Professional Documents

Culture Documents

Project Incident Date Incident Classification Incident Summary

Uploaded by

zaheerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project Incident Date Incident Classification Incident Summary

Uploaded by

zaheerCopyright:

Available Formats

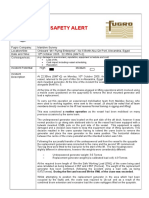

FOSTER WHEELER EASTERN PTE LTD

BLNG POWER PROJECT

FWEPL CONTRACT No. 1-FD-0165A BLNG-SAB-PP/001

Safety Awareness Bulletin

Project BLNG Power Plant Project, Lumut, Negera Brunei Darrussalam

Incident Date 3rd January 2006 : 1:50pm Incident Classification Near Miss

Incident Summary

At approximately 1:50pm 3rd

Jan 06, the subcontractor

Winch Cable employed to conduct micro-

Drill Head piling work finished a drilling a

hole and was removing the drill

rods in preparation for

grouting. During the removal of

a 3mtr section, weighing 65kg,

the rod was backed out of the

Drill Rod Hook and hole; tag lines and a guiding

Sling sleeve were attached before

being detached from the drill

Guiding head. When the rod was

sleeve lowered to the ground, the rod

end touched the ground

causing slack in the winch line.

This resulted in the sling

Guiding Sleeve (connected from the winch line

to the guiding sleeve) twisted

and rotated back on itself and

ending up covering the safety

catch of the hook.

The eye of the sling depressed the safety latch and come out of the hook. When the sling come out of the hook it

caused the rest of the assembly to go slack and the drill rod fell to the ground, landing on a hard barrier, which

had been erected to control the micro-piling area. Upon immediate investigation it was found that the hook and

lifting arrangement in this case was not suitable for the application and was changed to a shackle fitted with a

lock nut and split pin. No injuries or property damage were sustained.

Investigation Findings

The investigation found that the piling rig supplied to the site, had come fitted with a hook assembly fitted at the

end of the winch line. However, this had been changed, like for like, with the OEM because the OEM lifting

equipment was not certified and therefore did not meet the site requirements. It was also determined that the

hook arrangement was supplied in a standard size and frequently has to be changed to the appropriate SWL to fit

the drill rod size and weight.

The investigation also found that the drill rod were not supplied by the rig manufacturer, but by another vendor.

The guiding sleeve was also not supplied by the either vendor and was fabricated to suit the drill rod size. The

guiding sleeve has lifting lugs that were not certified, though the lifting lugs played no part in this incident.

Actions

1. Ensure that all micro-piling rigs are checked to ensure that the arrangement at the end of the winch line does

not have a hook with a safety catch, but is fitted with a self-locking clevis hook or a shackle, lock nut and split

pin, which is connected directly to the guide sleeve.

2. Ensure that all guiding sleeves fitted or used with the rig are tested and certified as lifting appliances .

You might also like

- 143367-Hyd Cylinder Repair GuideDocument3 pages143367-Hyd Cylinder Repair GuideheartofdixieNo ratings yet

- Attachment Copy No-24, Incident Log.Document1 pageAttachment Copy No-24, Incident Log.Shivinder BhandariNo ratings yet

- Izhmash TigrDocument9 pagesIzhmash TigrMuhammad SabbaghNo ratings yet

- Power Team Cribbing Blocks - CatalogDocument1 pagePower Team Cribbing Blocks - CatalogTitanplyNo ratings yet

- V-Belt Drive Failure AnalysisDocument1 pageV-Belt Drive Failure AnalysisMuhammad afzalNo ratings yet

- Hatlapa Chain Stopper InstructionsDocument10 pagesHatlapa Chain Stopper InstructionsPavel Taranets100% (1)

- General Description and Operation (See FIGURE 1. Through FIGURE 3.)Document8 pagesGeneral Description and Operation (See FIGURE 1. Through FIGURE 3.)weldsaidiNo ratings yet

- The Solenoid PDFDocument8 pagesThe Solenoid PDFweldsaidiNo ratings yet

- Joints in SteelDocument7 pagesJoints in SteelHemant SinghNo ratings yet

- QL5, DHD350: Disassembly Exploded ViewDocument1 pageQL5, DHD350: Disassembly Exploded ViewJORGE C. CHAO R.No ratings yet

- 1960 4 EngDocument15 pages1960 4 EngTateNo ratings yet

- Root Cause For IMR Liner Latch Bolt ShearDocument1 pageRoot Cause For IMR Liner Latch Bolt ShearShihab RahmanNo ratings yet

- Cola Yard 2Document11 pagesCola Yard 2pupung182No ratings yet

- Removing and Replacing Manhole CoversDocument10 pagesRemoving and Replacing Manhole CoversyunisaroxNo ratings yet

- Load Binder Warnings and Application Instructions Instructions - Lever Type Load BindersDocument1 pageLoad Binder Warnings and Application Instructions Instructions - Lever Type Load BindersRusdi BaccoNo ratings yet

- KP 31 Fire Control Group: How Good Can We Make This?' byDocument4 pagesKP 31 Fire Control Group: How Good Can We Make This?' byWim DekkerNo ratings yet

- Anchor Handling PDFDocument56 pagesAnchor Handling PDFEdwien Arif WicaksonoNo ratings yet

- Chin Strap Sealed Pull Pins Swing CatchDocument4 pagesChin Strap Sealed Pull Pins Swing CatchOzan EGEMENNo ratings yet

- 864air Service Manual (06 August 2018)Document47 pages864air Service Manual (06 August 2018)Zeljko SofijanicNo ratings yet

- Jsa CPBDocument3 pagesJsa CPBmd maroofNo ratings yet

- kiểm tra twistlocks (khó gù)Document5 pageskiểm tra twistlocks (khó gù)Nguyễn Văn HùngNo ratings yet

- MSRADocument8 pagesMSRAArsh MohammadNo ratings yet

- 1aha0000113 KRL160DDocument24 pages1aha0000113 KRL160Dyosy prastiyoNo ratings yet

- New Main Hoist Wire Rope Installation - Rev0Document1 pageNew Main Hoist Wire Rope Installation - Rev0shakhowiNo ratings yet

- Lesson Learnt!: Date: 11.02.2022 Ref. No.: LL/LN/78 Category of Incident - NM Description of IncidentDocument2 pagesLesson Learnt!: Date: 11.02.2022 Ref. No.: LL/LN/78 Category of Incident - NM Description of IncidentvitalengineerNo ratings yet

- Instruction Sheet Is Rvg5009 - Style Number Rvg5009Sm:: Package ContentsDocument4 pagesInstruction Sheet Is Rvg5009 - Style Number Rvg5009Sm:: Package Contentsdayshift5No ratings yet

- A Well Twisted and Tight Furl Is The Key To A Good Shorb LoopDocument3 pagesA Well Twisted and Tight Furl Is The Key To A Good Shorb LoopCarlos UrrutiaNo ratings yet

- Mercruiser Mechanical Trim Actuator Installation - 846063A1Document7 pagesMercruiser Mechanical Trim Actuator Installation - 846063A1JeffNo ratings yet

- TVF Tranšėjos Apsaugų Surinkimo Instrukcija ENDocument12 pagesTVF Tranšėjos Apsaugų Surinkimo Instrukcija ENemat41No ratings yet

- Heated GripsDocument6 pagesHeated GripsCarson McIntoshNo ratings yet

- Repair of Other Accessories 0000003475 - GBDocument10 pagesRepair of Other Accessories 0000003475 - GBrosariomodeipNo ratings yet

- Instruction Sheet Is-Srd1911 Style Number: Srd1911K: Package ContentsDocument5 pagesInstruction Sheet Is-Srd1911 Style Number: Srd1911K: Package Contentsdayshift5No ratings yet

- LiftechDocument3 pagesLiftechAhmed AliNo ratings yet

- Safety Alert PulleyDocument2 pagesSafety Alert PulleypaonemechNo ratings yet

- SF 01 24Document7 pagesSF 01 24Shahriyar ShahNo ratings yet

- 65R-C & 65R-TC Manual Pipe Threader Instructions: ThreadingDocument8 pages65R-C & 65R-TC Manual Pipe Threader Instructions: ThreadingJohnfromFresnoNo ratings yet

- Pag.45-64 GE INSTRUCTIONS DRILLING MOTOR-GENERATOR TYPE GE752Document10 pagesPag.45-64 GE INSTRUCTIONS DRILLING MOTOR-GENERATOR TYPE GE752sertecs polNo ratings yet

- Fire Safety 0Document53 pagesFire Safety 0Pankaj TuranNo ratings yet

- ABN 57 003 958 923 2 Coin Street, MOOROOKA. Q. 4105 PO Box 206, ACACIA RIDGE. Q. 4110 Ph. 0738751568 Fax 0732774316 Web Address: Email AddressDocument8 pagesABN 57 003 958 923 2 Coin Street, MOOROOKA. Q. 4105 PO Box 206, ACACIA RIDGE. Q. 4110 Ph. 0738751568 Fax 0732774316 Web Address: Email AddressPitri SuyatnoNo ratings yet

- ABN 57 003 958 923 2 Coin Street, MOOROOKA. Q. 4105 PO Box 206, ACACIA RIDGE. Q. 4110 Ph. 0738751568 Fax 0732774316 Web Address: Email AddressDocument8 pagesABN 57 003 958 923 2 Coin Street, MOOROOKA. Q. 4105 PO Box 206, ACACIA RIDGE. Q. 4110 Ph. 0738751568 Fax 0732774316 Web Address: Email AddressPitri SuyatnoNo ratings yet

- Belt Wear Monitor BlsDocument2 pagesBelt Wear Monitor BlsRenzo Malcolm Garcia PickmannNo ratings yet

- Manual For Furling Mast TYPE RB - RC - Seldén MastDocument16 pagesManual For Furling Mast TYPE RB - RC - Seldén MastDaniel LovatNo ratings yet

- Drilling and Well ConstructionDocument36 pagesDrilling and Well ConstructionMuhammad shahbazNo ratings yet

- Montgomery Ward 1903 Sewing Machine Instruction ManualDocument67 pagesMontgomery Ward 1903 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- 2019-01-25 AIB Safety Alert DanimarcaDocument10 pages2019-01-25 AIB Safety Alert Danimarcadoru cireasaNo ratings yet

- Week 12Document6 pagesWeek 12Denmark CruzadoNo ratings yet

- Crosby Model PL Hook Latch Kit: Warnings and Application InstructionsDocument1 pageCrosby Model PL Hook Latch Kit: Warnings and Application InstructionsMareg Engenharia de SegurançaNo ratings yet

- Pantera1100 o 2Document10 pagesPantera1100 o 2Emad Abu SafeihNo ratings yet

- Blind Back Off Tubing, Drill PipeDocument1 pageBlind Back Off Tubing, Drill PipeReda BoualiNo ratings yet

- Electric Chainsaw: Instruction ManualDocument10 pagesElectric Chainsaw: Instruction Manualshabab_14No ratings yet

- FED 2 (Фзд-2) - DIY Service & Cleaning: Recommended tools and suppliesDocument11 pagesFED 2 (Фзд-2) - DIY Service & Cleaning: Recommended tools and suppliesivanwkNo ratings yet

- Manual de Instalacion Mark IIDocument57 pagesManual de Instalacion Mark IIcuervohijoguachoNo ratings yet

- MC-10001 Service SeminarDocument25 pagesMC-10001 Service SeminarAndreiNo ratings yet

- Instruction Sheet Is-Rcn239 Style Number: Rcn239Aj: Package ContentsDocument5 pagesInstruction Sheet Is-Rcn239 Style Number: Rcn239Aj: Package Contentsdayshift5No ratings yet

- PART NO. 8200: Tune Up Kit For GM Hei V8 DistributorsDocument2 pagesPART NO. 8200: Tune Up Kit For GM Hei V8 DistributorschrispyNo ratings yet

- DGT - JIV1803B v2Document2 pagesDGT - JIV1803B v2deltastarconstruction.servicesNo ratings yet

- Hoist ManualDocument14 pagesHoist ManualgustavovicgarNo ratings yet

- 3RD Module of Activities - Q1eim10Document6 pages3RD Module of Activities - Q1eim10Cee TeeNo ratings yet

- Electronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionFrom EverandElectronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionRating: 5 out of 5 stars5/5 (1)

- The Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional RiggingFrom EverandThe Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional RiggingNo ratings yet

- Ib15 002Document2 pagesIb15 002zaheerNo ratings yet

- DS - 1410Document4 pagesDS - 1410zaheerNo ratings yet

- Informative Annex 2 - Surface FinishDocument10 pagesInformative Annex 2 - Surface FinishzaheerNo ratings yet

- FIFA World Cup 2022 Match List - 221113 - 022707Document6 pagesFIFA World Cup 2022 Match List - 221113 - 022707zaheerNo ratings yet

- Non-Metallic Applications in Oil - Gas IndustryDocument6 pagesNon-Metallic Applications in Oil - Gas IndustryzaheerNo ratings yet

- ASME IX - 2019 - Addenda - ChangesDocument7 pagesASME IX - 2019 - Addenda - ChangeszaheerNo ratings yet

- Construction Products Directive: Customer InformationDocument4 pagesConstruction Products Directive: Customer InformationzaheerNo ratings yet

- The American University in Cairo Engineering Department: ENGR 548: Facilities Planning and DesignDocument20 pagesThe American University in Cairo Engineering Department: ENGR 548: Facilities Planning and DesignzaheerNo ratings yet

- 2004 Advance Program PDFDocument36 pages2004 Advance Program PDFzaheerNo ratings yet

- European Product Safety Directives & CE Marking: A Guide For Manufacturers and ImportersDocument6 pagesEuropean Product Safety Directives & CE Marking: A Guide For Manufacturers and ImporterszaheerNo ratings yet

- Safety Alert: (E.g. Damage To Environment, Reputation, Equipment Schedule and Cost)Document5 pagesSafety Alert: (E.g. Damage To Environment, Reputation, Equipment Schedule and Cost)zaheerNo ratings yet

- GearDocument31 pagesGearzaheer100% (2)

- HPBH Safety Items Project ATG Medical Treatment Injury: SO11221 - 14 April 2005Document1 pageHPBH Safety Items Project ATG Medical Treatment Injury: SO11221 - 14 April 2005zaheerNo ratings yet

- The Future's Bright The Future's ..Tags!'Document1 pageThe Future's Bright The Future's ..Tags!'zaheerNo ratings yet

- Drawn To Danger: SHE Alert No 082Document1 pageDrawn To Danger: SHE Alert No 082zaheerNo ratings yet

- Safety Learning Event S G: Failure of Gantry WalkwayDocument1 pageSafety Learning Event S G: Failure of Gantry WalkwayzaheerNo ratings yet

- How To Read PWHT ChartDocument5 pagesHow To Read PWHT ChartzaheerNo ratings yet

- Thermaline 4700 PDSDocument2 pagesThermaline 4700 PDSzaheerNo ratings yet

- What Is Grain FlowDocument1 pageWhat Is Grain FlowzaheerNo ratings yet

- Lesson 1 Animal CareDocument8 pagesLesson 1 Animal CareLexi PetersonNo ratings yet

- Meyer-Andersen - Buddhism and Death Brain Centered CriteriaDocument25 pagesMeyer-Andersen - Buddhism and Death Brain Centered Criteriautube forNo ratings yet

- Marantz - dv-4200 DVD Player PDFDocument60 pagesMarantz - dv-4200 DVD Player PDFH.V KayaNo ratings yet

- Photosynthesis Knowledge OrganiserDocument1 pagePhotosynthesis Knowledge Organiserapi-422428700No ratings yet

- Energies: Numerical Simulations On The Application of A Closed-Loop Lake Water Heat Pump System in The Lake Soyang, KoreaDocument16 pagesEnergies: Numerical Simulations On The Application of A Closed-Loop Lake Water Heat Pump System in The Lake Soyang, KoreaMvikeli DlaminiNo ratings yet

- CHAPTER 3 Formwork Part 1Document39 pagesCHAPTER 3 Formwork Part 1nasNo ratings yet

- Akin To PityDocument356 pagesAkin To PityPaul StewartNo ratings yet

- EarthWear Clothier MaterialsDocument1 pageEarthWear Clothier MaterialsZhining LimNo ratings yet

- AudiometerDocument3 pagesAudiometerVasanth VasanthNo ratings yet

- WEEK 3 LAB EXERCISE - Cell Structures and Functions - UY-OCODocument4 pagesWEEK 3 LAB EXERCISE - Cell Structures and Functions - UY-OCOBianca LouiseNo ratings yet

- Selectivities in Ionic Reductions of Alcohols and Ketones With Triethyisilane - Trifluoroacetic AcidDocument4 pagesSelectivities in Ionic Reductions of Alcohols and Ketones With Triethyisilane - Trifluoroacetic AcidJan Andre EriksenNo ratings yet

- LNG Simulation PDFDocument28 pagesLNG Simulation PDFRobert WatersNo ratings yet

- LAB ActivityDocument2 pagesLAB ActivityNicole AquinoNo ratings yet

- Mapagbigay PT1 Group1Document4 pagesMapagbigay PT1 Group1Hazel SarmientoNo ratings yet

- Campus DrinkingDocument2 pagesCampus DrinkingLiHertzi DesignNo ratings yet

- Kerala Medico Legal Code - Annexure2Document19 pagesKerala Medico Legal Code - Annexure2doctor82No ratings yet

- Evolution Practice Test 2 With AnswersDocument10 pagesEvolution Practice Test 2 With AnswersSuhani SinhaNo ratings yet

- 8582d Soldering Station English User GuideDocument9 pages8582d Soldering Station English User Guide1valdasNo ratings yet

- Cardiac PacemakerDocument25 pagesCardiac PacemakerDhvij KmlNo ratings yet

- Insurance CodeDocument18 pagesInsurance CodeKenneth Holasca100% (1)

- Soduim Prescription in The Prevention of Intradialytic HypotensionDocument10 pagesSoduim Prescription in The Prevention of Intradialytic HypotensionTalala tililiNo ratings yet

- Report On Marketing of ArecanutDocument22 pagesReport On Marketing of ArecanutsivakkmNo ratings yet

- .. - Bcsbi - .Document2 pages.. - Bcsbi - .Varun GopalNo ratings yet

- Msla Business FeesDocument1 pageMsla Business FeesNBC MontanaNo ratings yet

- Study On Optimization and Performance of Biological Enhanced Activated Sludge Process For Pharmaceutical Wastewater TreatmentDocument9 pagesStudy On Optimization and Performance of Biological Enhanced Activated Sludge Process For Pharmaceutical Wastewater TreatmentVijaya GosuNo ratings yet

- Medicina 57 00032 (01 14)Document14 pagesMedicina 57 00032 (01 14)fauzan nandana yoshNo ratings yet

- EV-H-A1R 54C - M - EN - 2014 - D - Heat Detector SalwicoDocument2 pagesEV-H-A1R 54C - M - EN - 2014 - D - Heat Detector SalwicoCarolinaNo ratings yet

- SCL NotesDocument4 pagesSCL NotesmayaNo ratings yet

- Question Bank Chemistry (B.Tech.) : Solid StateDocument10 pagesQuestion Bank Chemistry (B.Tech.) : Solid StatenraiinNo ratings yet