolic profiles. The partial differ-

ential equations for both phases may be put into finite-

difference form by means of a Crank-Nicholson formula.

Henry’s law is used to describe the equilibrium relation-

Y/b ship at the interface. This assumption, along with the

equality of fluxes [Equations (19) and (20) ] is used to

fig. 10. Concentration (CA - CAO/CA$ - CAO) as a function of

distance from the interface with U,/Uo equal to 2/3 for the

define the connection between the two phases at the inter-

values of the Graetz numbers listed below. face. The resulting tridiagonal matrix is solved by the

usual techniques. In the case where both phases have

No. of curve Graetz No.

parabolic profiles in velocity, three independent parame-

ters are necessary to define the problem. Therefore, a

1 0.0005 general solution is not pragmatic. The experimentally im-

2 om1 portant cases were solved with this model, while the gen-

3 0.002 eral solution was carried out with a simplified velocity

4 0.004 profile. The three independent parameters necessary to

5 0.008 define each case may be reduced by one if a constant

6 0.016

7 0.032 velocity equal to the interfacial velocity is assumed in the

8 0.048 liquid phase. Since the effect of the mass transfer pene-

9 0.064 trates to only a small fraction of the total liquid depth,

10 0.080 this assumption is almost always applicable. The two re-

11 0.096 maining independent parameters are the velocity param-

I2

13

14

0.112

0.128

0.144

s

eter U,/Uo and the control arameter (DG/DL)1/2 ( H /

R T ) . This problem was solve for five different values of

the control parameter ( 5 , 2, 1, 0.5, and 0.25). Figures 11

15 0.16 and 12 are the results for u51 = 1. The other results are

16 0.24 also available (5). Figure 11 resents the local Shenvood

17

18

0.32

0.40

f

number based upon the initia driving force as a function

of the Graetz number. Figure 12 shows the average frac-

19 0.48

20 0.56 tion saturation as a function of the Graetz number.

21 0.64 This solution provides an opportunity to compare the

22 0.72 predictions of the addition of the resistances principle

23 0.80 with the exact solution for a cocurrent laminar confined

Page 634 AlChE Journal July, 1967

I I I I I I

I 1 I 1

Od 0.32 0.64 0.96 1.518 1.60

Graetz number

Fig. 12. Average fraction Saturation as a function of the Graetz

number for different values of the parameter U d U o with uH =

1.0 for a model with a confined gas and an infinite liquid.

-2.00 ' 1 1 -

1 mixing concentrations used as drivin forces. In this case

- 3.0 - 2.0 - 1.0

I

0.0 I.o E

the addition principle predicts too igh a mass transfer

Log,o ( Graetz n u m b e r )

Fig. 11. Local Sherwood numbers as a function of the Graetz num-

ber for different values of the parameter U,/Uo with a H = 1.0

s

coefficient at hi h Graetz numbers. This is at least partially

caused by the act that the local driving force approaches

zero at lower Graetz numbers for the individual gas phase

for a model with a confined gas and an infinite liquid, resistance than for the overall resistance to mass transfer.

Also shown in Figure 13 are comparisons for predicted

and actual values of the average Sherwood group. The

average Sherwood group based upon the log mean driving

force exhibits a deviation from the addition principle

flow case. Most other such comparisons have been made which is similar to that for the local Sherwood number

for models in which there are infinite media (12, 13, etc.) . based on the local driving force. The average Sherwood

One comparison which does exist for confined media pic- based on the initial driving force, on the other

tures a countercurrent turbulent confined phase to which

the film model is applied ( 1 5 ) ; another considers two

E

Z shows agreement with the addition principle to a

Graetz number of 2. This form of Sherwood group weights

confined streams in cylindrical ( 1 7 ) or flat plate ( 1 8 ) the initial mass transfer highly; it has already been shown

geometry with no interfacial motion. In the present solu- that the initial mass transfer follows a penetration model

tion it is interesting to ascertain whether the effect of the

penetration of the mass transfer to the wall may b e y p -

erly predicted by the addition of the two indepen ently

measured individual resistances. For the gas phase re-

sistance the confined flow case with a moving interface

is used, while the penetration model is chosen to describe

the liquid phase behavior. The addition of the resistances

principle was applied to predict local and average Sher-

wood numbers for the interphase mass transfer case. For

the sake of comparison, values of UH of 1 and a velocity

parameter of V = 4 were chosen. These probably repre-

sent the most severe test of the addition o the resistances

principle. The ratio of the predicted and actual Sherwood

numbers is shown in Figure 13. The solid curve repre-

sents the comparison of local Shenvood numbers as a

function of the Graetz number, with the Shenvood num-

bers based upon the initial driving force ( HCLO CCO) . At-

low Graetz numbers the situation reduces to the problem

previously analyzed for phases of infinite extent. As has

already been noted, the addition principle works well in

this range. At Graetz numbers above 0.5 the addition of

resistances rediction becomes increasingly erroneous. In

R

this range t e gas phase approaches saturation in the gas

phase-controlled case; this necessarily causes the individual

Fig. 13. A comparison of the exact solution for

interphase mass transfer from an infinite liquid

gas phase Sherwood number based on the initial driving phase to a confined gas phase with the re-

force to drop toward zero and causes the predicted overall

-

sults of the addition of resistances model for

U,/Uo equal to 4 and u?j! = 1.0.

coefficient to follow. In the interphase case the

is, less saturated at a given Graetz number an thephase

overall coe5cient remains high.

cr

true local Sherwood number based on initial driving

-- -

force,

-- -

average Sherwood number based

on initial driving force,

Because of this behavior one might expect that the ad-

-- -

local Shemood number based on local driving

dition principle would work better if applied to local force,- average Shemood

Sherwood numbers based upon the local driving force. number based on logarithmic mean driving

Such a comparison is also given in Figure 13, with cup- force.

Vol. 13, No. 4 AlChE Journal Page 635

in both phases and thus gives average overall coefficients Uo = interfacial velocity, cm./sec.

which a ree well with the addition principle. Thus, the V = velocity parameter, U J U o

%

preferre form of application of the addition principle is x = distance from start of exposure, cm.

that corresponding to the dashed curve in Figure 13: x = DGX/UOb2

y = direction and distance perpendicular to the inter-

face, cm.

(45)

Y = y/b

z = 2/3 1: s1I2

where the mass transfer coefficients are based on the Greek Letters

initial driving force and are averaged over the exposure.

€7 =u51+1

CONCLUSIONS

fl

y = 251 Uo2/3a

+

= [5 - 7 ( ~ 5 1 1)]/72

1. In many instances of gas-liquid mass transfer it is 6 = thickness of the liquid phase, cm.

important to allow for the effects of the interaction of 5 = ( U03/a2DG)1/2

the fluid mechanics of the contactin phases. e = constant as defined in Equation (20)

?

2. In most cases of laminar gas- iquid contacting the h

~.l

= constant as defined in Equation (25)

= viscosity, g./(cm.) (sec.)

liquid phase will follow a penetration model closely, but

the surface velocity to be used in the model may be u = (DG/DL)’/’

greater or less than 3/2 the average velocity. r =uH/F

3. Gas phase mass transfer in cocurrent, laminar, gas- Subscripts

liquid flow is influenced by the interfacial velocity. For A = of component A

well-developed flow with phases of infinite extent, the AV = average

mass transfer coefficient is given by Figure 3 and is greater C = based upon concentration difference driving force

than predicted by either the Lev&que or penetration G = of the gas phase

models. L = of the liquid phase

4. The effect of confining walls on cocurrent, laminar rn av.efay

gas-liquid mass transfer causes mass transfer coefficients o - initial y

to be less than those given by Figure 3 for the gas and s = at the interface

less than those given by the penetration model for the

Superscript

liquid. These effects become important above 50% equili- *

bration of either phase. = measured in the absence or suppression of resist-

5. The addition of the resistances principle should work ance in the other phase; average value over en-

well for gas and liquid phases of infinite extent (brief tire interface

exposures) in cocurrent, laminar flow. For confined phases LITERATURE CITED

the most effective form of the addition principle is that 1. Acrivos, Andreas, Chem. Eng. Sci., 9, 242 (1958).

given by Equation (45). 2. Beek, W. J., and C. A. P. Bakker, Appl. Sci. Res., A10,

241 (1961).

ACKNOWLEDGMENT 3. Bird, R. B., W. E. Stewart, and E. N. Lightfoot, “Trans-

port Phenomena,” pp. 54-56, Wiley, New York ( 1960).

This work was performed in the Lawrence Radiation Lab- 4. Butler, R. M., and A. C. Plewes, Chem. Eng. Progr. Symp.

oratory under the auspices of the US. Atomic Energy Com- Ser. No. 10, 50, 121 (1954).

mission. 5. Byers, C. H., and C. J. King, U.S. Atomic Energy Comm.

Rept. UCRL-I6535 ( 1966).

NOTATION 6. Carslaw, H. S., and J. C. Jaeger, “Operational Methods in

Applied Mathematics,” p. 350, Dover, New York (1963).

a = slope of the velocity of a phase at the interface, 7. Gilliland, E. R., and T. K. Sherwood, Ind. Eng. Chem.,

sec.-l 26,516 ( 1934).

u = area of mass transfer exposure, sq.cm. 8. Govindan, T. S., and J. A. Quinn, AIChE J., 10, 35 (1964).

b = thickness of gas phase, cm. (1964).

c = concentration of a transferring component in a 9. Graetz, L., Ann. Phys. Chim., 25, 338 (1885).

phase, Ac = 5 1 ~ -~ 0CGO, g.-moles/cc.

10. Hatch, T. F., Jr., and R. L. Pigford, Ind. Eng. Chem.

Fundamentals, 1, 209 (1962).

C = dimensionless concentration, ( C A - CAD)

/ ( CAS- 11. Johnstone, H. F., and R. L. Pigford, Trans. Am. Znst.

CAO) Chem. Engrs., 38, 25 ( 1942).

D = diffusion coefficient, sq.cm./sec. 12. King, C. J., AIChE J., 10, 671 (1964).

F = constant as defined in Equation (38) 13. - , Znd. Eng. Chem. Fundamentals, 4, 125 (1965).

H = Henry’s law constant, (atm.) (cc.)/g.-mole 14. Lapidus, Leon, “Digital Computation for Chemical Engi-

H = dimensionless Henry’s law constant, H / R T neers,” McGraw-Hill, New York (1962).

kc = local mass transfer coefficient based upon the ini- 15. Lightfoot, E. N., AIChE J., 8, 416 (1962).

tial concentration driving force, cm./sec. 16. Nunge, R. J., and W. N. Gill, Intern. J . Heat Mass Trans-

K = Bessel function of the second kind fer, 8, 873 ( 1965 ).

K, = overall mass transfer coefficient based upon the 17. , AIChE J., 12,279 ( 1966).

initial concentration driving force, cm./sec. 18. , and R. P. Stein, Znd. Eng. Chem. Funda-

mentals, in press,

L = length of exposure, cm. 19. Shulman, H. L., C. F. Ullrich, A. Z. Proulx, and J. 0.

la = index of series Zimmerman, AIChE I., 1,253 ( 1955).

= order of the Bessel function

i = universal gas constant, (atm.) (cc.) / (g.-mole)

20. Stein, R. P., ANL-6889 (Sept., 1964).

21. Tang, Y. P., and D. M. Himmelblau, AIChE J., 9, 630

(OK.) (1963).

Rn = remainder series as defined in reference 6 22. Vivian, J. E., and C. J. King, ibid., 10, 221 (1964).

s = Laplace transform variable 23. Vivian, J. E., and D. W. Peaceman, ibid., 2, 437 (1956).

Sn = remainder series as defined in reference 6 Manuscript received July 13, 1966; revision received August 15,

T = absolute temperature, O K . 1966; paper accepted October 14, 1966. Paper presented at AIChE

Detroit meeting.

Page 636 AlChE Journal July, 1967

You might also like

- Stability Analysis of Inclined Stratified Two-Phase Gas-Liquid FlowDocument43 pagesStability Analysis of Inclined Stratified Two-Phase Gas-Liquid FlowanellbmcNo ratings yet

- 1 Transport Laws: 1.1 Boundary Slip of LiquidsDocument14 pages1 Transport Laws: 1.1 Boundary Slip of Liquidshemendrag_1No ratings yet

- Near-surface motions and air-water gas transfer ratesDocument37 pagesNear-surface motions and air-water gas transfer ratesLeandro DijonNo ratings yet

- Convective Mass TransferDocument13 pagesConvective Mass TransferAriadne ChuaNo ratings yet

- Burr 2001Document12 pagesBurr 2001Kalusha Moron CruzNo ratings yet

- Mass Transfer in Bubble Columns: R. Krishna, J.M. Van BatenDocument9 pagesMass Transfer in Bubble Columns: R. Krishna, J.M. Van BatenDBS AuthorityNo ratings yet

- Convective Mass Transfer PDFDocument14 pagesConvective Mass Transfer PDFAnonymous 4XZYsImTW5100% (1)

- Toor Marchello膜渗透理论 PDFDocument5 pagesToor Marchello膜渗透理论 PDFGoKwo WongNo ratings yet

- Viscous Potential Flow Analysis of Kelvin-Helmholtz InstabilityDocument21 pagesViscous Potential Flow Analysis of Kelvin-Helmholtz InstabilityRebecca ClarkNo ratings yet

- Analytical Solution For Two-Dimensional Displacement Flow in A Curved Down-Sloping DuctDocument14 pagesAnalytical Solution For Two-Dimensional Displacement Flow in A Curved Down-Sloping DuctNasim KazemiNo ratings yet

- Measuring turbulent gas fluxes below the air-water interfaceDocument12 pagesMeasuring turbulent gas fluxes below the air-water interfaceFrancisco OppsNo ratings yet

- (1964-1) Criteria For The Break-Up of Thin Liquid Layers Flowing Isothermally Over Solid SurfacesDocument13 pages(1964-1) Criteria For The Break-Up of Thin Liquid Layers Flowing Isothermally Over Solid SurfacesClarissa OlivierNo ratings yet

- تقرير خواص مكمنDocument37 pagesتقرير خواص مكمنحسيننننن حسينننننNo ratings yet

- Fluid Mechanics GATE Preparation MaterialDocument5 pagesFluid Mechanics GATE Preparation MaterialAkash SoniNo ratings yet

- 2_fractures_seg07pdfDocument5 pages2_fractures_seg07pdfbrandonzhen02No ratings yet

- rheologyPRE08 PDFDocument14 pagesrheologyPRE08 PDFOscar Fernández DelgadoNo ratings yet

- Exploiting Wetting Phenomena To Tailor 1D Nano-And MicrostructuresDocument15 pagesExploiting Wetting Phenomena To Tailor 1D Nano-And Microstructuress1hahriarNo ratings yet

- CH 29Document29 pagesCH 29نزار الدهاميNo ratings yet

- Using A For: 6.4 The Convection Transfer AquationsDocument2 pagesUsing A For: 6.4 The Convection Transfer Aquationsedrin kuflaNo ratings yet

- Janzen Et Al 2010 Estimation of Mass Transfer VelocityDocument13 pagesJanzen Et Al 2010 Estimation of Mass Transfer VelocityFrancisco OppsNo ratings yet

- ST3 Surface Transfer Coefficients PDFDocument37 pagesST3 Surface Transfer Coefficients PDFanh thoNo ratings yet

- Two-Phase Flow Behavior and Spinner Data Analysis in Geothermal Wells PDFDocument8 pagesTwo-Phase Flow Behavior and Spinner Data Analysis in Geothermal Wells PDFWisnu ArdhiNo ratings yet

- Capillary Conduction of Liquids Through Porous Mediums: NOVEMBER, 1931 PhysicsDocument16 pagesCapillary Conduction of Liquids Through Porous Mediums: NOVEMBER, 1931 PhysicsCamilo AguilaNo ratings yet

- Mass Noneq U: Transfer Across A BR M N Te DaceDocument10 pagesMass Noneq U: Transfer Across A BR M N Te DaceGustavo Gabriel JimenezNo ratings yet

- Arti - Üculo Cienti - Üfico PaperDocument18 pagesArti - Üculo Cienti - Üfico PapersamanthapvNo ratings yet

- Pore-Scale Dynamics and The Multiphase Darcy LawDocument12 pagesPore-Scale Dynamics and The Multiphase Darcy LawSANDRA BALLESTEROSNo ratings yet

- Dynamic Effects in Capillary Pressure-Saturation RelationshipsDocument20 pagesDynamic Effects in Capillary Pressure-Saturation RelationshipsNarjes WalidNo ratings yet

- Progress in The Development of A Reynolds-Stress Turbulence ClosureDocument30 pagesProgress in The Development of A Reynolds-Stress Turbulence ClosureMutiaRezaNo ratings yet

- Viscous Potential Flow Analysis of Kelvin Helmholtz Instability in A ChannelDocument19 pagesViscous Potential Flow Analysis of Kelvin Helmholtz Instability in A Channelkevin ostos julcaNo ratings yet

- PhysRevLett 97-CsernaiDocument4 pagesPhysRevLett 97-CsernaiNoah MacKayNo ratings yet

- Open Channel Flow Friction Factor: Logarithmic LawDocument10 pagesOpen Channel Flow Friction Factor: Logarithmic LawKush DewanganNo ratings yet

- Effective and Relative Permeabilities of Anisotropic Porous MediaDocument16 pagesEffective and Relative Permeabilities of Anisotropic Porous MediaJavier E. Guerrero ArrietaNo ratings yet

- Non-Isothermal Liquid Droplet SpreadingDocument30 pagesNon-Isothermal Liquid Droplet SpreadingarazsanatiNo ratings yet

- Isotropy and AnisotropyDocument7 pagesIsotropy and AnisotropyFirsty Liliani LestariNo ratings yet

- Determinate Flow with Closed StreamlinesDocument14 pagesDeterminate Flow with Closed Streamlineschris_wsyNo ratings yet

- 6 Heat Transfer by Convection PDFDocument46 pages6 Heat Transfer by Convection PDFNavarre LatchmanNo ratings yet

- Approximations and Simplified Equations SPRING 2019Document12 pagesApproximations and Simplified Equations SPRING 2019Kula Segara PandiyanNo ratings yet

- Katul WRR 2011 PDFDocument15 pagesKatul WRR 2011 PDFAya AlmahdalyNo ratings yet

- Module 3: Mass Transfer Coefficients: Lecture No. 7Document3 pagesModule 3: Mass Transfer Coefficients: Lecture No. 7Rajat SonkarNo ratings yet

- CH 01Document7 pagesCH 01Ximena RuizNo ratings yet

- Nonlinear Transformation of Waves in FinDocument12 pagesNonlinear Transformation of Waves in Finmfgobbi4515No ratings yet

- Two-Phase Flow Behavior and Spinner Data Analysis in Geothermal WellsDocument8 pagesTwo-Phase Flow Behavior and Spinner Data Analysis in Geothermal WellsIrwan JanuarNo ratings yet

- Boundaty Dominated FlowDocument10 pagesBoundaty Dominated FlowfreddyescobarNo ratings yet

- Liquid-Liquid: and Heat Transfer From in ExtractionDocument10 pagesLiquid-Liquid: and Heat Transfer From in ExtractionGustavo Gabriel JimenezNo ratings yet

- A Model For Pressure Drop and Liquid Saturation in Gas-Liquid Cocurrent Upflow Through Packed BedsDocument8 pagesA Model For Pressure Drop and Liquid Saturation in Gas-Liquid Cocurrent Upflow Through Packed BedsJoão RibeiroNo ratings yet

- Layer ConvectionDocument4 pagesLayer ConvectionDarkNo ratings yet

- Week 2 Interphase Mass TransferDocument17 pagesWeek 2 Interphase Mass TransferKagendren AyanNo ratings yet

- THE FLOODING TRANSITION WITH GASSED RUSHTON TURBINES - 1984 - Fluid Mixing IIDocument9 pagesTHE FLOODING TRANSITION WITH GASSED RUSHTON TURBINES - 1984 - Fluid Mixing IIvane-16No ratings yet

- VIS enDocument10 pagesVIS enاحمد عبد المحسن ناجيNo ratings yet

- SCH1612 - Unit 2Document9 pagesSCH1612 - Unit 2Jaya ChandraNo ratings yet

- Common Approximations SPRING 2005Document7 pagesCommon Approximations SPRING 2005Vinay GuptaNo ratings yet

- MIT Fluids CoursenotesDocument704 pagesMIT Fluids CoursenotesLaura NovoaNo ratings yet

- Averaging Hydraulic Head, Pressure Head, and Gravitational Head in Subsurface Hydrology, and Implications For Averaged Fluxes, and Hydraulic ConductivityDocument10 pagesAveraging Hydraulic Head, Pressure Head, and Gravitational Head in Subsurface Hydrology, and Implications For Averaged Fluxes, and Hydraulic ConductivityZida Idhum Ma'rifaNo ratings yet

- Amili Yortsos2006 PDFDocument25 pagesAmili Yortsos2006 PDFJavier E. Guerrero ArrietaNo ratings yet

- Hanjalic-Launder JFM Vol52 1972Document30 pagesHanjalic-Launder JFM Vol52 1972LucaNo ratings yet

- Wolfshtien Original ArticleDocument18 pagesWolfshtien Original ArticleSai Theja KandakurthiNo ratings yet

- David E. Loper and H.K. Moffatt - Small-Scale Hydromagnetic Flow in The Earth's Core: Rise of A Vertical Buoyant PlumeDocument26 pagesDavid E. Loper and H.K. Moffatt - Small-Scale Hydromagnetic Flow in The Earth's Core: Rise of A Vertical Buoyant PlumeVortices3443No ratings yet

- How a Second-Moment Closure Model Captures Effects of Rotation on Turbulent Channel FlowDocument13 pagesHow a Second-Moment Closure Model Captures Effects of Rotation on Turbulent Channel Flowyaser AlahmadiNo ratings yet

- Motivation: Prof. Leena ChatterjeeDocument29 pagesMotivation: Prof. Leena ChatterjeeRahul SharmaNo ratings yet

- Patanajali Tejas Mar17 PDFDocument32 pagesPatanajali Tejas Mar17 PDFAnonymous wilcWdgMeq89% (18)

- List of ReadingsDocument2 pagesList of ReadingsSamarthJaiswalNo ratings yet

- Mid Term Project ReportDocument8 pagesMid Term Project ReportSamarthJaiswalNo ratings yet

- CHL 331 Fluid Particle Mechanics: Lecture 18: Packed BedsDocument20 pagesCHL 331 Fluid Particle Mechanics: Lecture 18: Packed BedsSamarthJaiswalNo ratings yet

- New Text KjhhjkdocumentDocument2 pagesNew Text KjhhjkdocumentSamarthJaiswalNo ratings yet

- Gate 2013Document13 pagesGate 2013DeepakNo ratings yet

- CLQDocument4 pagesCLQSamarthJaiswalNo ratings yet

- Gate 2013Document13 pagesGate 2013DeepakNo ratings yet

- Purification of Benzoic AcidDocument5 pagesPurification of Benzoic AcidHope CariñoNo ratings yet

- Synthesis, Characterization and Exploratory ApplicationDocument9 pagesSynthesis, Characterization and Exploratory ApplicationhammadahmedNo ratings yet

- Hafta PDFDocument38 pagesHafta PDFAdu GilbertNo ratings yet

- Ap Biology Basic Chemistry Exam1Document11 pagesAp Biology Basic Chemistry Exam1api-237801056No ratings yet

- ChemistryDocument10 pagesChemistryMaame Ama FrempongNo ratings yet

- Electric Conductivity ApparatusDocument4 pagesElectric Conductivity Apparatusapi-3759646No ratings yet

- EPA 1668 A, Ag-2003Document129 pagesEPA 1668 A, Ag-2003Karina Rondon RivadeneyraNo ratings yet

- Practice Problems - StoichiometryDocument2 pagesPractice Problems - StoichiometryAriel Raye Rica100% (1)

- Dke199 ch12Document40 pagesDke199 ch12qhqhqNo ratings yet

- Theory of Transport in MembranesDocument17 pagesTheory of Transport in MembranesMuhammad Fattah Romdhoni100% (1)

- 3rd Grading Exam G-8Document3 pages3rd Grading Exam G-8Sarah Chua DonascoNo ratings yet

- Ceramic Powder Synthesis by Spray PyrolysisDocument20 pagesCeramic Powder Synthesis by Spray PyrolysisMohamed KhalifaNo ratings yet

- O Level NOTES CIE SYLLABUS CODE 5070 201 PDFDocument14 pagesO Level NOTES CIE SYLLABUS CODE 5070 201 PDFSaad ButtNo ratings yet

- Fun Kitchen ChemistryDocument8 pagesFun Kitchen ChemistryAgata WrobelNo ratings yet

- Pharmaceutical Incompatibility 1Document25 pagesPharmaceutical Incompatibility 1Fitrah Craoenk Blauw LiefhebbersNo ratings yet

- Paracetamol Oral Solution:: Final Text For Addition To THE INTERNATIONALDocument4 pagesParacetamol Oral Solution:: Final Text For Addition To THE INTERNATIONALjado thirlwallNo ratings yet

- CP Chemistry Chapter 18: SolutionsDocument11 pagesCP Chemistry Chapter 18: SolutionsArione ArtisNo ratings yet

- Practice Typing SkillsDocument6 pagesPractice Typing SkillsJaifah AzaleahNo ratings yet

- Acetaminophen Oral SuspDocument2 pagesAcetaminophen Oral SuspgeeenaaNo ratings yet

- European Pharmacopoeia document on colestyramineDocument2 pagesEuropean Pharmacopoeia document on colestyramineLaurentiu DinuNo ratings yet

- Introduction to the Extraction ProcessDocument2 pagesIntroduction to the Extraction ProcessSun Jacob Javier CapundagNo ratings yet

- Dr. Frank J. Hayden Secondary School Exam InformationDocument3 pagesDr. Frank J. Hayden Secondary School Exam InformationcalvinNo ratings yet

- Britishhomoeopat 00 BritialaDocument448 pagesBritishhomoeopat 00 BritialaAlbena Trifonova0% (2)

- Balmer Exp 6Document6 pagesBalmer Exp 6Collin ChuNo ratings yet

- Yearly Lesson Plan 2018 (SN)Document37 pagesYearly Lesson Plan 2018 (SN)Mary IdrusNo ratings yet

- G 170 - 01 - Rze3mc0wmq - PDFDocument17 pagesG 170 - 01 - Rze3mc0wmq - PDFSamuel EduardoNo ratings yet

- Phase Equilibria and the Phase Rule ExplainedDocument65 pagesPhase Equilibria and the Phase Rule ExplainedFritzel Pallon SusbillaNo ratings yet

- Sodium and Potassium Silicates Brochure Eng Oct 2004 PDFDocument16 pagesSodium and Potassium Silicates Brochure Eng Oct 2004 PDFandrei12320003181No ratings yet

- PovidoneDocument2 pagesPovidoneElizabeth WalshNo ratings yet